- Products

-

-

-

Categories

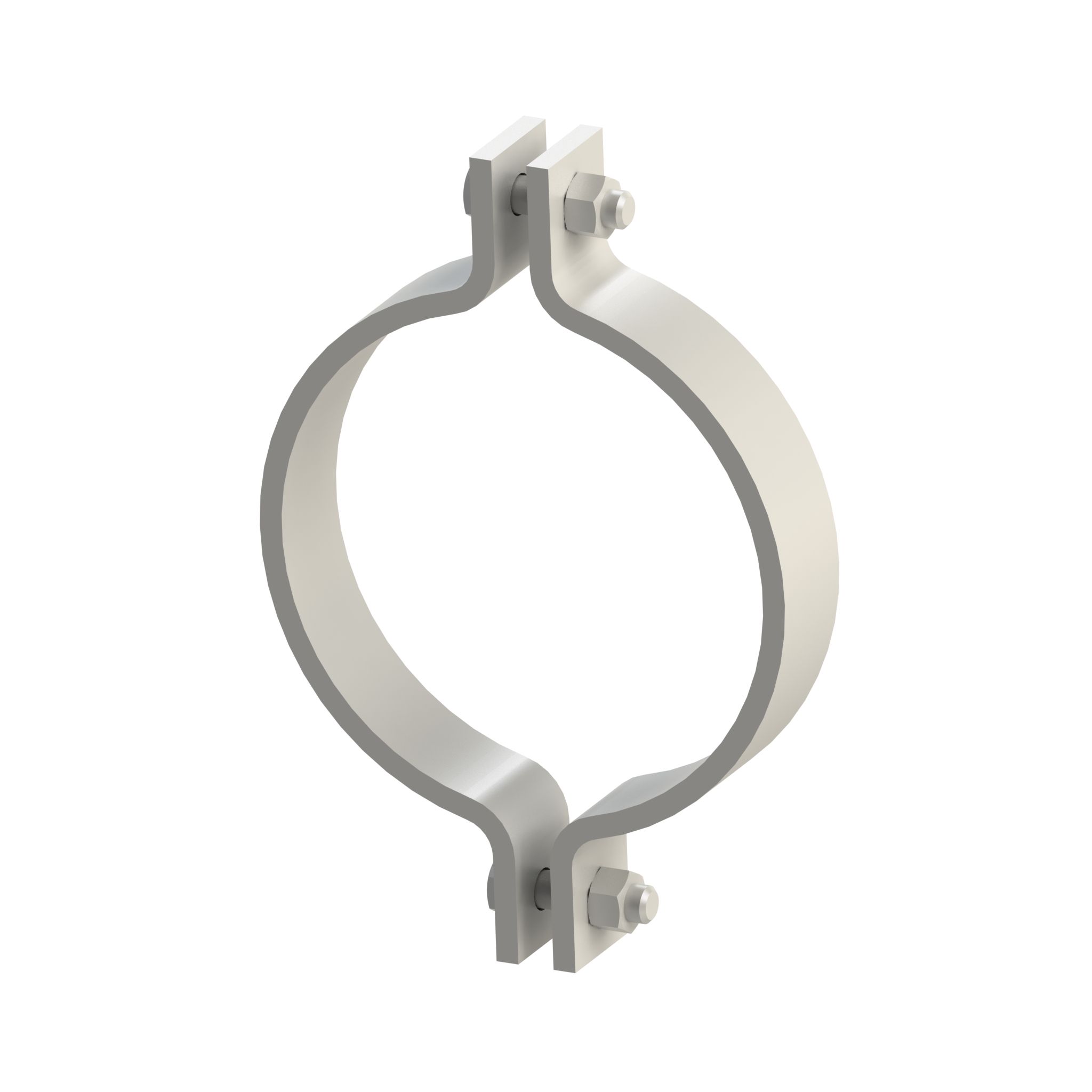

BG100

BG100LIGHT DUTY 2-BOLT CLAMP

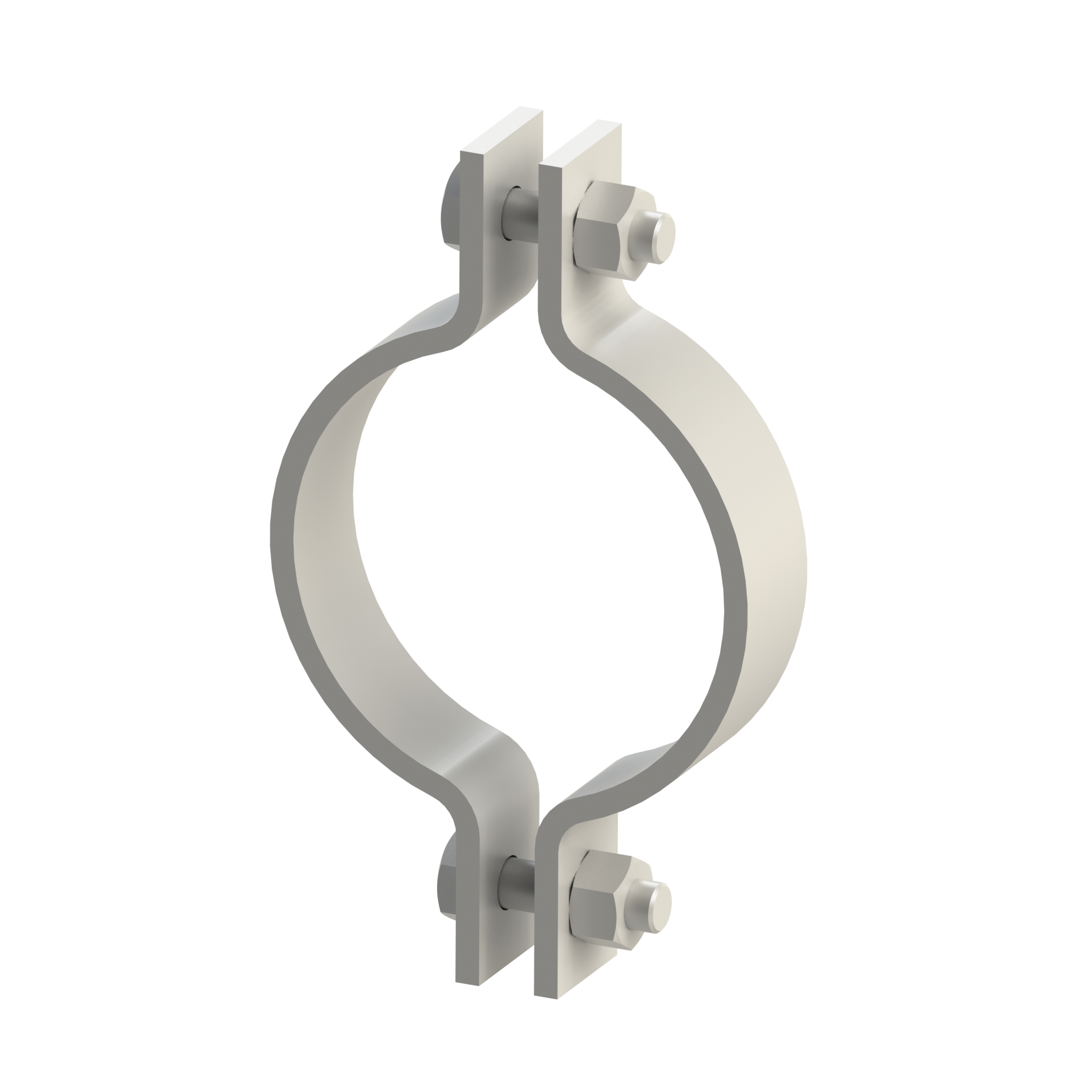

BG170

BG170MEDIUM DUTY 2-BOLT PIPE CLAMP

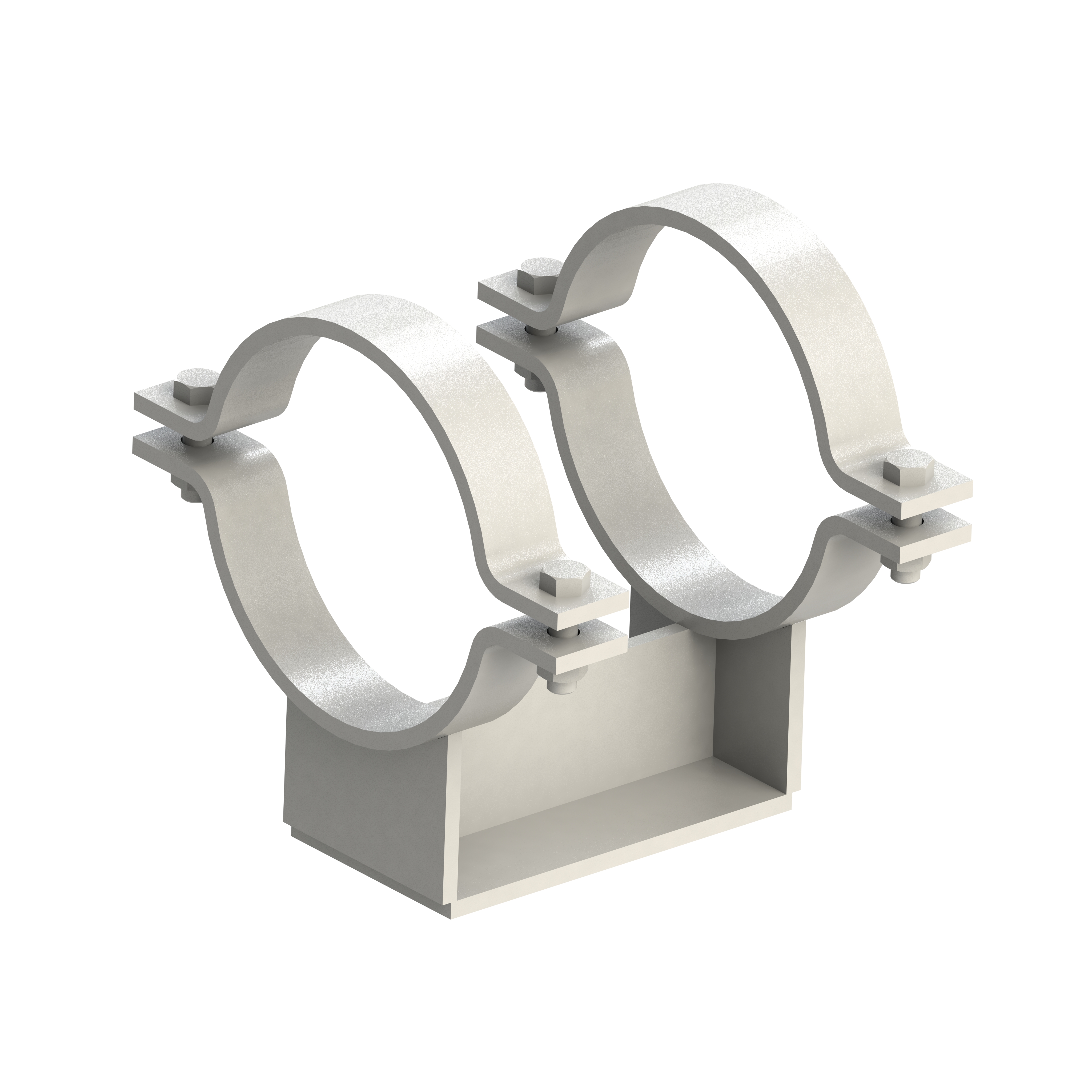

BG50

BG50HEAVY DUTY 2-BOLT PIPE CLAMP

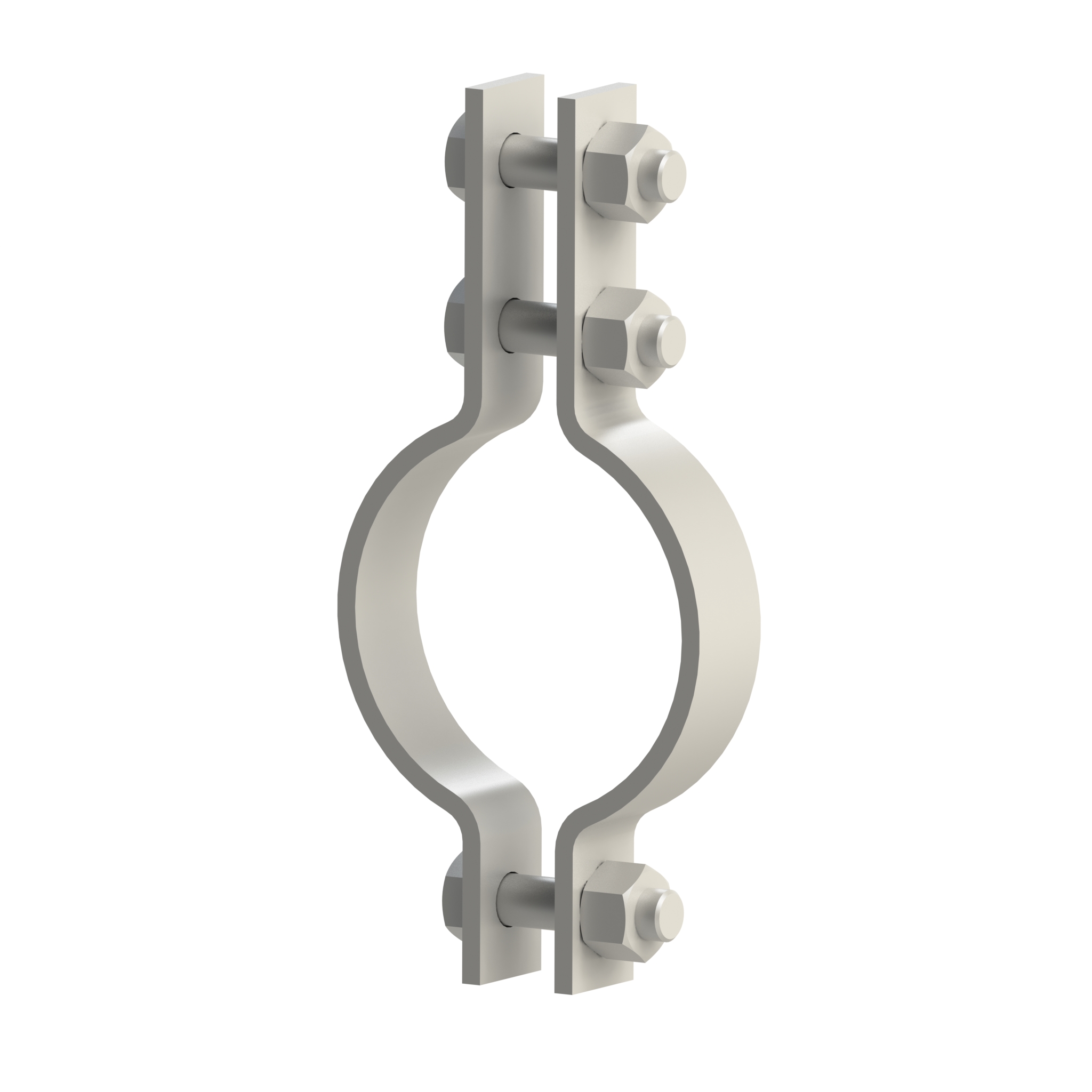

BG101

BG101LIGHT DUTY 3-BOLT PIPE CLAMP

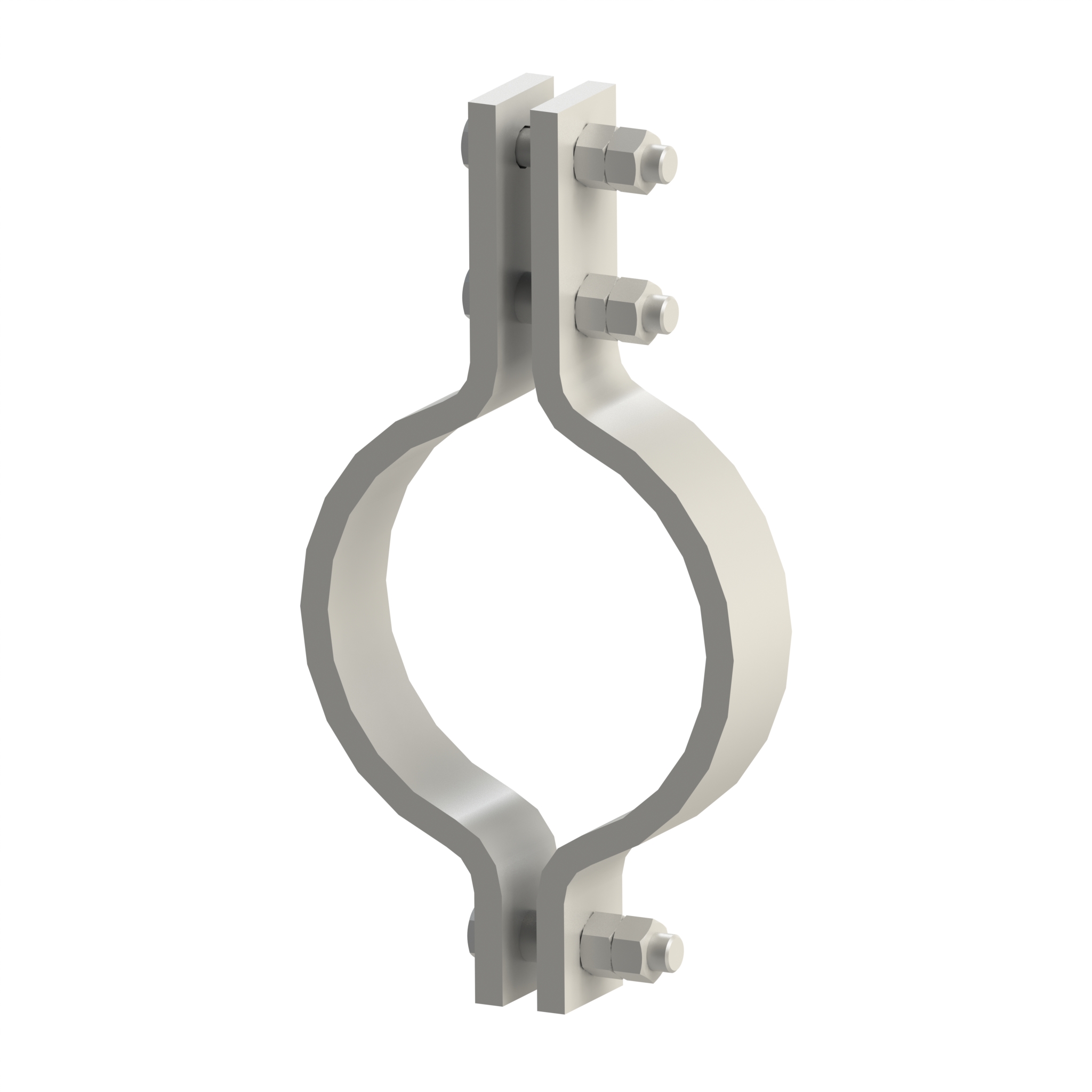

BG171

