- Products

-

-

-

Categories

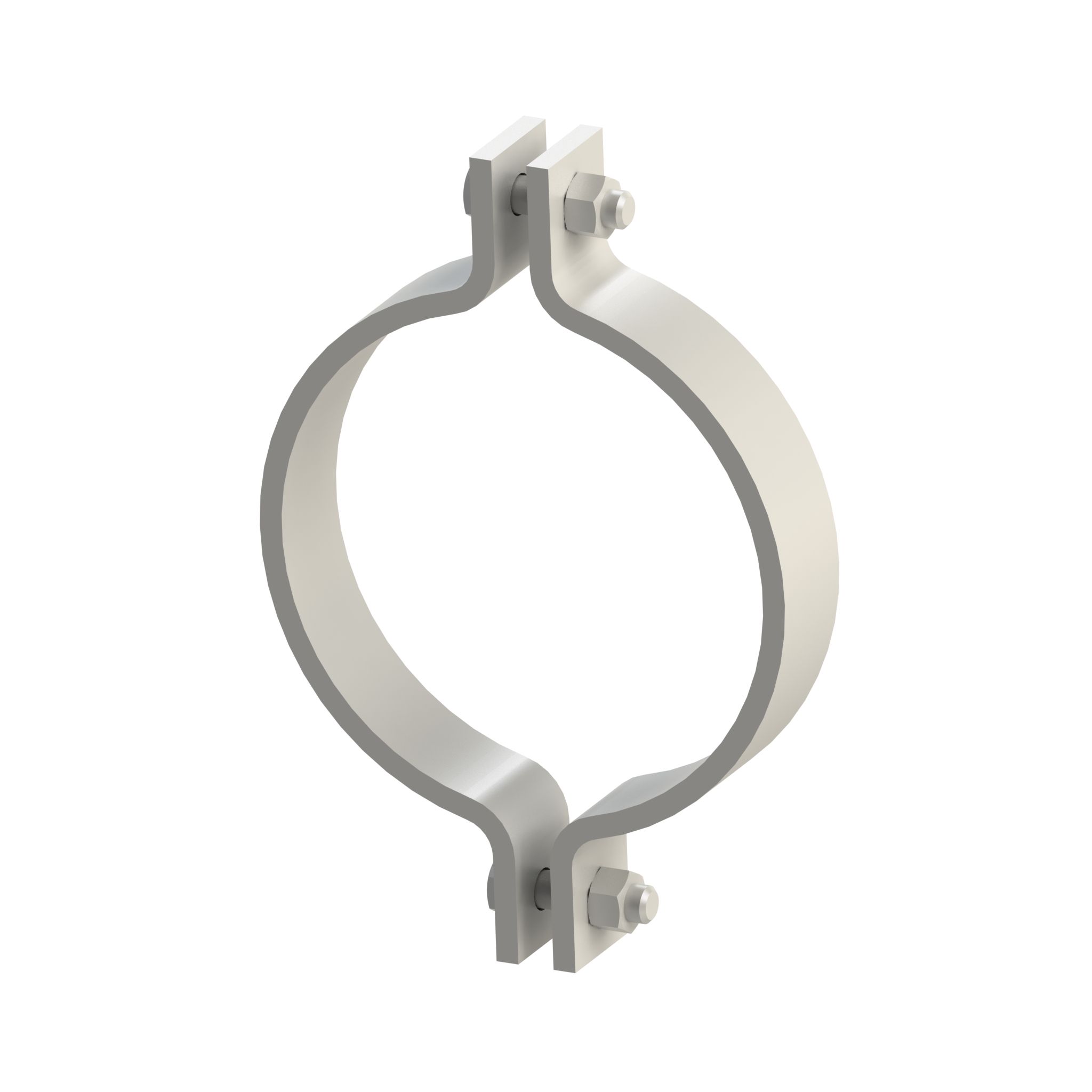

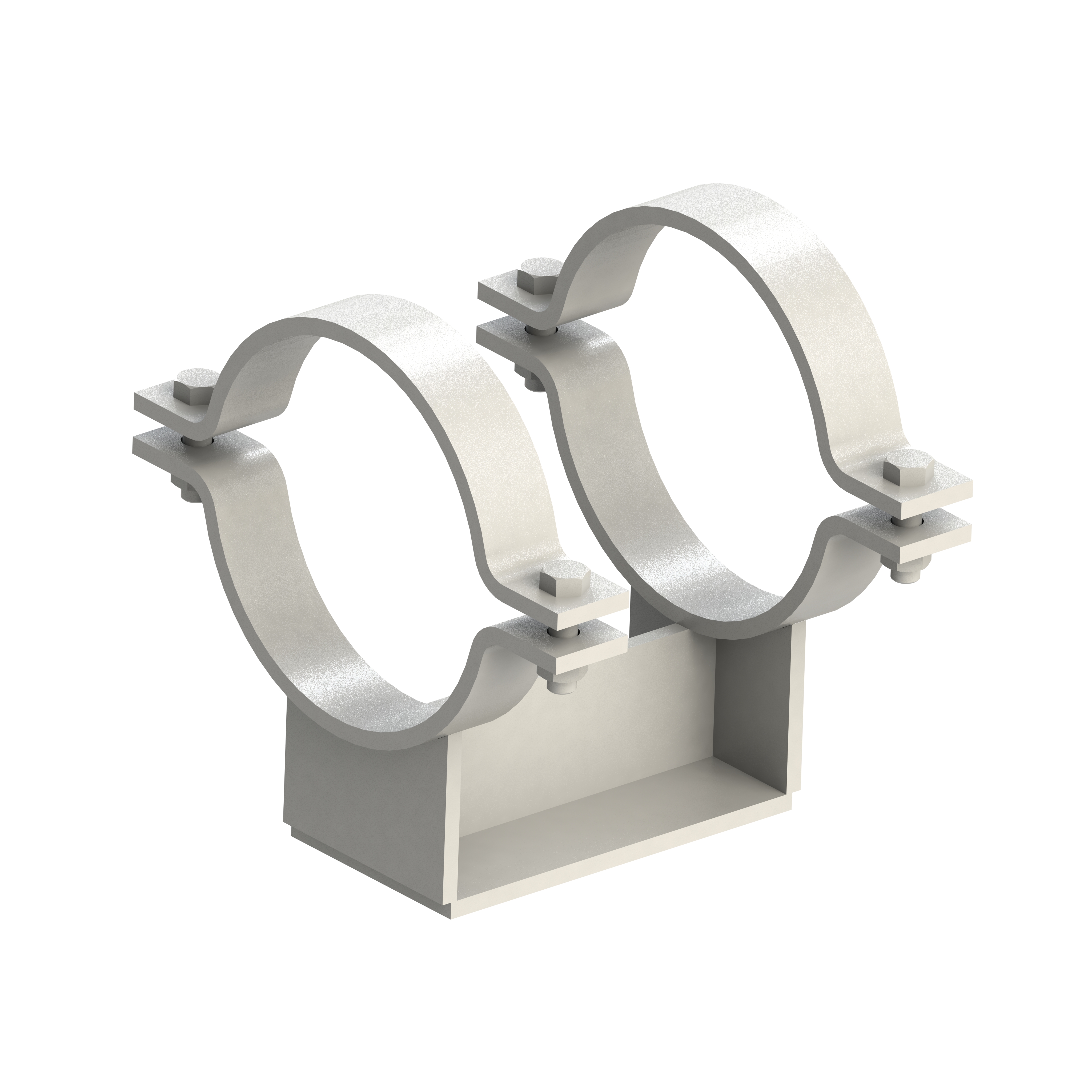

BG100

BG100LIGHT DUTY 2-BOLT CLAMP

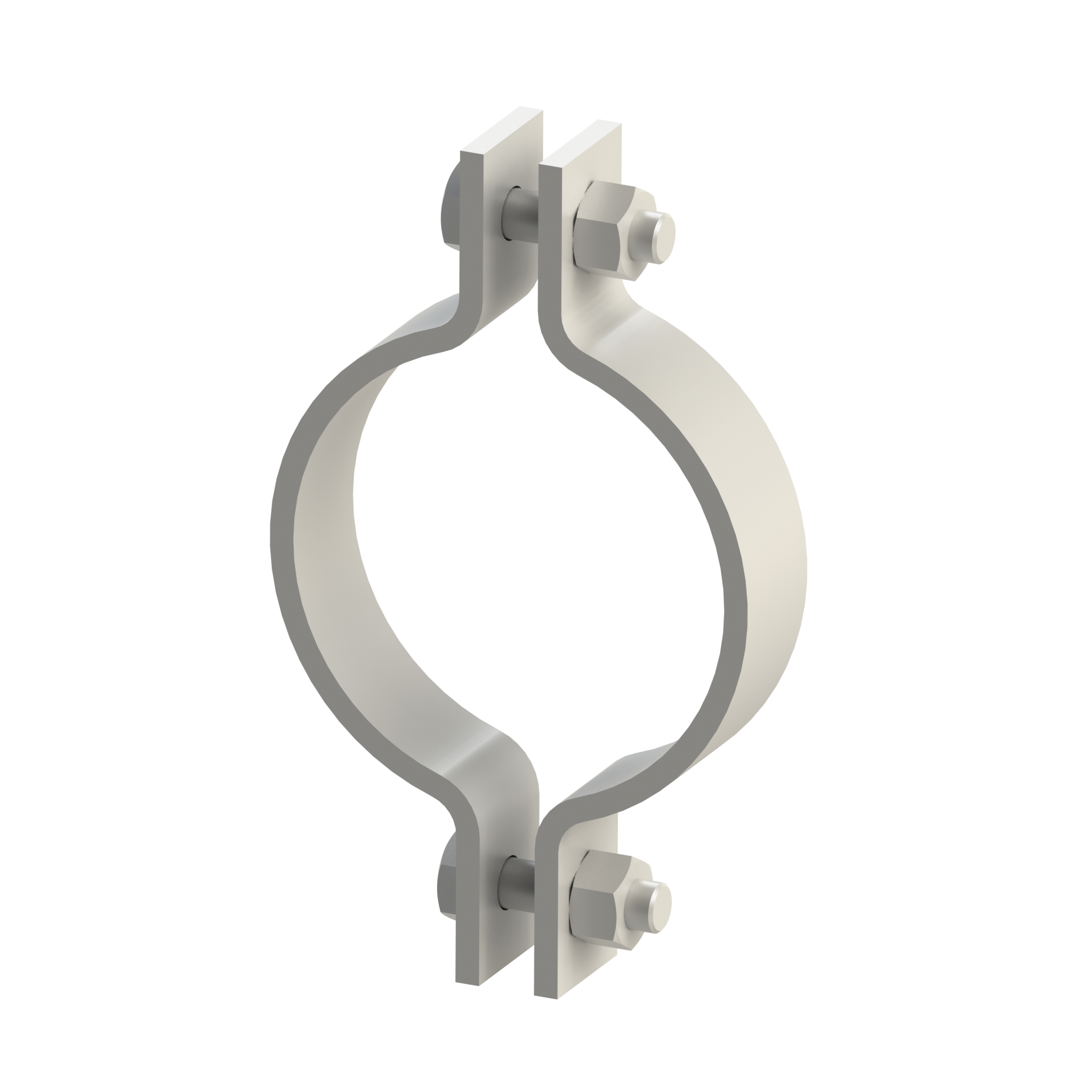

BG170

BG170MEDIUM DUTY 2-BOLT PIPE CLAMP

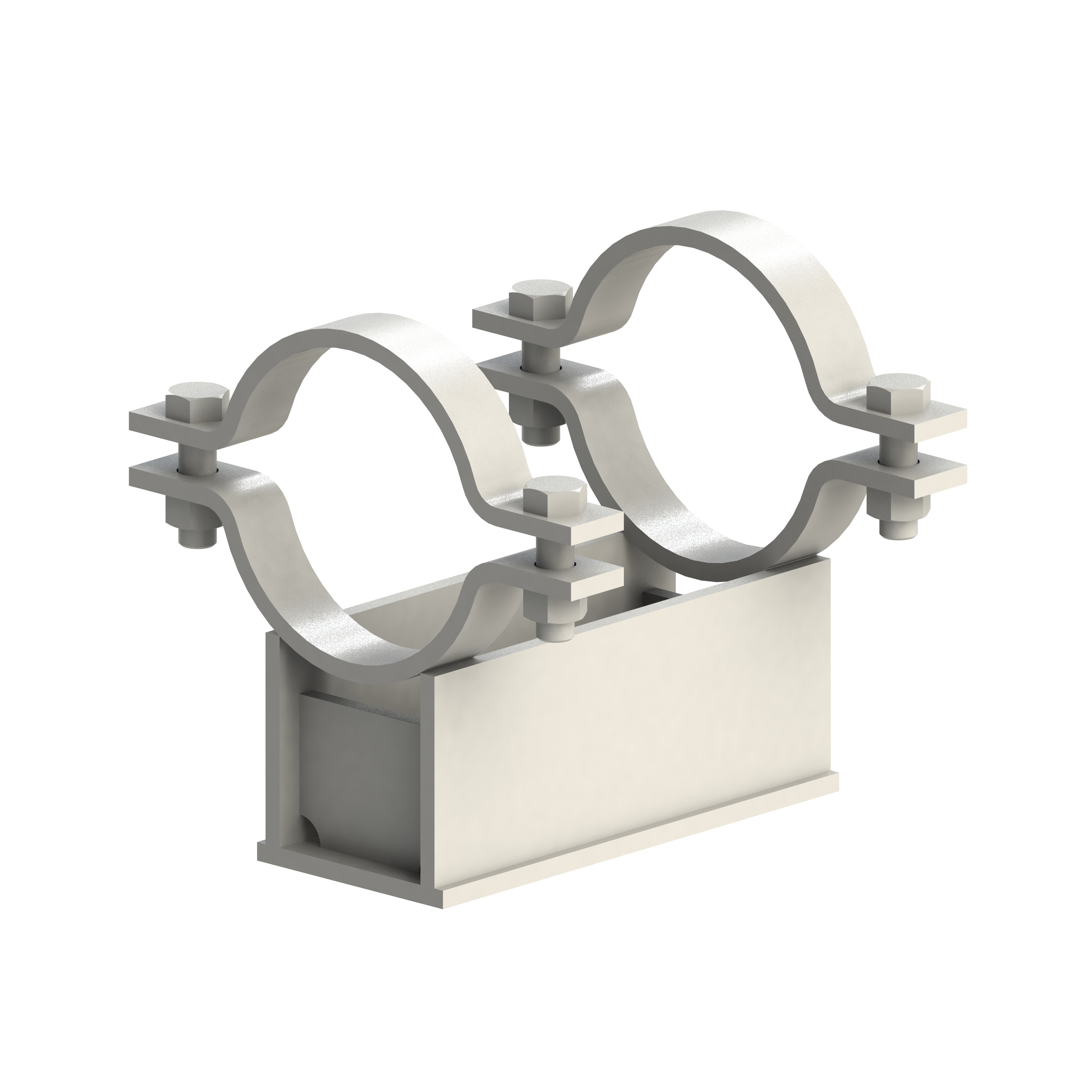

BG50

BG50HEAVY DUTY 2-BOLT PIPE CLAMP

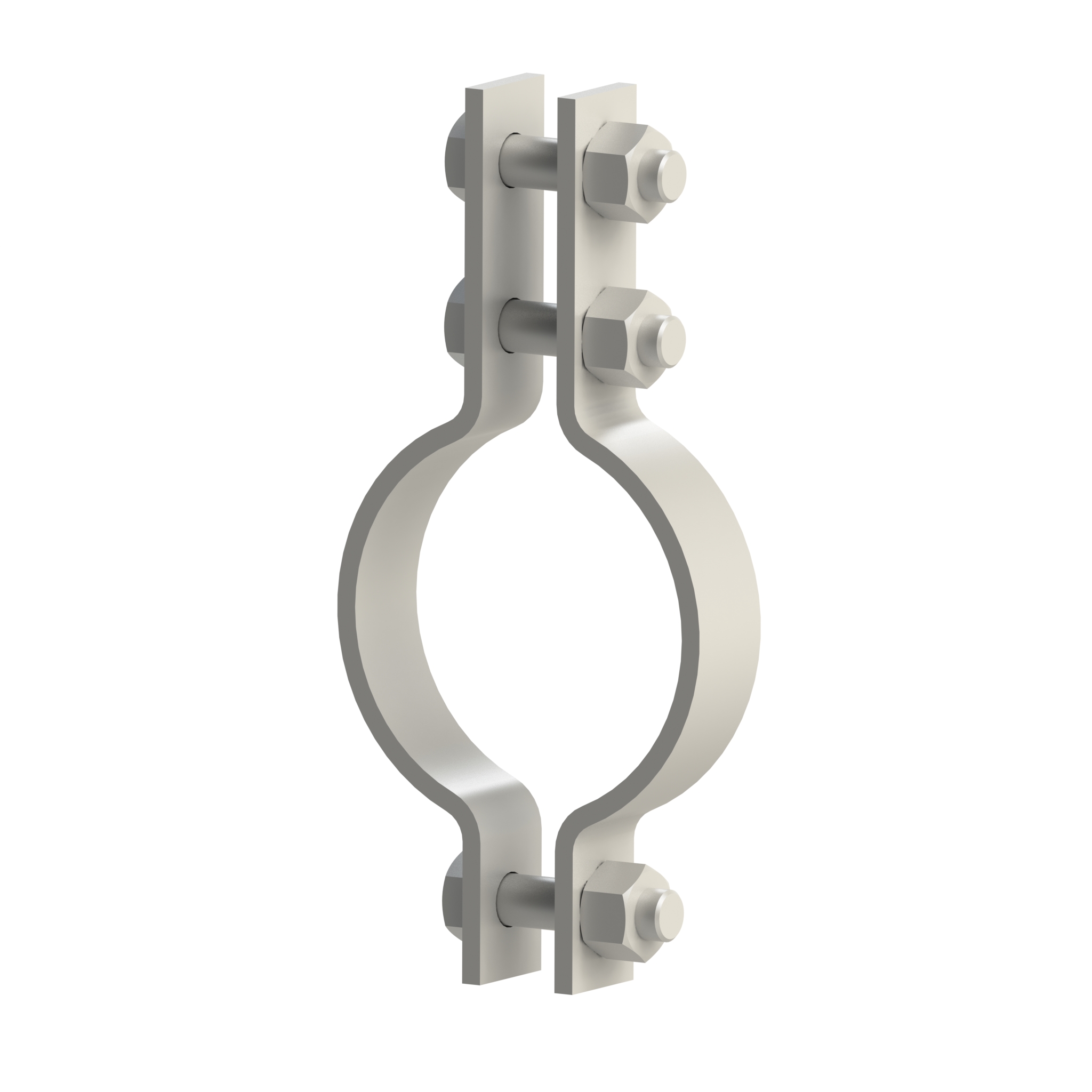

BG101

BG101LIGHT DUTY 3-BOLT PIPE CLAMP

