- Products

-

-

-

Categories

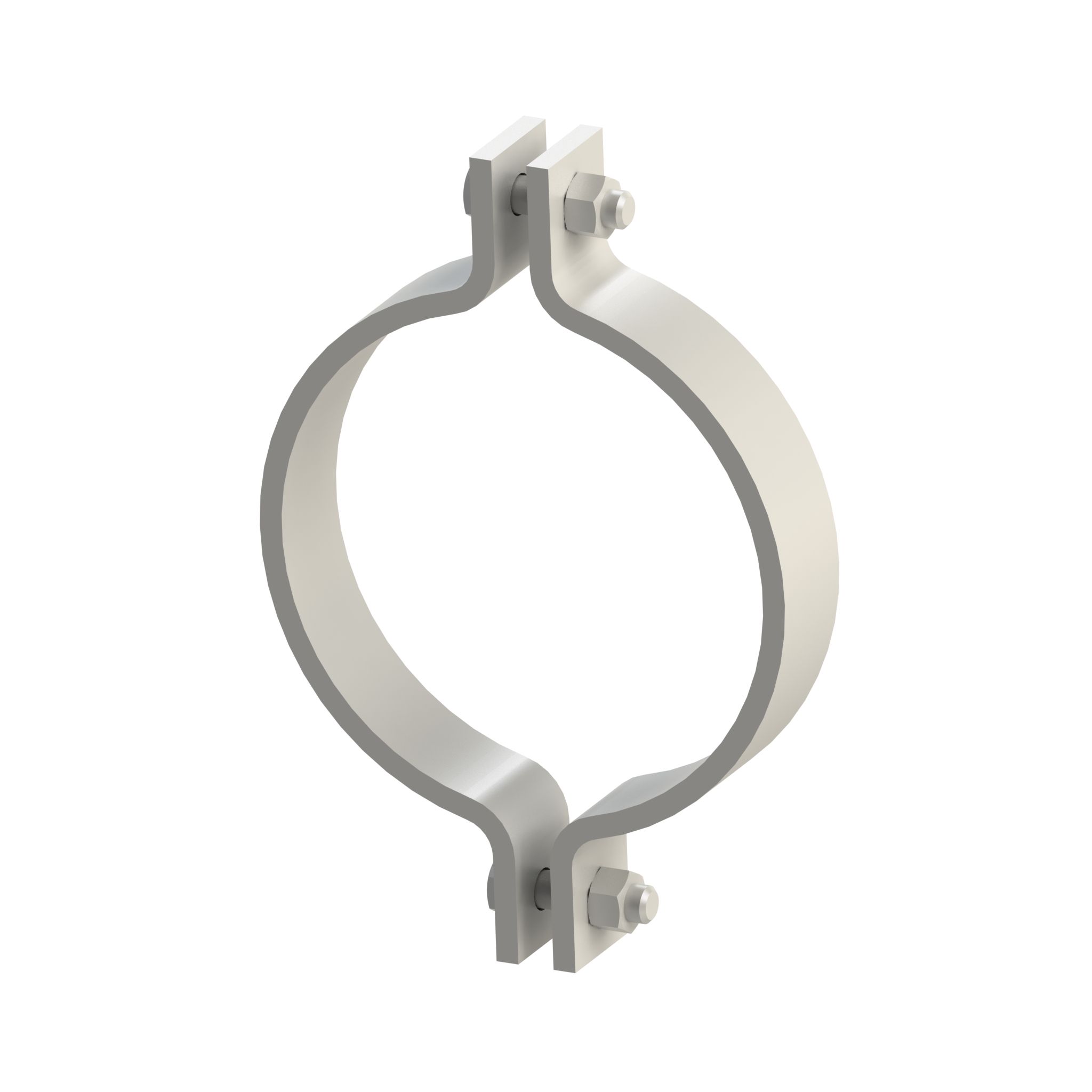

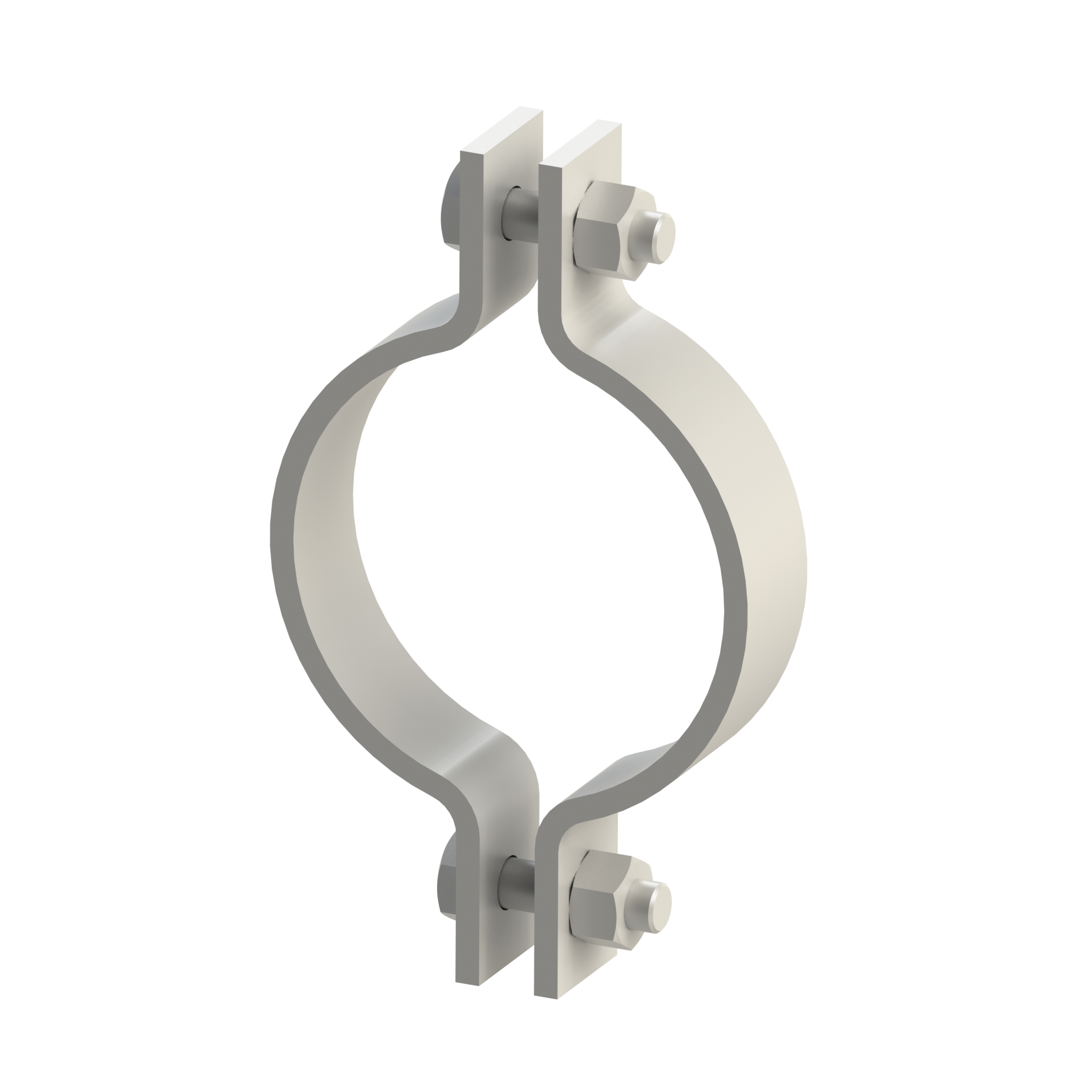

BG100

BG100LIGHT DUTY 2-BOLT CLAMP

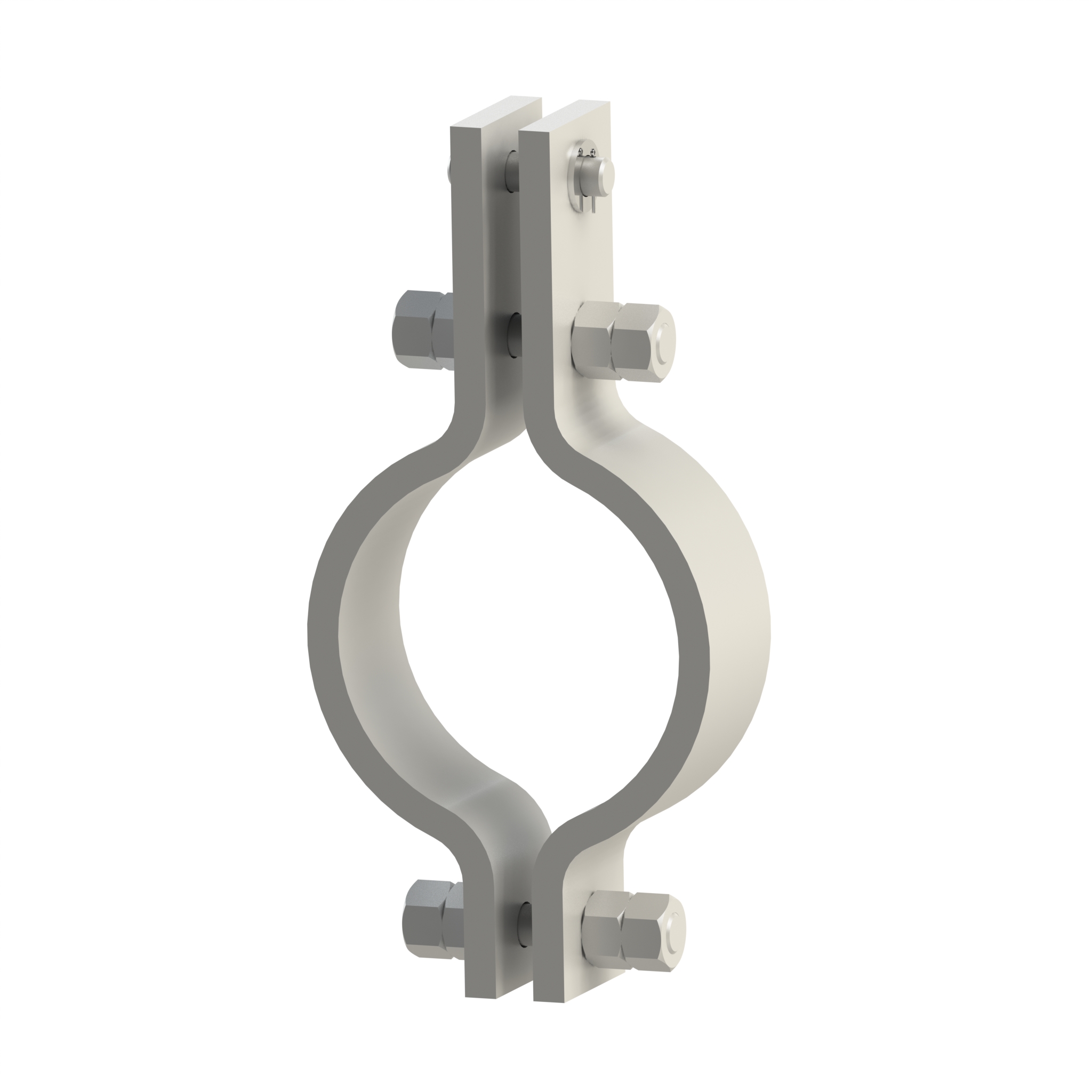

BG170

BG170MEDIUM DUTY 2-BOLT PIPE CLAMP

BG50

BG50HEAVY DUTY 2-BOLT PIPE CLAMP

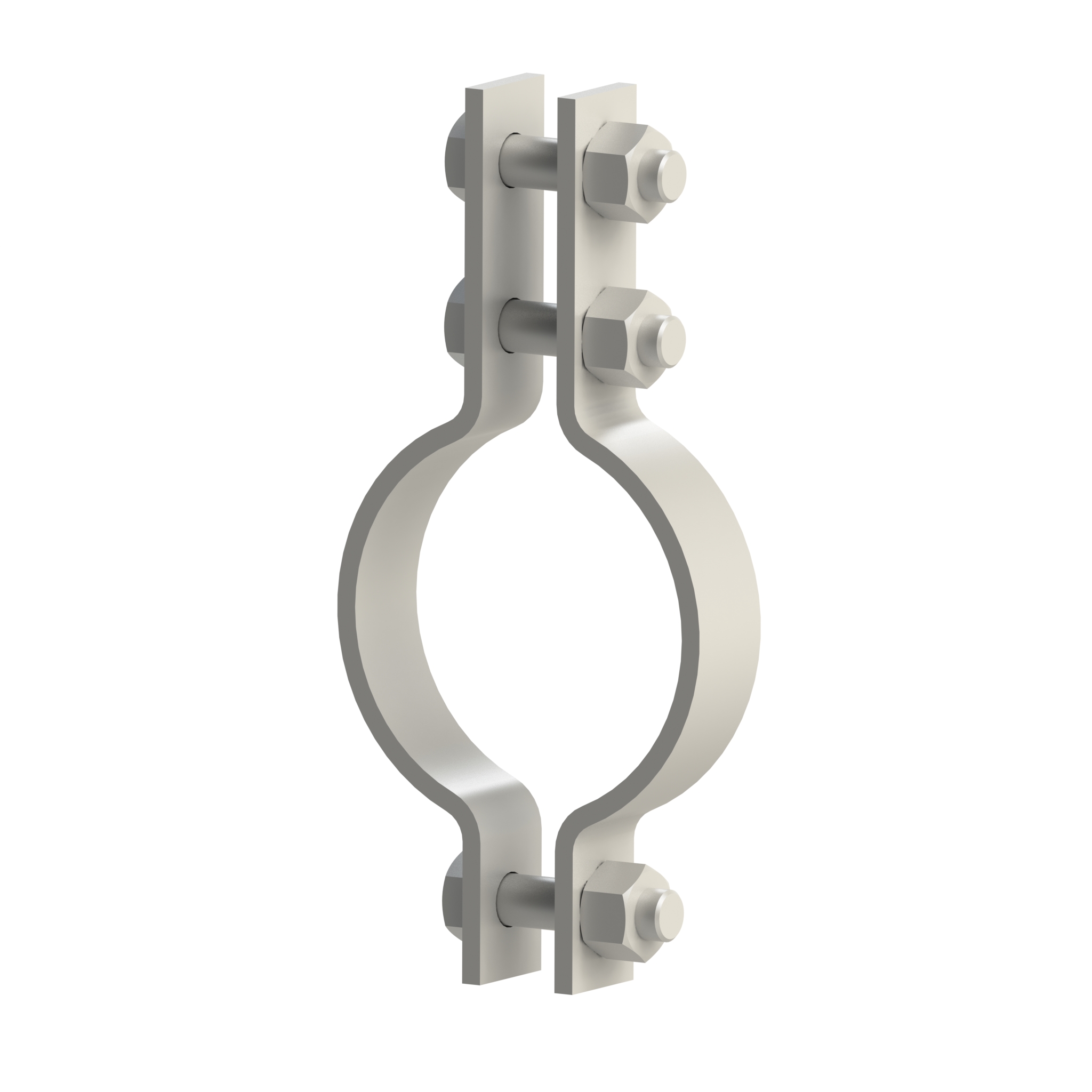

BG101

BG101LIGHT DUTY 3-BOLT PIPE CLAMP

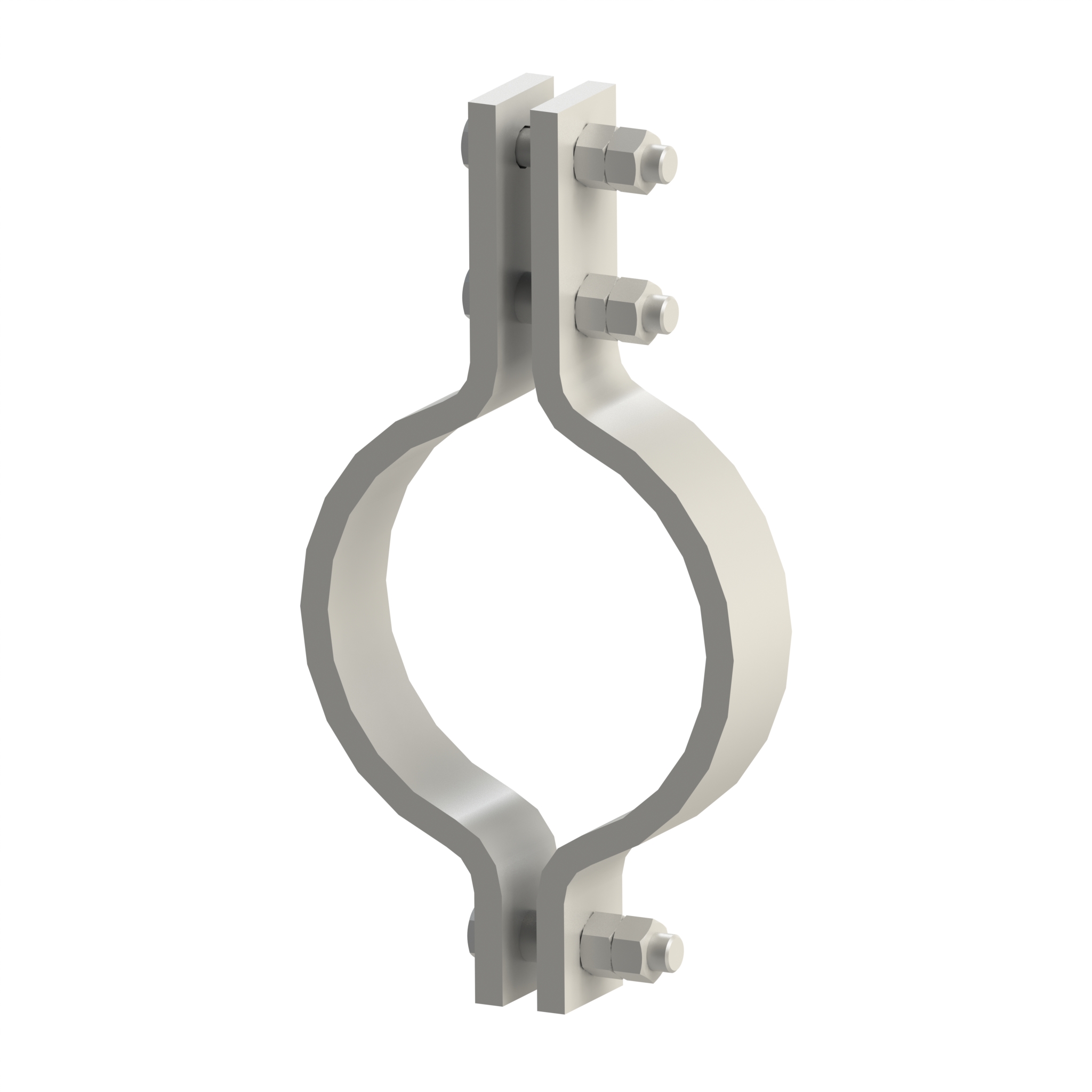

BG171

BG171MEDIUM DUTY 3-BOLT PIPE CLAMP FOR STEEL PIPE

BG75

BG75HEAVY DUTY 3-BOLT PIPE CLAMP

BG172

BG172HIGH TEMPERATURE 3-BOLT PIPE CLAMP

BG173

BG173ALLOY PIPE CLAMP - VERY HIGH TEMPERATURE

