- Products

-

-

-

Categories

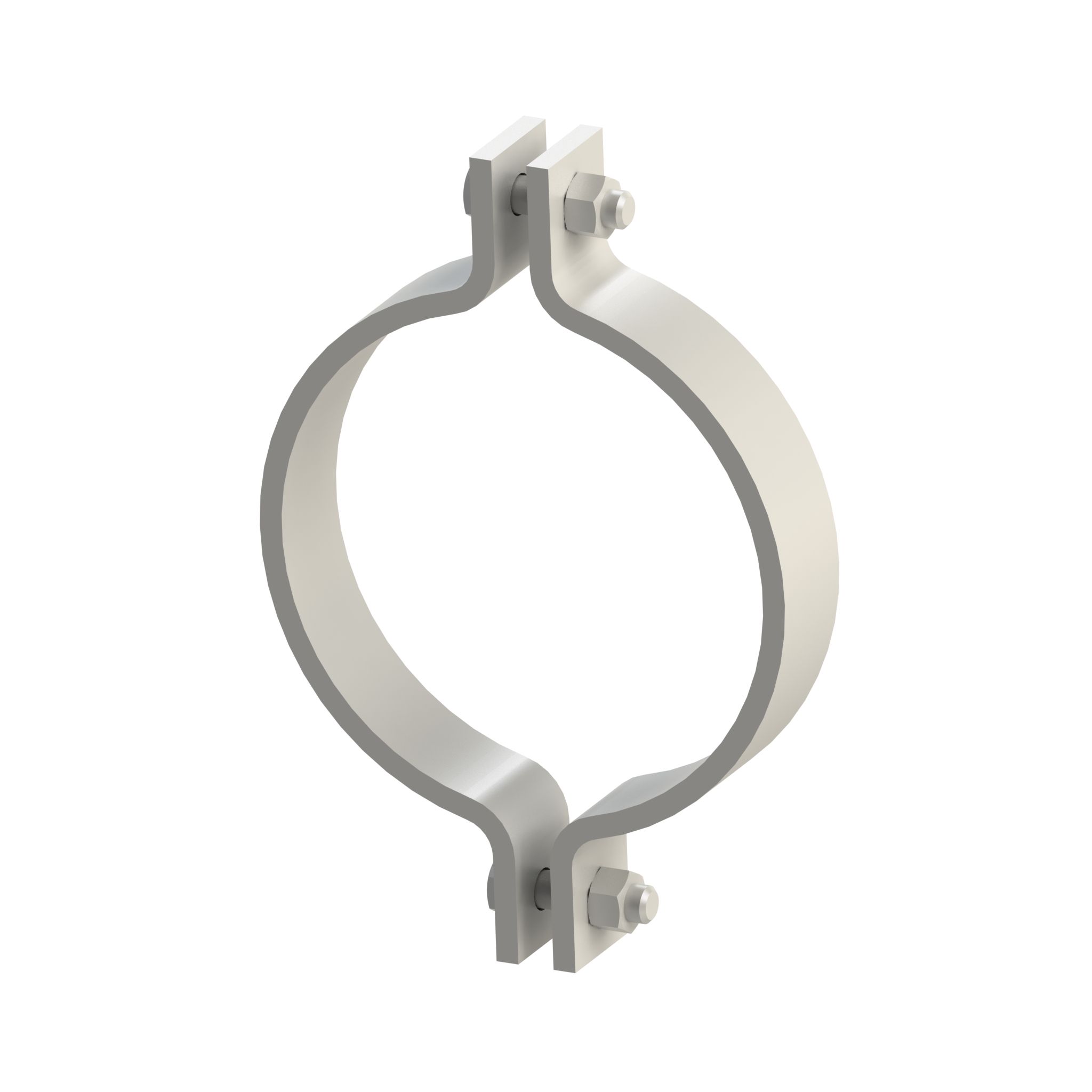

BG100

BG100LIGHT DUTY 2-BOLT CLAMP

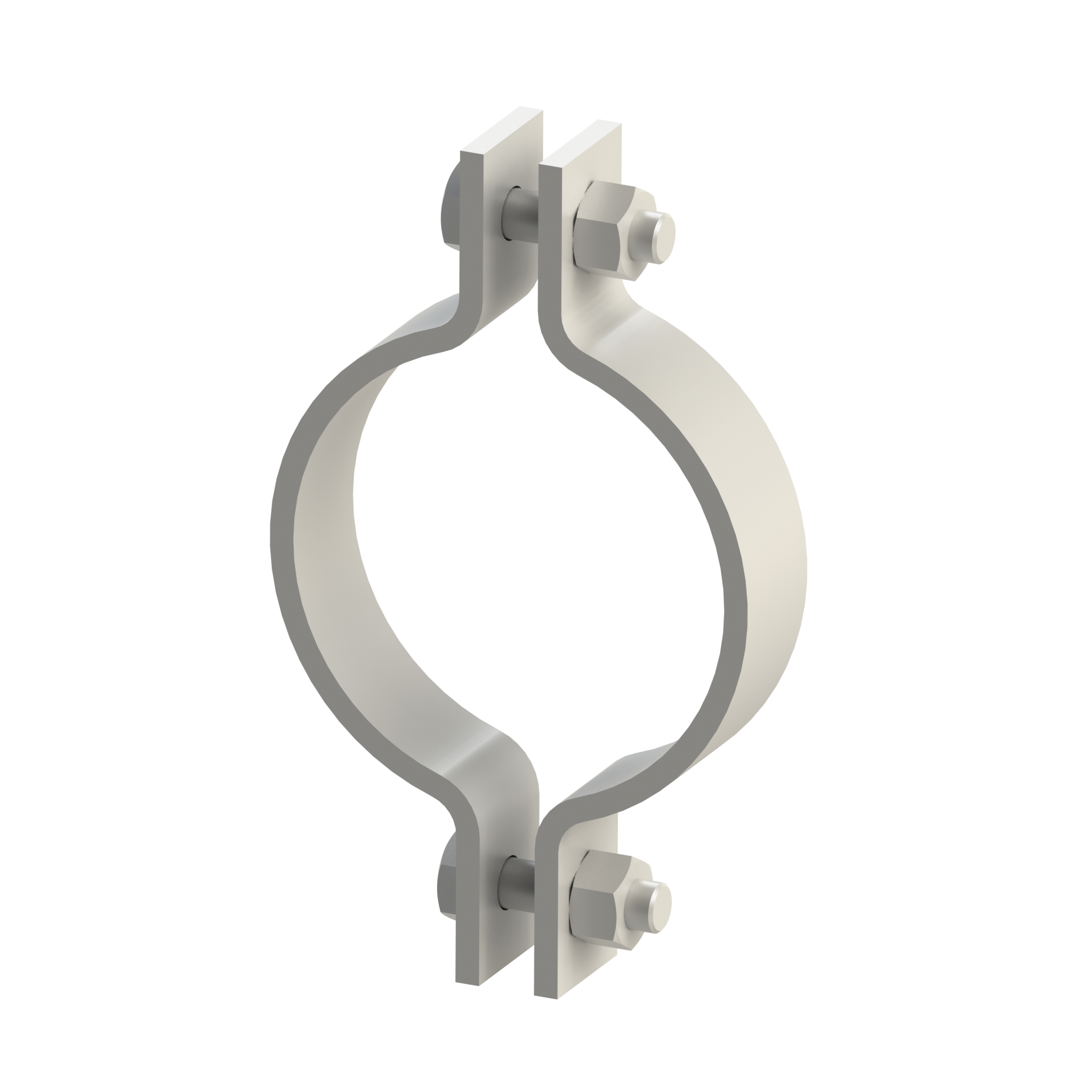

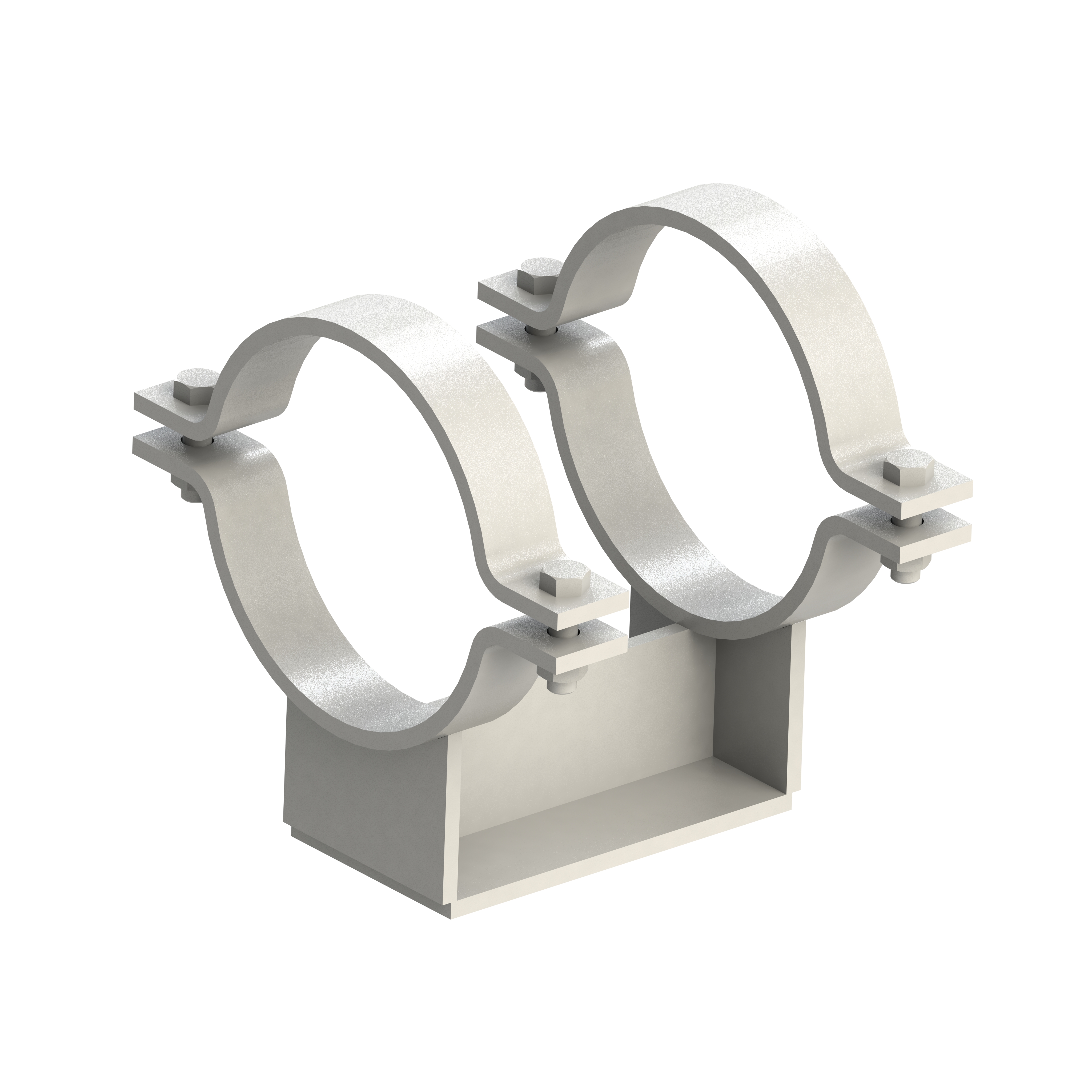

BG170

BG170MEDIUM DUTY 2-BOLT PIPE CLAMP

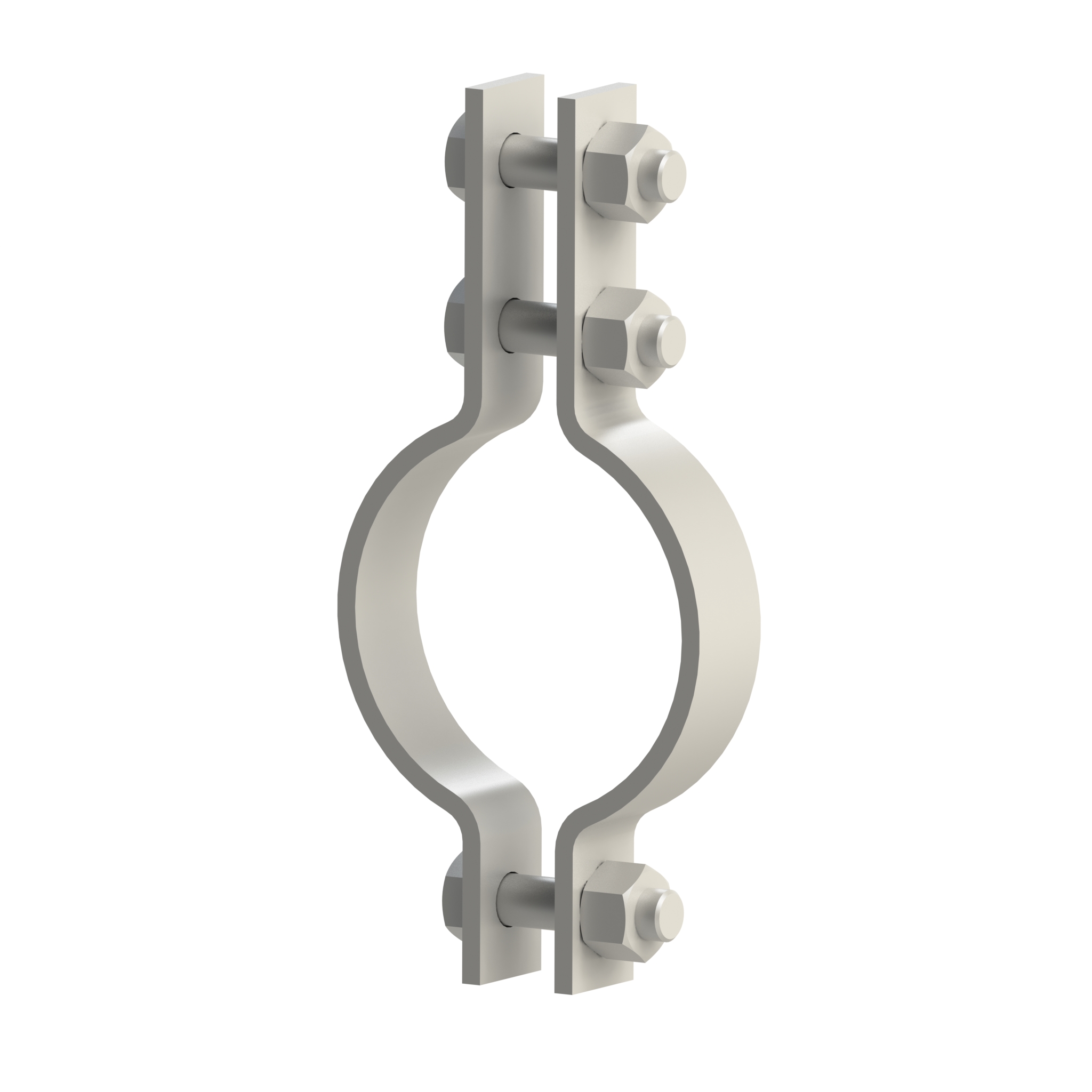

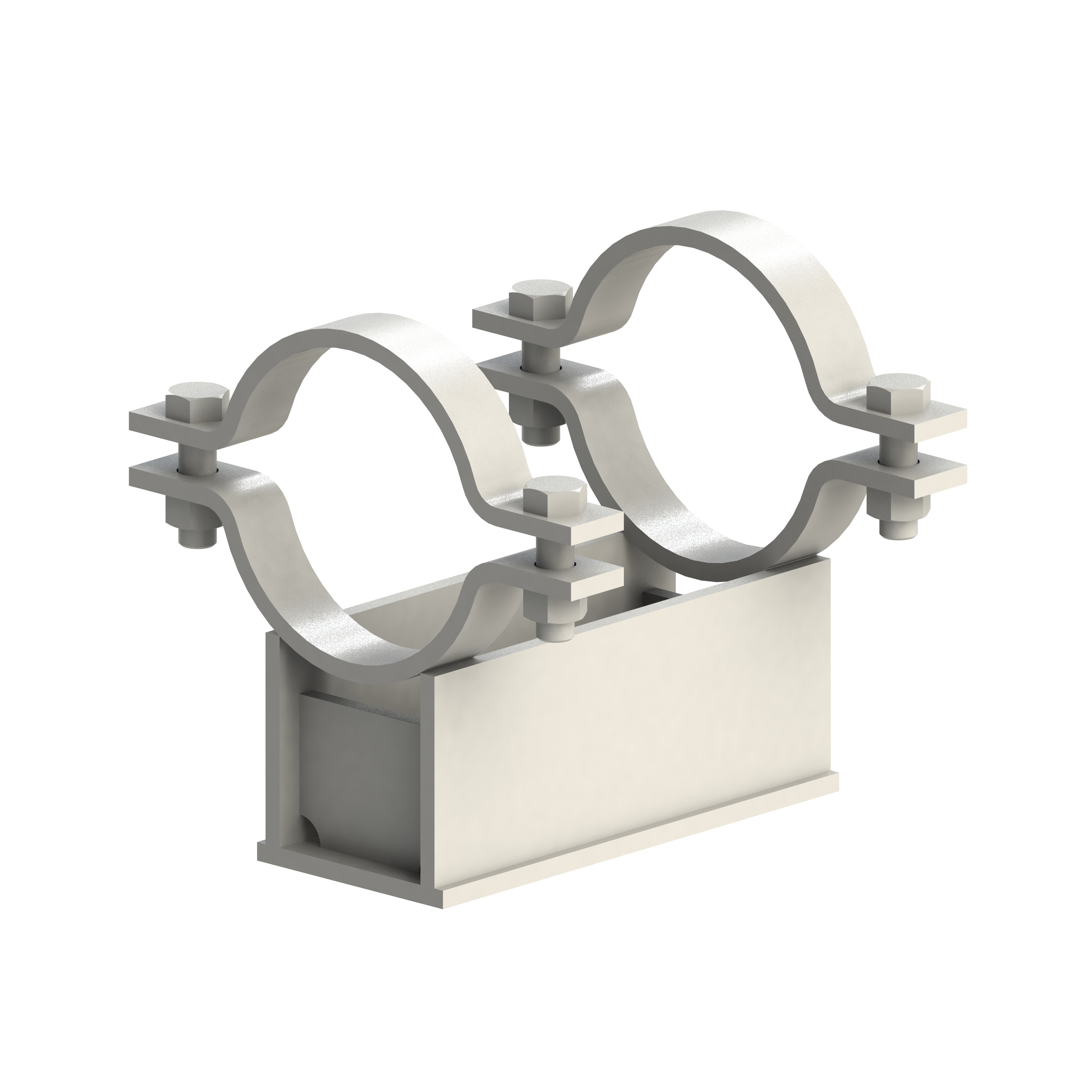

BG50

BG50HEAVY DUTY 2-BOLT PIPE CLAMP

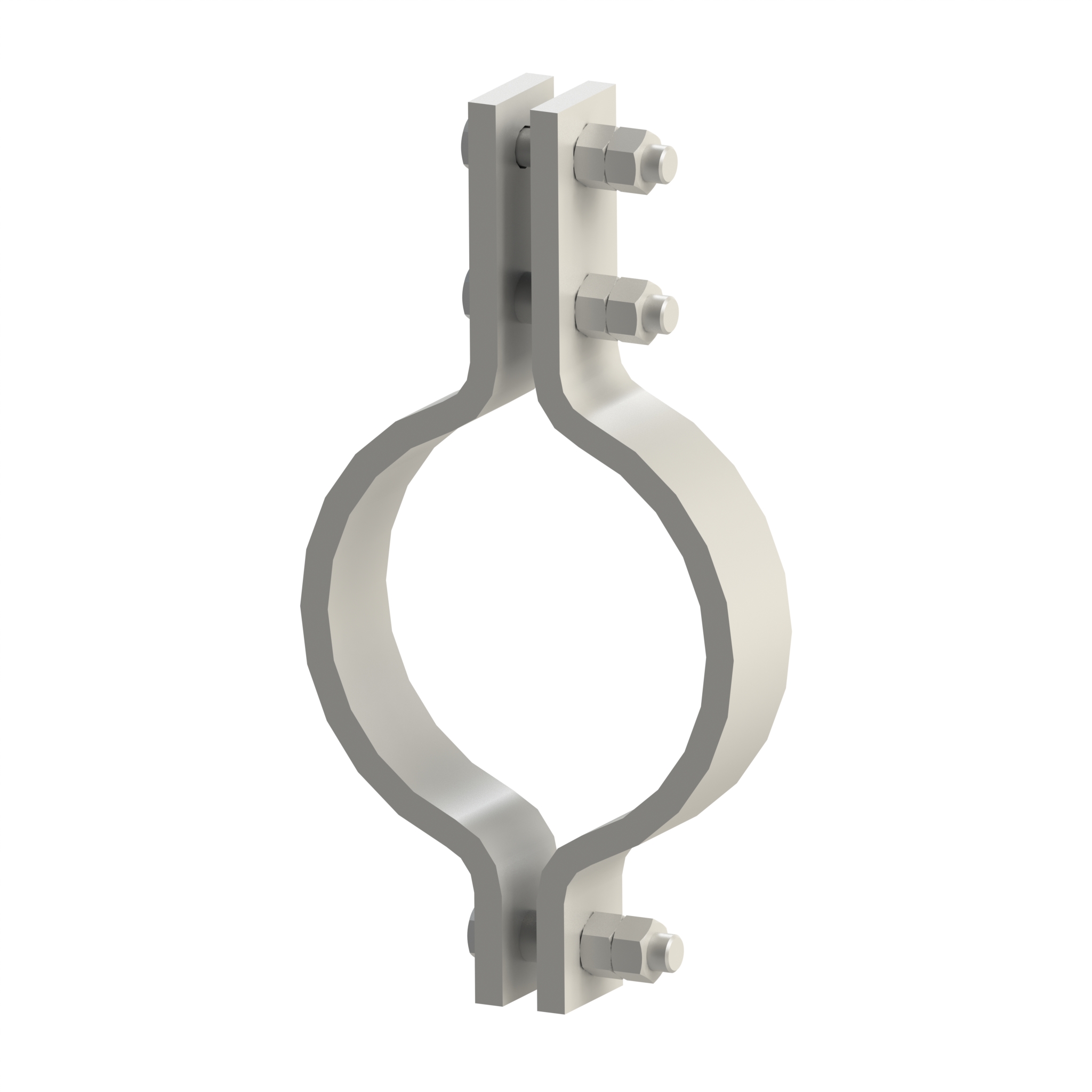

BG101

BG101LIGHT DUTY 3-BOLT PIPE CLAMP

BG171

