- Products

-

-

-

Categories

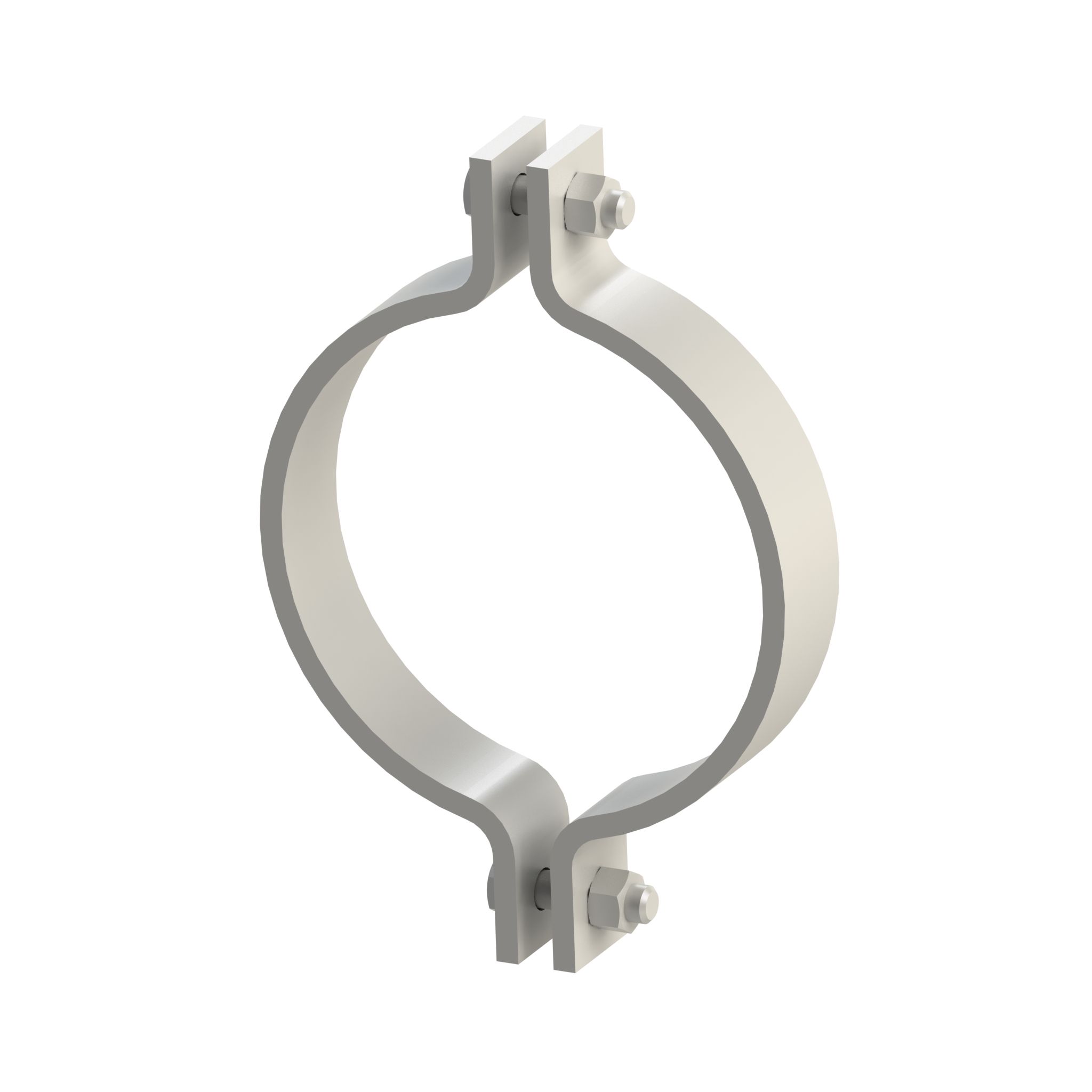

BG100