BG140

BG140INSULATED 2-BOLT PIPE CLAMP

BG141

BG141INSULATED 2-BOLT PIPE CLAMP FOR CU/NI

BG145

BG145INSULATED 3-BOLT PIPE CLAMP

BG146

BG146INSULATED 3-BOLT PIPE CLAMP FOR CU/NI

BG108

BG108CLEVIS CLAMP

BG222

BG222BEAM CLAMP

BG174

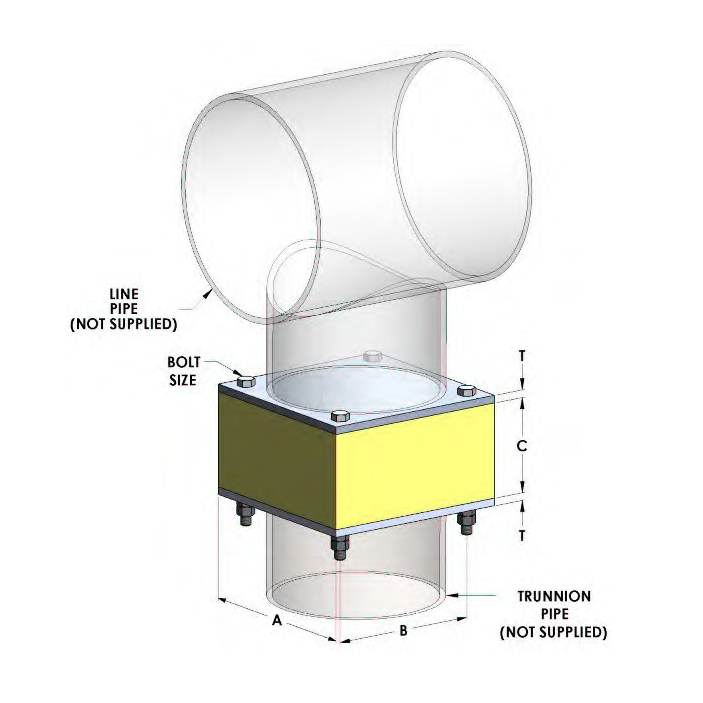

BG174RISER SUPPORT – STD TEMPERATURE

BG175

BG175RISER SUPPORT – HIGH TEMPERATURE

BG176

BG176ALLOY RISER SUPPORT - VERY HIGH TEMPERATURE

BG202

BG202ALLTHREAD ROD

BG209

BG209FORGED CLEVIS AND PIN

BG210

BG210FORGED TURNBUCKLE

BG204

BG204FORGED WELDLESS EYE NUT

BG215