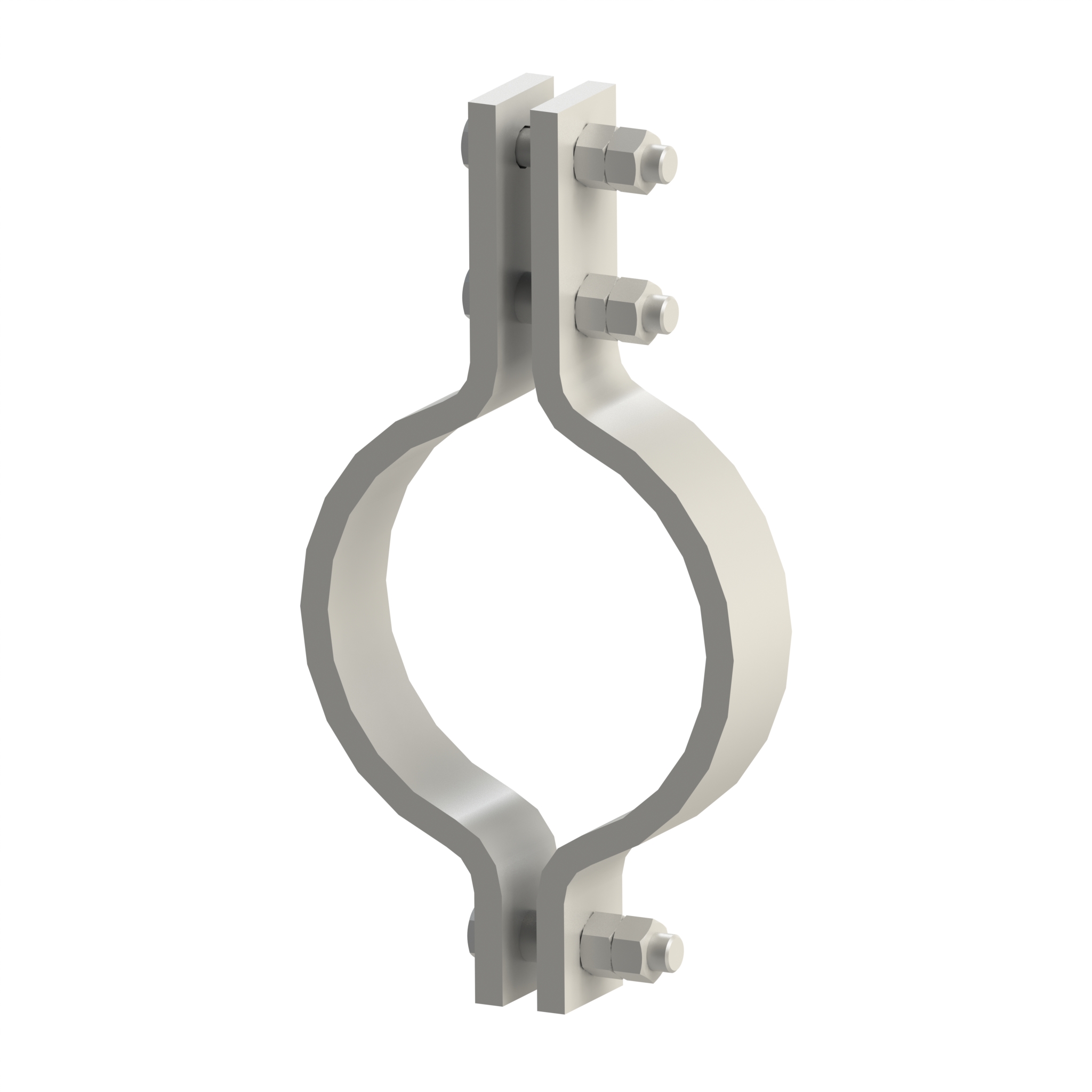

BG171

BG171MEDIUM DUTY 3-BOLT PIPE CLAMP FOR STEEL PIPE

BG75

BG75HEAVY DUTY 3-BOLT PIPE CLAMP

BG172

BG172HIGH TEMPERATURE 3-BOLT PIPE CLAMP

BG173

BG173ALLOY PIPE CLAMP - VERY HIGH TEMPERATURE

BG140

BG140INSULATED 2-BOLT PIPE CLAMP

BG141

BG141INSULATED 2-BOLT PIPE CLAMP FOR CU/NI

BG145

BG145INSULATED 3-BOLT PIPE CLAMP

BG146

BG146INSULATED 3-BOLT PIPE CLAMP FOR CU/NI