BG100LIGHT DUTY 2-BOLT CLAMP

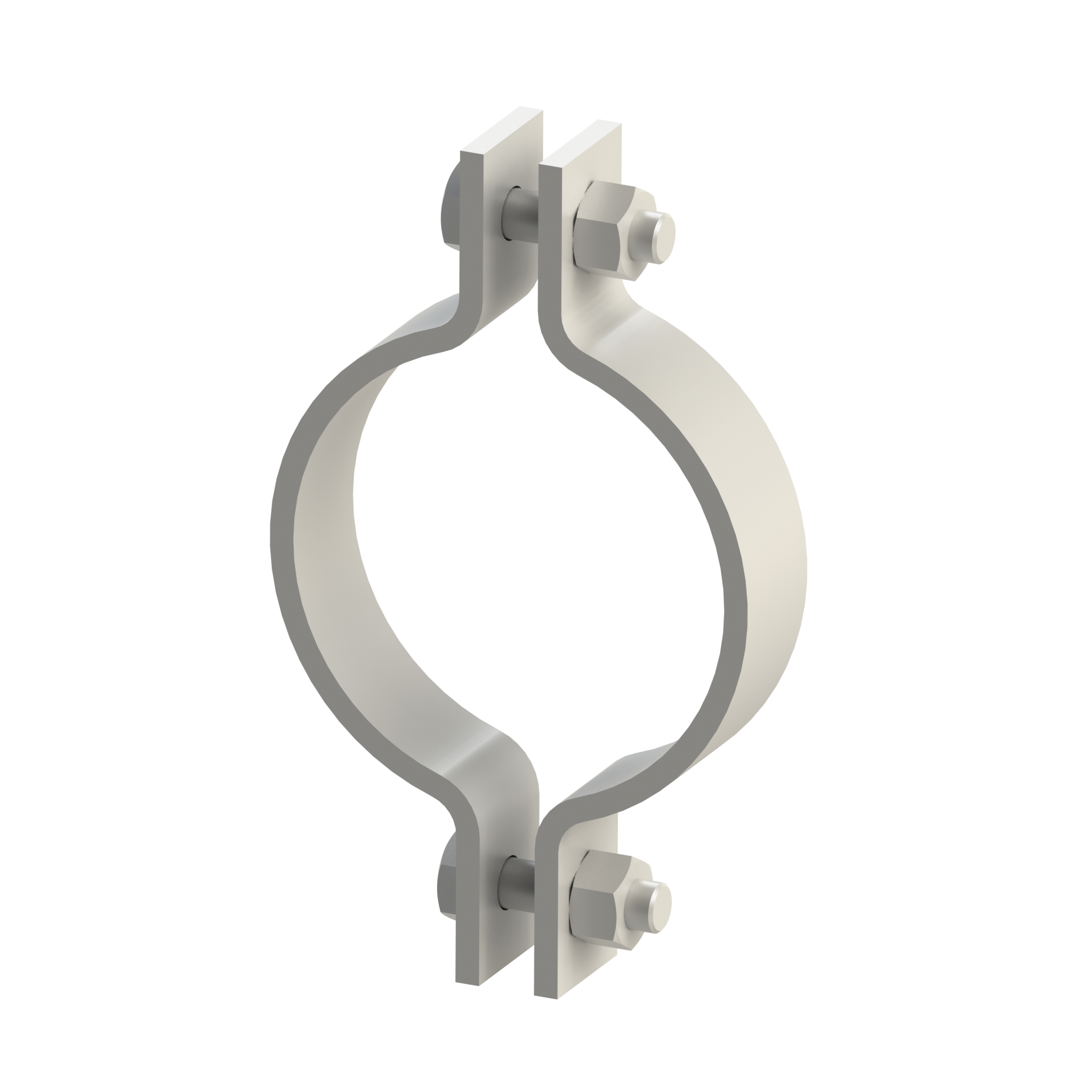

BG170