BG215HEMISPHERICAL CUP

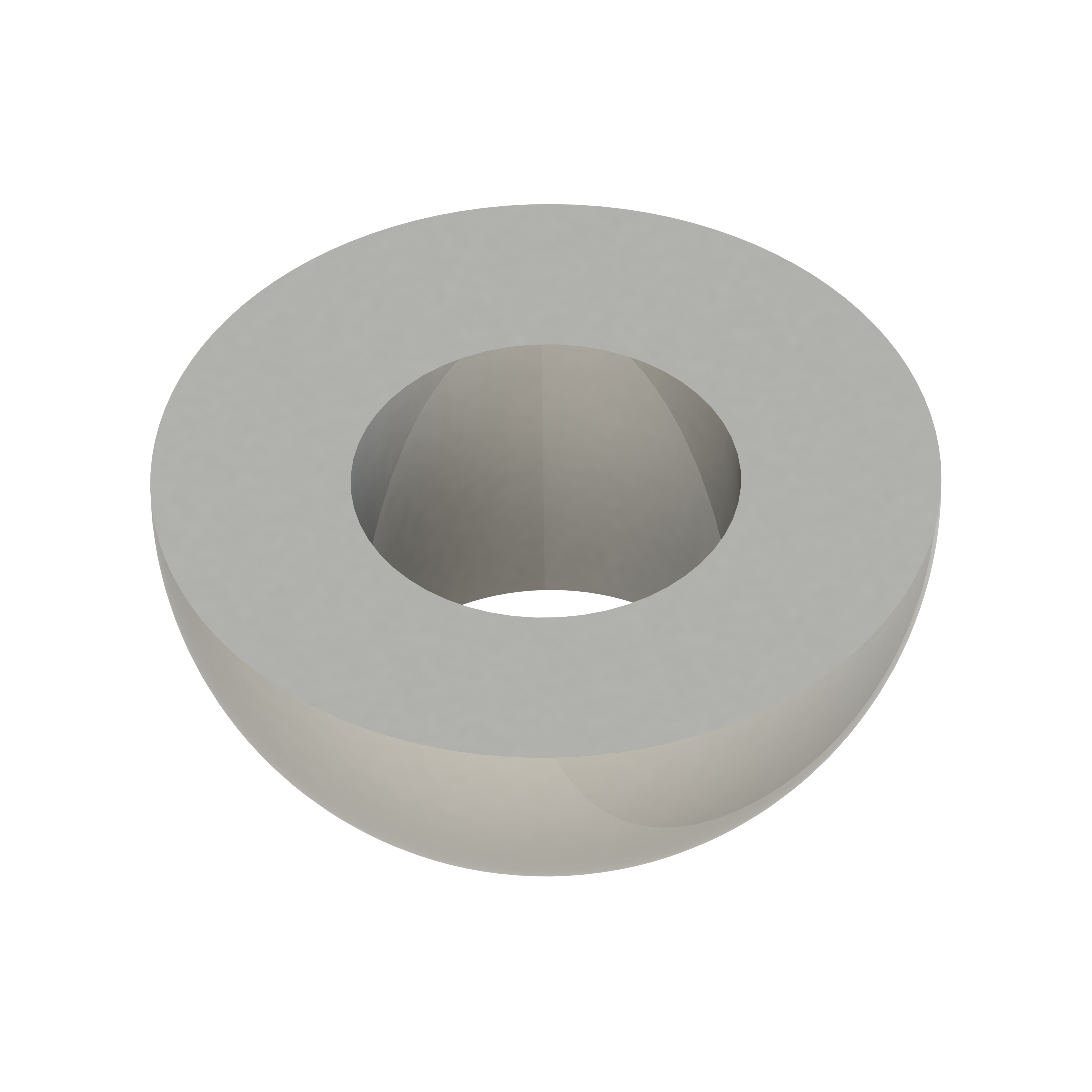

BG214

BG214HEMISPHERICAL WASHER

BG206

BG206HEXAGONAL CONNECTOR

BG216

BG216PIPE WELDING LUG

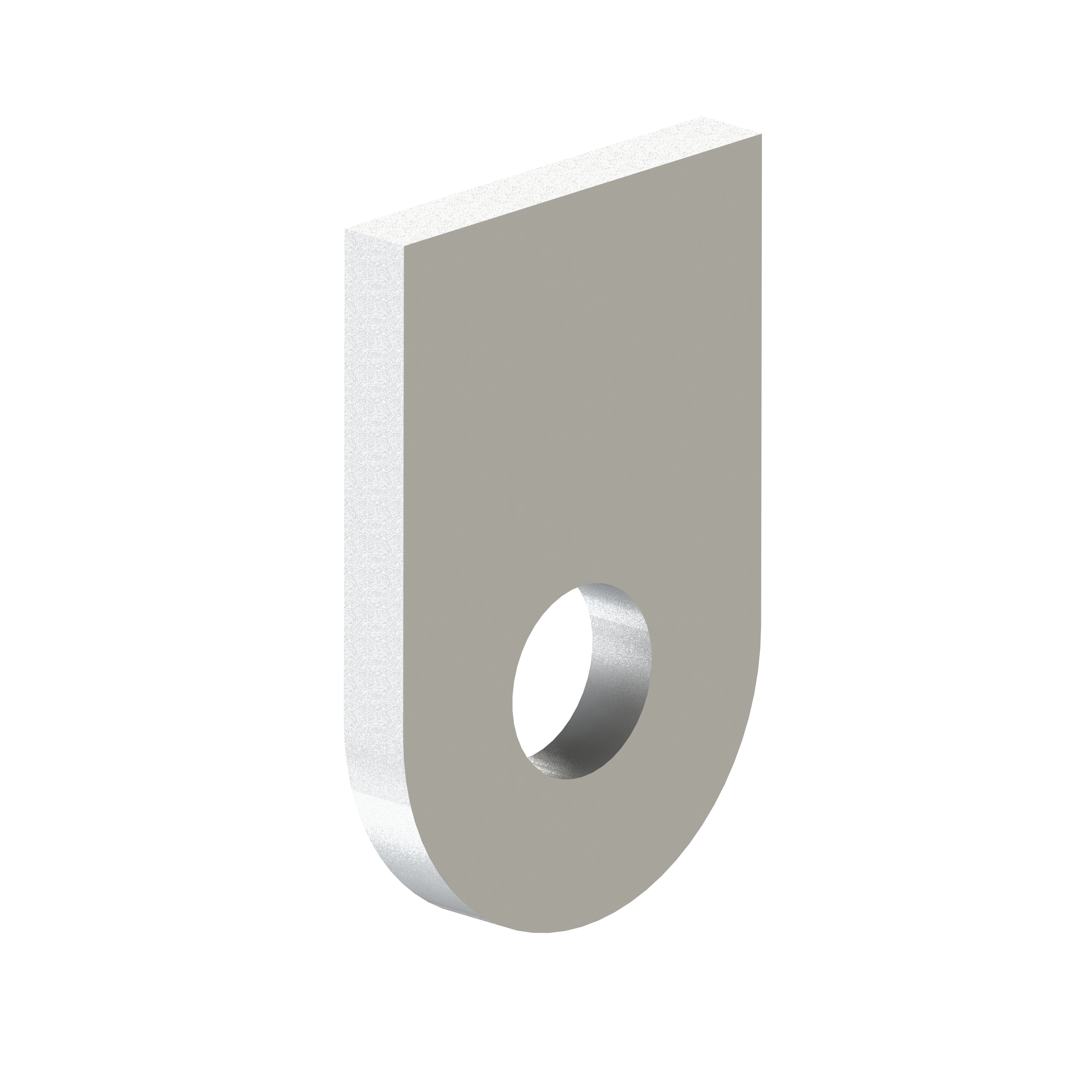

BG217

BG217PLATE WASHER

BG207

BG207SPADE NUT

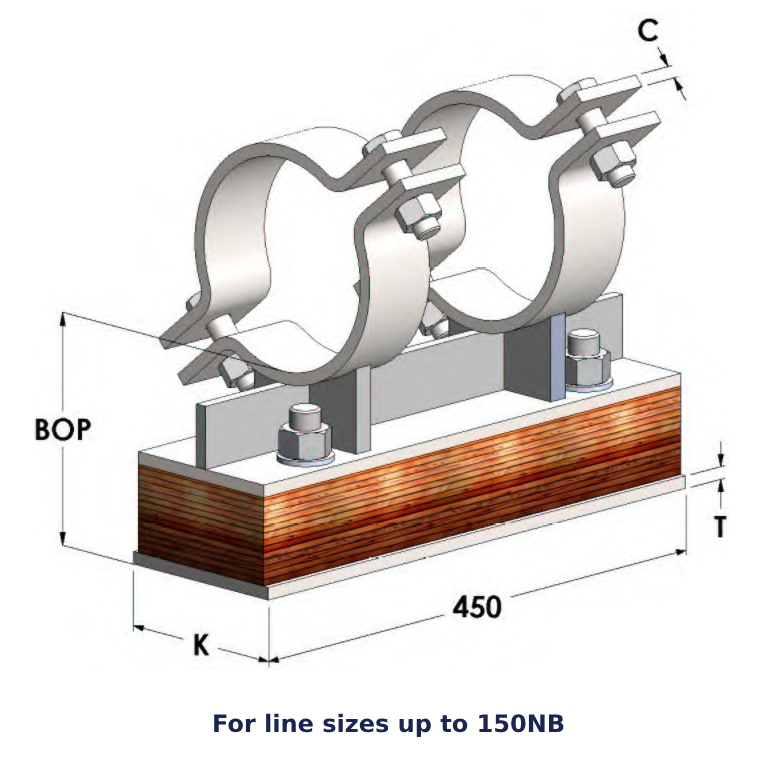

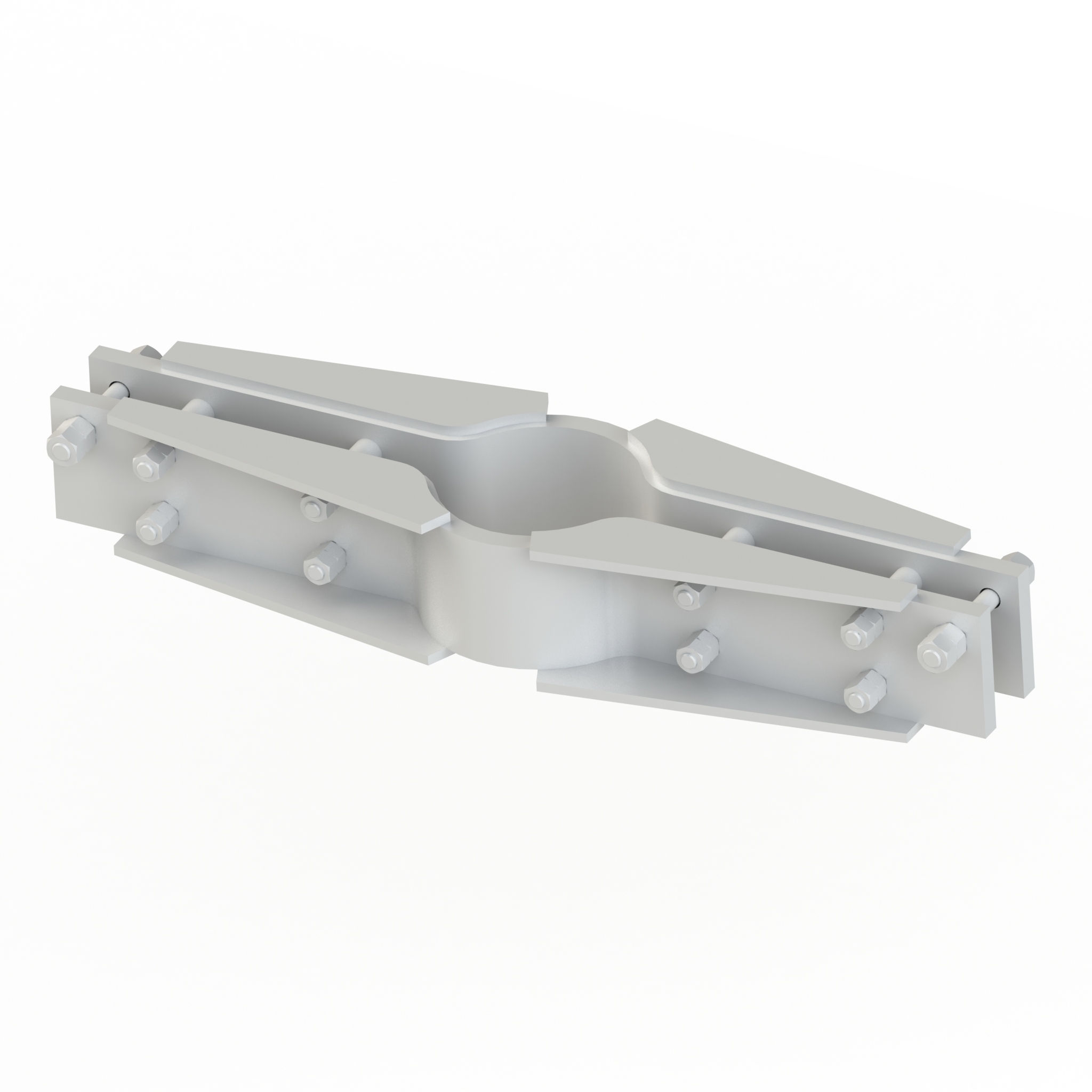

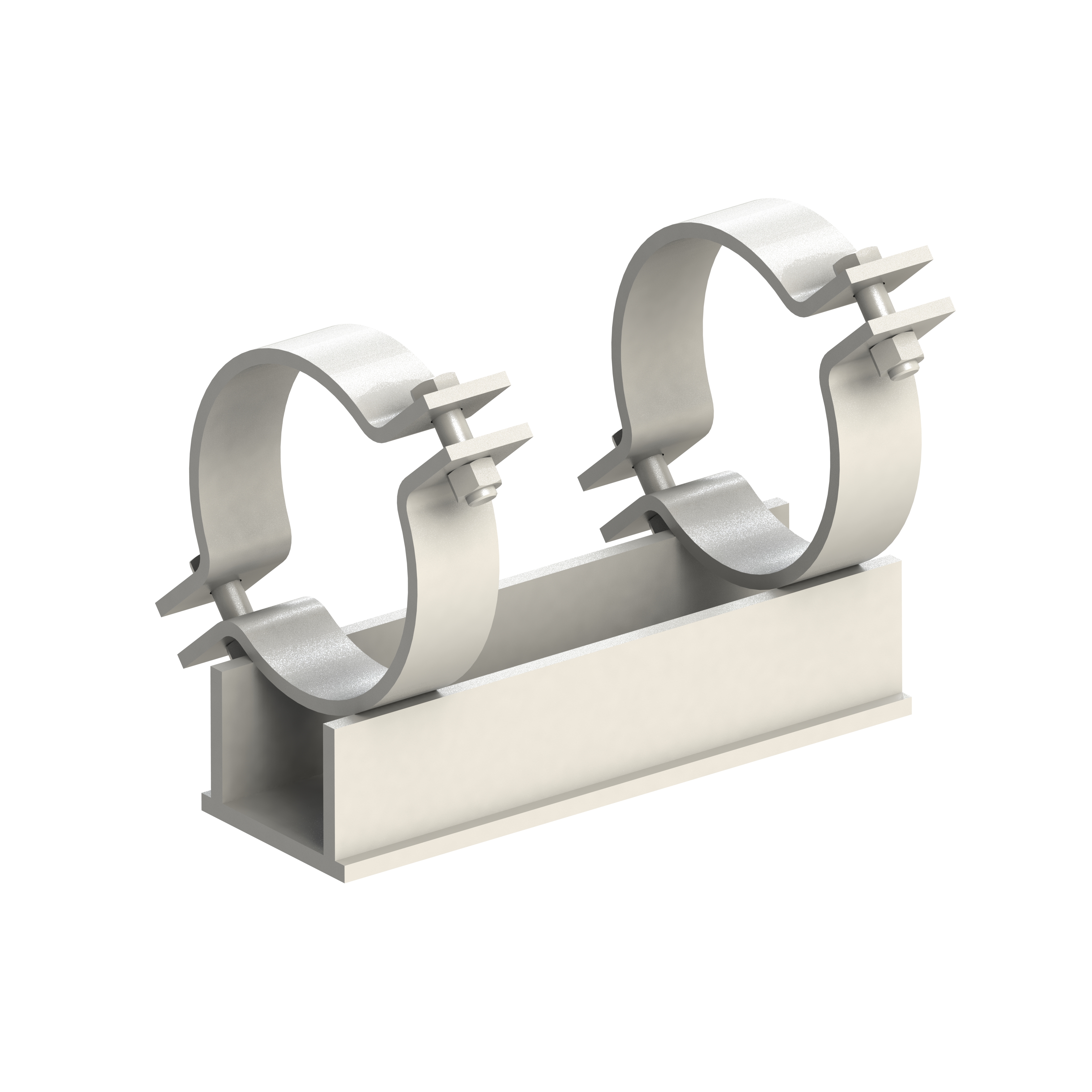

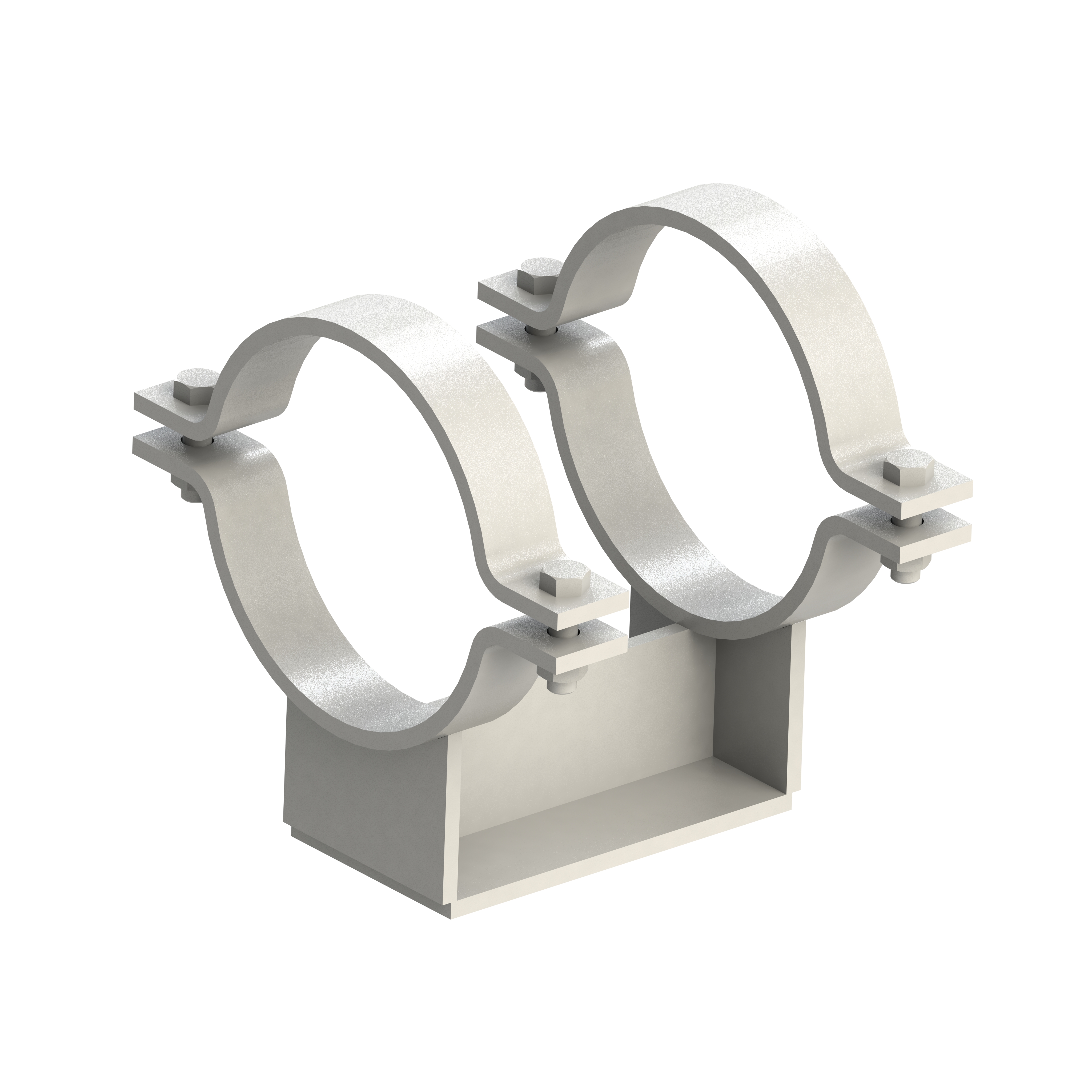

BG245

BG245STANDARD TRAPEZE

BG203

BG203THREADED DROP ROD – RH/LH

BG219

BG219WELDED BEAM ATTACHMENT

BG220

BG220WELDED BEAM ATTACHMENT (WITH LOAD PIN)