BG171MEDIUM DUTY 3-BOLT PIPE CLAMP FOR STEEL PIPE

BG75

BG75HEAVY DUTY 3-BOLT PIPE CLAMP

BG172

BG172HIGH TEMPERATURE 3-BOLT PIPE CLAMP

BG173

BG173ALLOY PIPE CLAMP - VERY HIGH TEMPERATURE

BG140

BG140INSULATED 2-BOLT PIPE CLAMP

BG141

BG141INSULATED 2-BOLT PIPE CLAMP FOR CU/NI

BG145

BG145INSULATED 3-BOLT PIPE CLAMP

BG146

BG146INSULATED 3-BOLT PIPE CLAMP FOR CU/NI

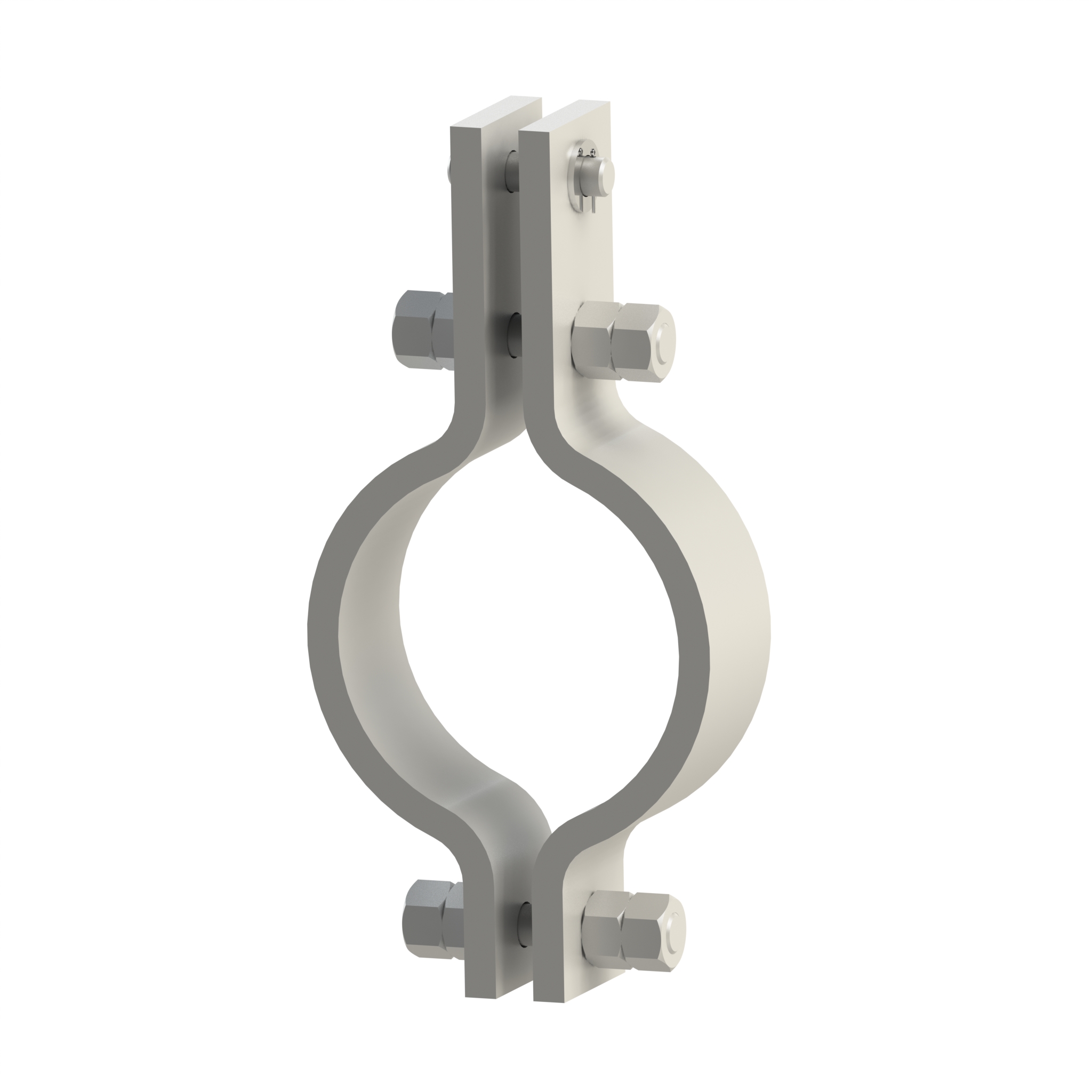

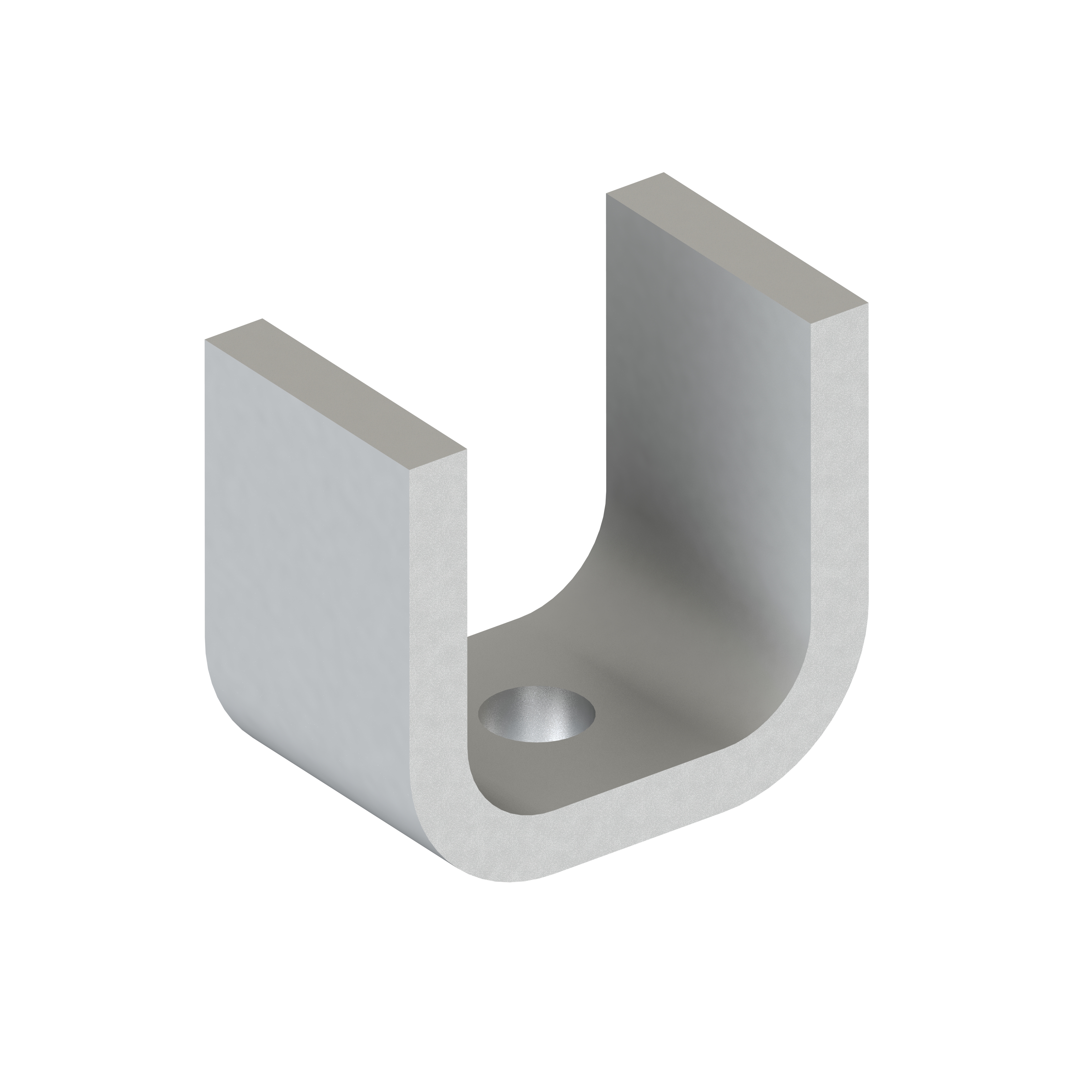

BG108

BG108CLEVIS CLAMP

BG222