BG171MEDIUM DUTY 3-BOLT PIPE CLAMP FOR STEEL PIPE

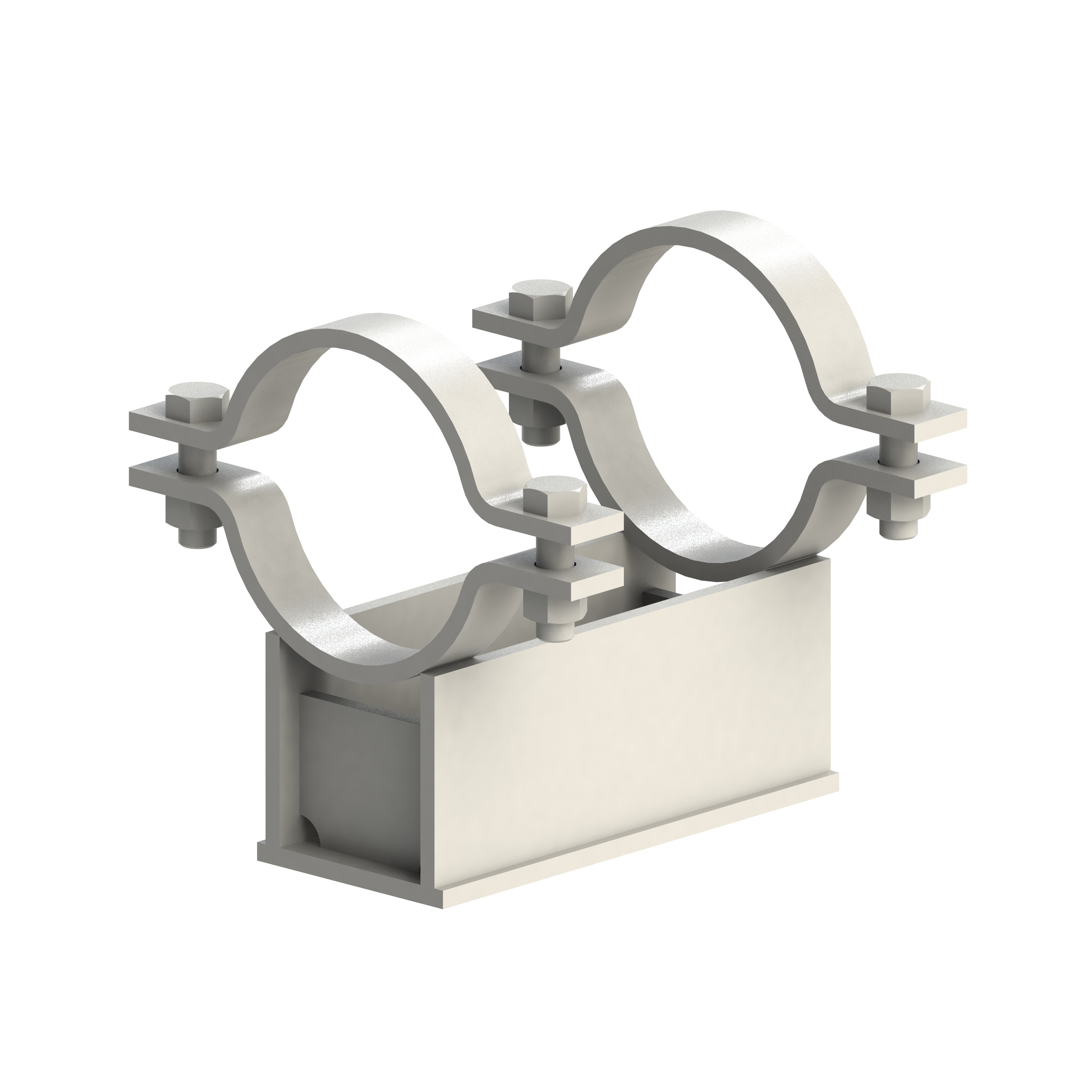

BG75

BG75HEAVY DUTY 3-BOLT PIPE CLAMP

BG172

BG172HIGH TEMPERATURE 3-BOLT PIPE CLAMP

BG173

BG173ALLOY PIPE CLAMP - VERY HIGH TEMPERATURE

BG140

BG140INSULATED 2-BOLT PIPE CLAMP

BG141

BG141INSULATED 2-BOLT PIPE CLAMP FOR CU/NI

BG145

BG145INSULATED 3-BOLT PIPE CLAMP

BG146

BG146INSULATED 3-BOLT PIPE CLAMP FOR CU/NI

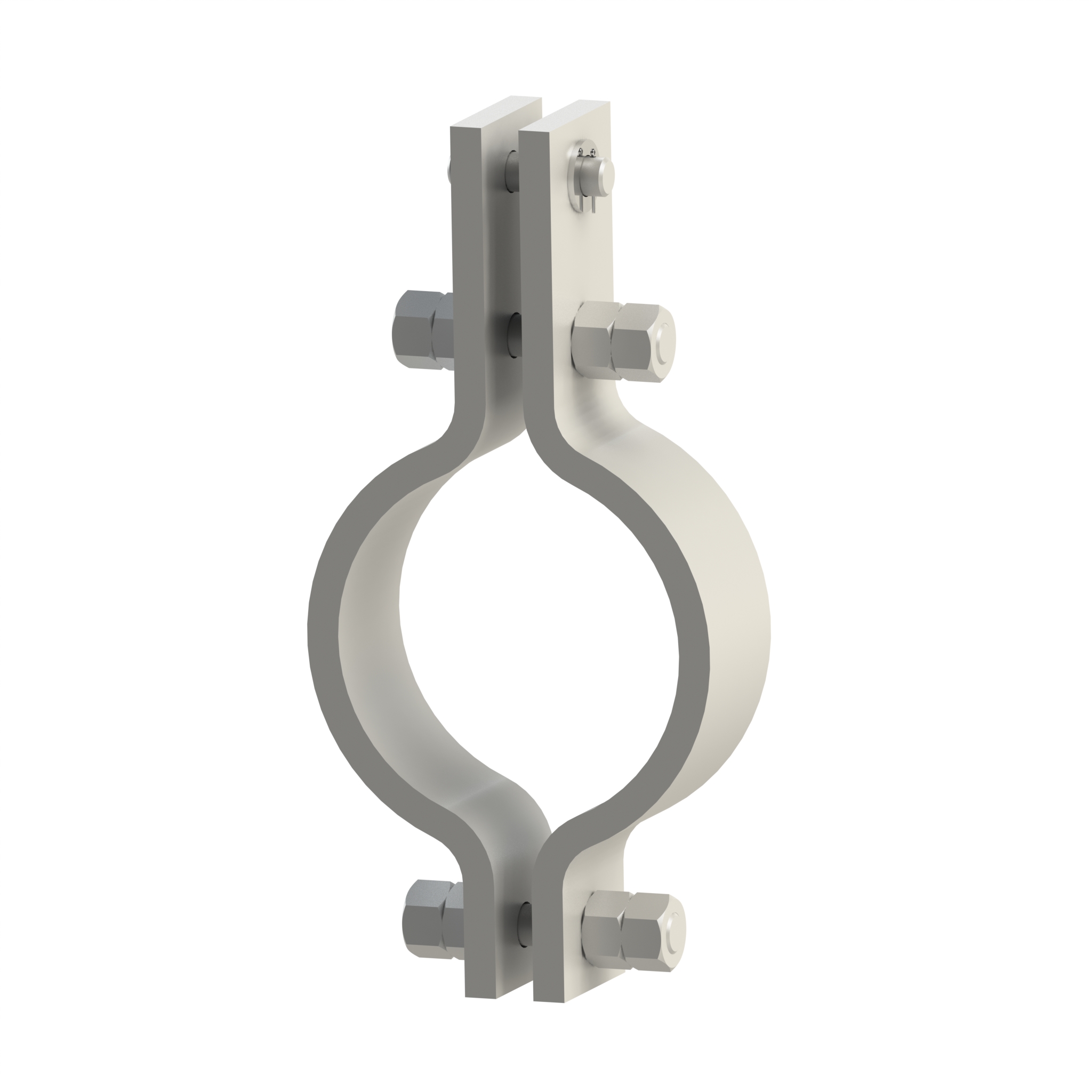