BG225

BG225WELDING LUG

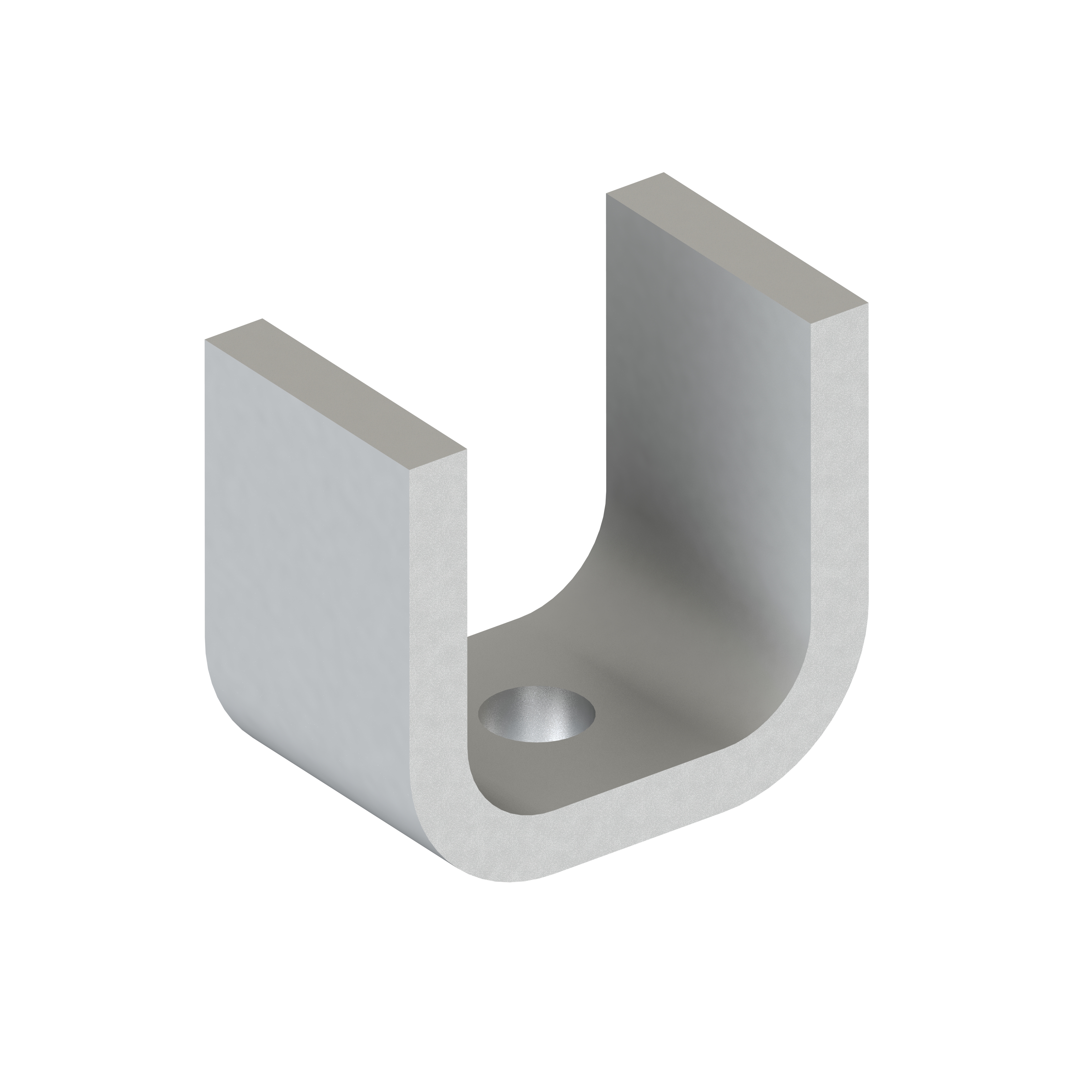

BG180

BG180U-BOLT GUIDE

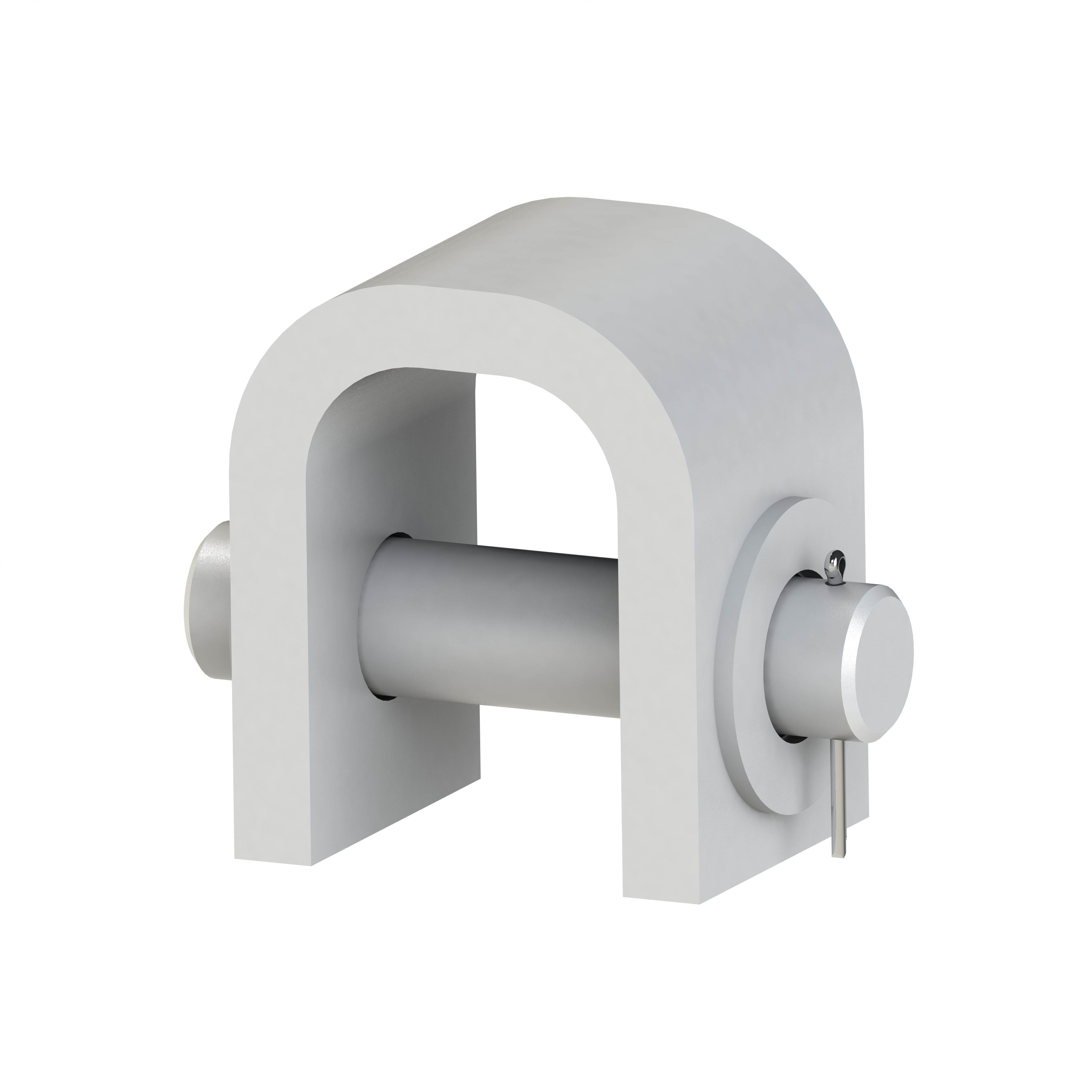

BG181

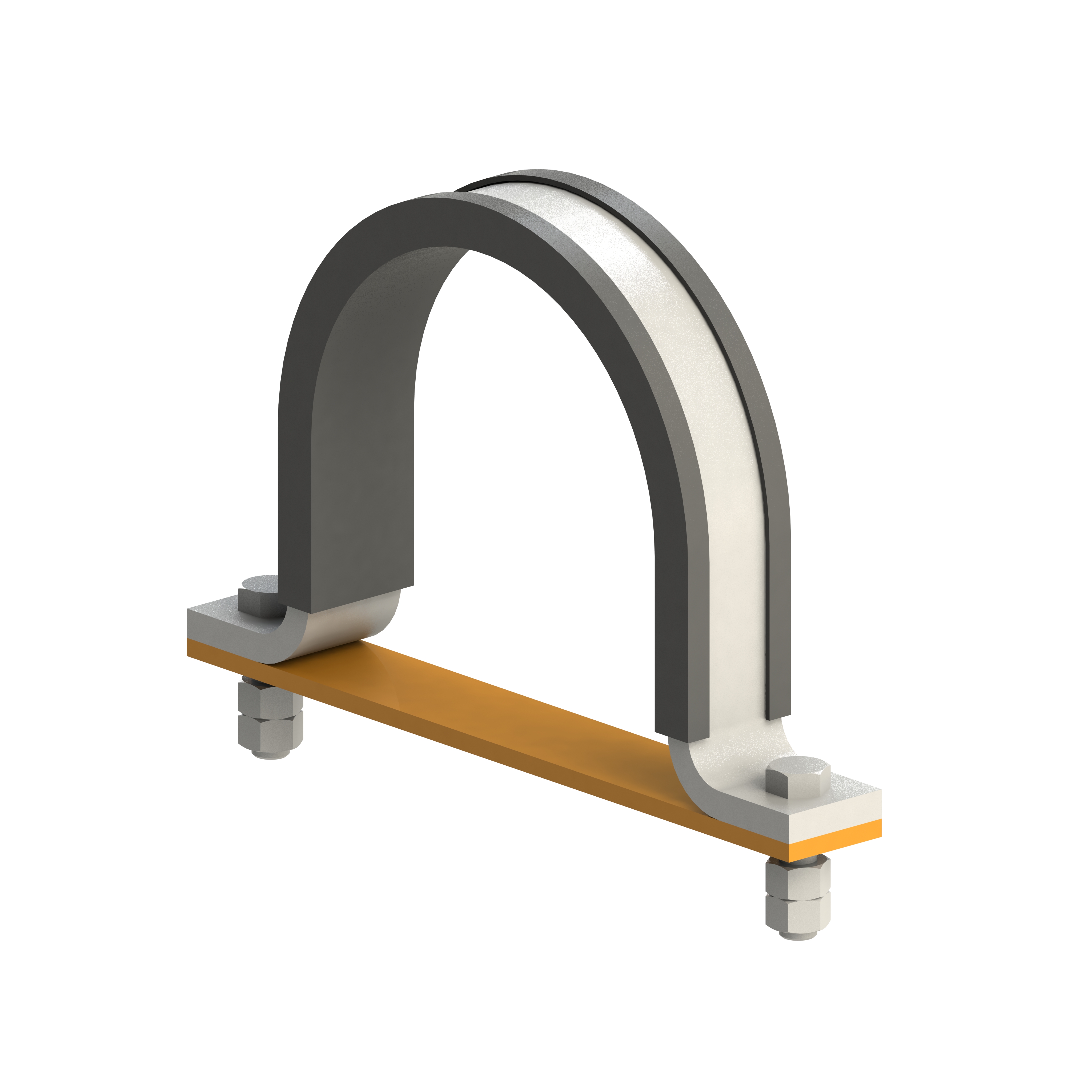

BG181U-BOLT CLAMP

BG150

BG150INSULATED U-BOLT CLAMP

BG152

BG152INSULATED U-BOLT GUIDE

BG154

BG154INSULATED U-BOLT GUIDE (WITH TEFLON)

BG190

BG190INSULATED U-BOLT CLAMP

BG192

BG192INSULATED U-BOLT GUIDE

BG151

BG151INSULATED U-BOLT CLAMP FOR CU/NI

BG153

BG153INSULATED U-BOLT GUIDE FOR CU/NI

For Cu/Ni Pipe BG155

BG155INSULATED U-BOLT GUIDE (WITH TEFLON)

For Cu/Ni Pipe BG177

BG177SADDLE GUIDE

BG178

BG178SADDLE CLAMP

BG160

BG160INSULATED PIPE SADDLE

BG161

BG161INSULATED PIPE SADDLE

BG162