BG222BEAM CLAMP

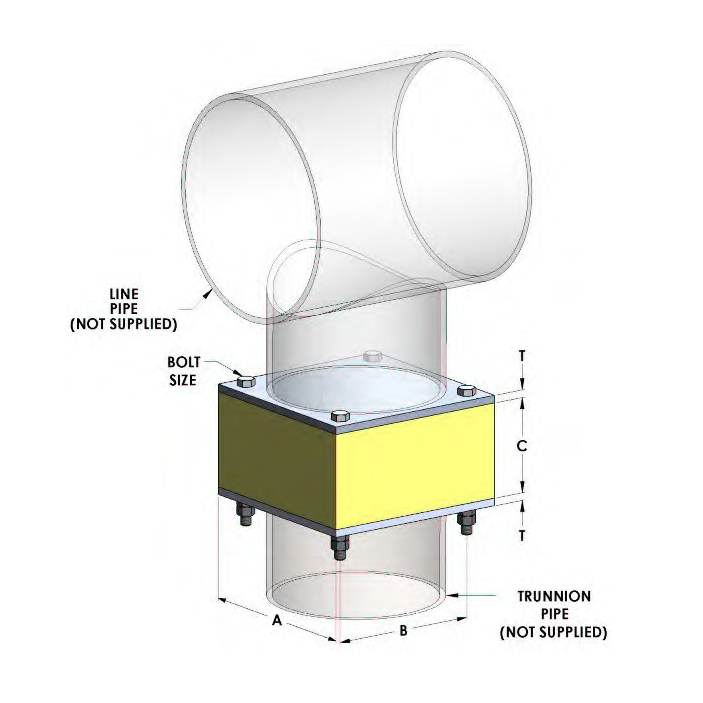

BG174

BG174RISER SUPPORT – STD TEMPERATURE

BG175

BG175RISER SUPPORT – HIGH TEMPERATURE

BG176

BG176ALLOY RISER SUPPORT - VERY HIGH TEMPERATURE

BG202

BG202ALLTHREAD ROD

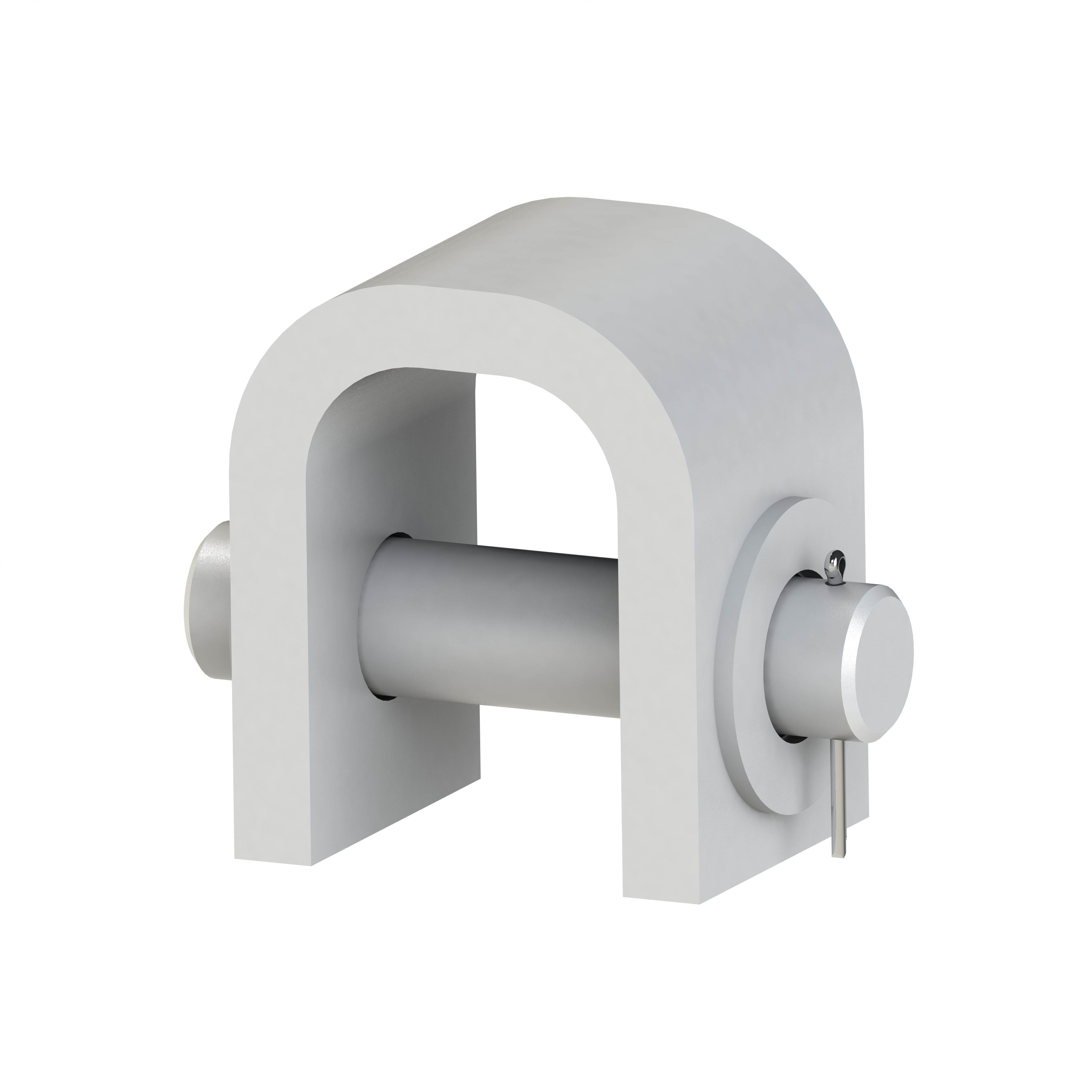

BG209

BG209FORGED CLEVIS AND PIN

BG210

BG210FORGED TURNBUCKLE

BG204

BG204FORGED WELDLESS EYE NUT

BG215

BG215HEMISPHERICAL CUP

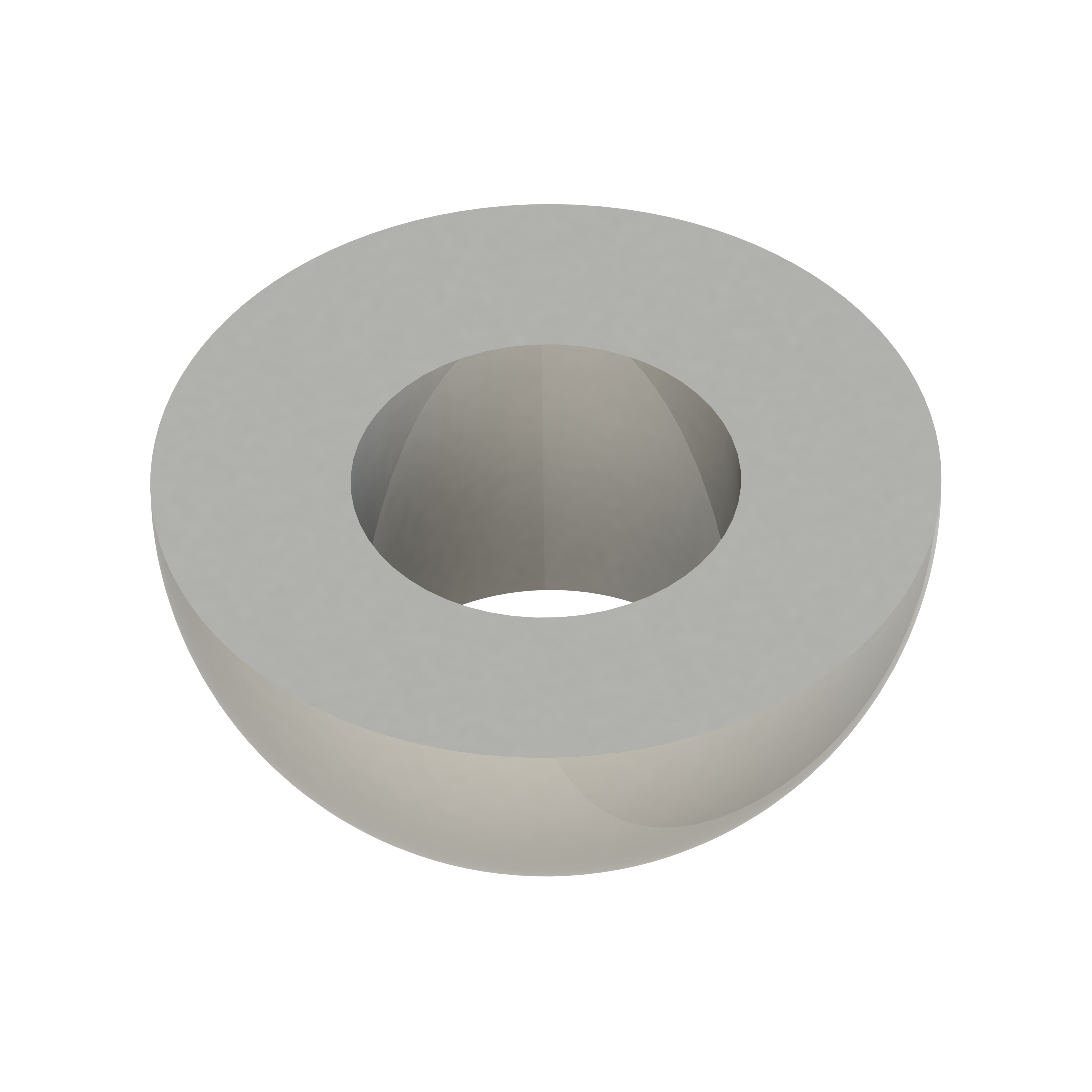

BG214

BG214HEMISPHERICAL WASHER