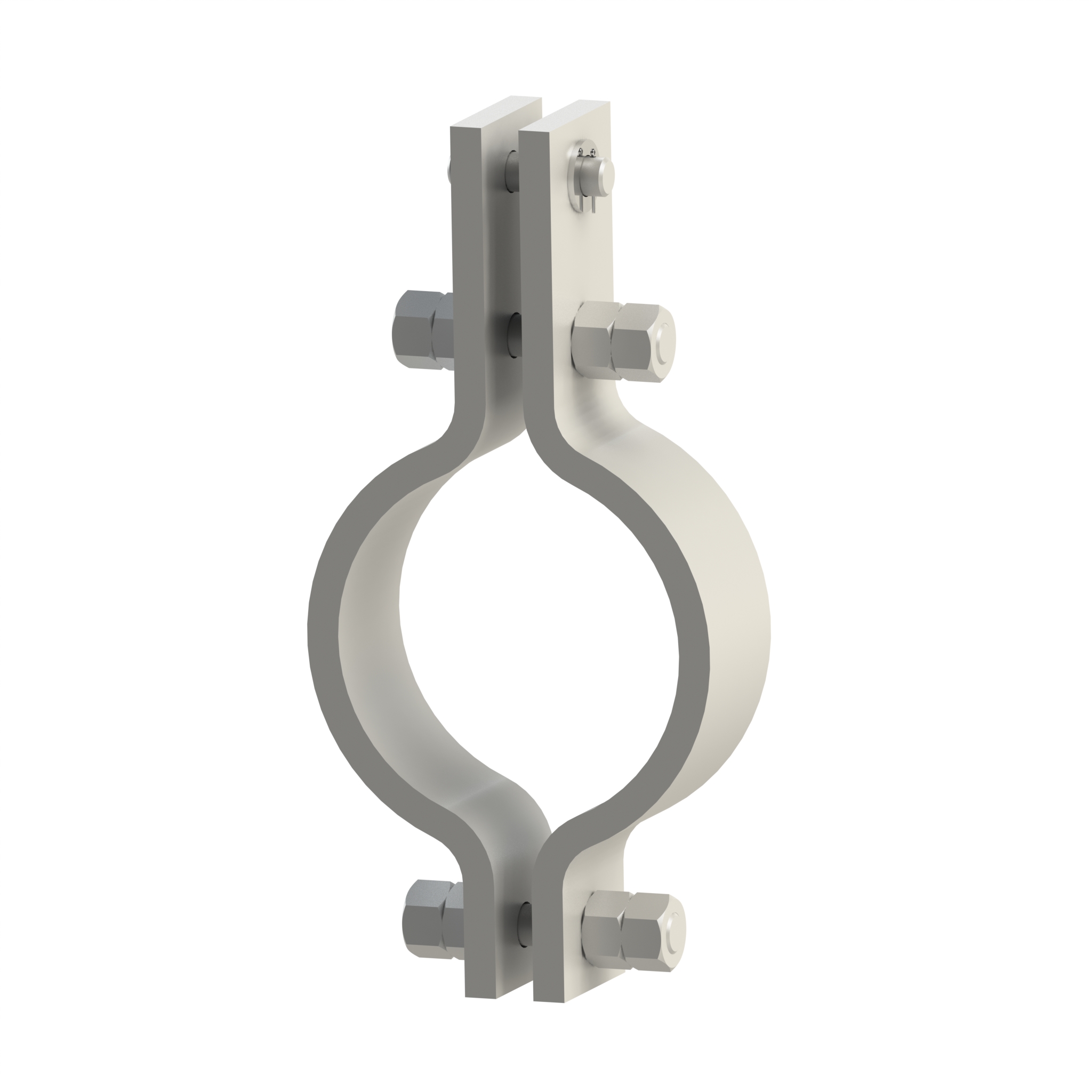

BG108

BG108CLEVIS CLAMP

BG222

BG222BEAM CLAMP

BG174

BG174RISER SUPPORT – STD TEMPERATURE

BG175

BG175RISER SUPPORT – HIGH TEMPERATURE

BG176

BG176ALLOY RISER SUPPORT - VERY HIGH TEMPERATURE

BG202

BG202ALLTHREAD ROD

BG209

BG209FORGED CLEVIS AND PIN

BG210

BG210FORGED TURNBUCKLE

BG204

BG204FORGED WELDLESS EYE NUT

BG215

BG215HEMISPHERICAL CUP

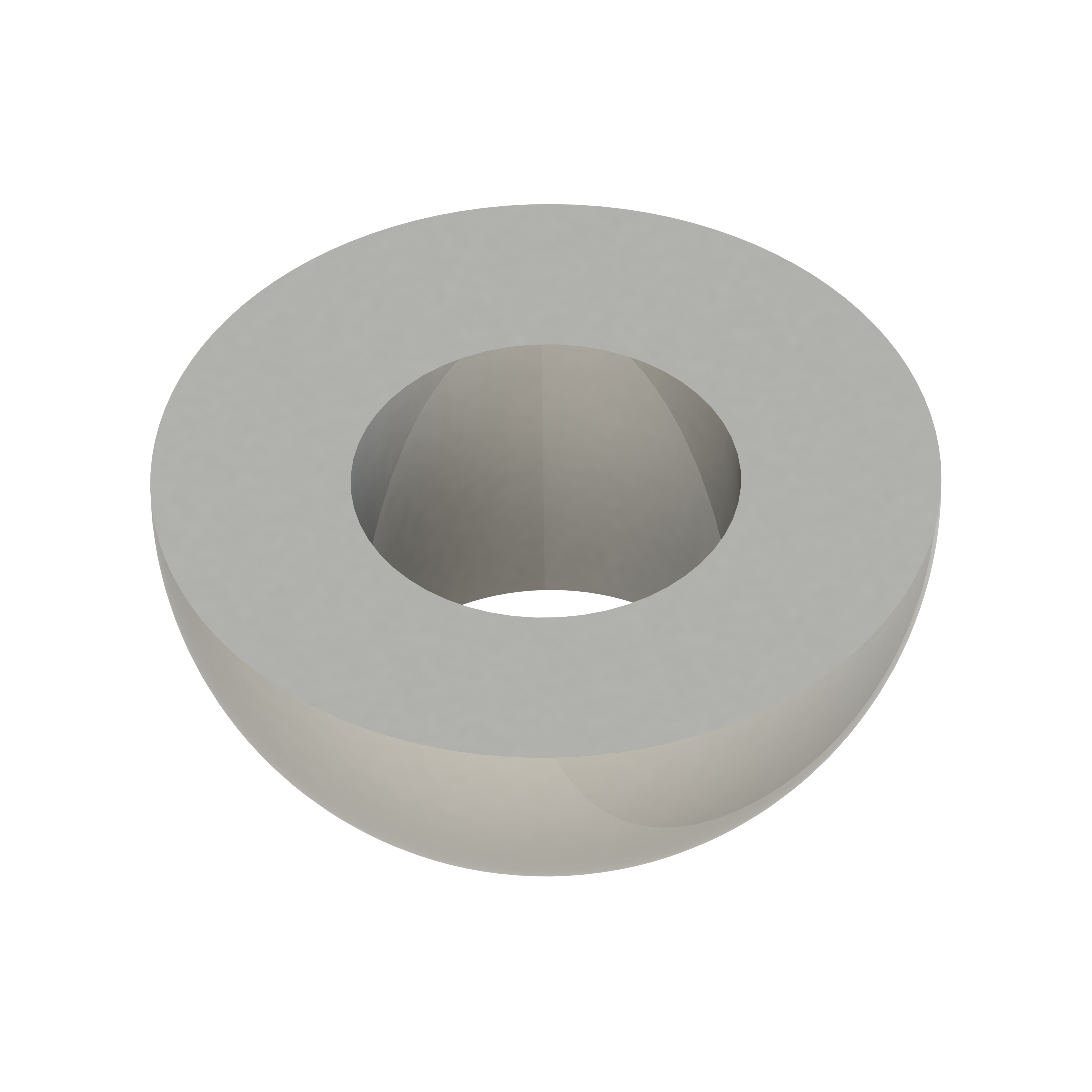