BG162INSULATED PIPE SADDLE

BG135-136

BG135-136ADJUSTABLE PIPE STANDS

BG515

BG515STANDARD CLAMPED PIPE SHOE

BG550

BG550SLIDE PLATES

BG517

BG517COMPACT PIPE SHOE

BG400

BG400CLAMPED HOT PIPE SHOE

BG156

BG156INSULATED PIPE SHOE

BG157

BG157INSULATED PIPE SHOE

BG510

BG510STANDARD WELDED PIPE SHOE

BG518

BG518COMPACT WELDED PIPE SHOE

BG555

BG555STANDARD LINE STOPS

BG560

BG560STANDARD PIPE GUIDES

BG570

BG570STANDARD SHOE GUIDES

BG580

BG580STANDARD SHOE GUIDES

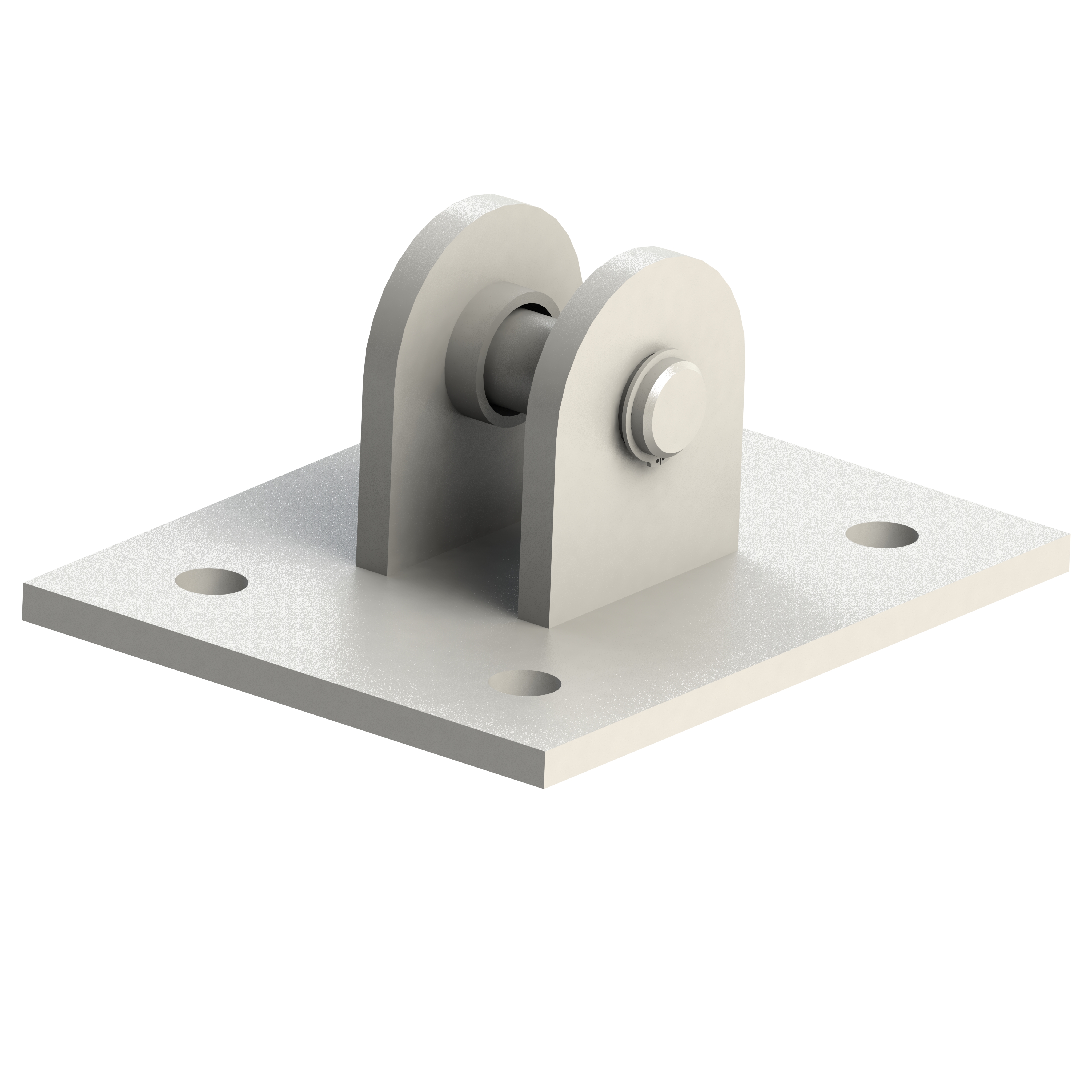

BG315

BG315END ATTACHMENT FOR HYDRAULIC SNUBBERS

BG355

BG355END ATTACHMENT FOR RIGID STRUT & SWAY BRACE

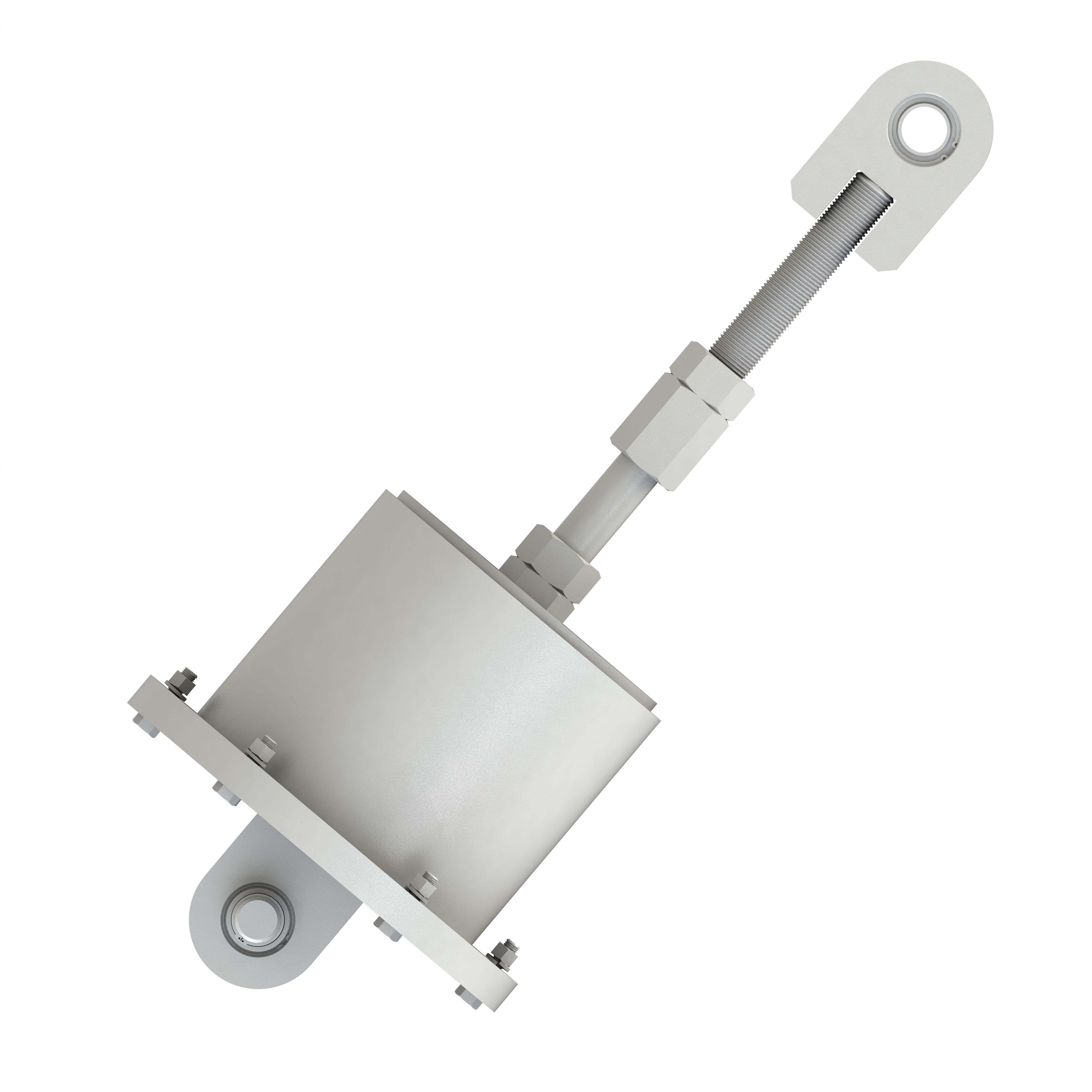

BG310

BG310HYDRAULIC SNUBBERS (SHOCK ARRESTORS)