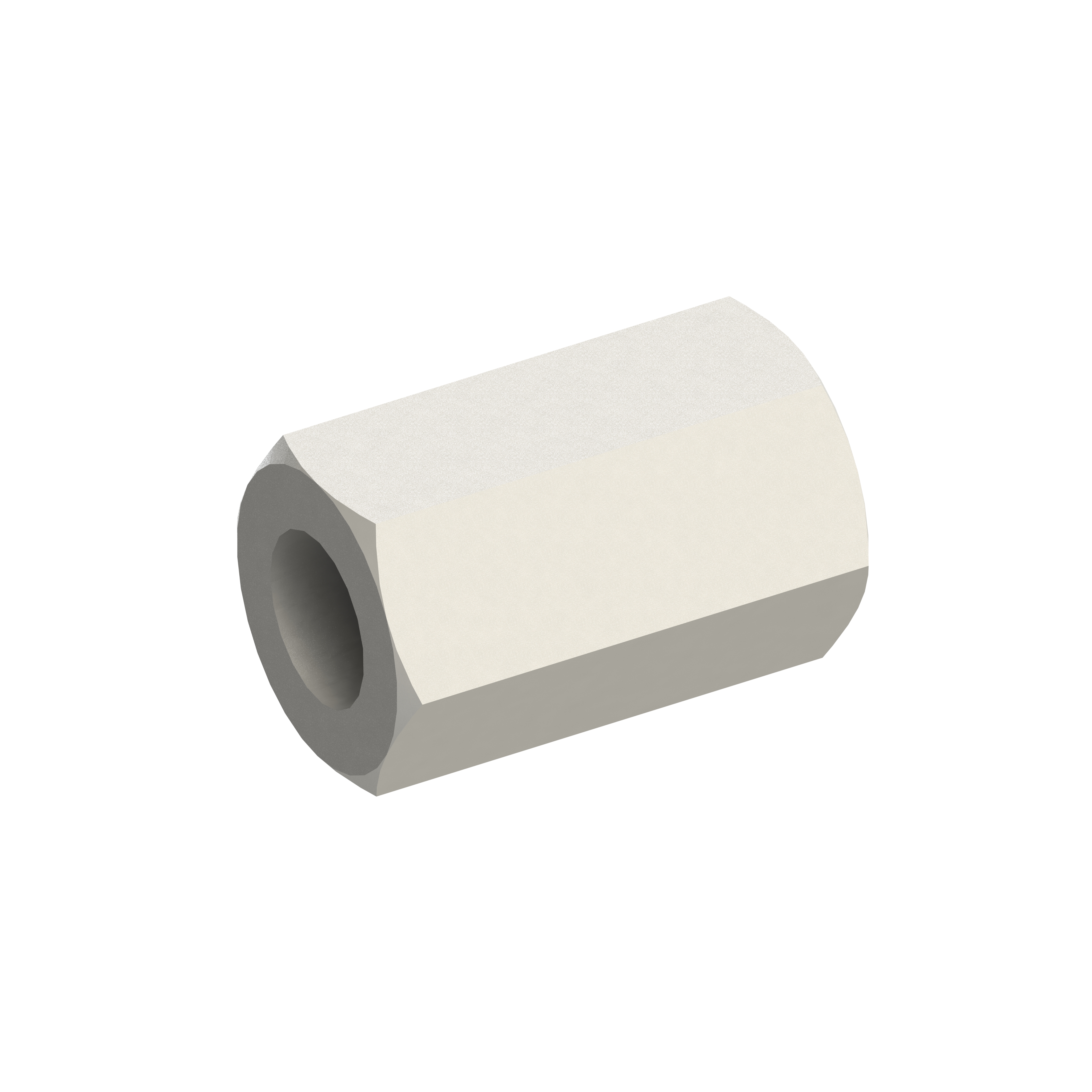

BG206

BG206HEXAGONAL CONNECTOR

BG216

BG216PIPE WELDING LUG

BG217

BG217PLATE WASHER

BG207

BG207SPADE NUT

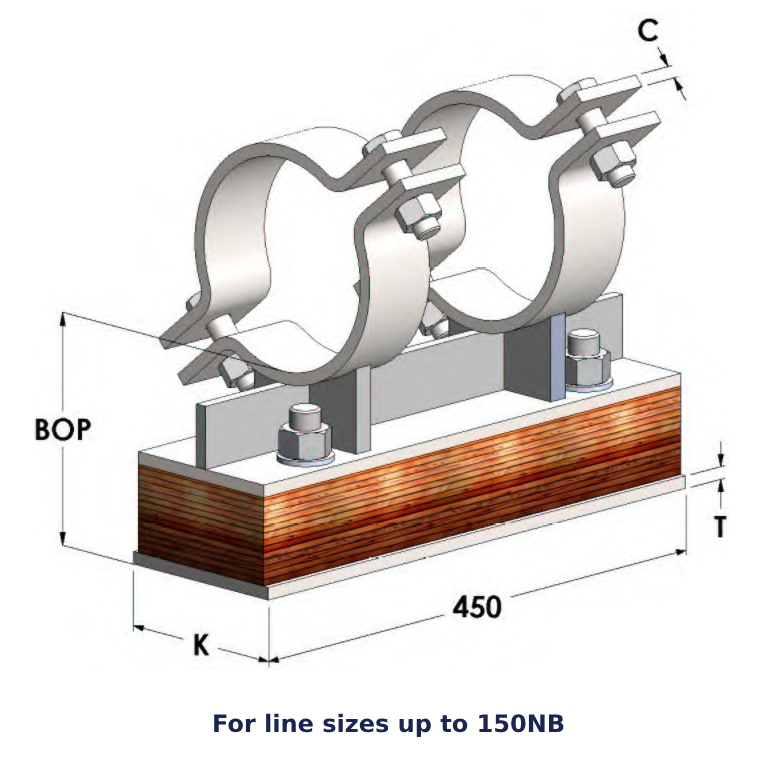

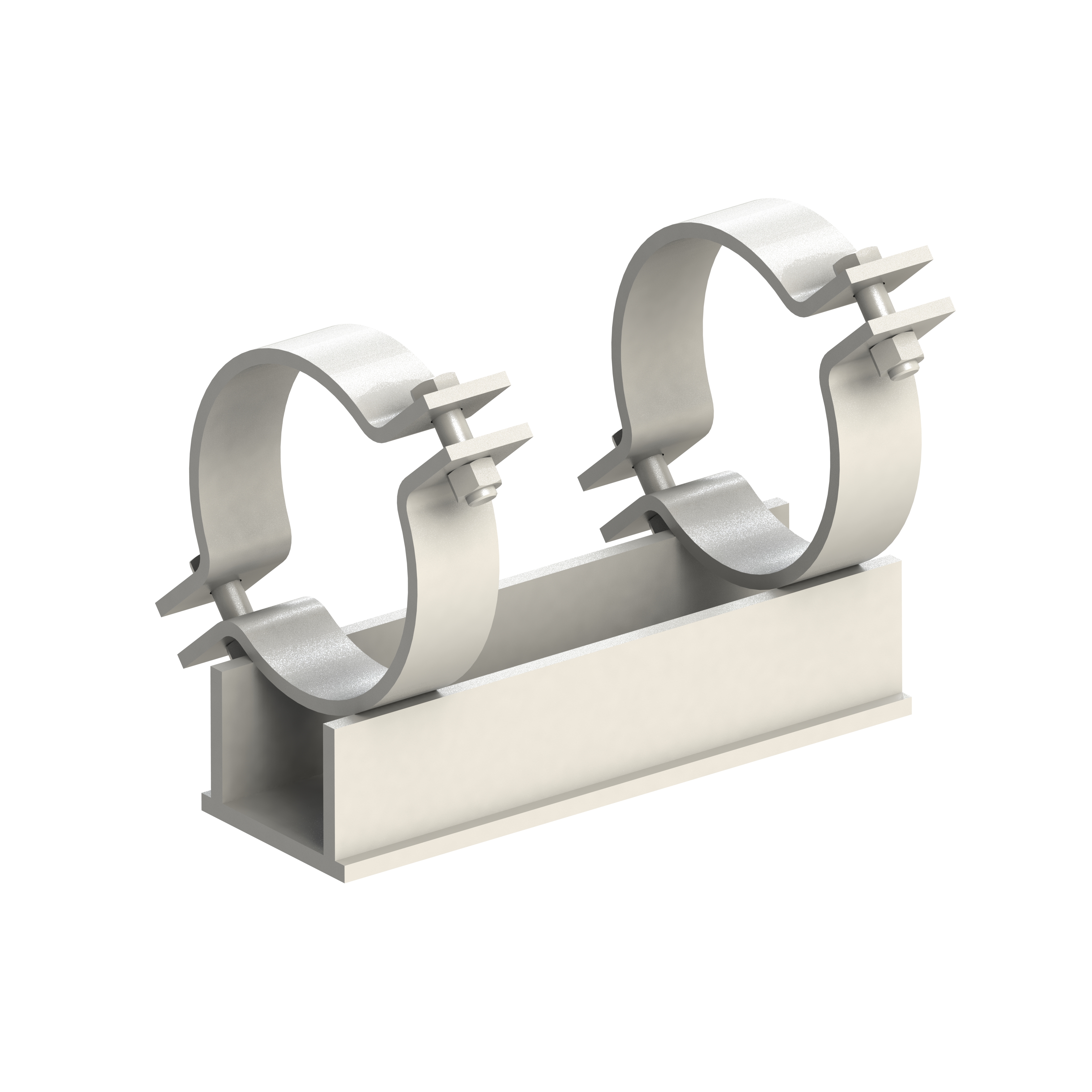

BG245

BG245STANDARD TRAPEZE

BG203

BG203THREADED DROP ROD – RH/LH

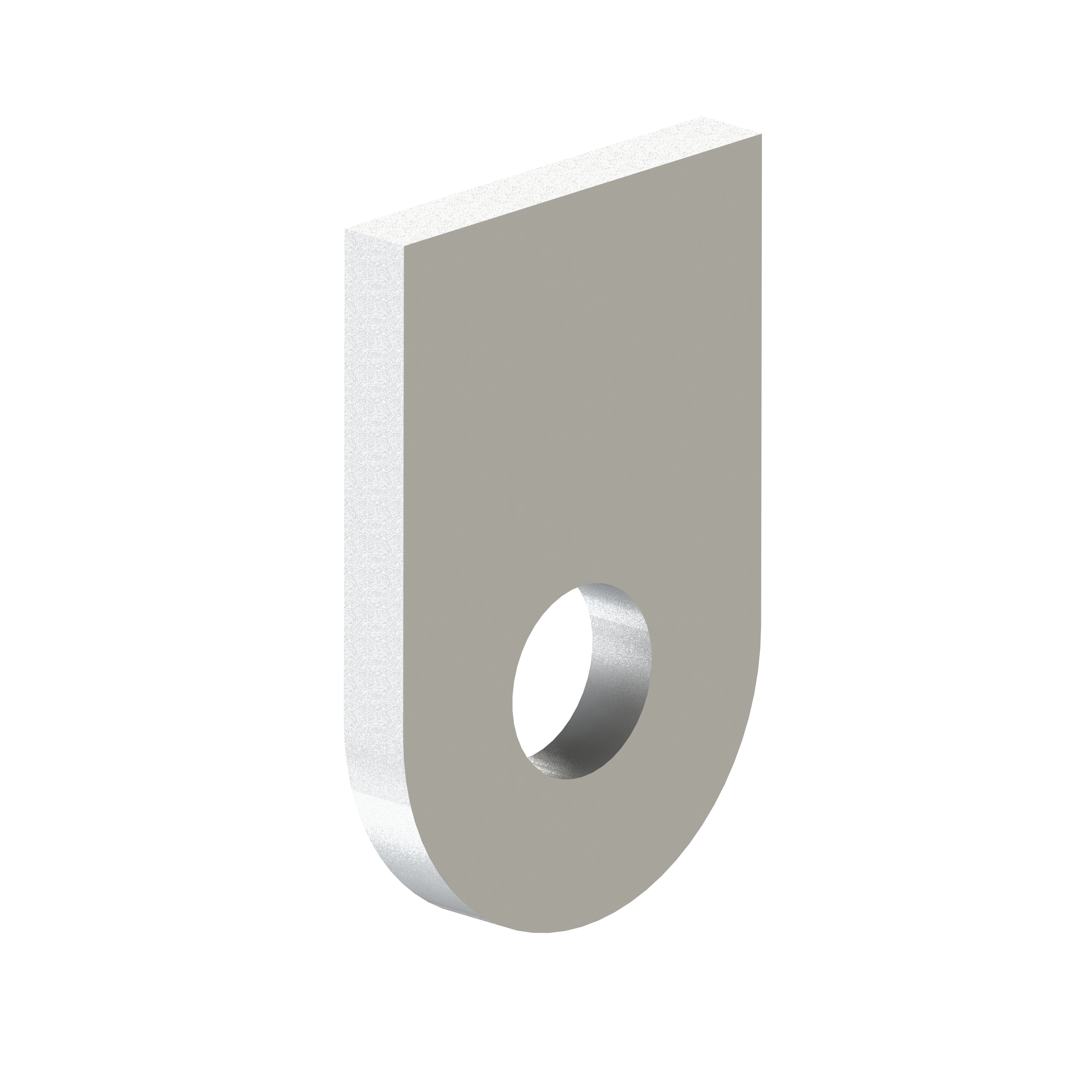

BG219

BG219WELDED BEAM ATTACHMENT

BG220

BG220WELDED BEAM ATTACHMENT (WITH LOAD PIN)

BG225

BG225WELDING LUG

BG180