BG214

BG214HEMISPHERICAL WASHER

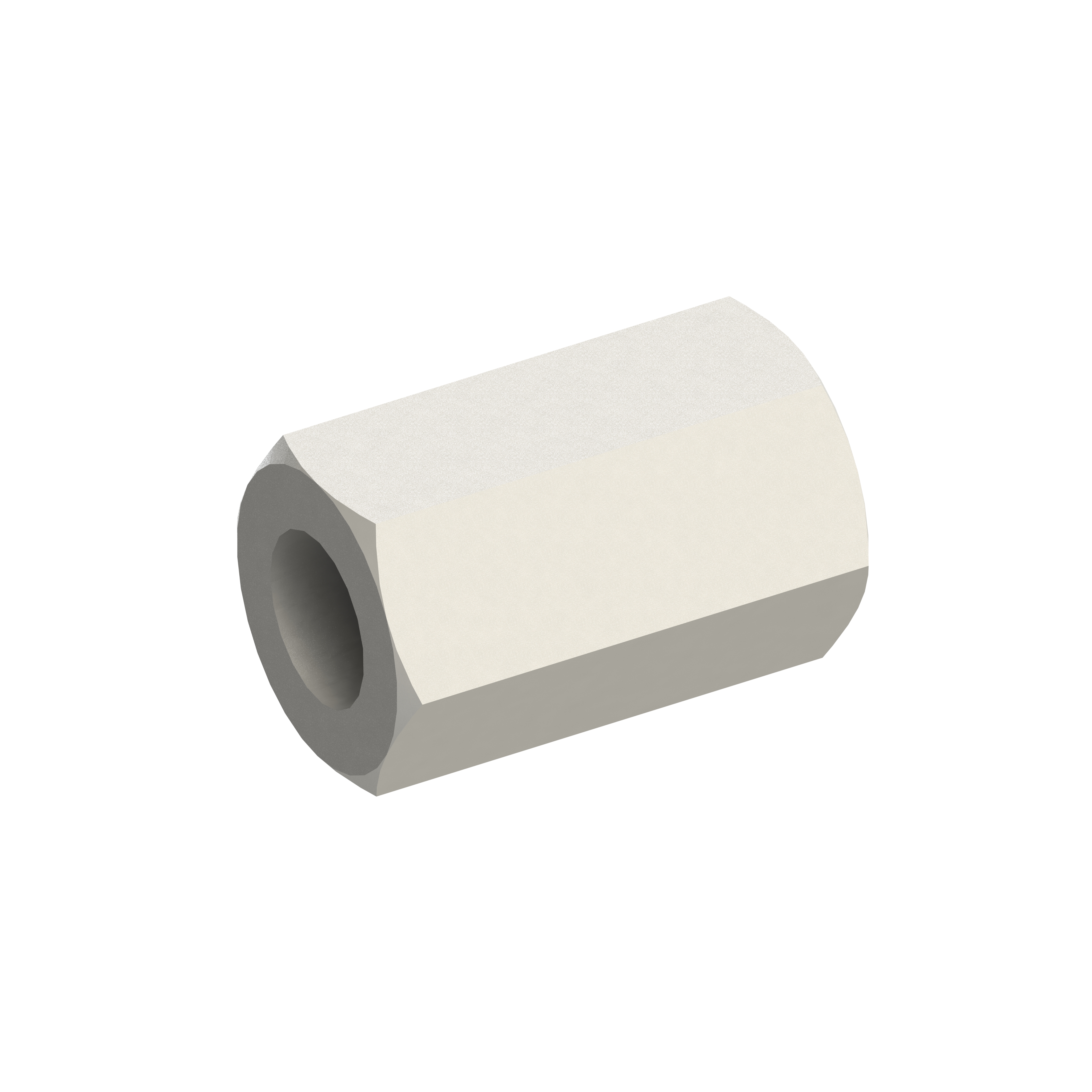

BG206

BG206HEXAGONAL CONNECTOR

BG216

BG216PIPE WELDING LUG

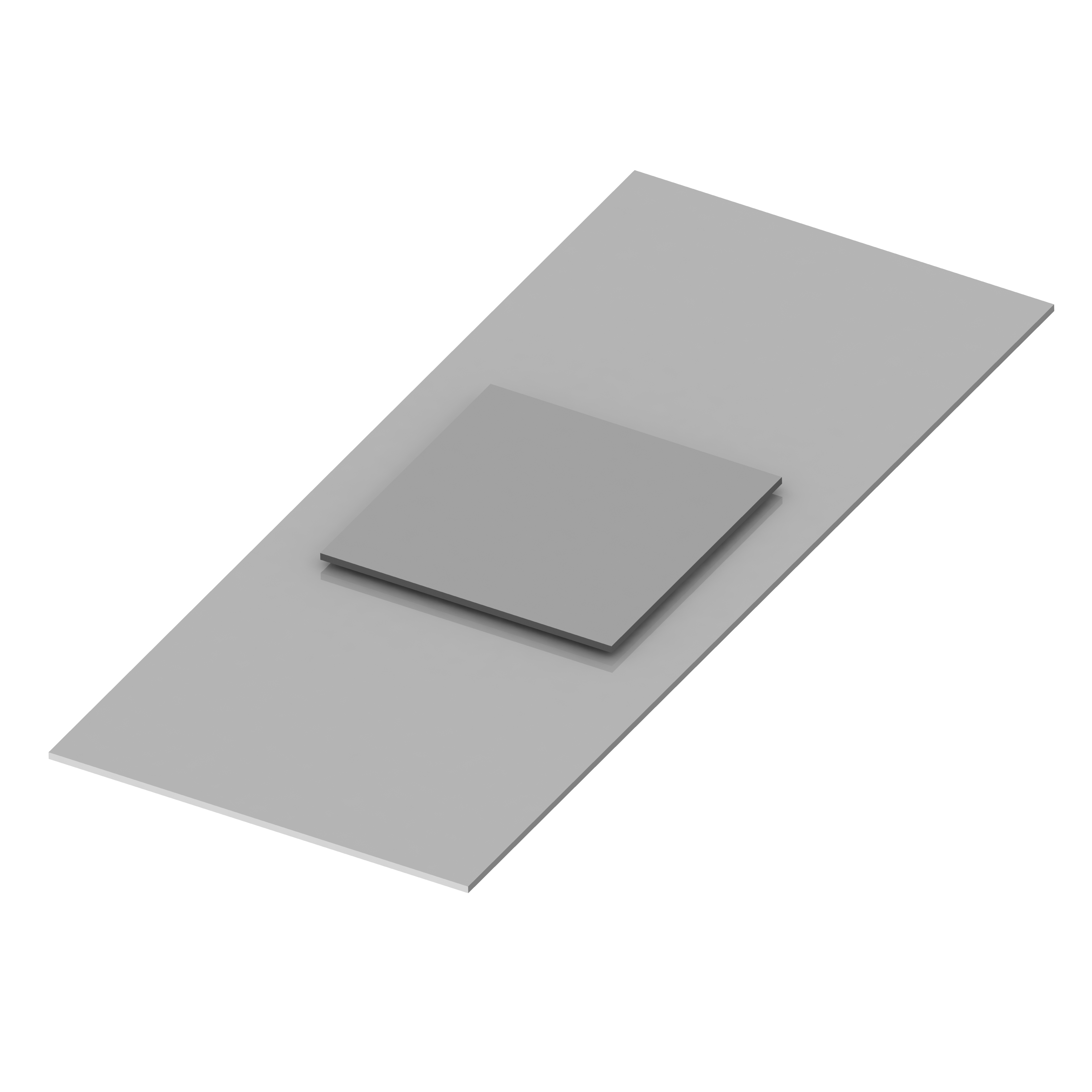

BG217

BG217PLATE WASHER

BG207

BG207SPADE NUT

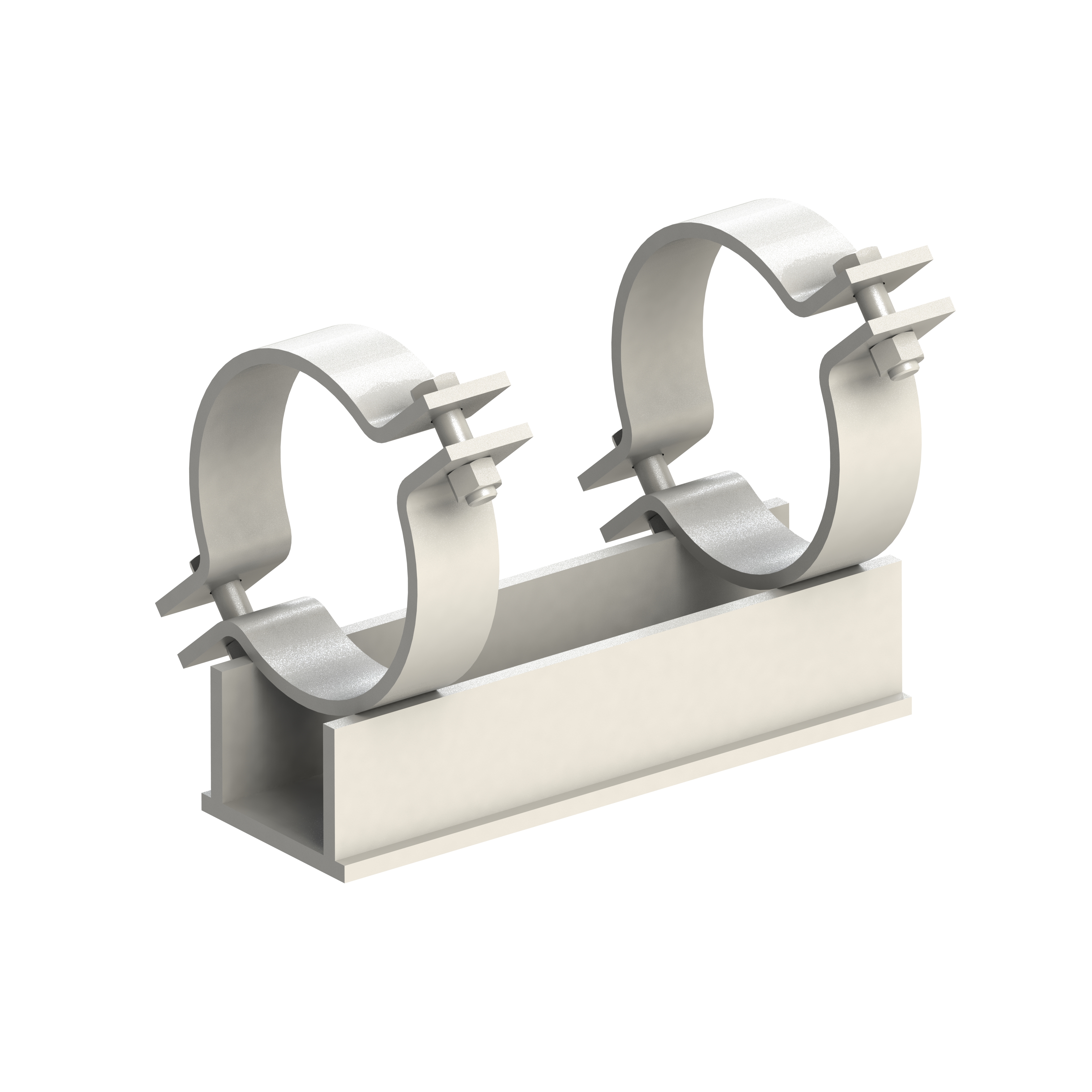

BG245

BG245STANDARD TRAPEZE

BG203

BG203THREADED DROP ROD – RH/LH

BG219

BG219WELDED BEAM ATTACHMENT

BG220

BG220WELDED BEAM ATTACHMENT (WITH LOAD PIN)