BG108

BG108CLEVIS CLAMP

BG222

BG222BEAM CLAMP

BG174

BG174RISER SUPPORT – STD TEMPERATURE

BG175

BG175RISER SUPPORT – HIGH TEMPERATURE

BG176

BG176ALLOY RISER SUPPORT - VERY HIGH TEMPERATURE

BG202

BG202ALLTHREAD ROD

BG209

BG209FORGED CLEVIS AND PIN

BG210

BG210FORGED TURNBUCKLE

BG204

BG204FORGED WELDLESS EYE NUT

BG215

BG215HEMISPHERICAL CUP

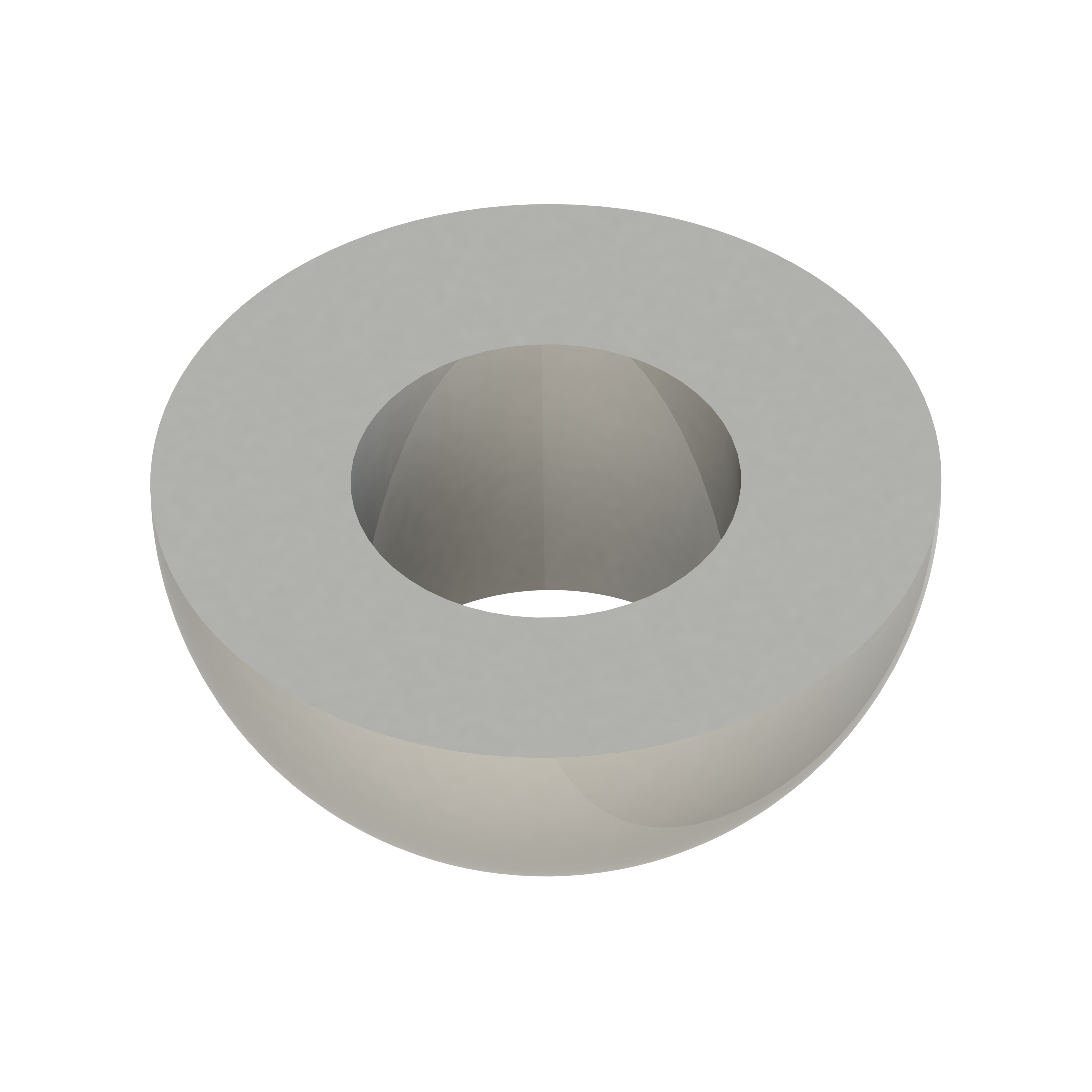

BG214

BG214HEMISPHERICAL WASHER