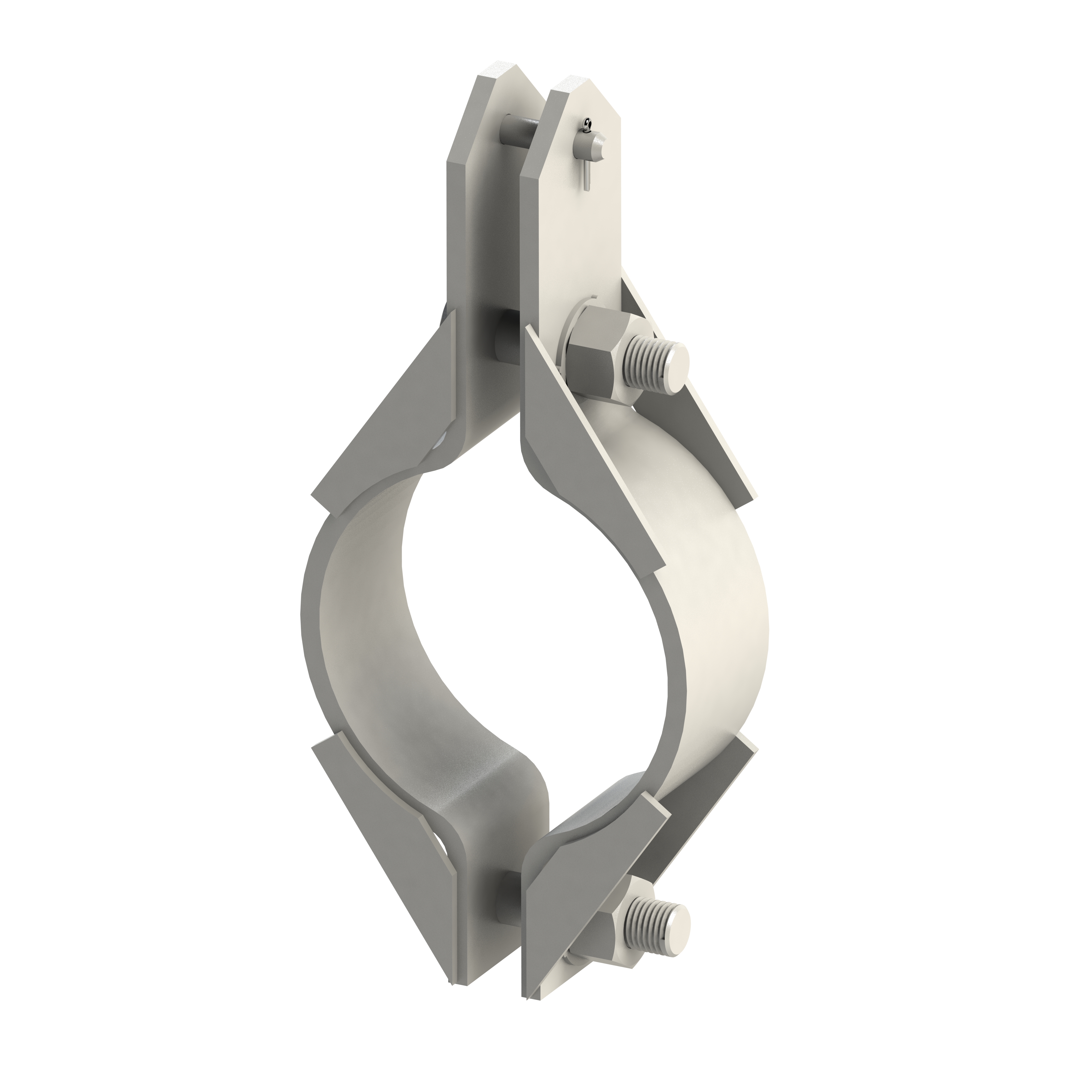

BG321

BG321PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG322

BG322PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG320

BG320PIPE CLAMP FOR HYDRAULIC SNUBBER – LOW TEMPERATURE

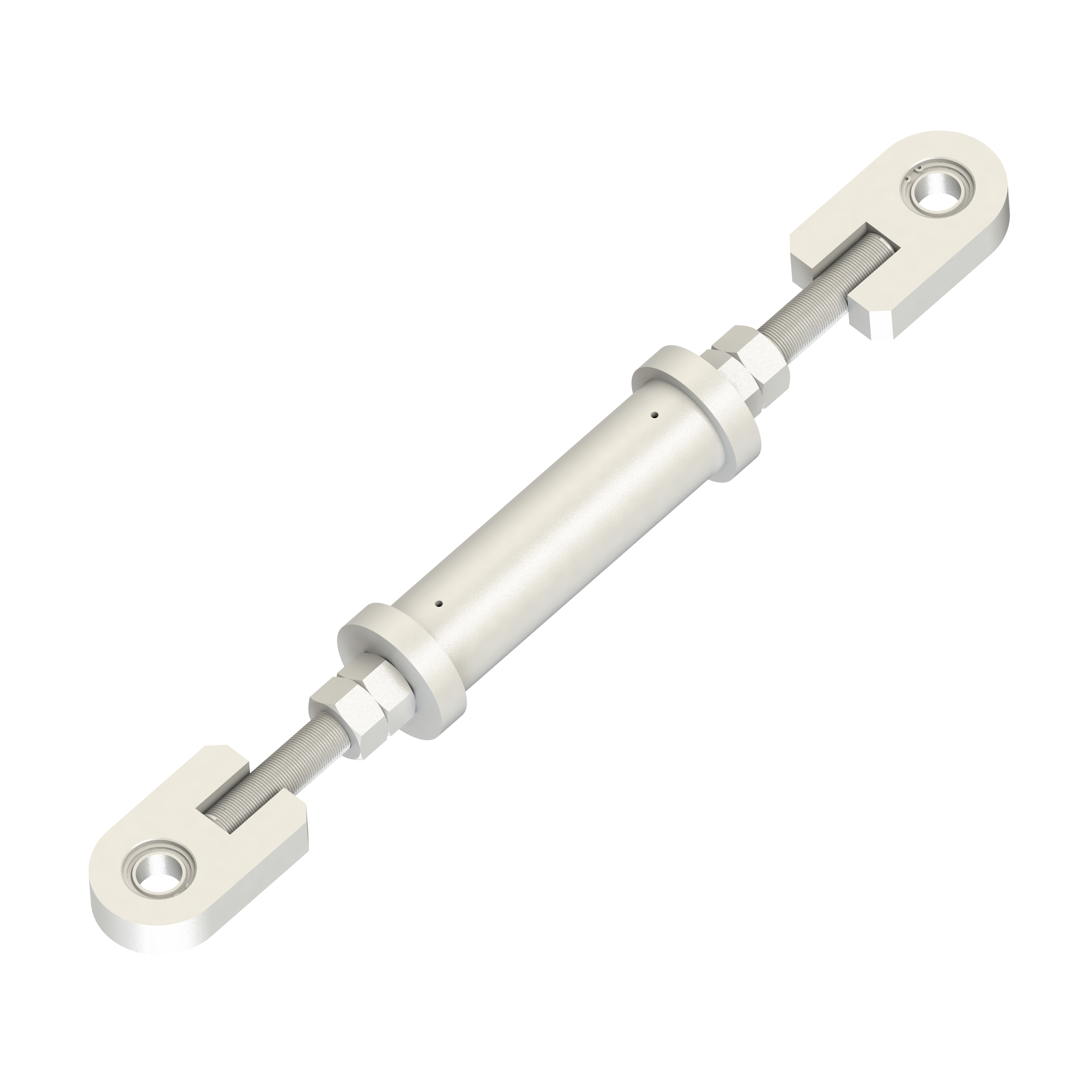

BG350

BG350RIGID STRUTS

BG340

BG340SWAY BRACE

#691028

#691028All Stainless Steel Gauge Adapter #691028

#520XL

#520XLAll Stainless Steel Gauge Adapter #520XL

#691023

#691023Brass Gauge Adapter #691023

#500BSP

#500BSPBrass Gauge Adapter #500BSP

#691024

#691024Brass Gauge Adapter #691024

#500XLBSP

#500XLBSPBrass Gauge Adapter #500XLBSP

691026

691026Brass Gauge Adapter #691026

#691027

#691027Brass Gauge Adapter #691027

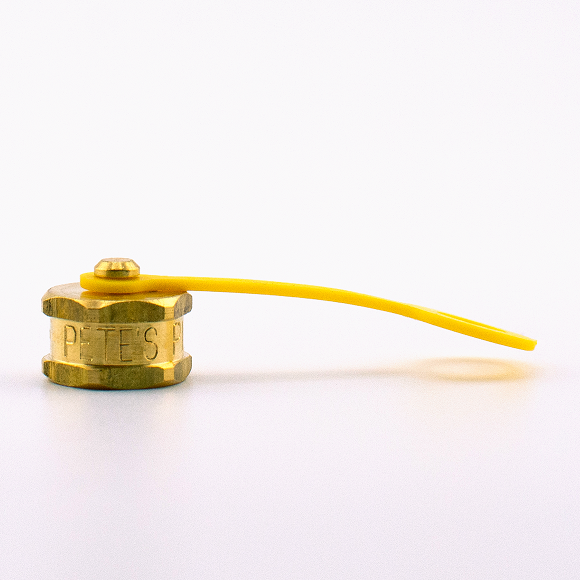

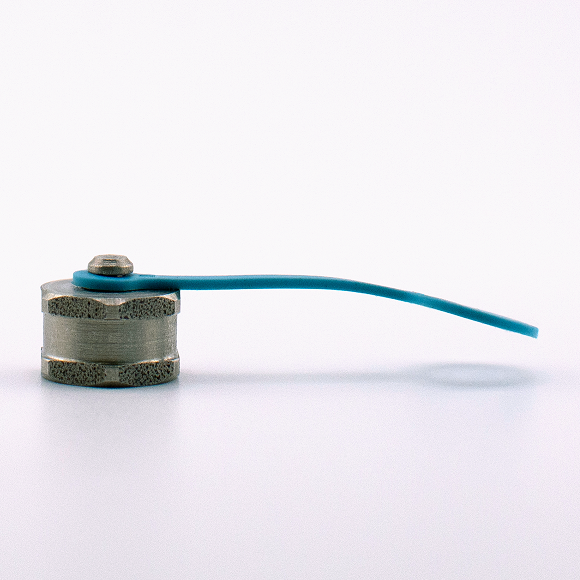

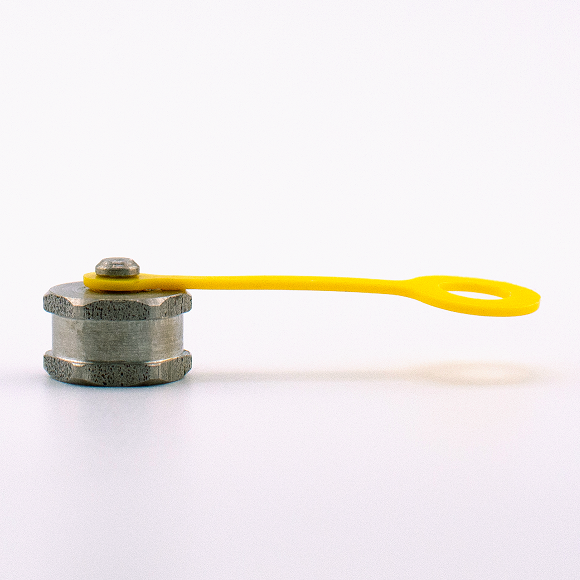

#104-1BS

#104-1BSCap Assembly #104-1BS

#104-1YS

#104-1YSCap Assembly #104-1YS

#104-2BS

#104-2BSCap Assembly #104-2BS

#104-2YS

#104-2YSCap Assembly #104-2YS

#691003

#691003Pete's Plug #691003

#691002

#691002Pete's Plug #691002

#691010

#691010Pete's Plug #691010

#691001

#691001Pete's Plug #691001

#691000

#691000Pete's Plug #691000

#691017

#691017Pete's Plug #691017

#12510

#12510Pete's Plug #12510

691020

691020Pete's Plug #691020

#691008

#691008Pete's Plug #691008

#691005

#691005Pete's Plug #691005

#691007

#691007Pete's Plug #691007

#691004

#691004Pete's Plug #691004

#572

#572Pete's Plug #572

#691019

#691019Pete's Plug #691019

#691018

#691018Pete's Plug #691018

#760

#760Pete's Plug #760

#691016

#691016Pete's Plug #691016

#691022

#691022Pete's Plug #691022

#691021

#691021Pete's Plug #691021

#691014

#691014Pete’s Plug #691014

#691013

#691013Pete’s Plug #691013

#562

#562Pete’s Plug #562

#691012

#691012Pete’s Plug #691012

#691011

#691011Pete’s Plug #691011

#750XL

#750XLPete’s Plug #750XL

#691015

#691015Pete’s Plug #691015

#691029

#691029Pressure & Temperature Test Kit 0-100psi

#691030

#691030Pressure & Temperature Test Kit 0-100psi for XL

#1500-5

#1500-5Pressure Gauge 0-100 PSI BSP Stem

#1500-4

#1500-4Pressure Gauge 0-100 PSI NPT Stem

#606

#606Thermometer -58°F to 550°F

-

-

-

- About

- Resources

- Contact

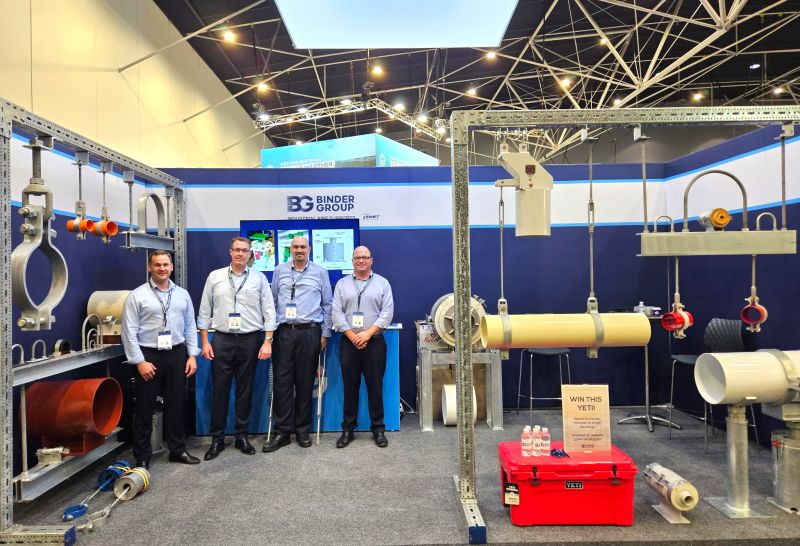

WHAT WE LEARNED AT EXA 2025 – REAL CONVERSATIONS, REAL CHALLENGES, REAL SOLUTIONS

EXA 2025 was more than an event—it was a pulse check on what really matters to Australia’s heavy industry projects.