BG225

BG225WELDING LUG

BG180

BG180U-BOLT GUIDE

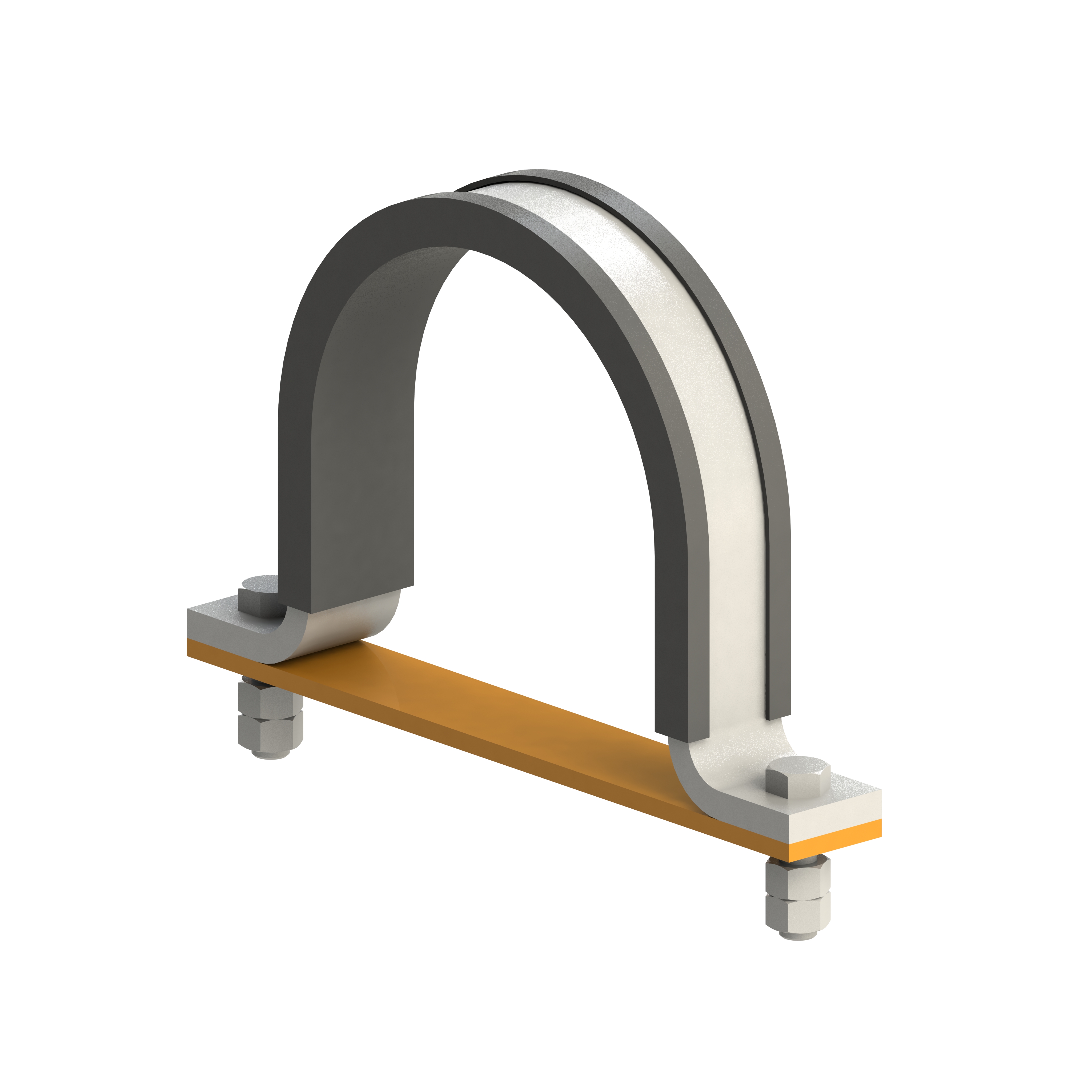

BG181

BG181U-BOLT CLAMP

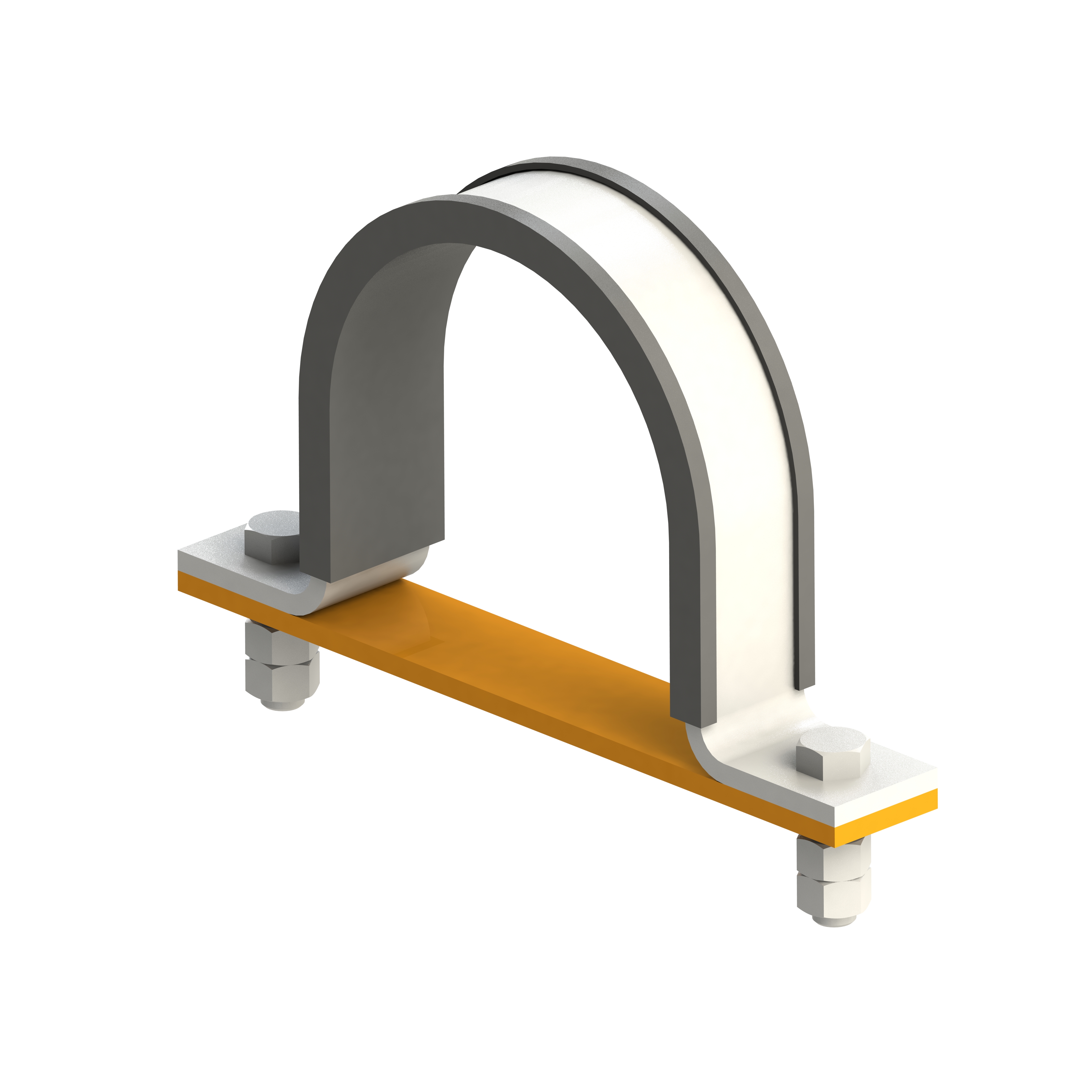

BG150

BG150INSULATED U-BOLT CLAMP

BG152

BG152INSULATED U-BOLT GUIDE

BG154

BG154INSULATED U-BOLT GUIDE (WITH TEFLON)

BG190

BG190INSULATED U-BOLT CLAMP

BG192

BG192INSULATED U-BOLT GUIDE

BG151

BG151INSULATED U-BOLT CLAMP FOR CU/NI

BG153

BG153INSULATED U-BOLT GUIDE FOR CU/NI

For Cu/Ni Pipe BG155

BG155INSULATED U-BOLT GUIDE (WITH TEFLON)