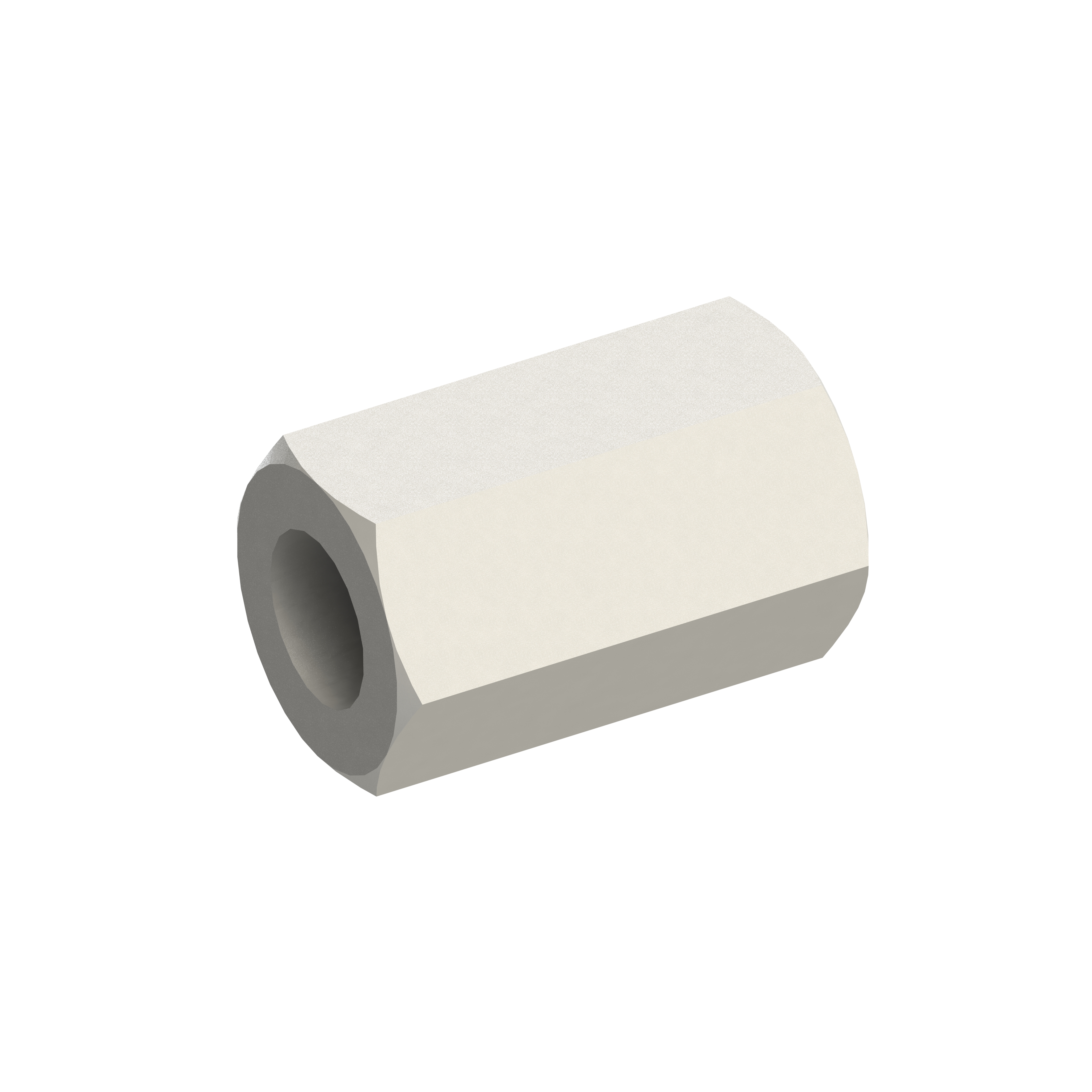

BG206

BG206HEXAGONAL CONNECTOR

BG216

BG216PIPE WELDING LUG

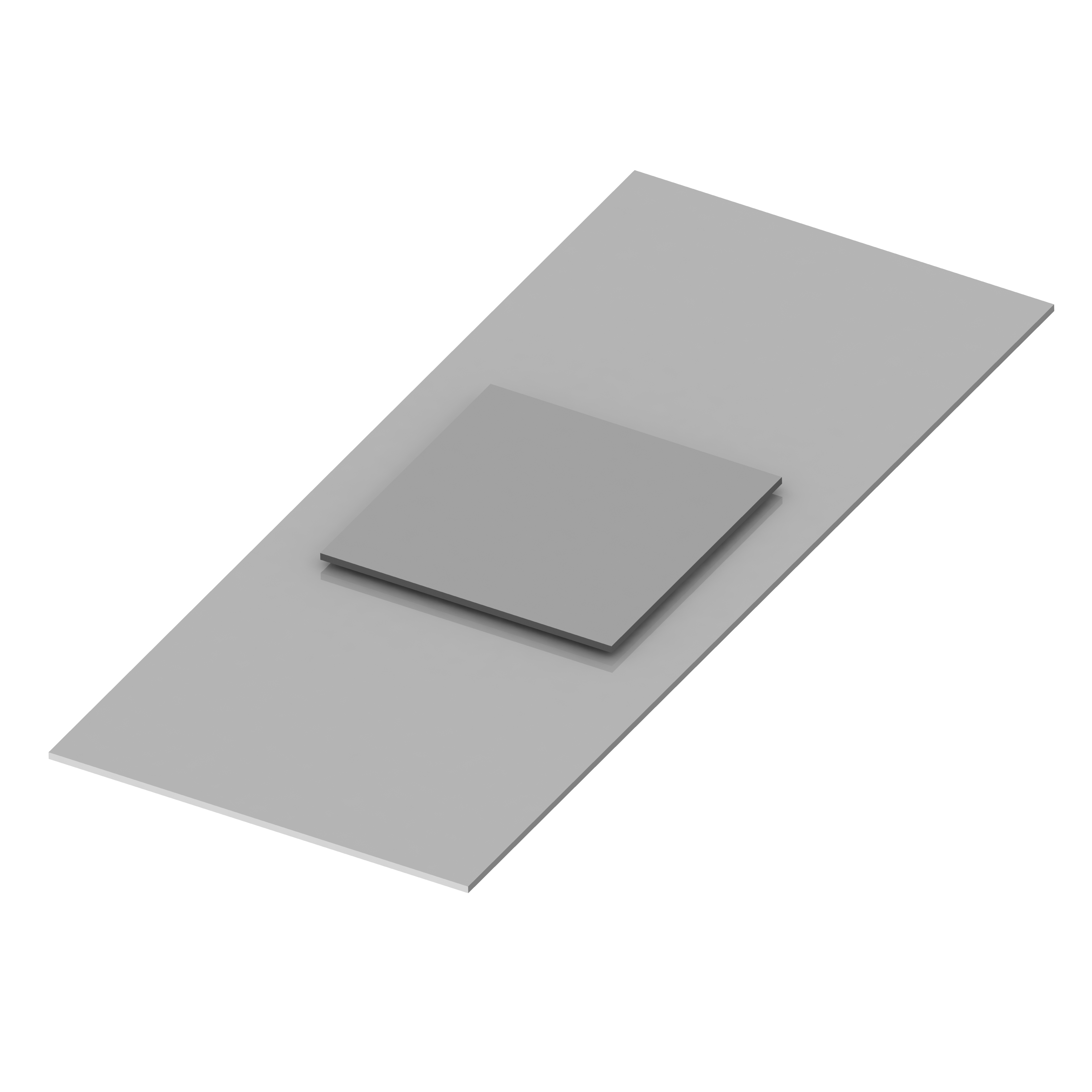

BG217

BG217PLATE WASHER

BG207

BG207SPADE NUT

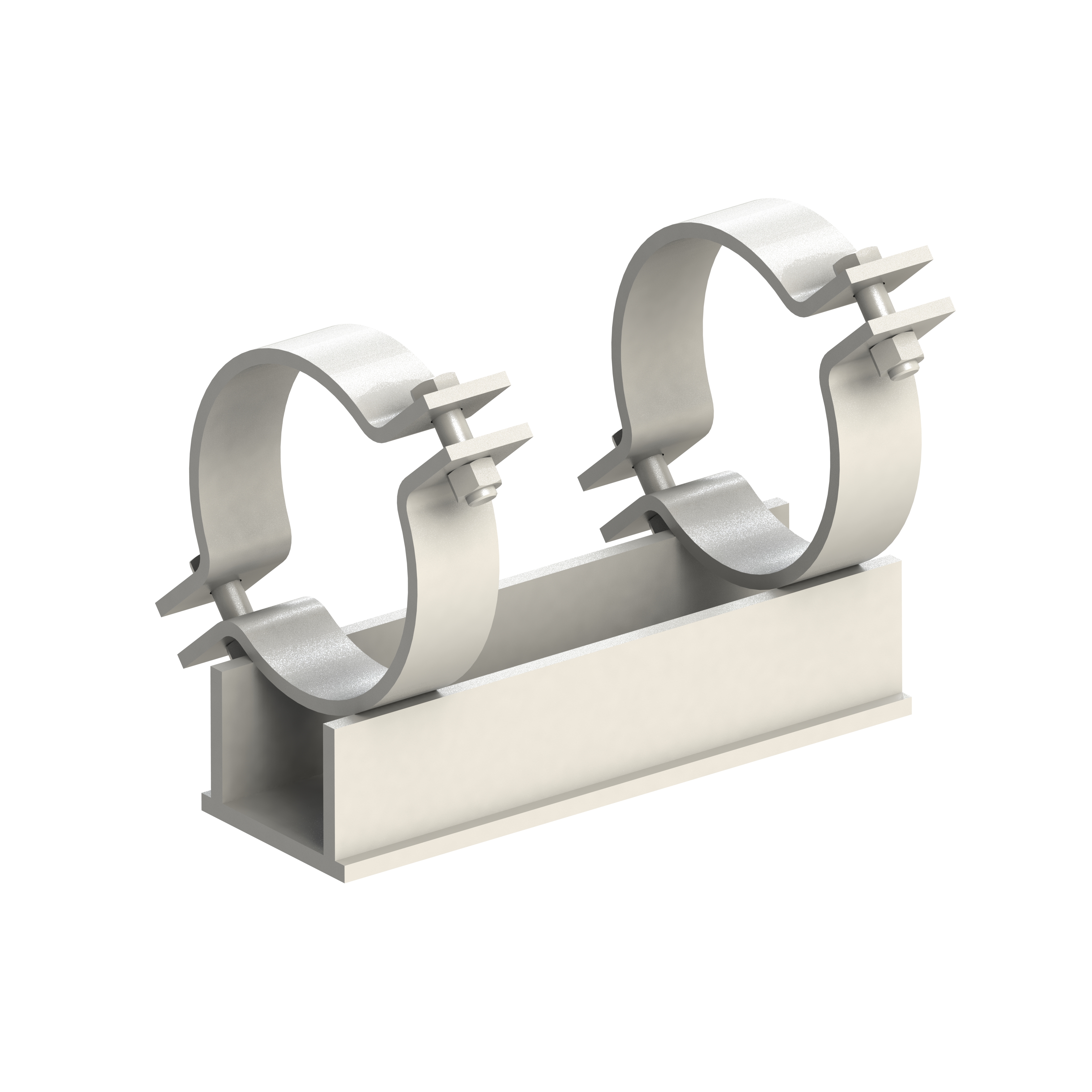

BG245

BG245STANDARD TRAPEZE

BG203

BG203THREADED DROP ROD – RH/LH

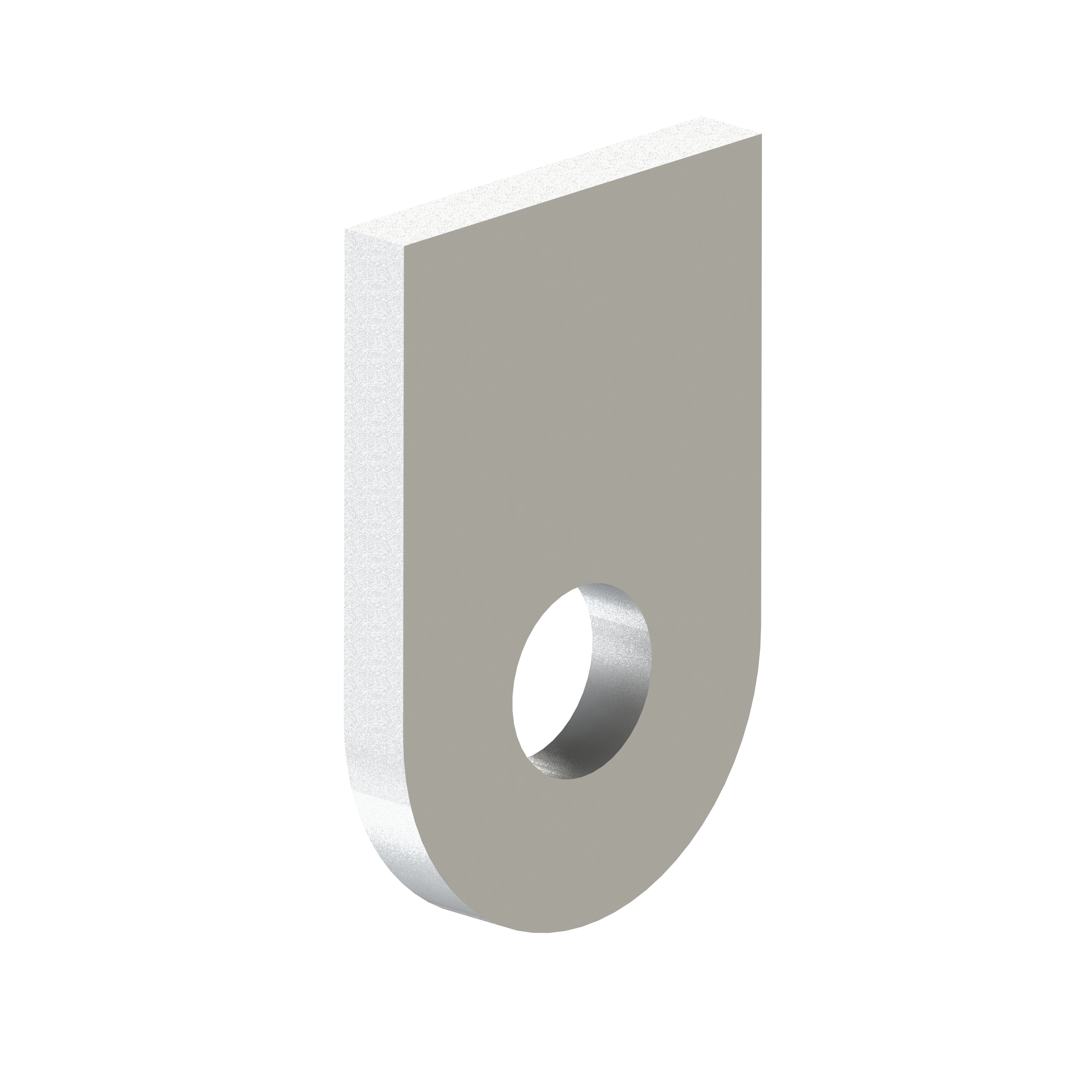

BG219

BG219WELDED BEAM ATTACHMENT

BG220

BG220WELDED BEAM ATTACHMENT (WITH LOAD PIN)