BG180U-BOLT GUIDE

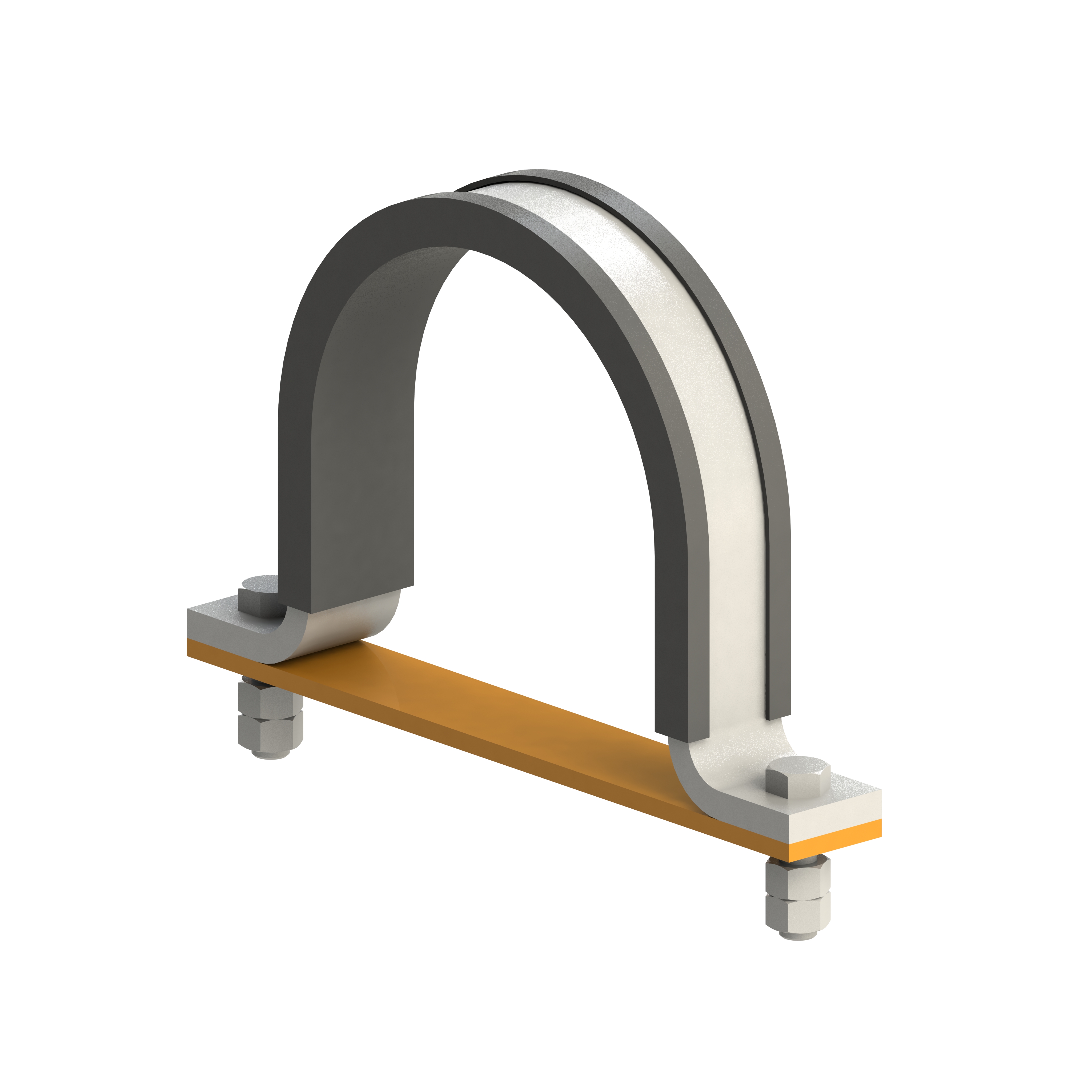

BG181

BG181U-BOLT CLAMP

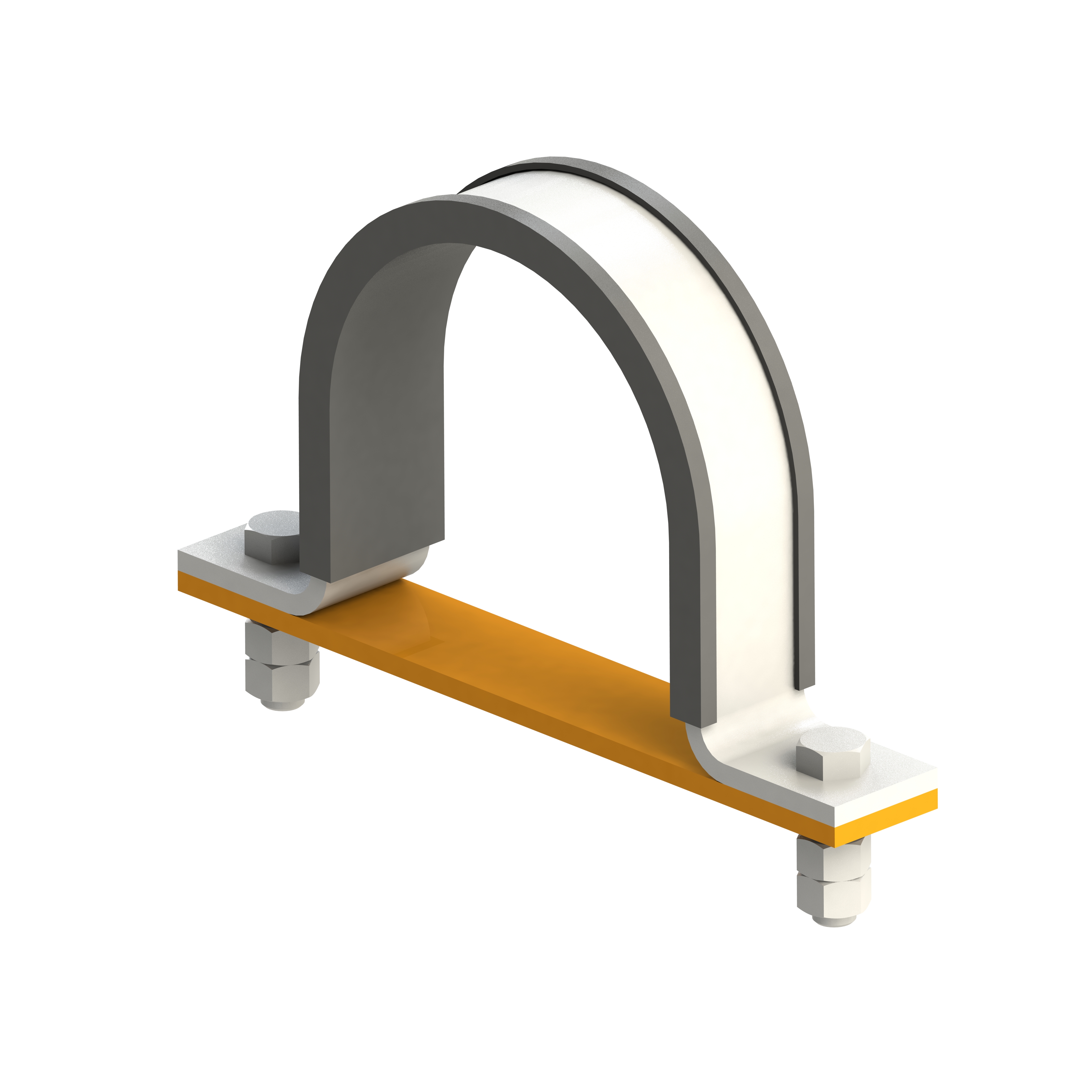

BG150

BG150INSULATED U-BOLT CLAMP

BG152

BG152INSULATED U-BOLT GUIDE

BG154

BG154INSULATED U-BOLT GUIDE (WITH TEFLON)

BG190

BG190INSULATED U-BOLT CLAMP

BG192

BG192INSULATED U-BOLT GUIDE

BG151

BG151INSULATED U-BOLT CLAMP FOR CU/NI

BG153

BG153INSULATED U-BOLT GUIDE FOR CU/NI

For Cu/Ni Pipe BG155

BG155INSULATED U-BOLT GUIDE (WITH TEFLON)