Held at the Perth Convention & Exhibition Centre, the Energy Exchange Australia (EXA) Exhibition brought together the key players in energy, infrastructure, and industrial project delivery. For Binder Group, it was a chance to reconnect with existing clients, engage with new contacts, and hear firsthand what’s driving decisions in the market today.

Here’s what stood out.

1. Speed and Supply Chain Certainty Are No Longer Optional

Across every conversation, one theme kept coming up: lead times. Project teams are under pressure. Delays from offshore suppliers are putting critical timelines at risk, and there’s a clear shift towards local, responsive manufacturing.

Visitors to our stand were looking for:

- Shorter delivery cycles

- Suppliers that can adapt to changes mid-project

- Better visibility and communication throughout the process

At Binder Group, we’re responding with:

- Guaranteed lead times backed by in-house manufacturing

- A responsive team that can adapt to design or scheduling changes

- Transparent project tracking and local support

For project managers, specifiers, and engineers alike, the reliability of supply is just as important as the product itself.

2. Australian-Made Is Now a Business Advantage

The appetite for Australian-made products is growing—not as a checkbox, but as a practical strategy for reducing risk and ensuring consistent quality.

Attendees shared their concern about:

- Inconsistent product standards from overseas

- Lack of traceability

- Delayed deliveries and port congestion

Binder Group’s full return to Australian ownership and manufacturing resonated with many. Our focus on quality control, local sourcing, and technical collaboration gives project teams confidence from design through to delivery.

We’re not just bringing production back—we’re reinvesting in capability, tools, and people to support Australia’s infrastructure, energy, and resource sectors.

3. Specifiers and Engineers Want Support, Not Just Products

Today’s engineering teams don’t just want a datasheet. They want a supplier who can step in early, understand the design intent, and help solve challenges before they become issues on site.

Here’s what they asked us at EXA:

- Can you customise a support to suit our layout?

- Do you provide technical support?

- Can you provide compliance documentation upfront?

Binder Group is built around answering “yes” to all of the above. With in-house technical experts, BIM/CAD capability, and a dedicated project support team, we help engineers deliver outcomes—not just components.

What We Showcased at EXA 2025

This year, we brought a selection of engineered pipe support solutions that sparked real interest among engineers, specifiers, and contractors. Here’s what drew attention—and why it matters.

1. Cryogenic Cold Shoe

What it is: A heavy-duty pipe support designed to maintain insulation and load-bearing capacity in extremely low-temperature environments (e.g. LNG facilities, cold storage, petrochemical plants).

Why it matters:

At cryogenic temperatures, standard pipe supports can fail due to thermal bridging, material contraction, or moisture ingress. Our Cryogenic Cold Shoe uses multi-layer insulation, vapour barriers, and a robust steel cradle to:

- Prevent heat transfer

- Protect the integrity of the pipe

- Ensure structural stability throughout the system

Visitors were impressed by the scale, design detail, and application-specific engineering that went into this solution. For engineers working in LNG and similar sectors, it’s a critical component that must perform under extreme conditions.

2. Spring Supports

Why it matters:

When high-temperature fluids pass through pipelines, thermal expansion can cause vertical movement. If the system is rigid, that stress gets transferred into nearby structures or equipment—risking damage and shutdowns.

What it is: A dynamic support that accommodates vertical movement in piping systems due to thermal expansion, vibration, or structural shifts.movement. If the system is rigid, that stress gets transferred into nearby structures or equipment—risking damage and shutdowns.

Our Spring Supports:

- Provide controlled, continuous support even during movement

- Are available in variable and constant load designs

- Can be pre-calculated to match exact project specifications (load, travel, spring rate)

At EXA, this sparked interesting technical conversations about application fit, code compliance, and onsite adjustability. Specifiers appreciated that our team could talk through load tables and installation considerations without needing to “get back to them later.”