BG225

BG225WELDING LUG

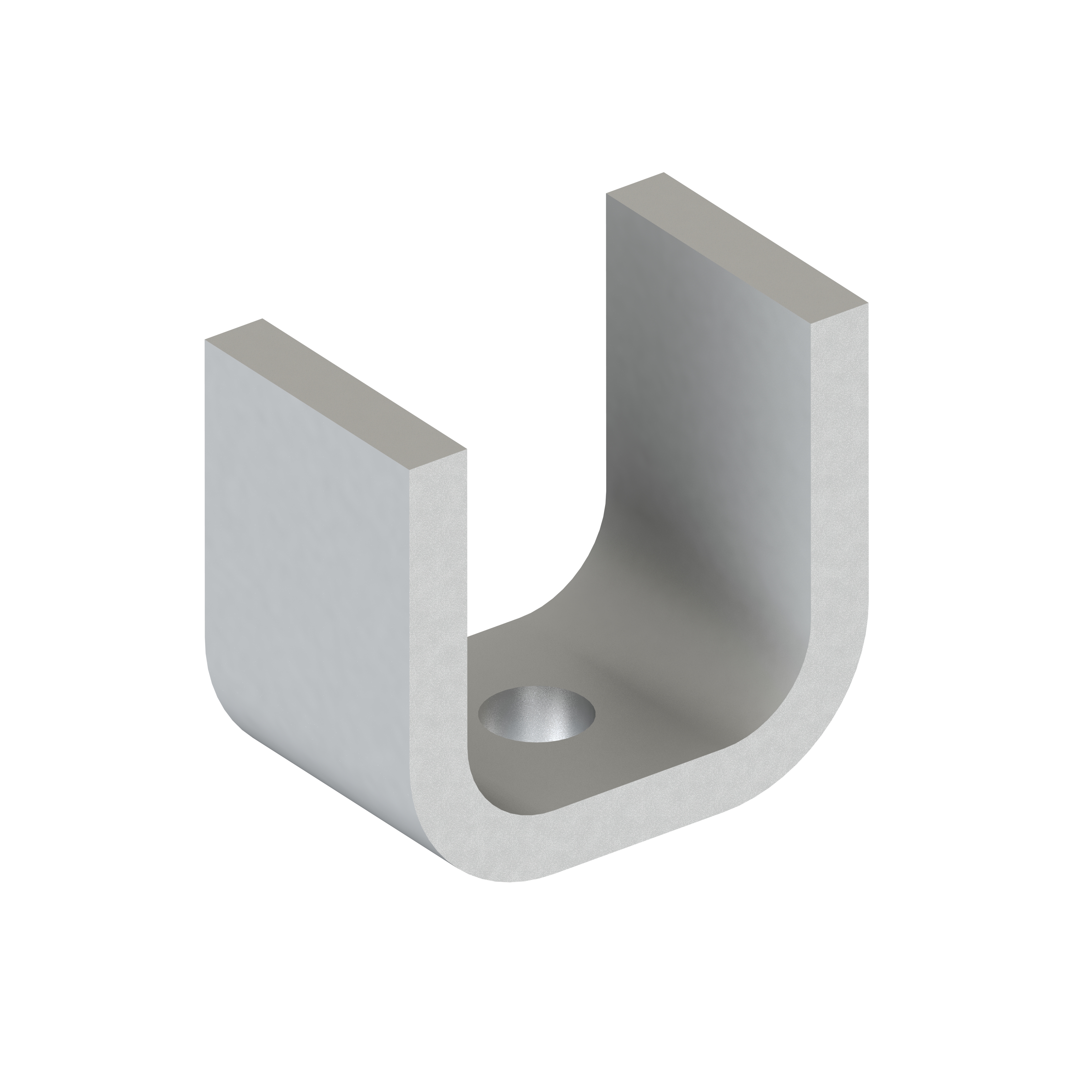

BG180

BG180U-BOLT GUIDE

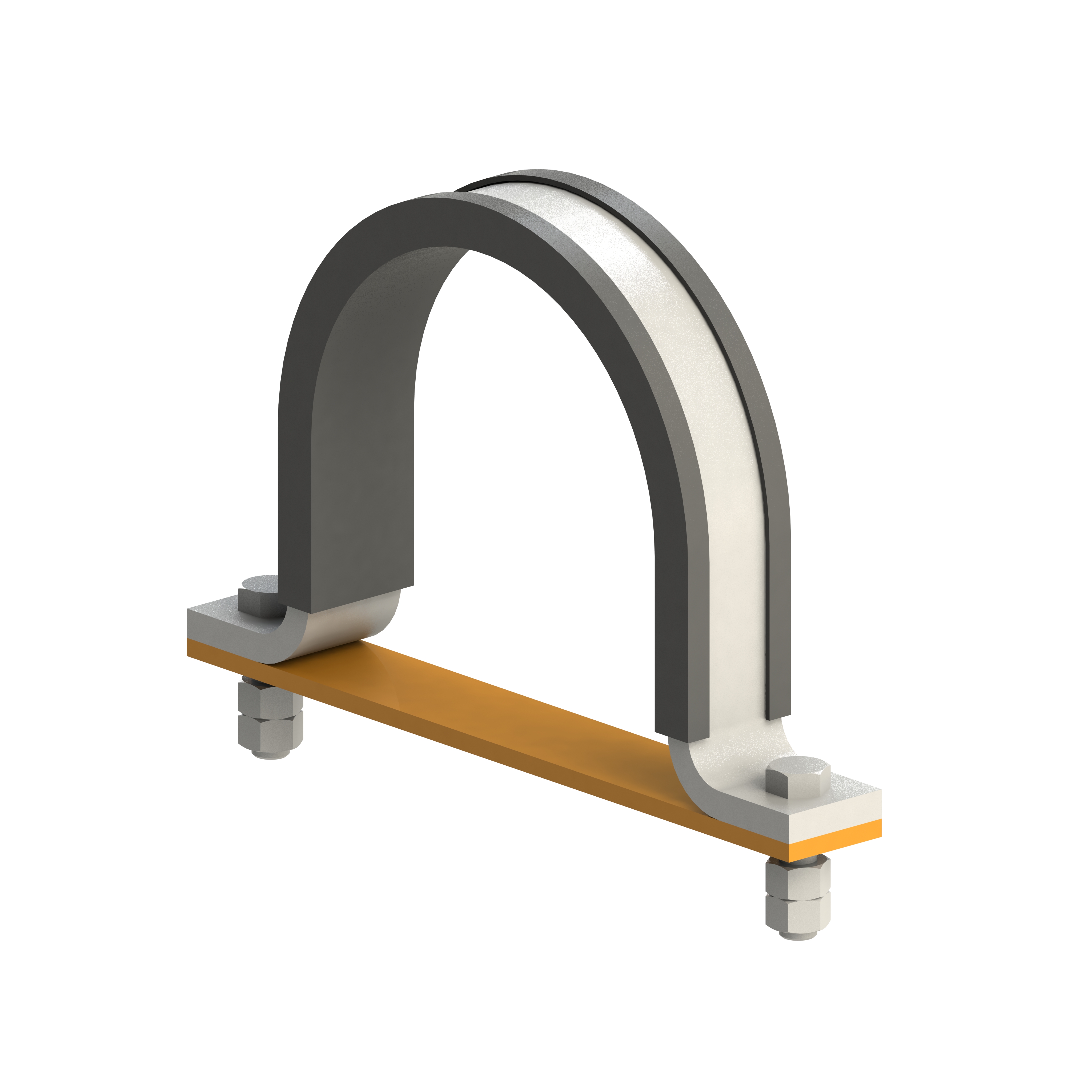

BG181

BG181U-BOLT CLAMP

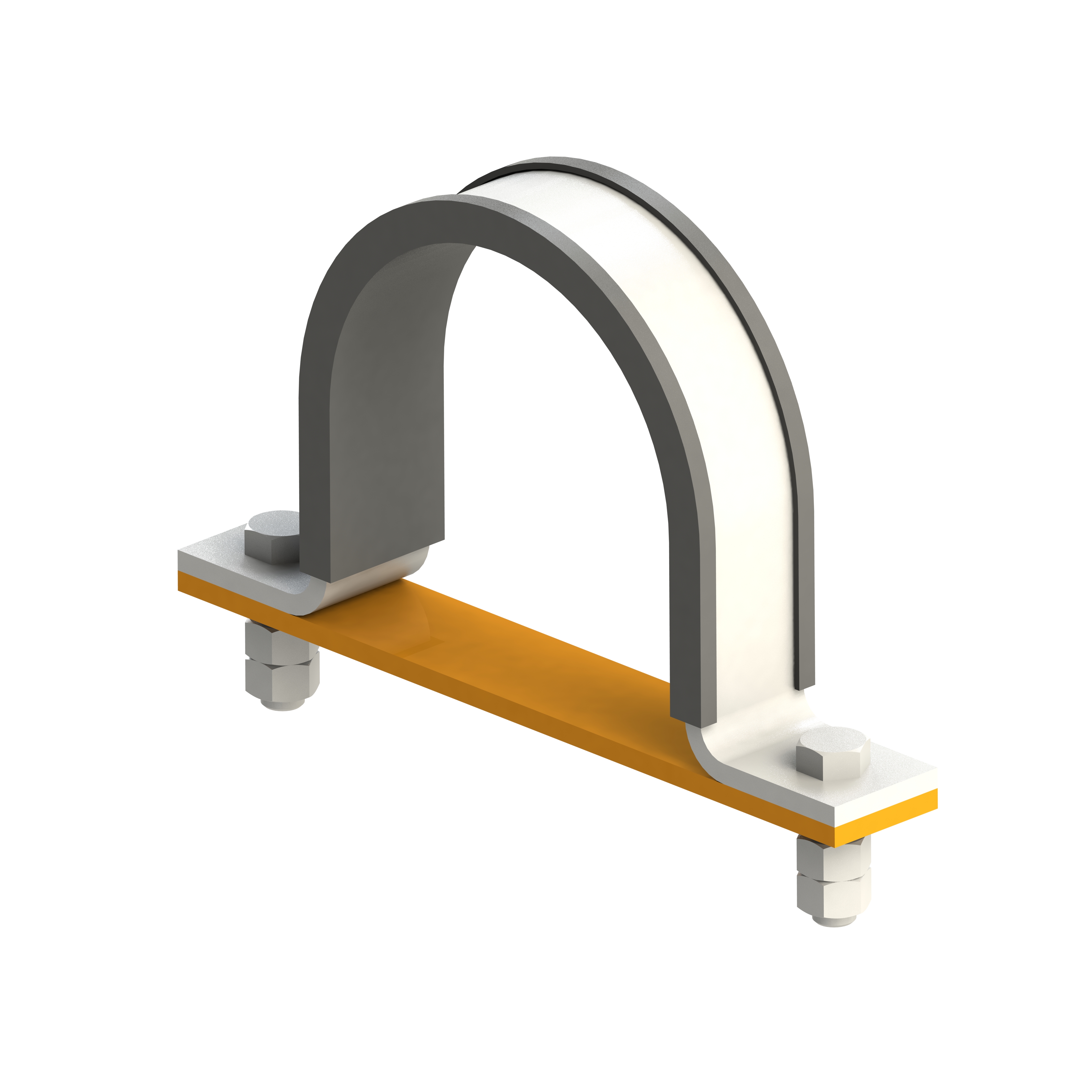

BG150

BG150INSULATED U-BOLT CLAMP

BG152

BG152INSULATED U-BOLT GUIDE

BG154

BG154INSULATED U-BOLT GUIDE (WITH TEFLON)

BG190

BG190INSULATED U-BOLT CLAMP

BG192

BG192INSULATED U-BOLT GUIDE

BG151

BG151INSULATED U-BOLT CLAMP FOR CU/NI

BG153

BG153INSULATED U-BOLT GUIDE FOR CU/NI

For Cu/Ni Pipe BG155

BG155INSULATED U-BOLT GUIDE (WITH TEFLON)