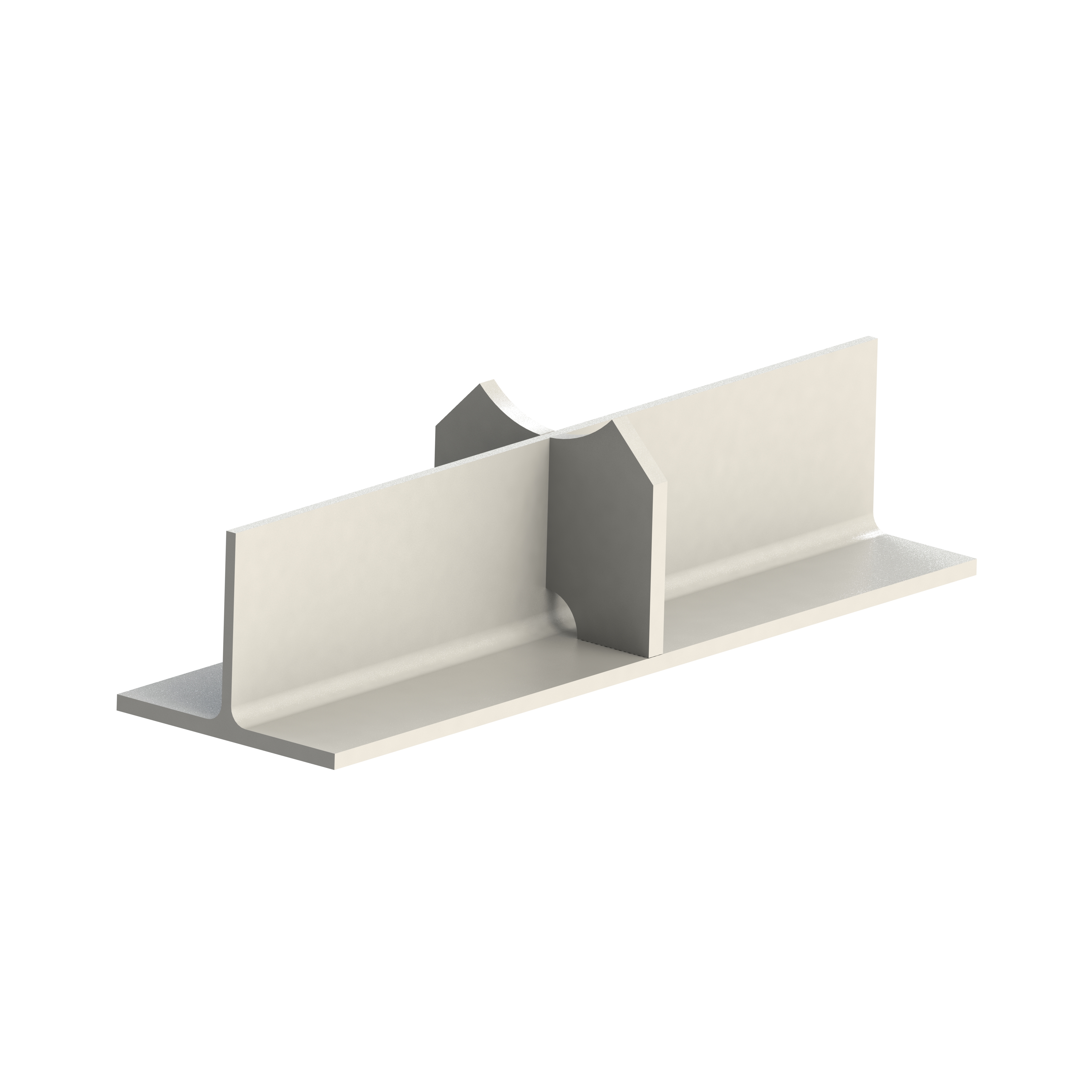

For Cu/Ni Pipe BG177

BG177SADDLE GUIDE

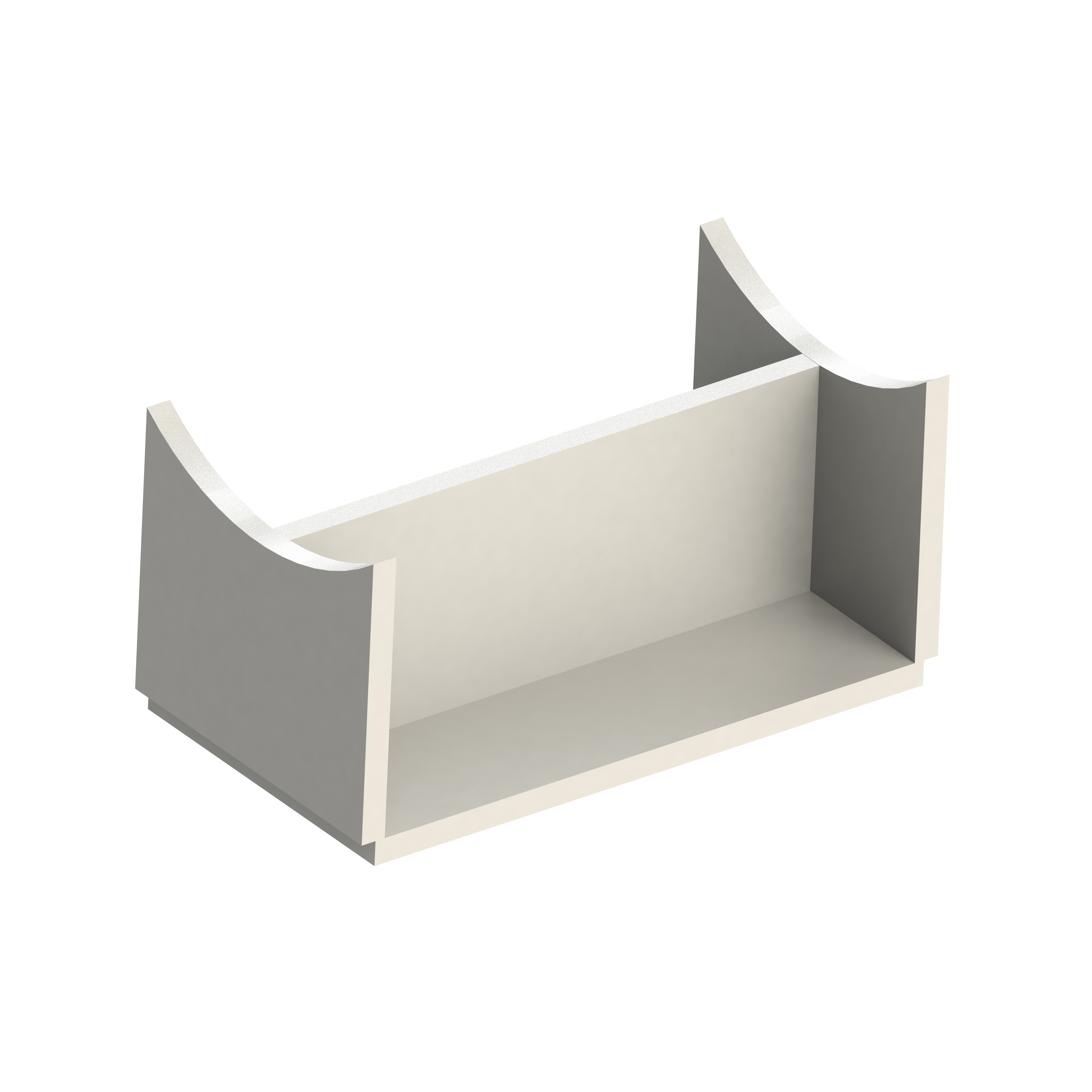

BG178

BG178SADDLE CLAMP

BG160

BG160INSULATED PIPE SADDLE

BG161

BG161INSULATED PIPE SADDLE

BG162

BG162INSULATED PIPE SADDLE

BG135-136

BG135-136ADJUSTABLE PIPE STANDS

BG515

BG515STANDARD CLAMPED PIPE SHOE

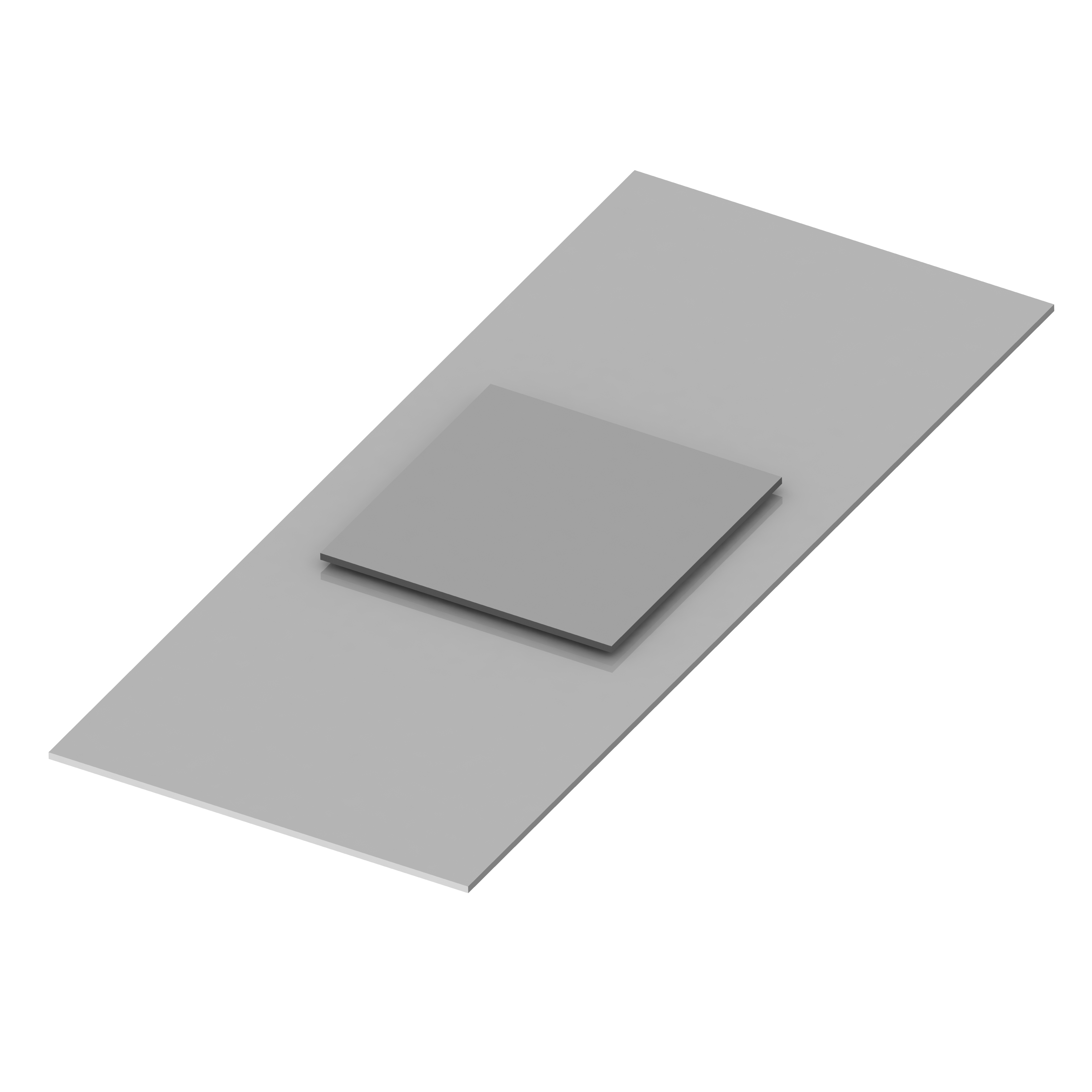

BG550

BG550SLIDE PLATES

BG517

BG517COMPACT PIPE SHOE

BG400

BG400CLAMPED HOT PIPE SHOE

BG156

BG156INSULATED PIPE SHOE

BG157

BG157INSULATED PIPE SHOE

BG510

BG510STANDARD WELDED PIPE SHOE

BG518

BG518COMPACT WELDED PIPE SHOE

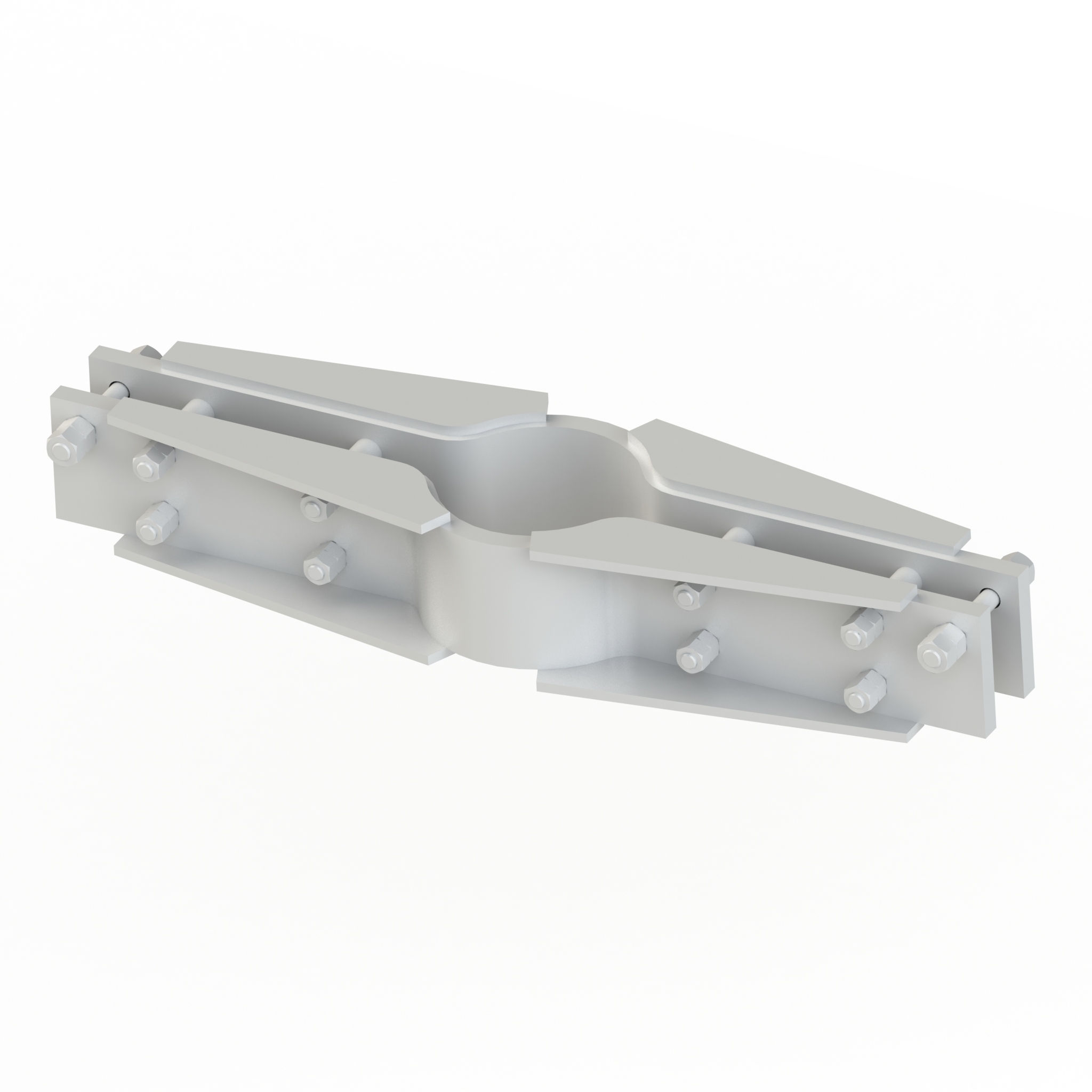

BG555

BG555STANDARD LINE STOPS

BG560

BG560STANDARD PIPE GUIDES

BG570

BG570STANDARD SHOE GUIDES

BG580

BG580STANDARD SHOE GUIDES

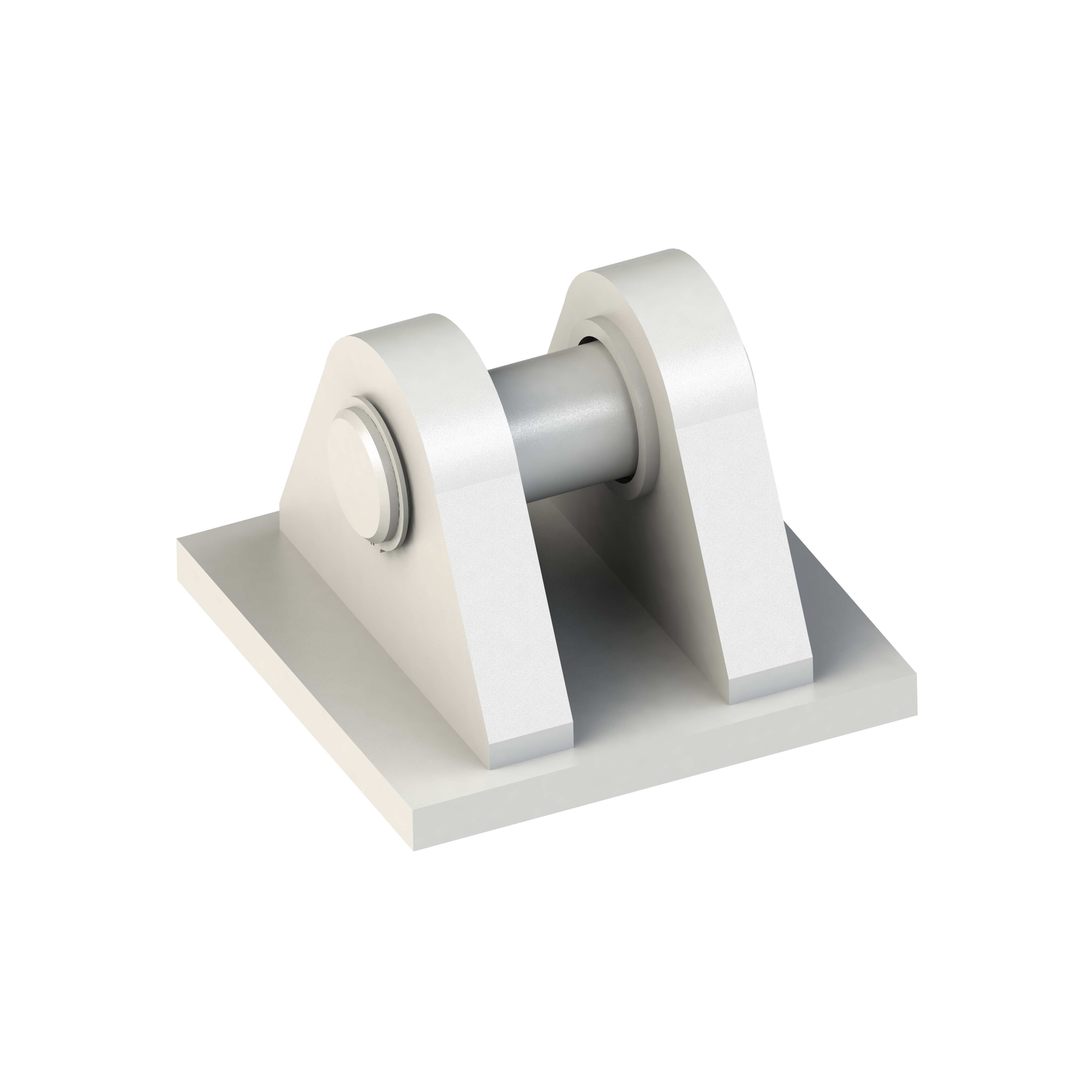

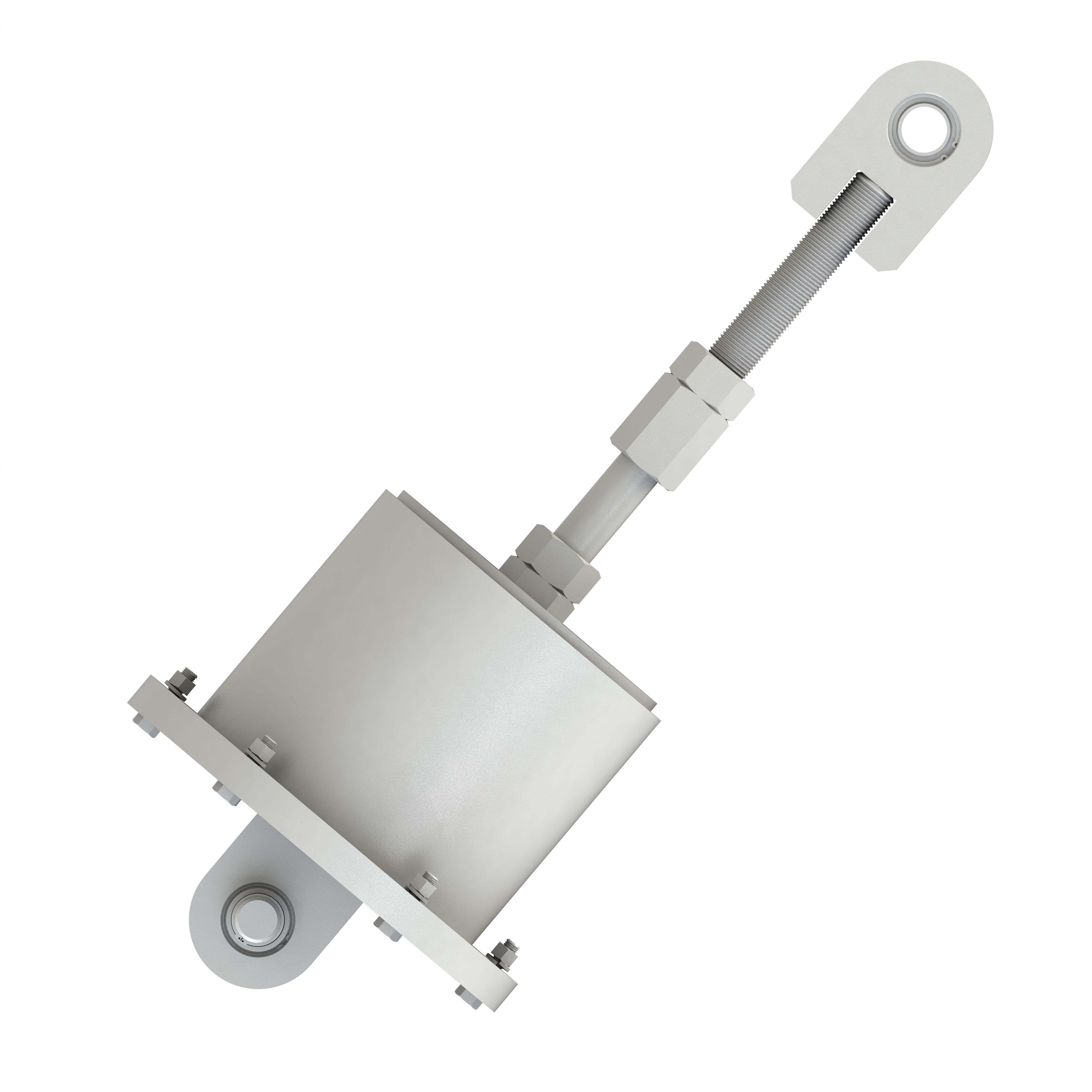

BG315

BG315END ATTACHMENT FOR HYDRAULIC SNUBBERS

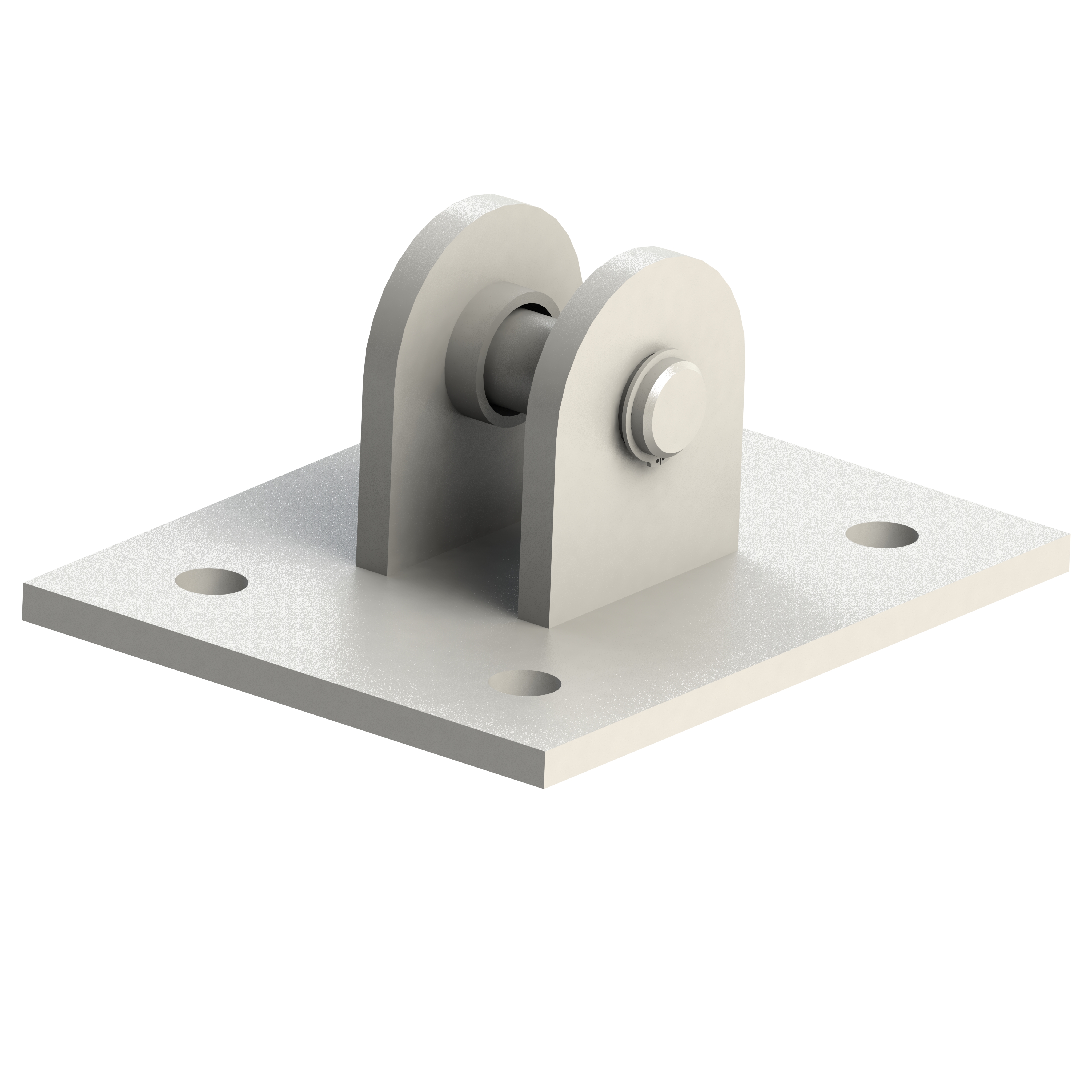

BG355

BG355END ATTACHMENT FOR RIGID STRUT & SWAY BRACE

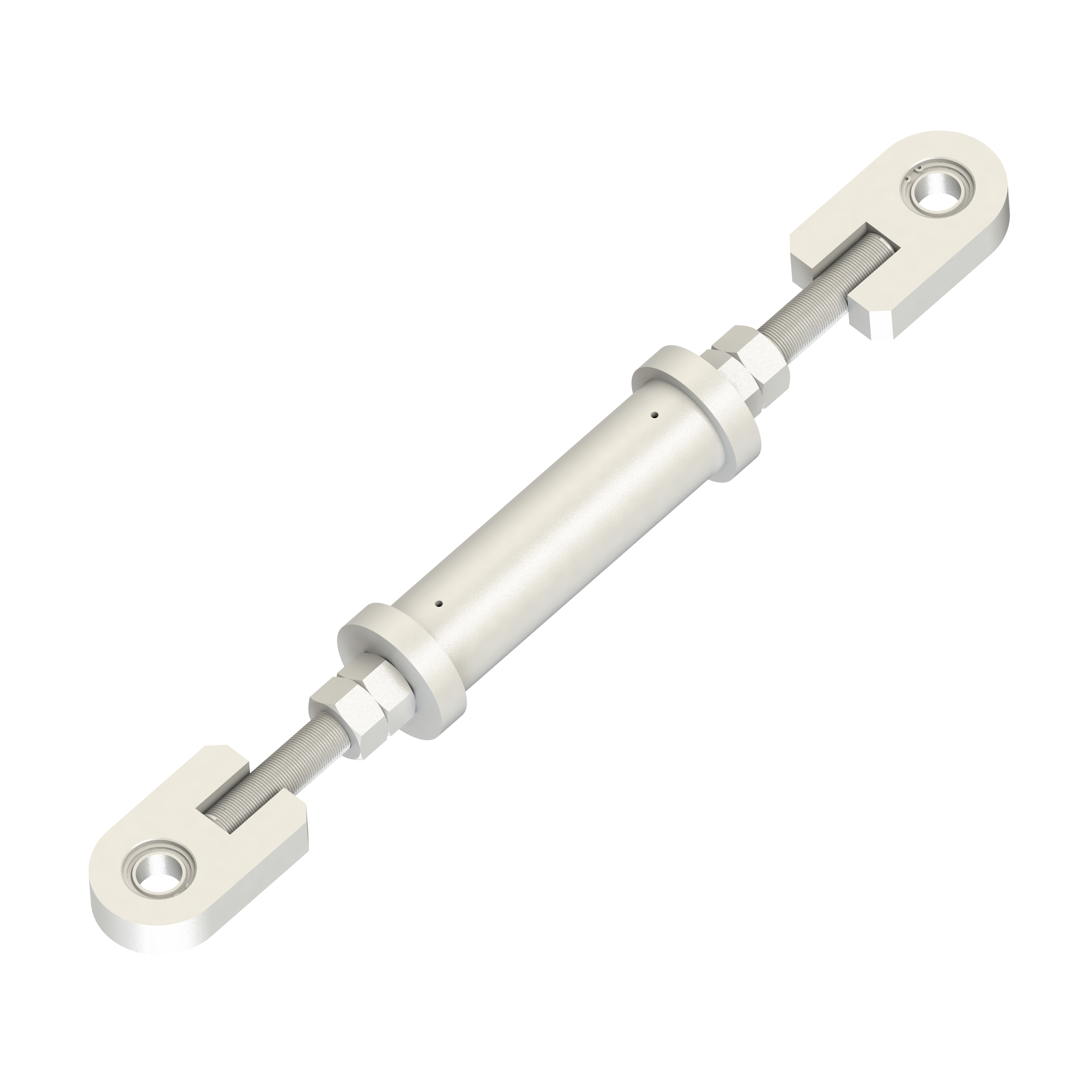

BG310

BG310HYDRAULIC SNUBBERS (SHOCK ARRESTORS)

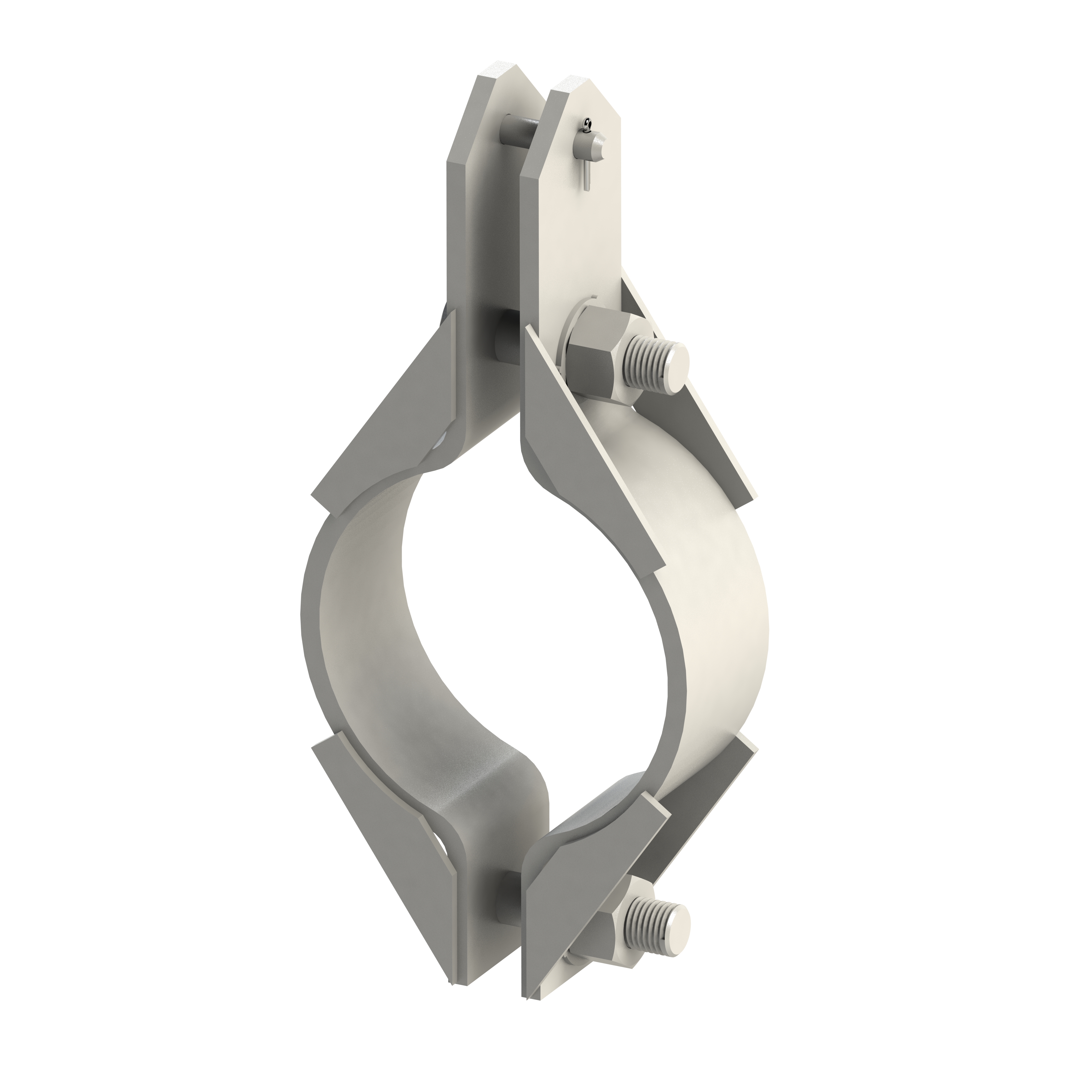

BG321

BG321PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG322