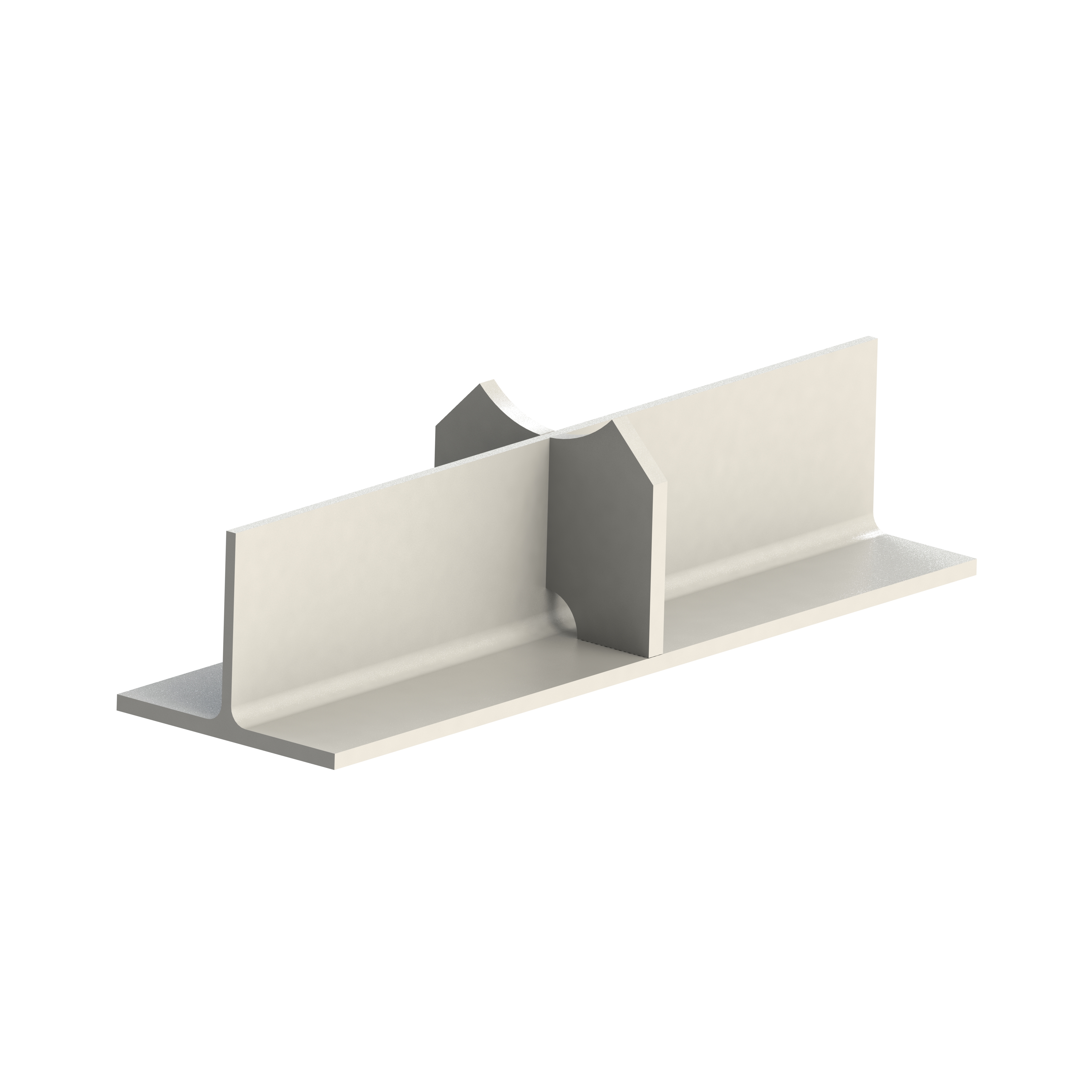

For Cu/Ni Pipe BG177

BG177SADDLE GUIDE

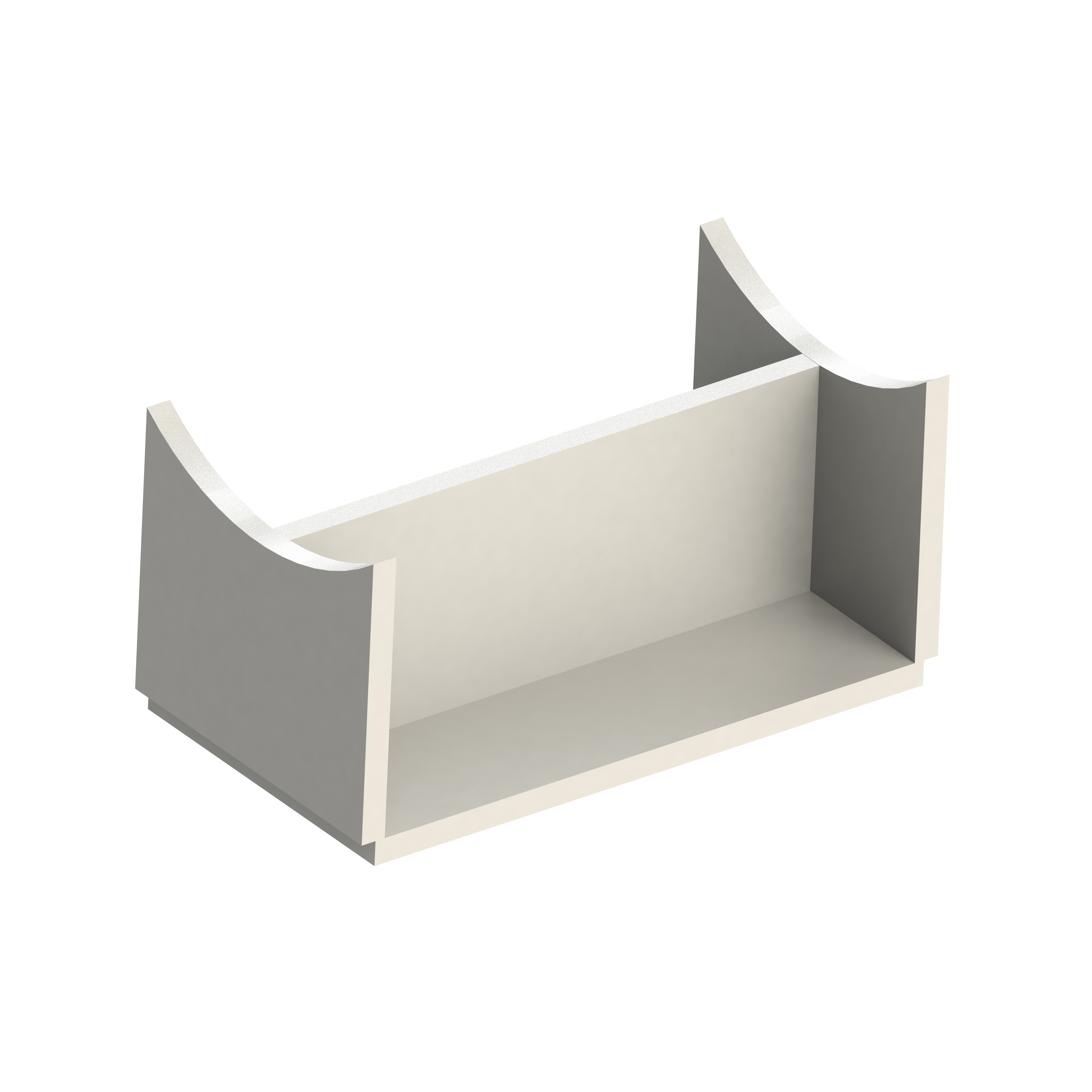

BG178

BG178SADDLE CLAMP

BG160

BG160INSULATED PIPE SADDLE

BG161

BG161INSULATED PIPE SADDLE

BG162

BG162INSULATED PIPE SADDLE

BG135-136

BG135-136ADJUSTABLE PIPE STANDS

BG515

BG515STANDARD CLAMPED PIPE SHOE

BG550

BG550SLIDE PLATES

BG517

BG517COMPACT PIPE SHOE

BG400

BG400CLAMPED HOT PIPE SHOE

BG156

BG156INSULATED PIPE SHOE

BG157

BG157INSULATED PIPE SHOE

BG510

BG510STANDARD WELDED PIPE SHOE

BG518

BG518COMPACT WELDED PIPE SHOE