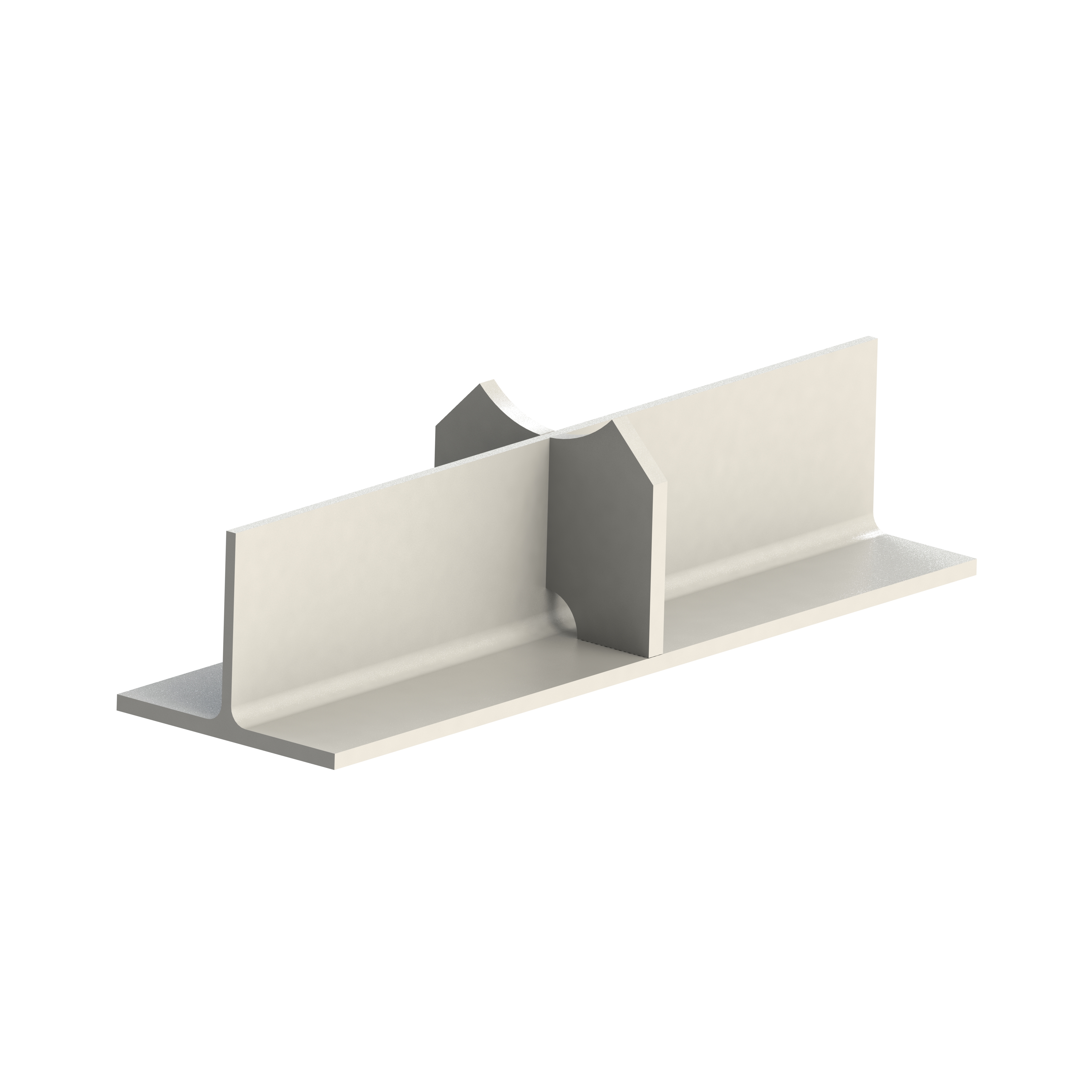

For Cu/Ni Pipe BG177

BG177SADDLE GUIDE

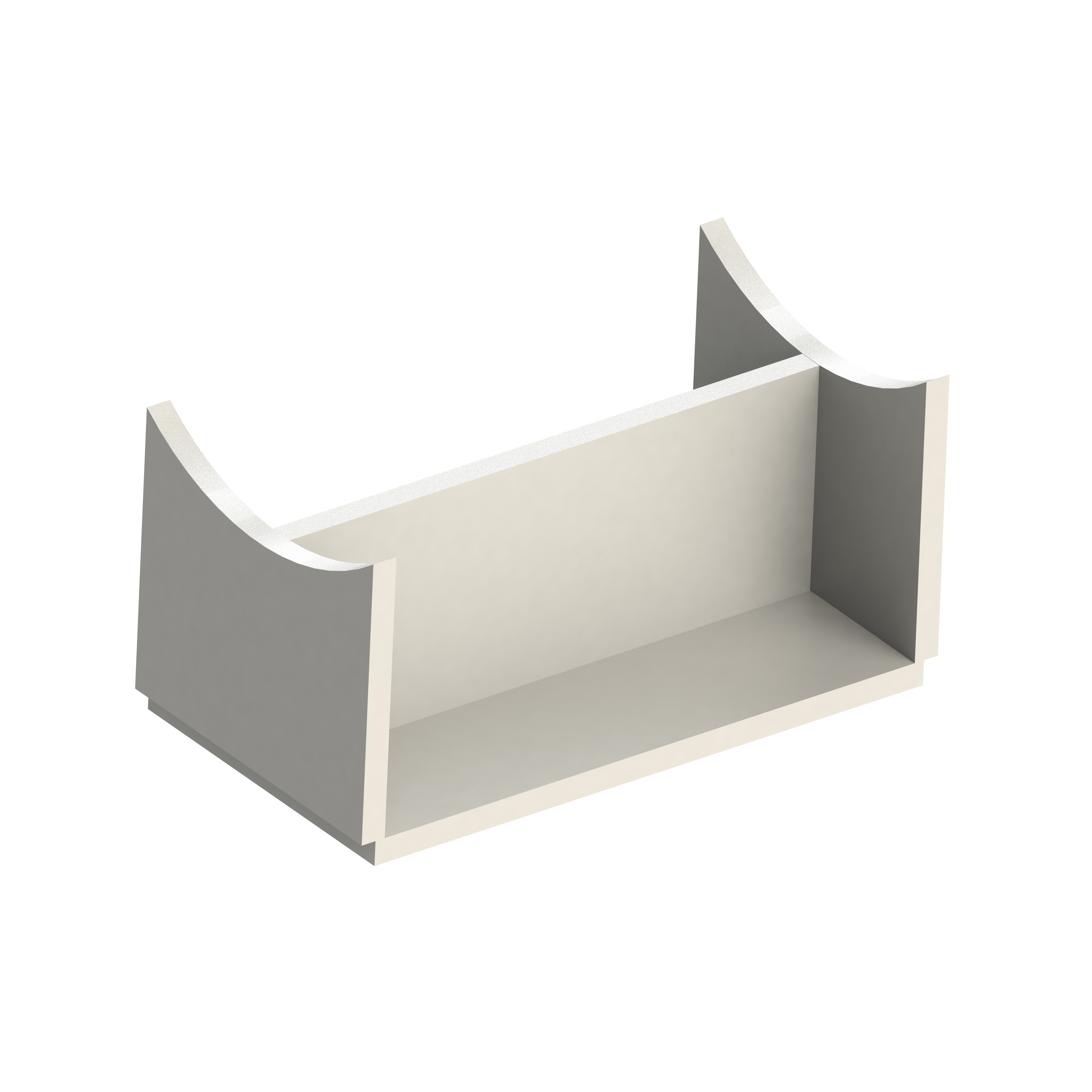

BG178

BG178SADDLE CLAMP

BG160

BG160INSULATED PIPE SADDLE

BG161

BG161INSULATED PIPE SADDLE

BG162

BG162INSULATED PIPE SADDLE

BG135-136

BG135-136ADJUSTABLE PIPE STANDS

BG515

BG515STANDARD CLAMPED PIPE SHOE

BG550

BG550SLIDE PLATES

BG517

BG517COMPACT PIPE SHOE

BG400

BG400CLAMPED HOT PIPE SHOE

BG156

BG156INSULATED PIPE SHOE

BG157

BG157INSULATED PIPE SHOE

BG510

BG510STANDARD WELDED PIPE SHOE

BG518

BG518COMPACT WELDED PIPE SHOE