BG322PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG320

BG320PIPE CLAMP FOR HYDRAULIC SNUBBER – LOW TEMPERATURE

BG350

BG350RIGID STRUTS

BG340

BG340SWAY BRACE

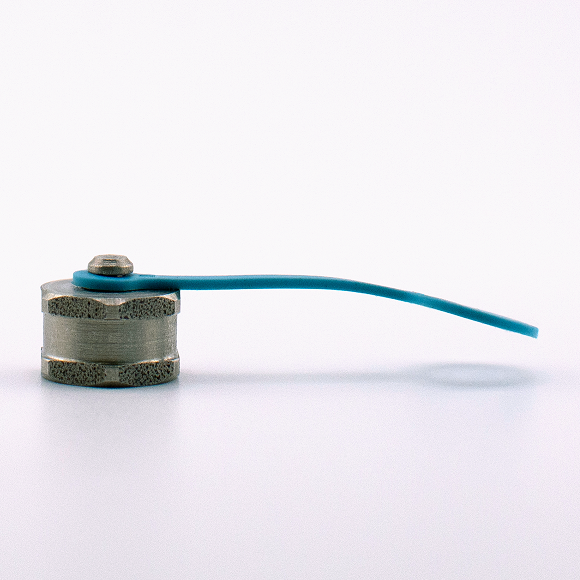

#691028

#691028All Stainless Steel Gauge Adapter #691028

#520XL

#520XLAll Stainless Steel Gauge Adapter #520XL

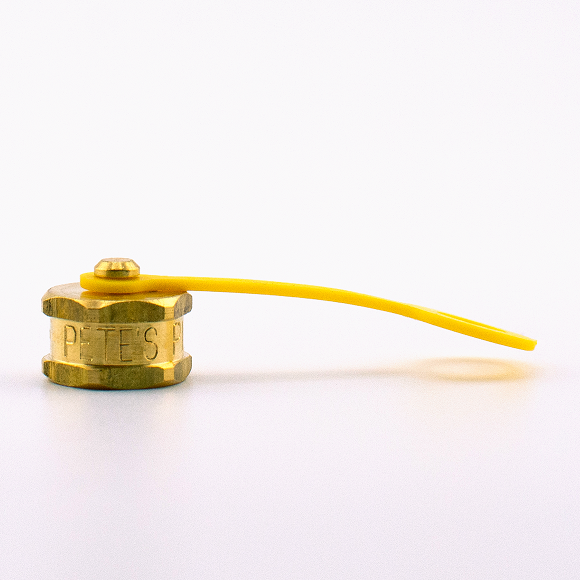

#691023

#691023Brass Gauge Adapter #691023

#500BSP

#500BSPBrass Gauge Adapter #500BSP

#691024

#691024Brass Gauge Adapter #691024

#500XLBSP

#500XLBSPBrass Gauge Adapter #500XLBSP

691026

691026Brass Gauge Adapter #691026

#691027

#691027Brass Gauge Adapter #691027

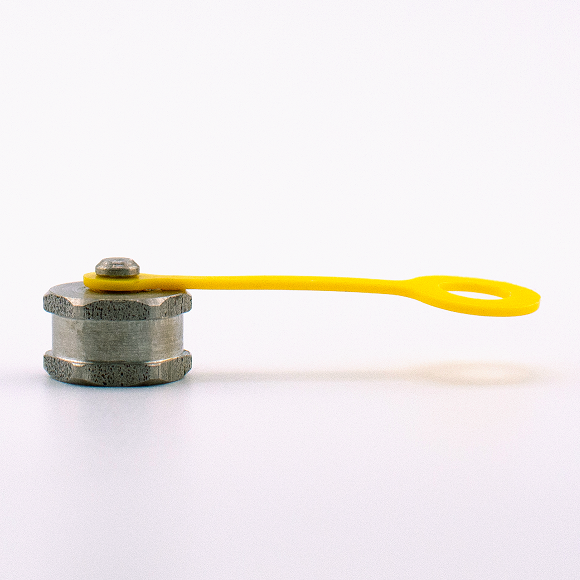

#104-1BS

#104-1BSCap Assembly #104-1BS

#104-1YS

#104-1YSCap Assembly #104-1YS

#104-2BS

#104-2BSCap Assembly #104-2BS

#104-2YS

#104-2YSCap Assembly #104-2YS

#691003

#691003Pete's Plug #691003

#691002

#691002Pete's Plug #691002

#691010

#691010Pete's Plug #691010

#691001

#691001Pete's Plug #691001

#691000

#691000Pete's Plug #691000

#691017

#691017Pete's Plug #691017

#12510

#12510Pete's Plug #12510

691020

691020Pete's Plug #691020

#691008

#691008Pete's Plug #691008

#691005

#691005Pete's Plug #691005

#691007