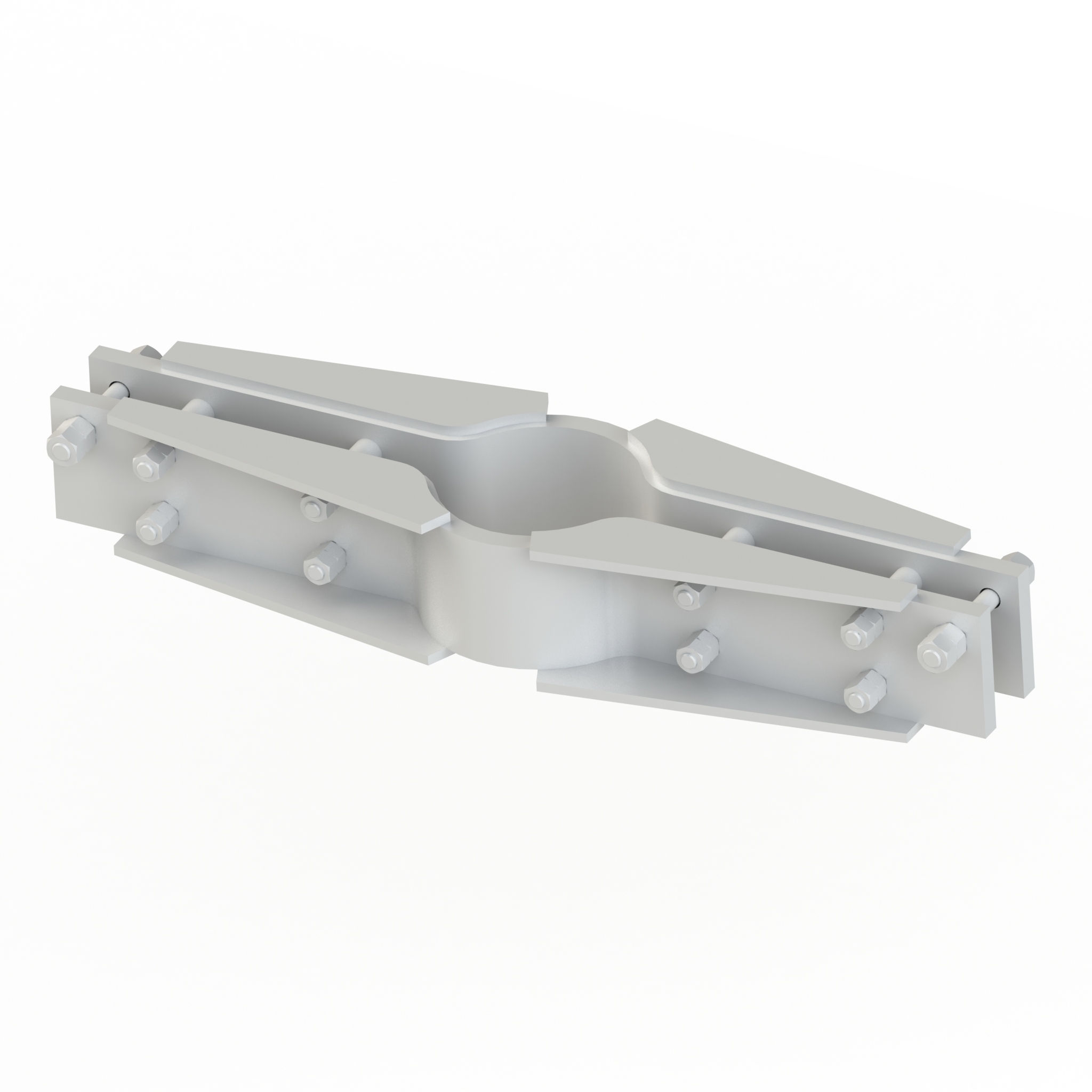

BG555

BG555STANDARD LINE STOPS

BG560

BG560STANDARD PIPE GUIDES

BG570

BG570STANDARD SHOE GUIDES

BG580

BG580STANDARD SHOE GUIDES

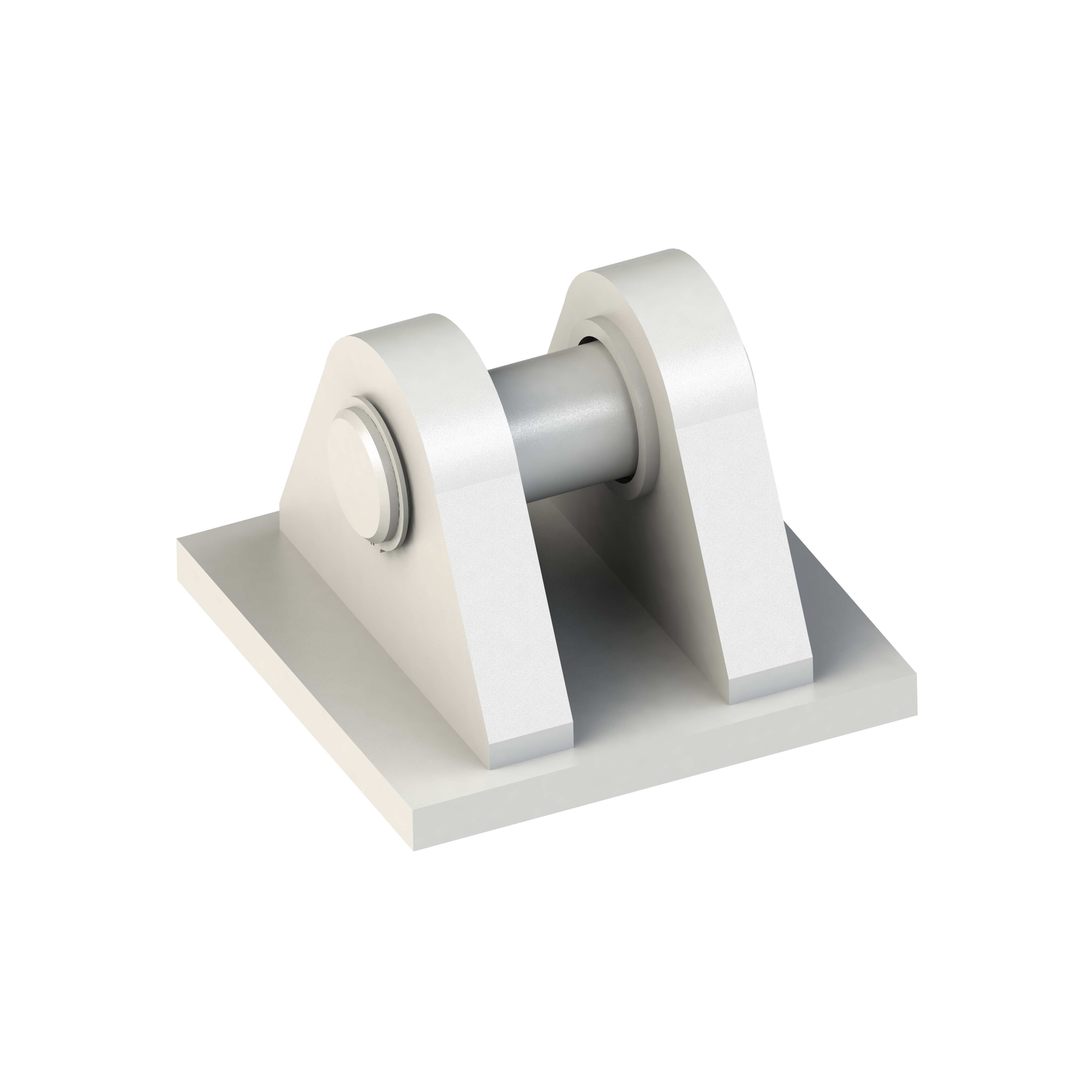

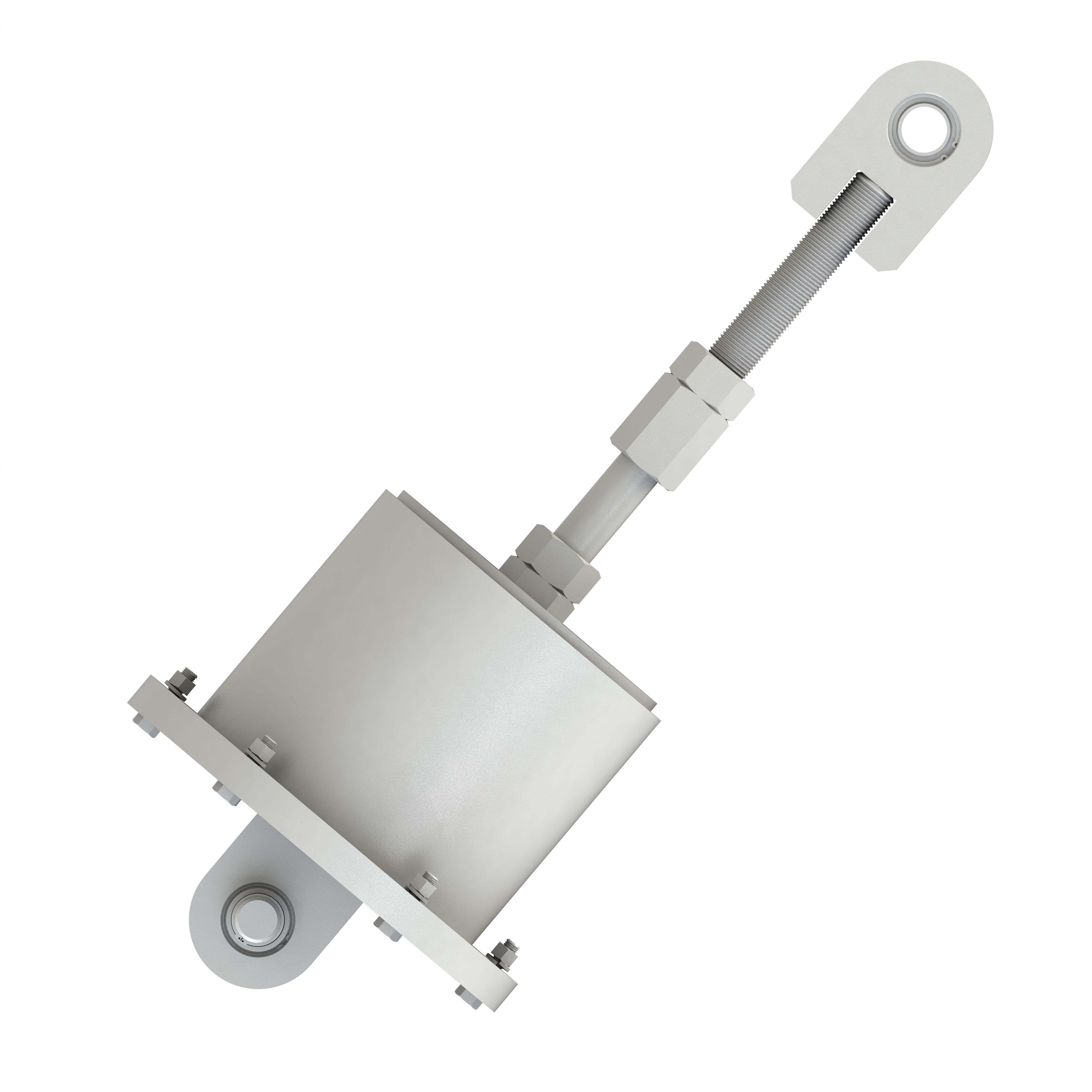

BG315

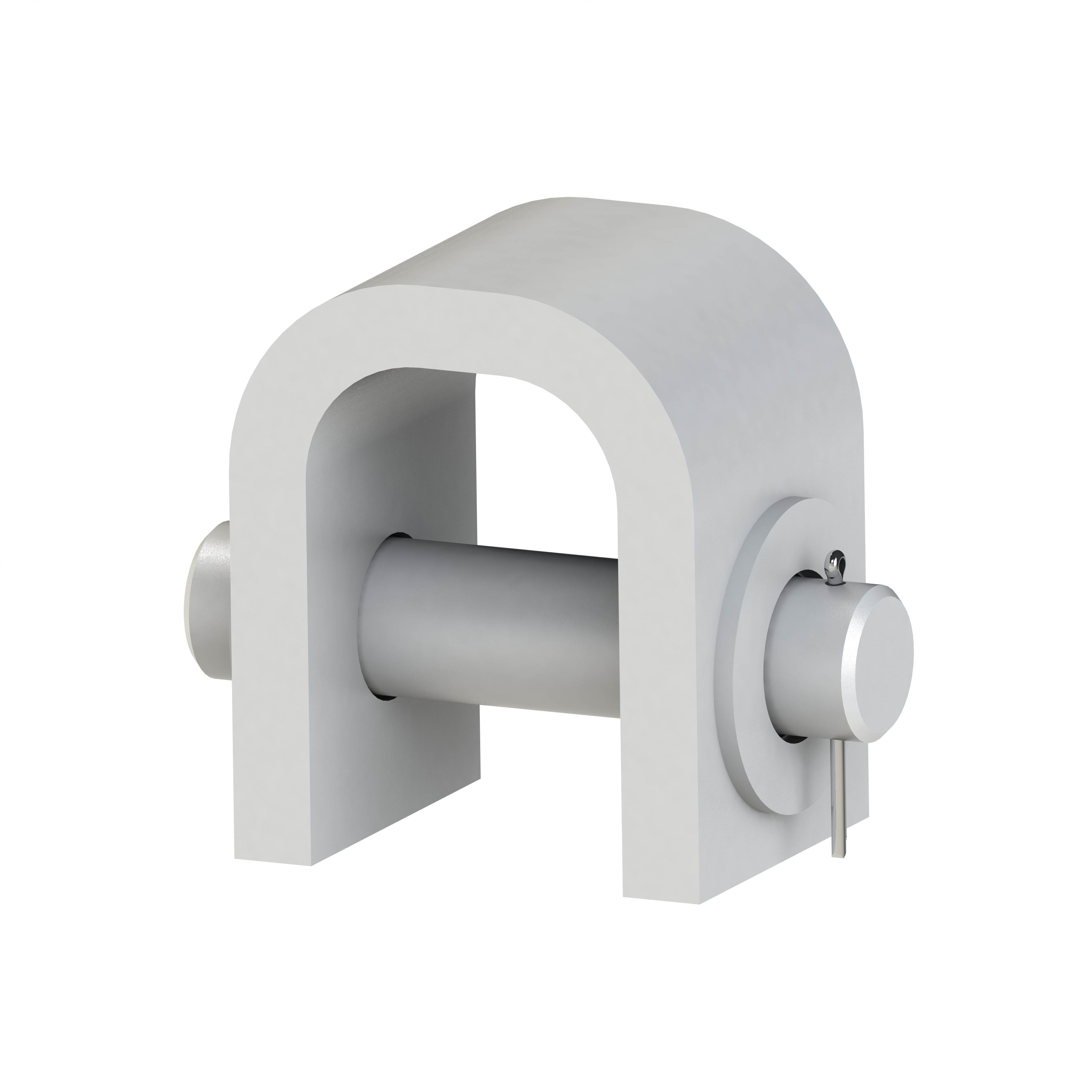

BG315END ATTACHMENT FOR HYDRAULIC SNUBBERS

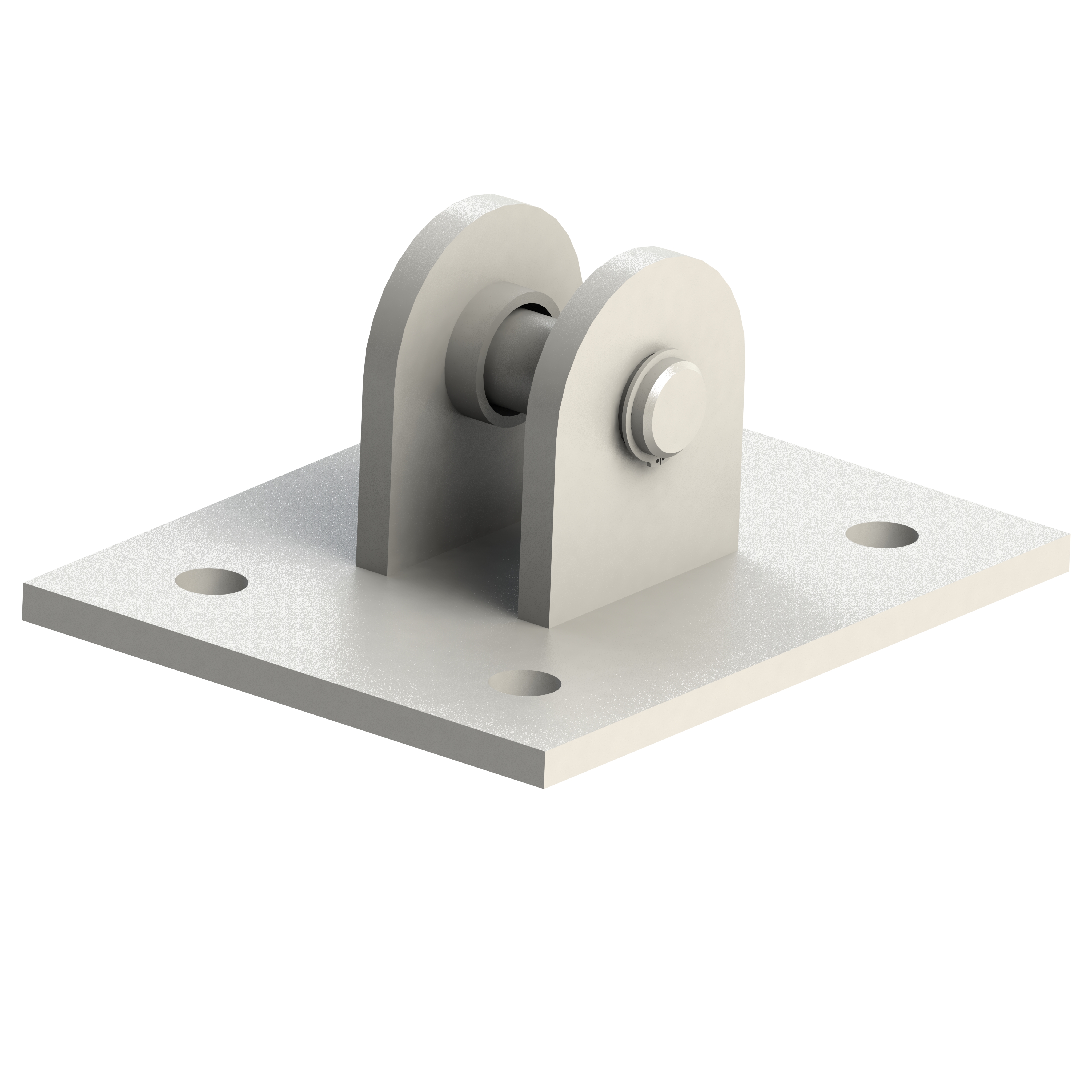

BG355

BG355END ATTACHMENT FOR RIGID STRUT & SWAY BRACE

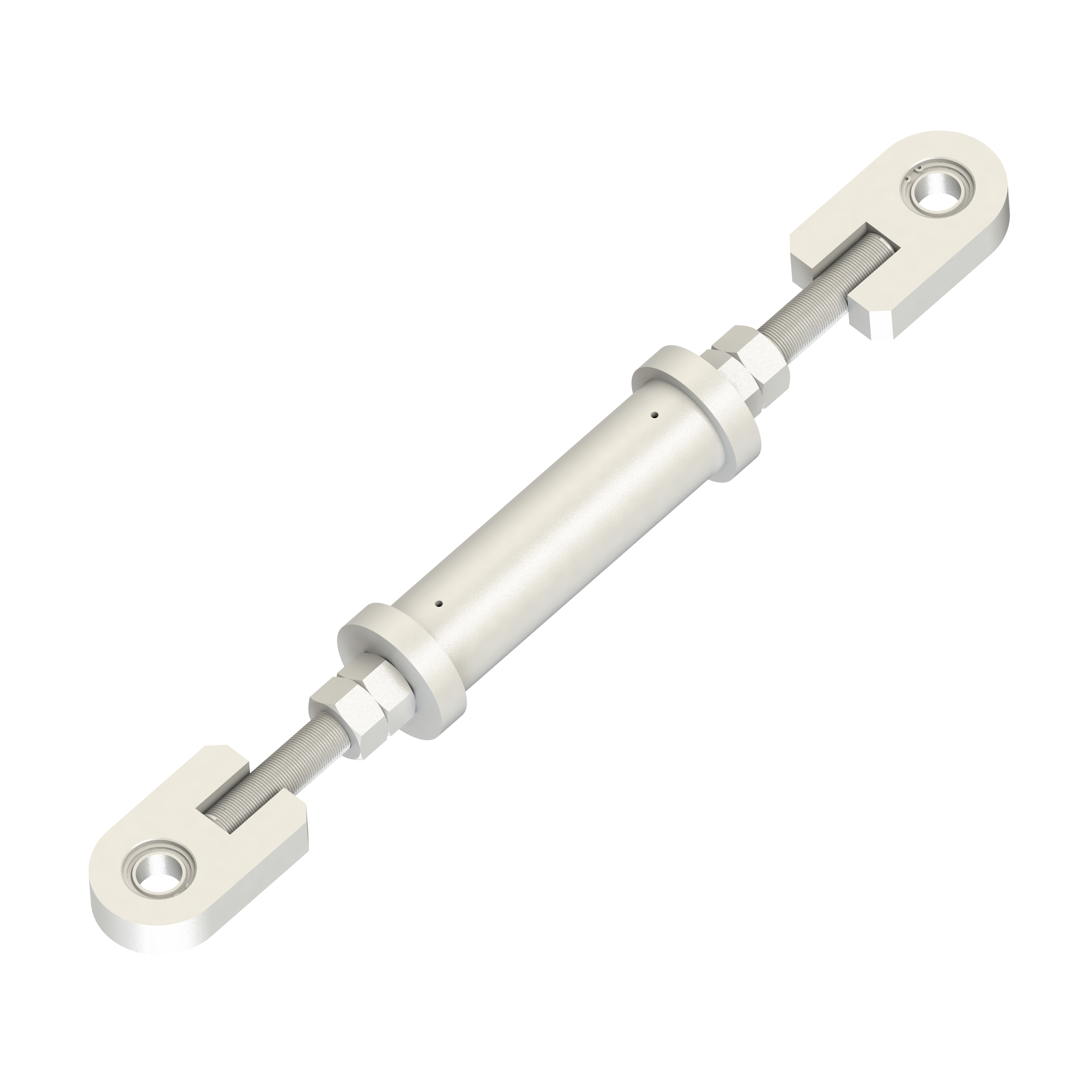

BG310

BG310HYDRAULIC SNUBBERS (SHOCK ARRESTORS)