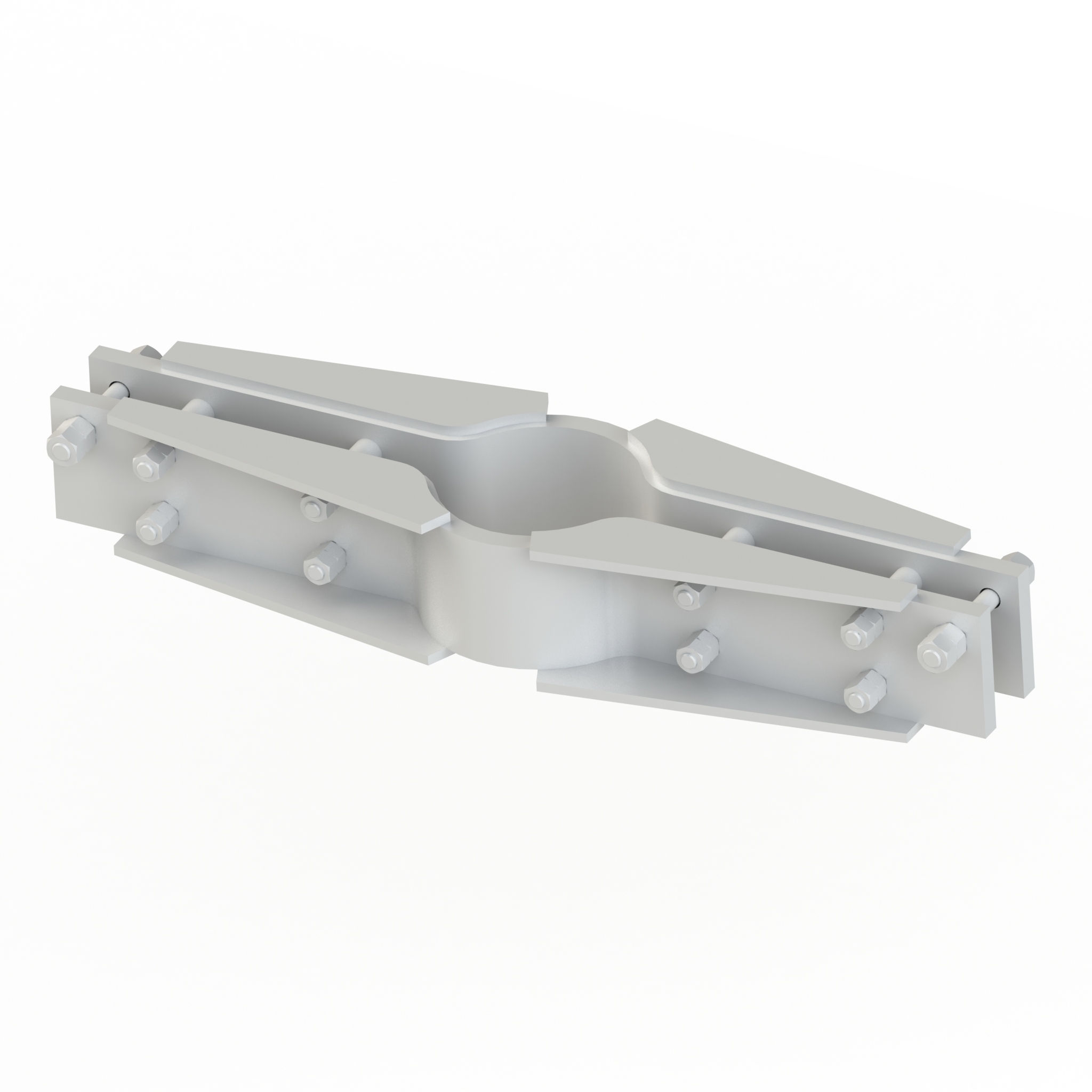

BG555

BG555STANDARD LINE STOPS

BG560

BG560STANDARD PIPE GUIDES

BG570

BG570STANDARD SHOE GUIDES

BG580

BG580STANDARD SHOE GUIDES

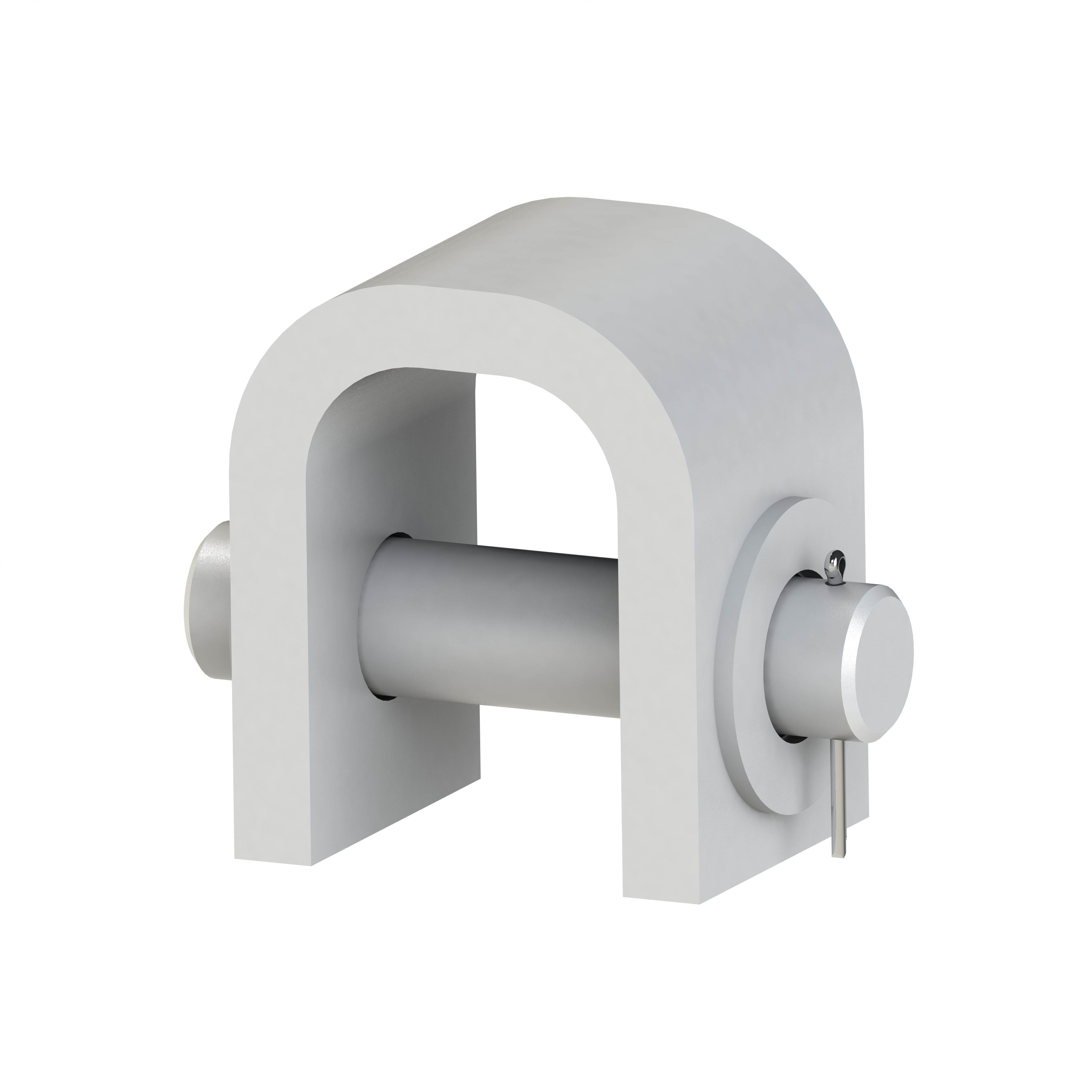

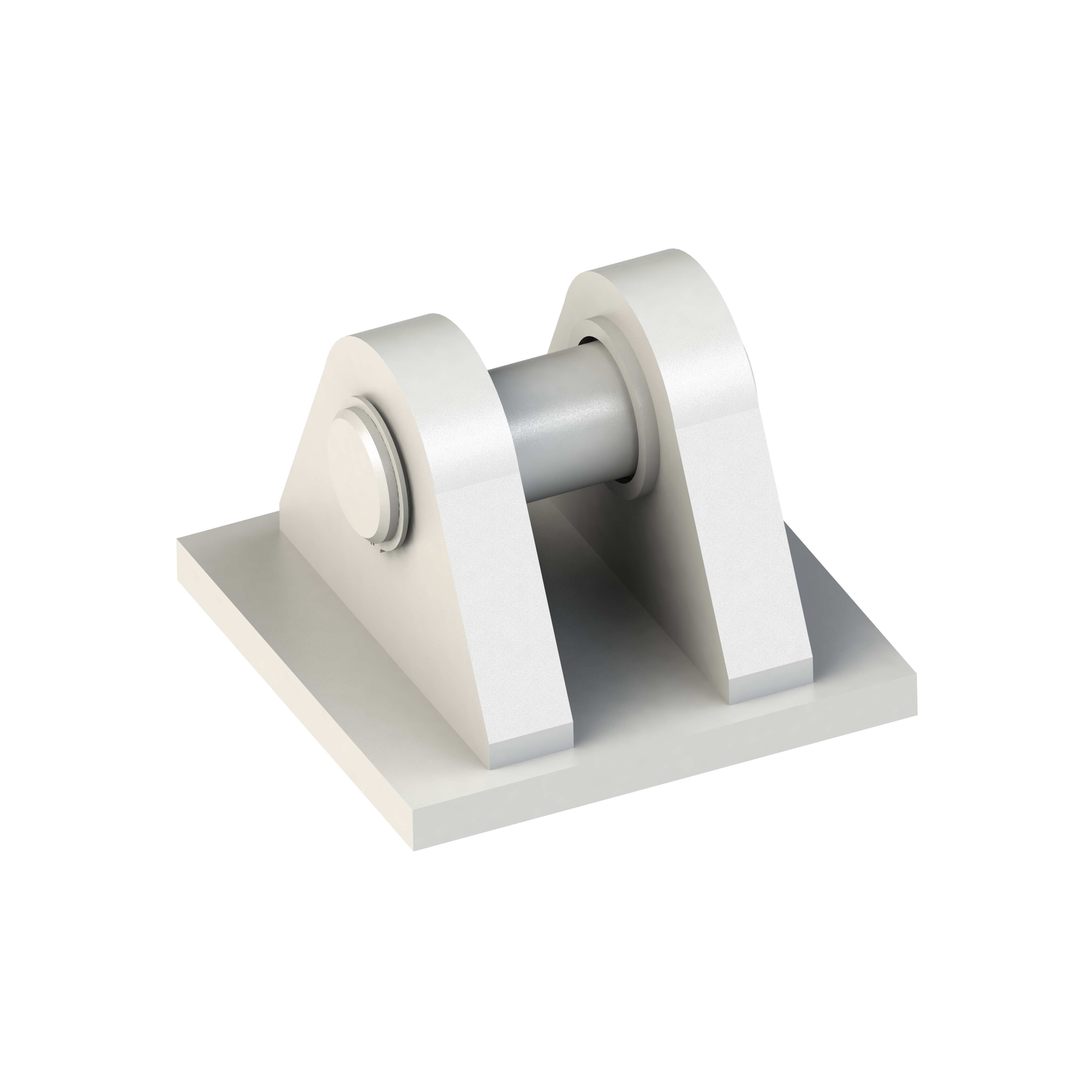

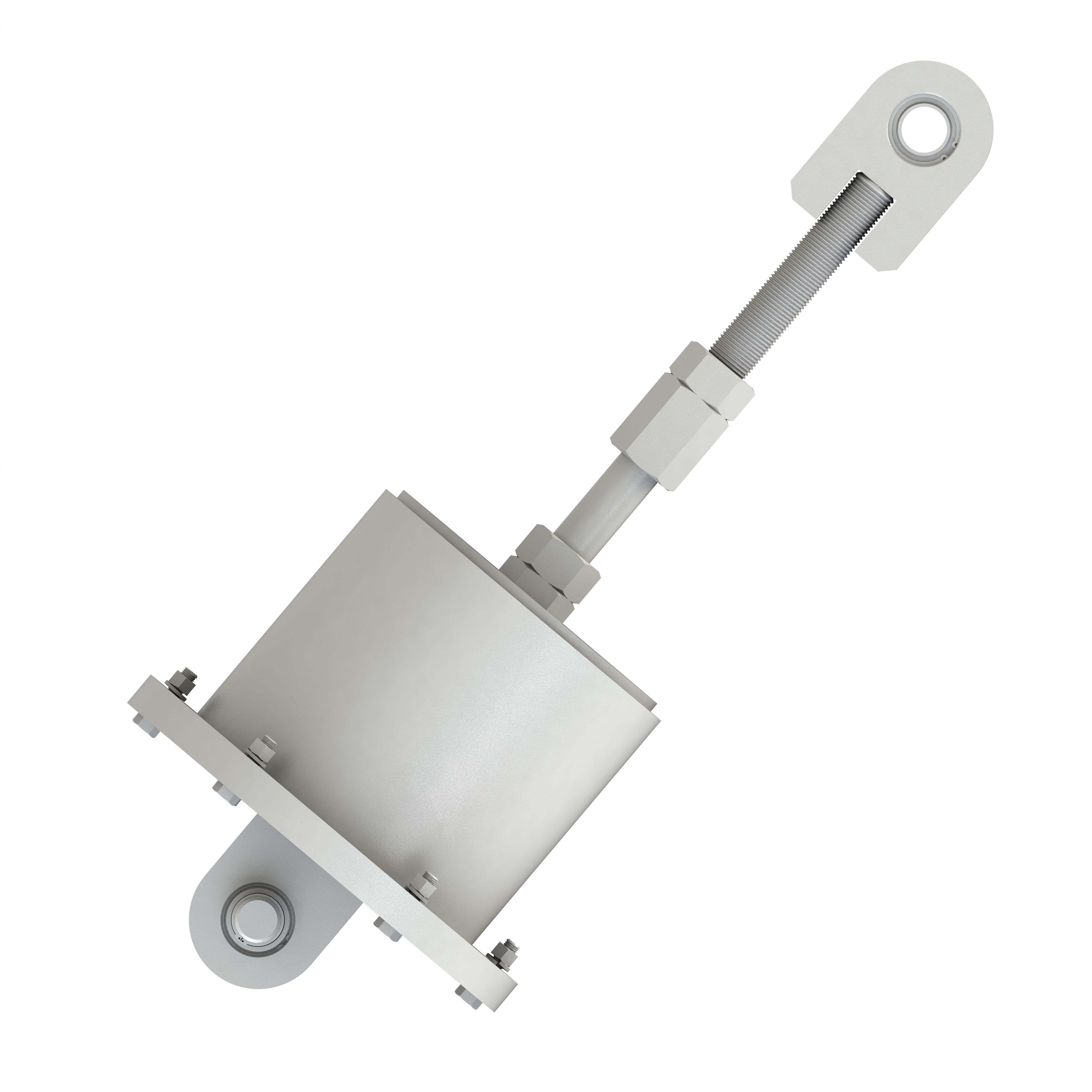

BG315

BG315END ATTACHMENT FOR HYDRAULIC SNUBBERS

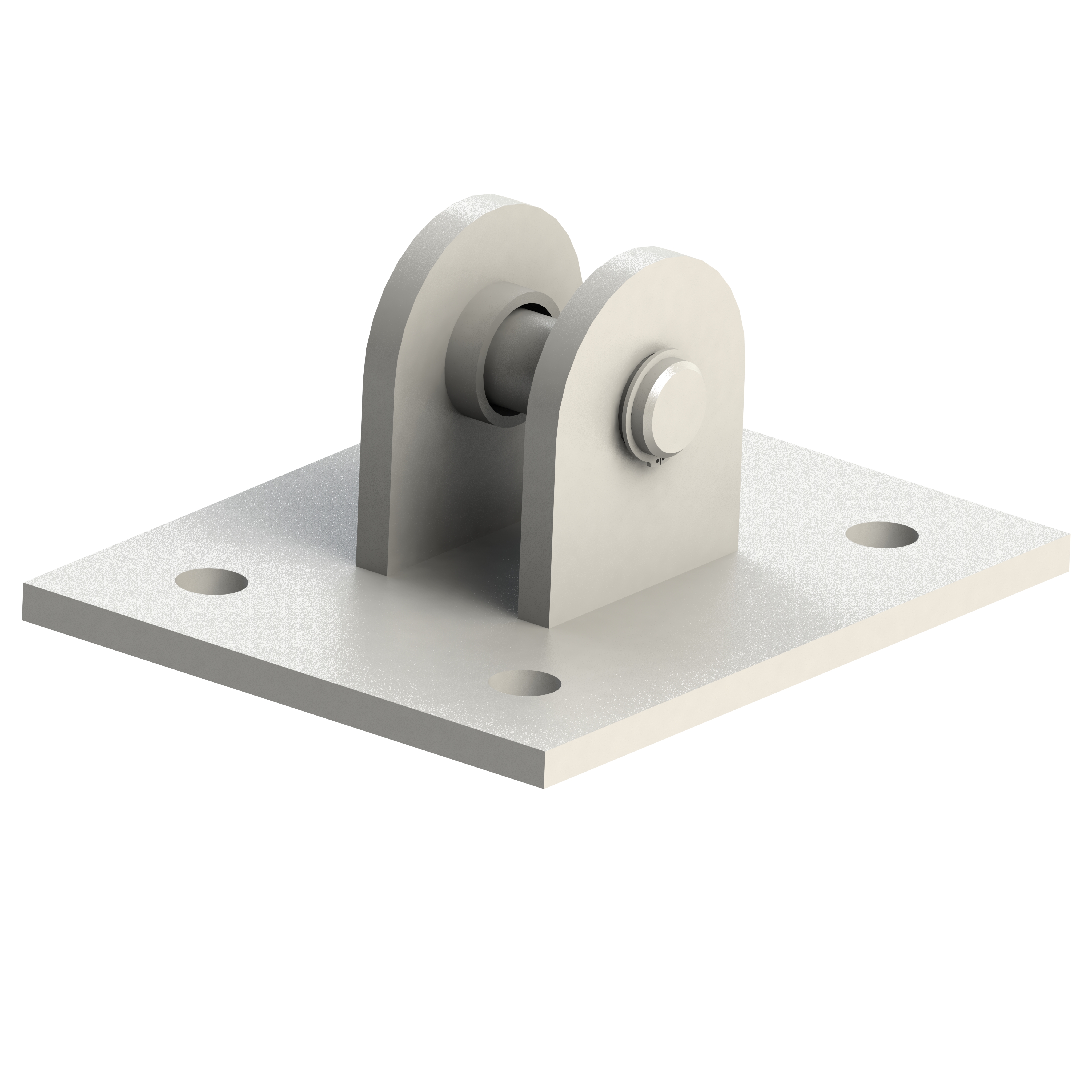

BG355

BG355END ATTACHMENT FOR RIGID STRUT & SWAY BRACE

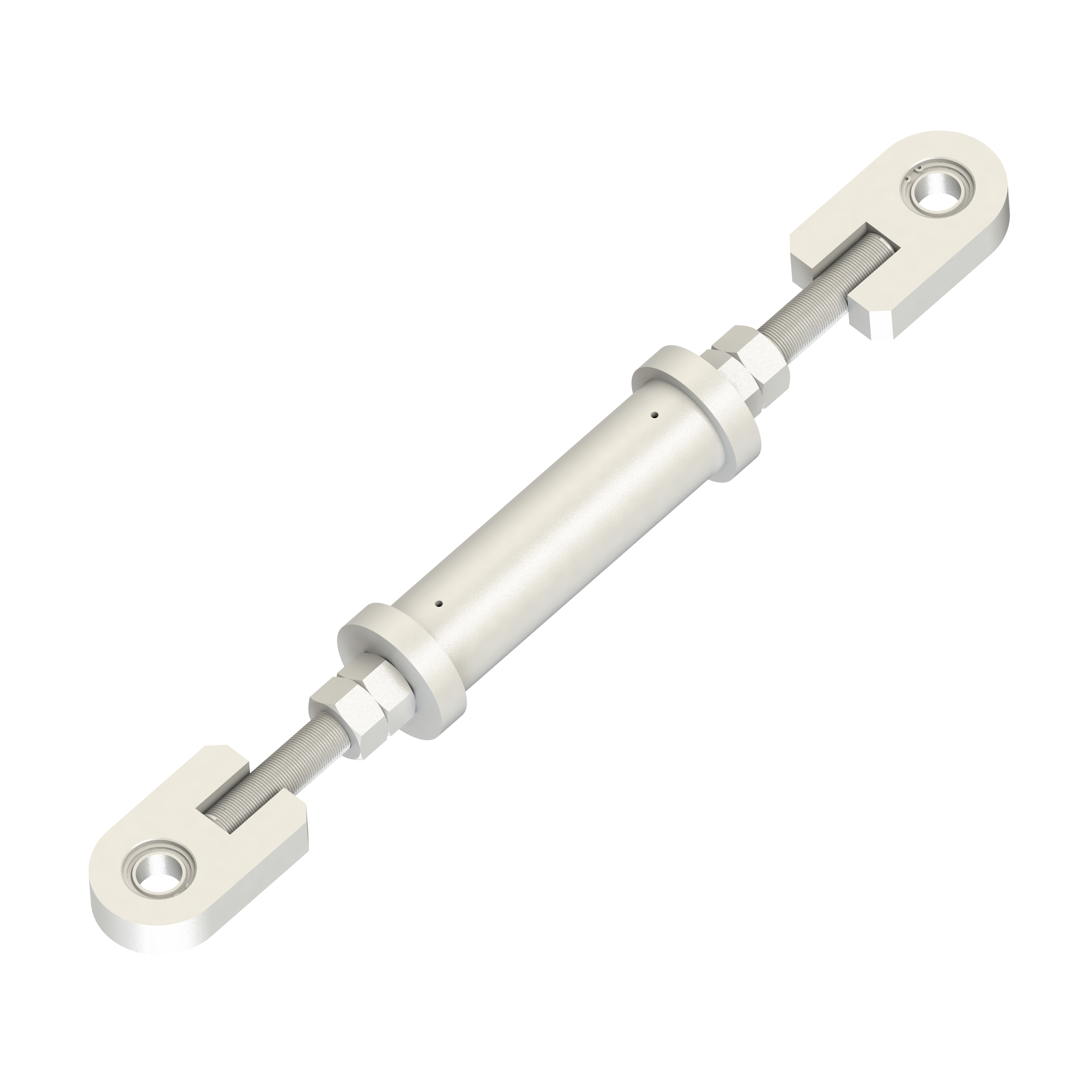

BG310

BG310HYDRAULIC SNUBBERS (SHOCK ARRESTORS)