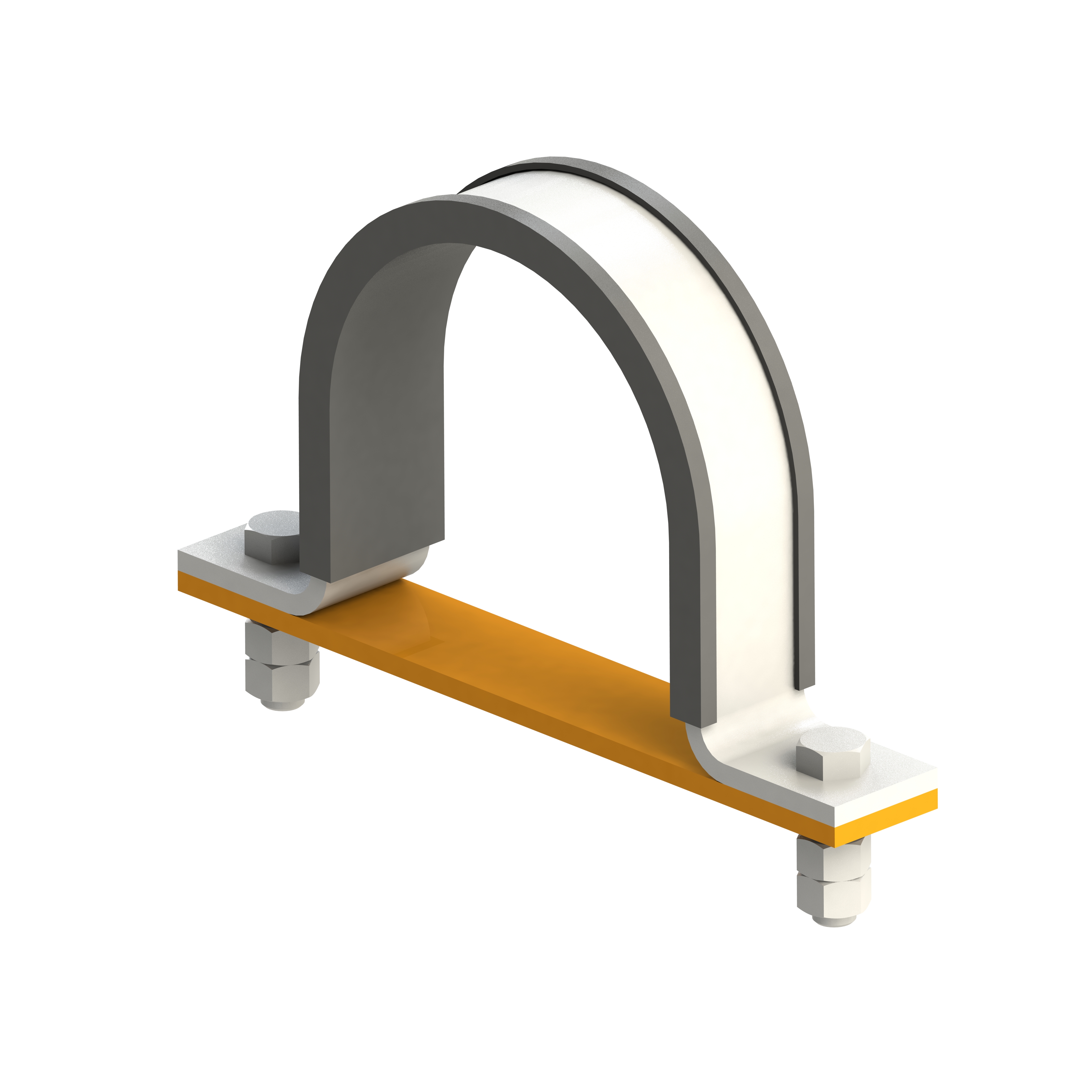

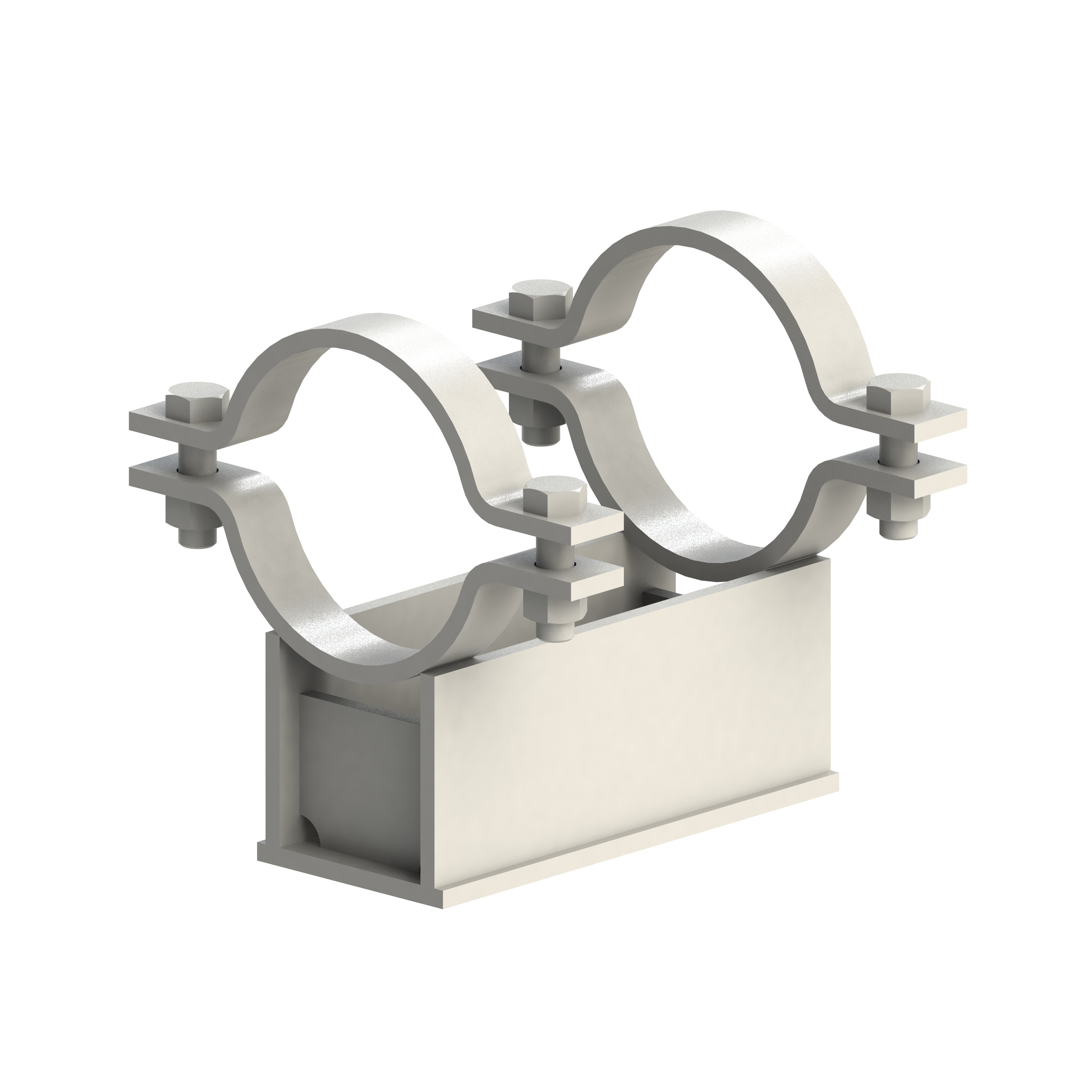

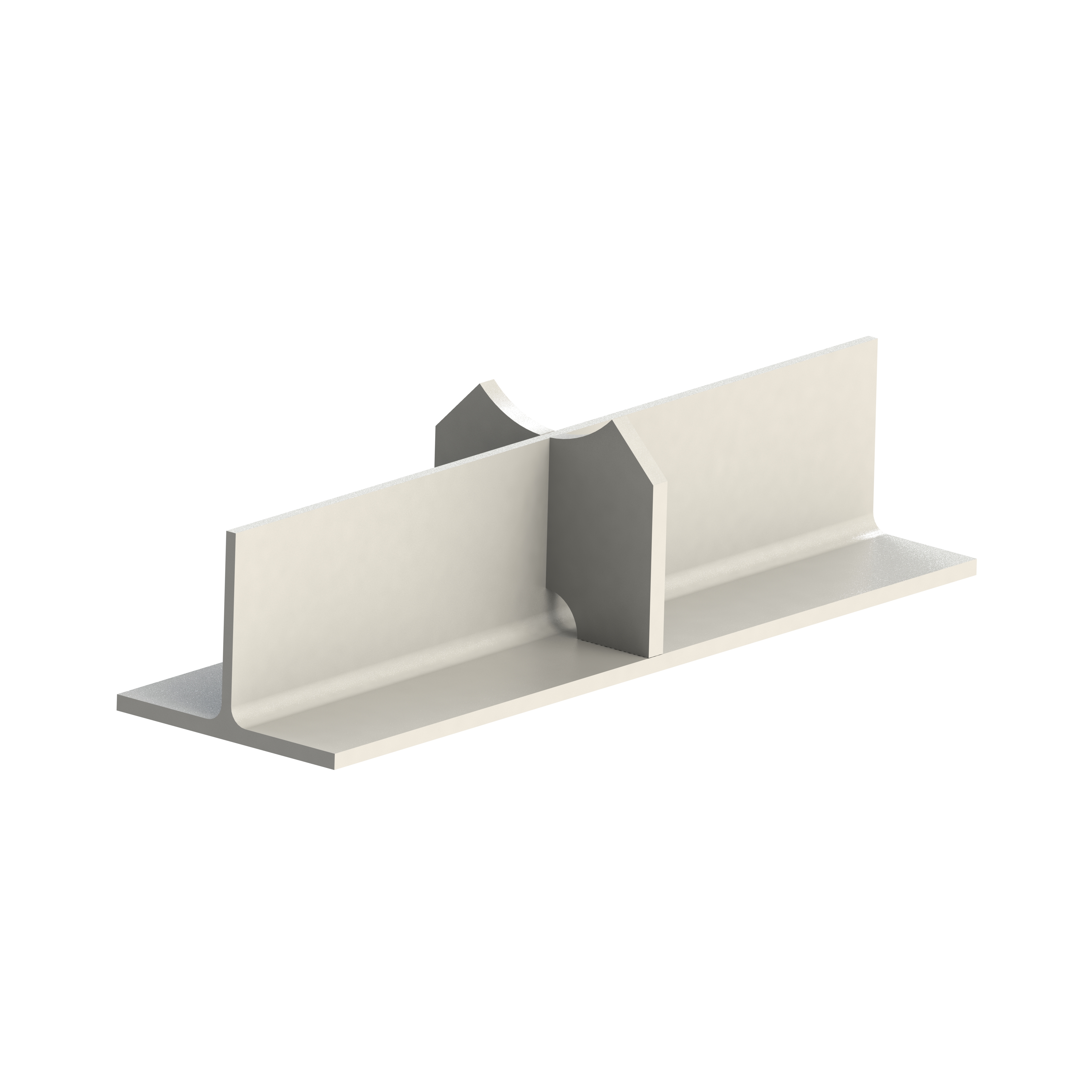

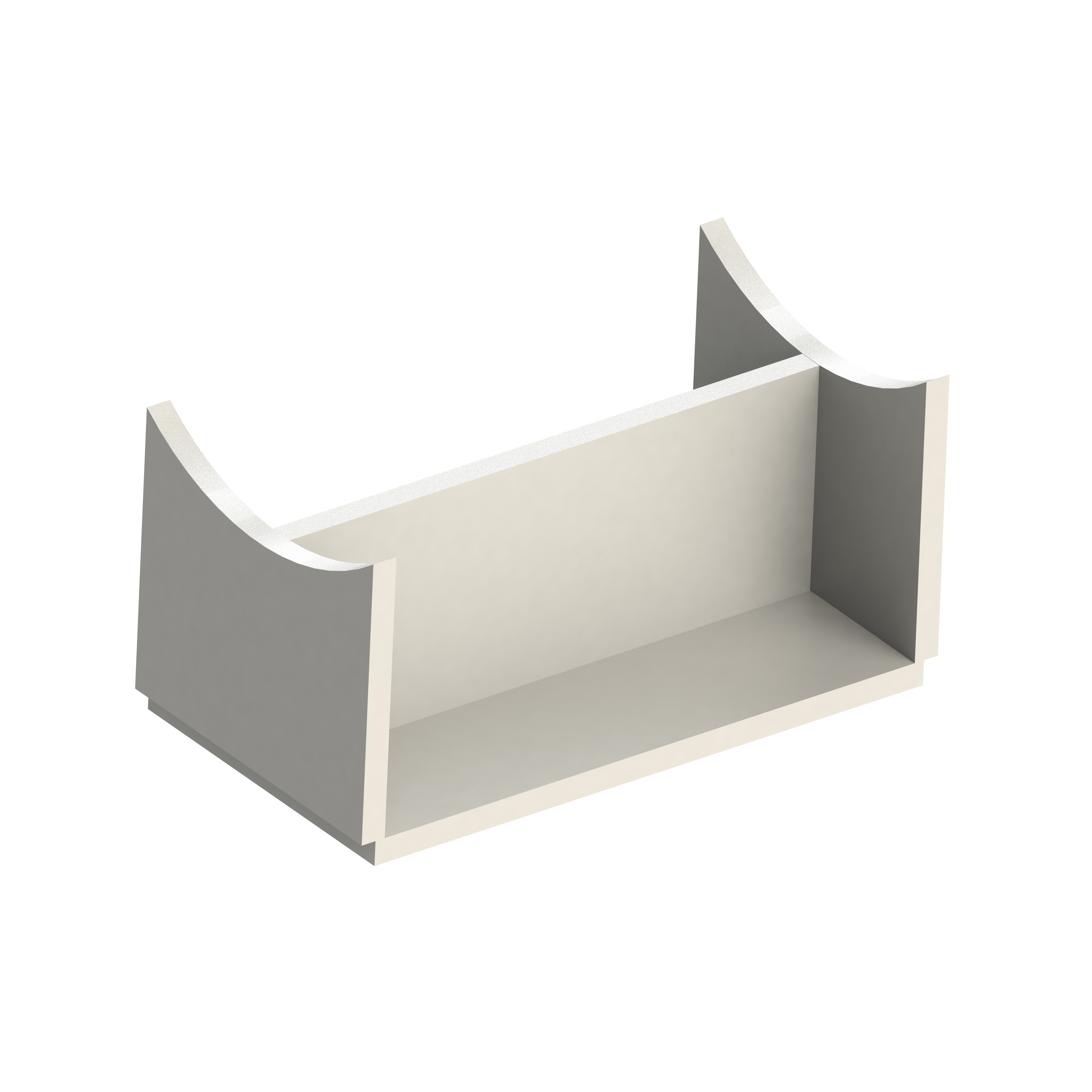

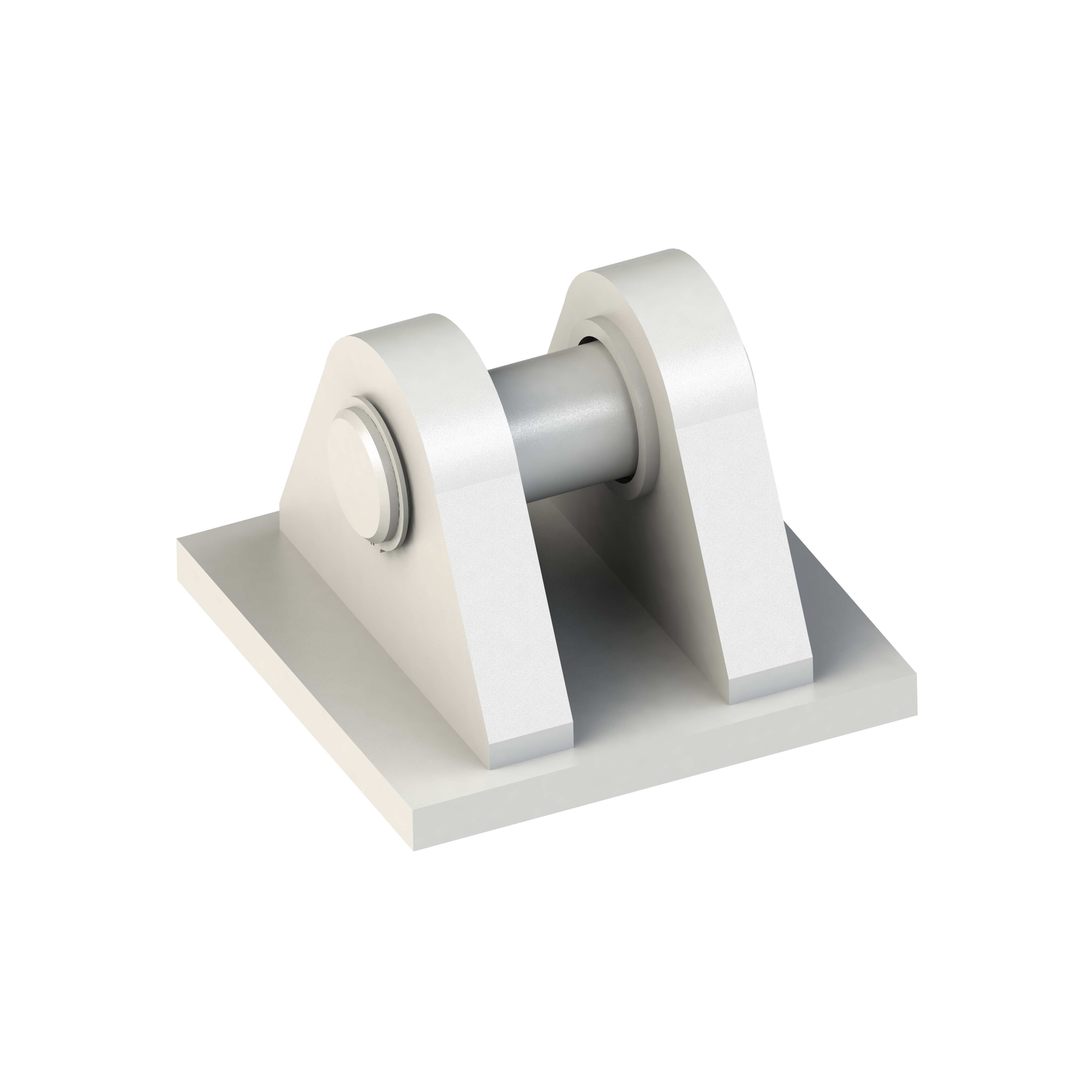

3. Pipe Shoes, Clamps, and Guides

What they are: Common support elements designed for practical use on site—ideal for high-load applications, corrosion resistance, and pipe isolation.

Why they matter:

Though they seem simple, components like pipe shoes and clamps often define how easy a system is to install and maintain. If these aren’t chosen and engineered properly:

- You get uneven load distribution

- You risk damaging pipe coatings

- Maintenance and inspection become harder and more costly

Our range includes:

- Insulated pipe shoes for high-temp and chilled applications

- Heavy-duty clamps for structural anchoring

At EXA, both designers and contractors valued our customisation options, wide range of materials, and local manufacturing—ensuring reliable lead times even in today’s unpredictable global markets.

Engagement Was High—And It Meant Something

We were blown away by the number of quality conversations. Many long-term clients came to say hello, while others told us they were hearing about Binder Group again for the first time in years—thanks to our return to Australian ownership.

“There’s no other event nationally where we could have met so many long-term customers, new & potential customers, design engineers, and other aligned organisations.”

— Binder Group

It confirmed that face-to-face conversations still matter, and that people value dealing with a supplier who understands their projects, their pressure points, and their expectations.

Next Steps

Whether we met you at EXA 2025 or you couldn’t make it, we’d love to talk about how we can support your upcoming projects.

We are ready to help you with:

- Technical specification support

- Custom-engineered pipe supports

- Guaranteed local lead times

- Compliance-ready documentation

Let’s talk about your next project. Book a meeting with our technical team