#691007Pete's Plug #691007

#691004

#691004Pete's Plug #691004

#572

#572Pete's Plug #572

#691019

#691019Pete's Plug #691019

#691018

#691018Pete's Plug #691018

#760

#760Pete's Plug #760

#691016

#691016Pete's Plug #691016

#691022

#691022Pete's Plug #691022

#691021

#691021Pete's Plug #691021

#691014

#691014Pete’s Plug #691014

#691013

#691013Pete’s Plug #691013

#562

#562Pete’s Plug #562

#691012

#691012Pete’s Plug #691012

#691011

#691011Pete’s Plug #691011

#750XL

#750XLPete’s Plug #750XL

#691015

#691015Pete’s Plug #691015

#691029

#691029Pressure & Temperature Test Kit 0-100psi

#691030

#691030Pressure & Temperature Test Kit 0-100psi for XL

#1500-5

#1500-5Pressure Gauge 0-100 PSI BSP Stem

#1500-4

#1500-4Pressure Gauge 0-100 PSI NPT Stem

#606

#606Thermometer -58°F to 550°F

-

-

-

- About

- Resources

- Contact

Complete Range

Explore our extensive range of top-tier pipe support products designed to meet all your needs. From pipe clamps to specialised hanger systems and ancillary components, this diverse selection caters to all pipe configurations and support requirements. Find your perfect pipe support solutions and ensure the stability and longevity of your piping systems here.