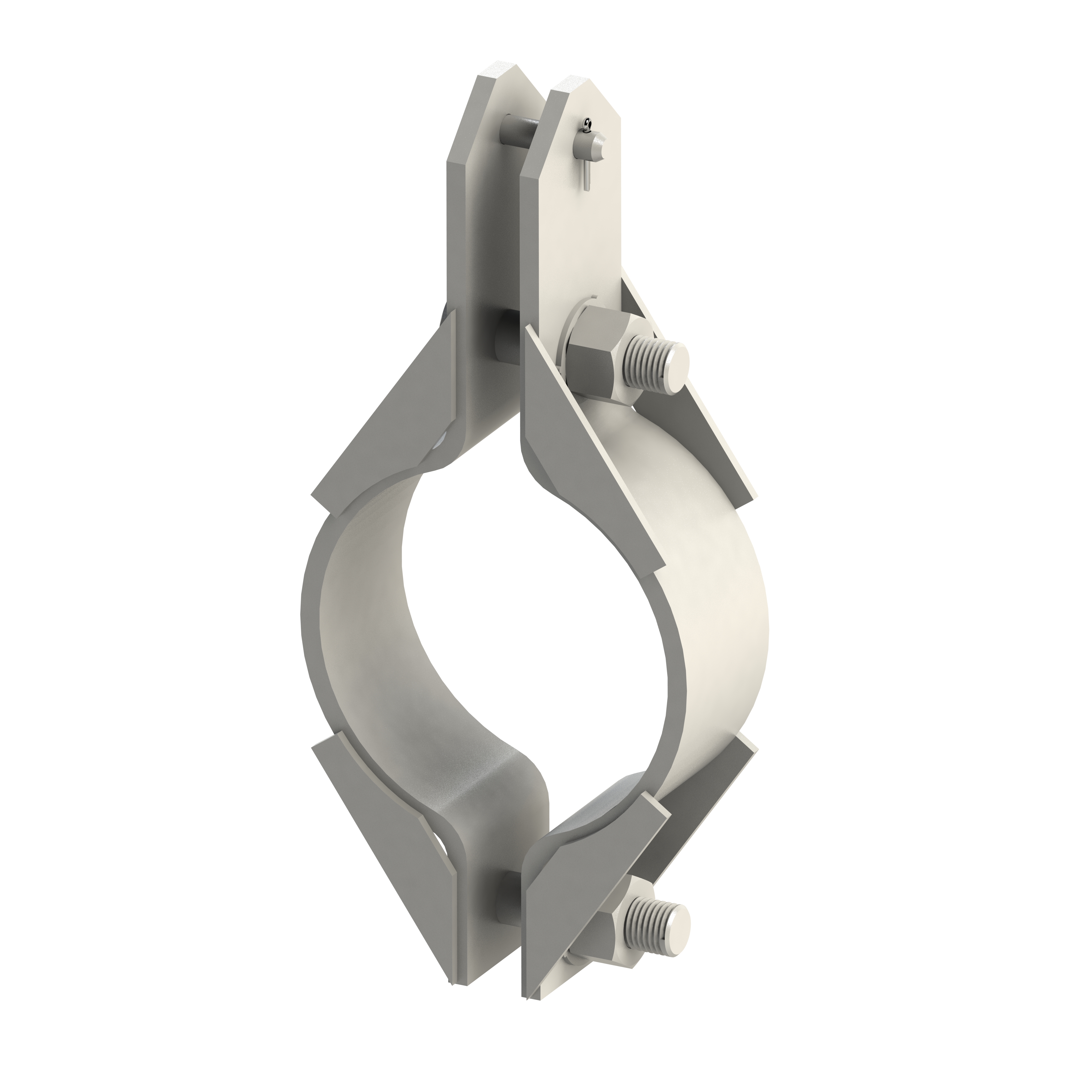

BG321

BG321PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG322

BG322PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG320

BG320PIPE CLAMP FOR HYDRAULIC SNUBBER – LOW TEMPERATURE

BG350

BG350RIGID STRUTS

BG340

BG340SWAY BRACE

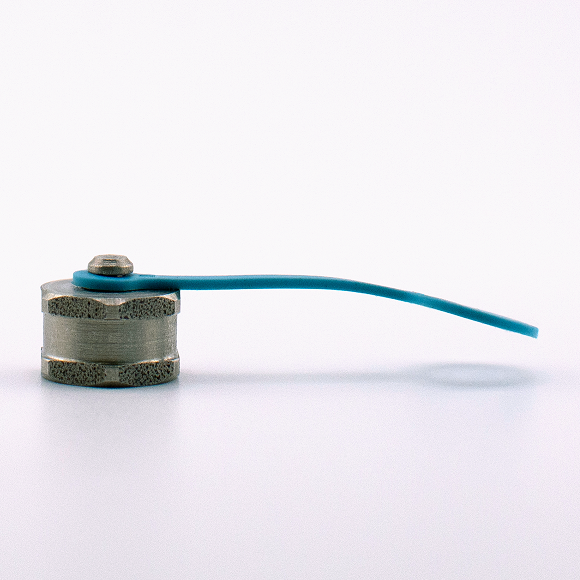

#691028

#691028All Stainless Steel Gauge Adapter #691028

#520XL

#520XLAll Stainless Steel Gauge Adapter #520XL

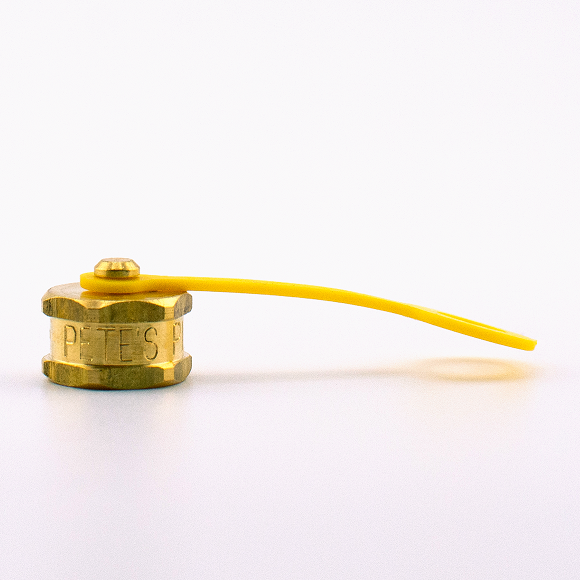

#691023

#691023Brass Gauge Adapter #691023

#500BSP

#500BSPBrass Gauge Adapter #500BSP

#691024

#691024Brass Gauge Adapter #691024

#500XLBSP

#500XLBSPBrass Gauge Adapter #500XLBSP

691026

691026Brass Gauge Adapter #691026

#691027

#691027Brass Gauge Adapter #691027

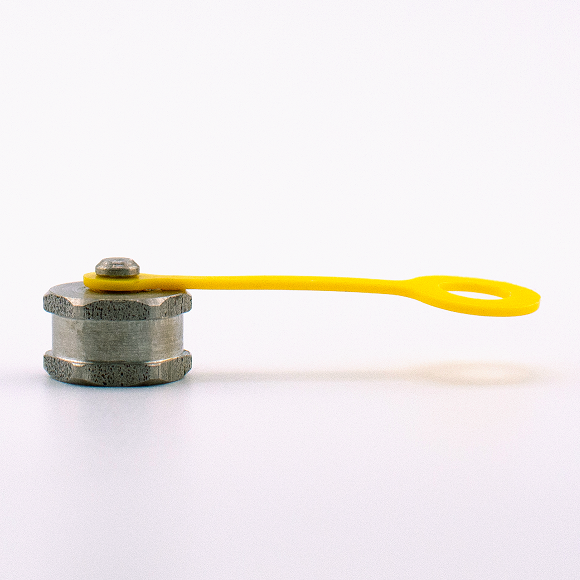

#104-1BS

#104-1BSCap Assembly #104-1BS

#104-1YS

#104-1YSCap Assembly #104-1YS

#104-2BS

#104-2BSCap Assembly #104-2BS

#104-2YS

#104-2YSCap Assembly #104-2YS

#691003

#691003Pete's Plug #691003

#691002

#691002Pete's Plug #691002

#691010

#691010Pete's Plug #691010

#691001

#691001Pete's Plug #691001

#691000

#691000Pete's Plug #691000

#691017

#691017Pete's Plug #691017

#12510

#12510Pete's Plug #12510

691020

691020Pete's Plug #691020

#691008

#691008Pete's Plug #691008

#691005

#691005Pete's Plug #691005

#691007

#691007Pete's Plug #691007

#691004

#691004Pete's Plug #691004

#572

#572Pete's Plug #572

#691019

#691019Pete's Plug #691019

#691018

#691018Pete's Plug #691018

#760

#760Pete's Plug #760

#691016

#691016Pete's Plug #691016

#691022

#691022Pete's Plug #691022

#691021

#691021Pete's Plug #691021

#691014

#691014Pete’s Plug #691014

#691013

#691013Pete’s Plug #691013

#562

#562Pete’s Plug #562

#691012

#691012Pete’s Plug #691012

#691011

#691011Pete’s Plug #691011

#750XL

#750XLPete’s Plug #750XL

#691015

#691015Pete’s Plug #691015

#691029

#691029Pressure & Temperature Test Kit 0-100psi

#691030

#691030Pressure & Temperature Test Kit 0-100psi for XL

#1500-5

#1500-5Pressure Gauge 0-100 PSI BSP Stem

#1500-4

#1500-4Pressure Gauge 0-100 PSI NPT Stem

#606

#606Thermometer -58°F to 550°F

-

-

-

- About

- Resources

- Contact

When Critical Components Arrive Late, Mining Projects Suffer

Late deliveries in mining projects cost much more than time. They threaten production schedules, stretch budgets, and damage credibility. In a sector where downtime burns capital fast, delivery performance is no longer a nice-to-have—it’s a core risk control.

When Deliveries Fail, Projects Slide

Delays don’t just disrupt installation. They trigger cost overruns, compress downstream schedules, and introduce penalties that can distort financial forecasts.

Case in point: Mineral Resources of Australia recently downgraded its iron ore output by 2.9 million tonnes after weather-related logistics issues. The market responded with its worst stock day in 16 years. This wasn’t just bad luck. It was a supply chain fragility that went unmitigated.

Australia’s Mining Sector Faces a Logistics Crunch

Across mining projects, delivery risk is rising. Coal logistics costs have surged—by up to 50% in some cases. That pressure comes from a mix of labour shortages, shifting regulations, and vendors stretched beyond their capacity.

In this context, procurement teams are adapting. They’re no longer just looking at unit price and technical spec. They’re asking whether the supplier can meet the timeline and deliver exactly what’s needed, when it’s needed. This new operating environment demands tougher scrutiny of who gets selected to supply critical components like pipe supports.

Why Vendor Performance Can’t Be an Afterthought

Vendor reliability has to be proven, not promised. That means looking beyond product catalogues and checking the operational reality of what a supplier can deliver—and when.

Key Performance Checks:

Fit-for-Purpose Delivery: Pipe supports must match job specifications and site-specific needs—no workarounds, no delays.

Delivery Visibility: Look for clear communication around lead times and delivery milestones. Transparent tracking and timely updates help avoid last-minute issues and keep projects on schedule. Binder appoints a project manager to keep stakeholders informed, coordinate production schedules, and ensure alignment from order to delivery.

Manufacturing Standards: Know what standards your vendor holds. All Binder products are manufactured in strict accordance with AS4041:2006 to ensure precision, reliability, and compliance with project requirements.

Meeting Project Requirements

At Binder, we are committed to complying with the project’s technical requirements, that’s why our focus is on delivering supports that:

- Match project drawings exactly

- Suit environmental and load conditions

- Are built right the first time

To support this, we offer:

- Direct access to technical support during planning and procurement

- A free online CAD library for smooth integration into design workflows

- Flexible customisation options

- A dedicated Project Manager

- Technical Support throughout the project lifetime.

Protecting Multi-Billion Dollar Investments Starts with Delivery

Western Australia’s mining pipeline includes $48 billion in planned and active projects. In this context, delayed materials do more than cause short-term disruption—they affect procurement schedules, delay construction progress, and complicate commissioning. The knock-on effects can be hard to recover from.

Project managers aren’t in a position to absorb these risks. To manage them, they need to engage suppliers early, establish realistic delivery expectations, and stay closely aligned throughout the project. Tracking key performance indicators helps identify problems before they escalate, while clear contractual terms hold vendors accountable for delivery performance.

Binder Rebuilding Confidence in Delivery

We know the perception: that long lead times are a blocker. We also know the reality—delayed pipe supports have a direct cost.

That’s why we’ve sharpened our approach:

- Clear production timelines from day one

- Transparent documentation for every order

- A local manufacturing model that keeps quality and schedule under control

Reliable supply isn’t just about speed. It’s about clarity, traceability, and making sure nothing on site waits for a bracket, clamp, or shoe to arrive.

Work With Us

If you’re managing risk on a high-value mining project and want delivery certainty—not just delivery promises—talk to us early. We’ll show you exactly how we meet spec, hit timelines, and help you avoid the cost of delay.