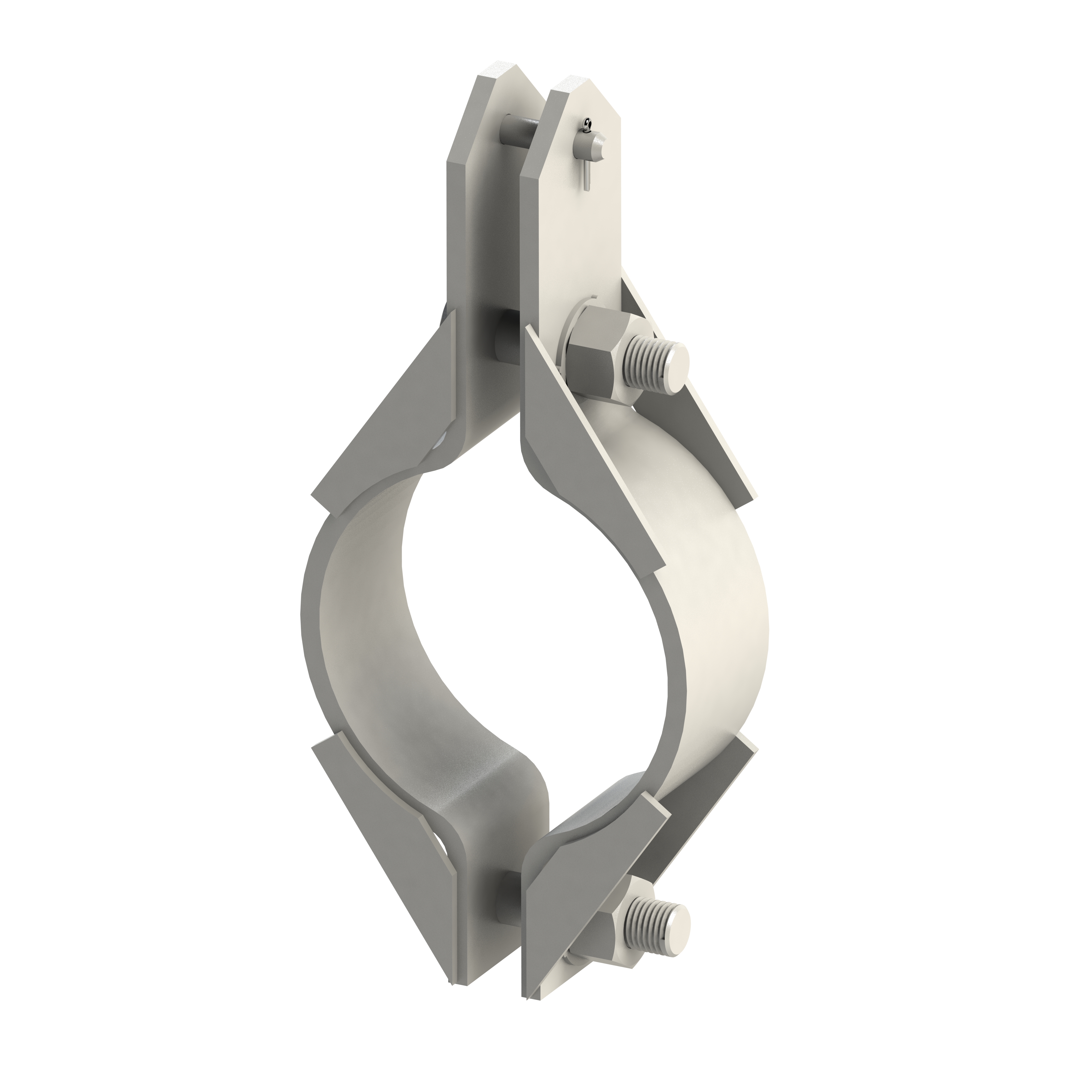

BG321

BG321PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG322

BG322PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG320

BG320PIPE CLAMP FOR HYDRAULIC SNUBBER – LOW TEMPERATURE

BG350

BG350RIGID STRUTS

BG340

BG340SWAY BRACE

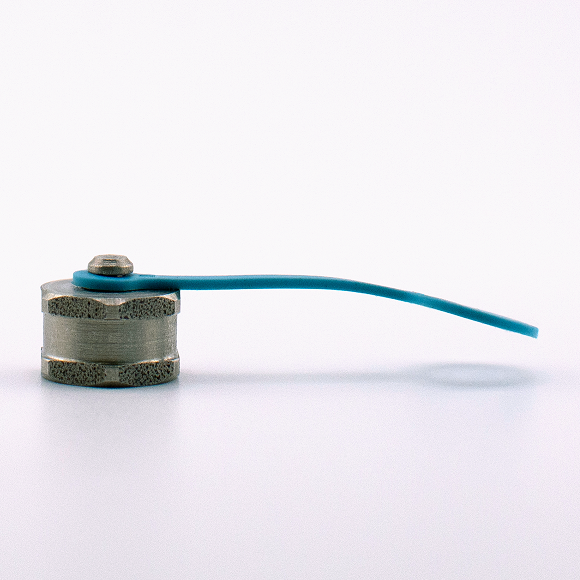

#691028

#691028All Stainless Steel Gauge Adapter #691028

#520XL

#520XLAll Stainless Steel Gauge Adapter #520XL

#691023

#691023Brass Gauge Adapter #691023

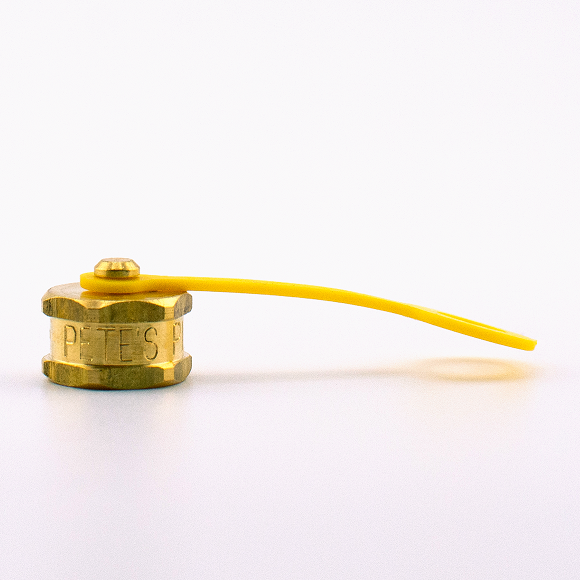

#500BSP

#500BSPBrass Gauge Adapter #500BSP

#691024

#691024Brass Gauge Adapter #691024

#500XLBSP

#500XLBSPBrass Gauge Adapter #500XLBSP

691026

691026Brass Gauge Adapter #691026

#691027

#691027Brass Gauge Adapter #691027

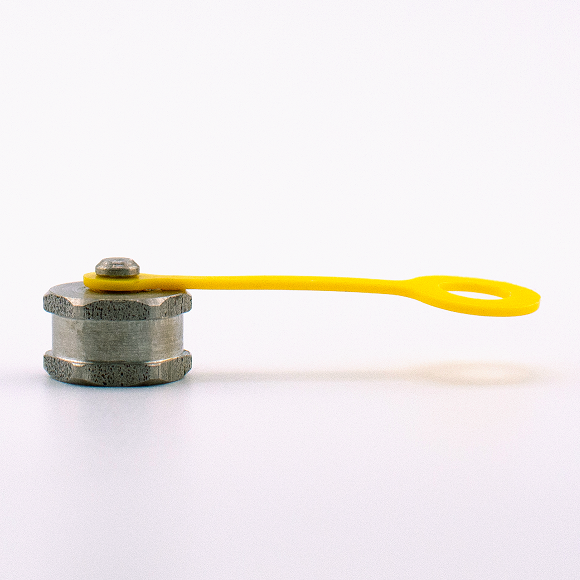

#104-1BS

#104-1BSCap Assembly #104-1BS

#104-1YS

#104-1YSCap Assembly #104-1YS

#104-2BS

#104-2BSCap Assembly #104-2BS

#104-2YS

#104-2YSCap Assembly #104-2YS

#691003

#691003Pete's Plug #691003

#691002

#691002Pete's Plug #691002

#691010

#691010Pete's Plug #691010

#691001

#691001Pete's Plug #691001

#691000

#691000Pete's Plug #691000

#691017

#691017Pete's Plug #691017

#12510

#12510Pete's Plug #12510

691020

691020Pete's Plug #691020

#691008

#691008Pete's Plug #691008

#691005

#691005Pete's Plug #691005

#691007

#691007Pete's Plug #691007

#691004

#691004Pete's Plug #691004

#572

#572Pete's Plug #572

#691019

#691019Pete's Plug #691019

#691018

#691018Pete's Plug #691018

#760

#760Pete's Plug #760

#691016

#691016Pete's Plug #691016

#691022

#691022Pete's Plug #691022

#691021

#691021Pete's Plug #691021

#691014

#691014Pete’s Plug #691014

#691013

#691013Pete’s Plug #691013

#562

#562Pete’s Plug #562

#691012

#691012Pete’s Plug #691012

#691011

#691011Pete’s Plug #691011

#750XL

#750XLPete’s Plug #750XL

#691015

#691015Pete’s Plug #691015

#691029

#691029Pressure & Temperature Test Kit 0-100psi

#691030

#691030Pressure & Temperature Test Kit 0-100psi for XL

#1500-5

#1500-5Pressure Gauge 0-100 PSI BSP Stem

#1500-4

#1500-4Pressure Gauge 0-100 PSI NPT Stem

#606

#606Thermometer -58°F to 550°F

-

-

-

- About

- Resources

- Contact

The Top 4 Pipe Support Failures Found in QA Audits (And How to Prevent Them)

In the high-stakes arenas of Australia’s mining, oil, and gas sectors, pipe support failures are significant operational hazards. These failures stem from issues like incomplete weld certifications, material traceability gaps, and specification misalignment, with the potential to disrupt project timelines, incur hefty non-compliance penalties, and elevate safety risks. For project managers under pressure to uphold safety and reliability, addressing these threats is crucial. This post delves into how reinforcing compliance through thorough weld certification to AS/NZS 1163 standards, maintaining meticulous traceability, and rigorously testing against AS/NZS 3725:2007 can minimise these risks, streamline audits, and maintain project integrity and financial health.

Incomplete or Missing Weld Certifications

Incomplete weld certifications can cause significant schedule delays, often resulting in hold points under the AS/NZS 1163 standard during QA audits. These certifications are essential to establish compliance and verify the integrity of welded components. Lacking these documents can severely disrupt project timelines, affecting delivery and contractual obligations.

Moreover, missing weld information complicates pipe weld traceability, an essential step in maintaining records that ensure the structural integrity of pipe assemblies. Absence of weld data undermines compliance efforts, possibly compromising safety and structural reliability, leading to costly remedial actions and increased scrutiny from regulators.

Conducting early and thorough weld certification checks is crucial to support quality control piping standards. Proactive inspections and validations before audits can avert potential findings and hold points, ensuring alignment with industry standards. This is particularly important when incorporating Binder’s custom-engineered pipe supports, designed for high performance in demanding environments.

Material Traceability and Certification Gaps

Incomplete batch records often lead to missing or incorrect material certificates during QA audits, a major red flag that can derail project timelines. Using a traceability checklist for the oil and gas sector assists in mitigating these risks. Ensuring material alignment with standards such as AS/NZS 3678 and AS/NZS 1594 helps maintain compliance and streamline the audit process.

Comprehensive QA audits pipe supports documentation prevents costly rework and avoids project handover holds. Binder’s Documentation Pack and QA/QC Sets are crucial tools for ensuring complete traceability and certification verification, particularly useful for pre-handover audits to secure financial and operational stability by rigorously addressing compliance gaps upfront.

Lack of Compaction Testing for Bedding and Side Supports

Insufficient compaction tests for buried piping can lead to settlement issues and structural stress, posing significant risks for project managers. This can result in pipe misalignment and unexpected maintenance costs, especially in harsh environments like the mining and oil & gas sectors, where ground conditions can exacerbate weaknesses.

Pipe support inspection protocols must encompass thorough checks of bedding layers, as mandated by AS/NZS 3725:2007. Skipping this step escalates the risk of structural failures, leading to expensive downtime and rework. Incorporating these checks into inspection protocols is crucial to safeguard structural integrity and operational safety.

Maintaining QA recordkeeping for pipe support systems enables project teams to demonstrate compliance and avoid repeat inspections. Accurate records not only support audit requirements but also help swiftly identify non-compliance issues, preventing delays during project execution.

Neglecting these steps increases support settlement risks, introducing long-term integrity challenges. Settlement can compromise the support structure, necessitating premature repairs. Proactive management through rigorous testing and documentation mitigates these risks, ensuring pipeline infrastructure durability and reliability.

Binder’s Custom-Engineered Pipe Supports incorporate preventive measures to ensure project safety and efficiency through extensive compaction testing and meticulous recordkeeping.

Precision Prevents Penalties: Ensuring Specification Alignment

Ensuring that design specifications align with actual installations is vital in preventing common pipe support failures. Discrepancies here, particularly in seismic or high-vibration settings, can lead to structural failures and noncompliance, endangering asset integrity.

Compliance with standards such as AS/NZS 1170 and NZS 4219 is essential for effective prevention. These standards require adherence to specific parameters that protect against architectural inadequacies. Failure to adhere jeopardizes safety, necessitates costly reworks, and leads to schedule overruns.

The financial impacts of insufficient alignment with design specifications underline the importance of comprehensive audits and compliance adherence. Investing in Binder’s Custom-Engineered Pipe Supports reduces discrepancies, ensuring projects meet compliance from the outset.