BG170MEDIUM DUTY 2-BOLT PIPE CLAMP

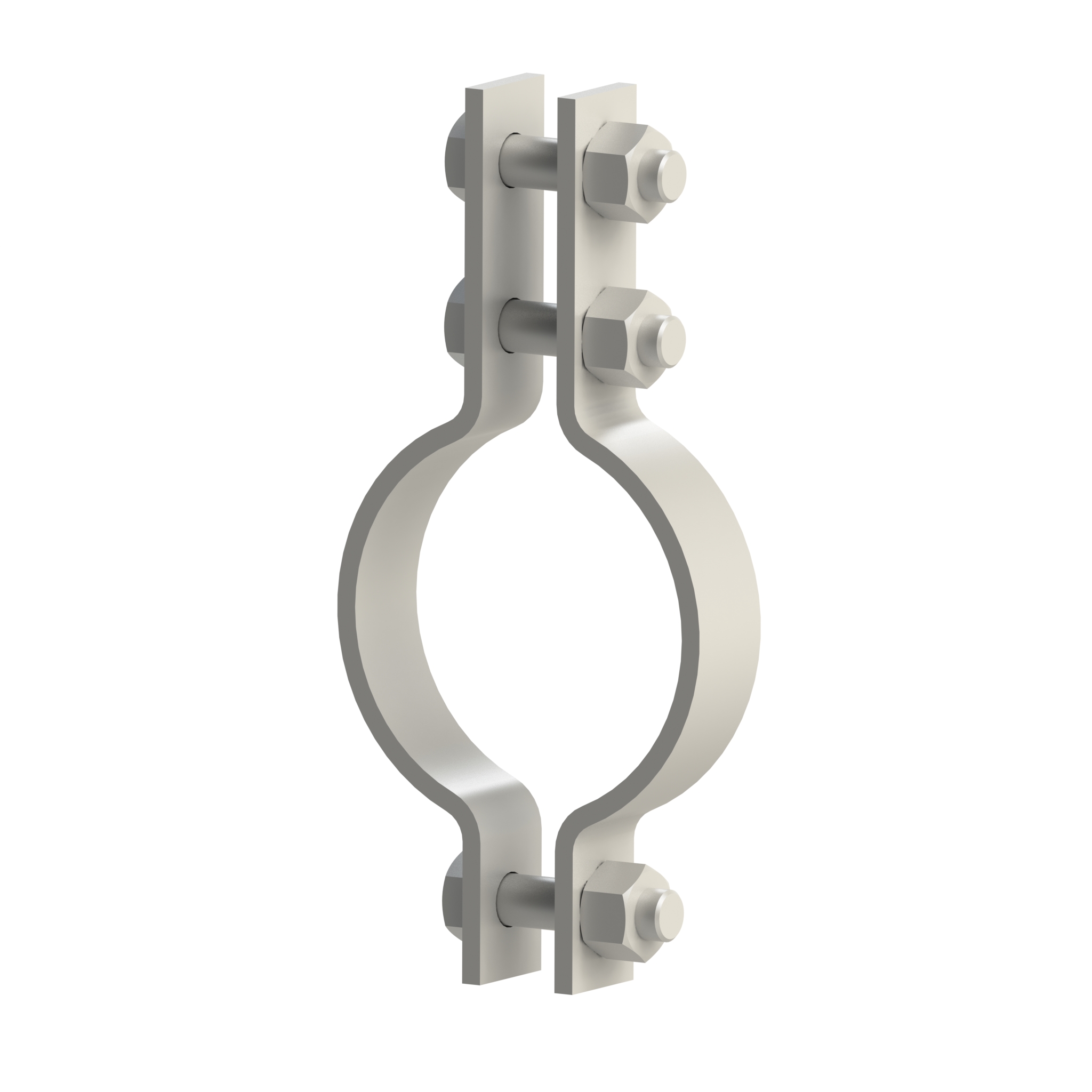

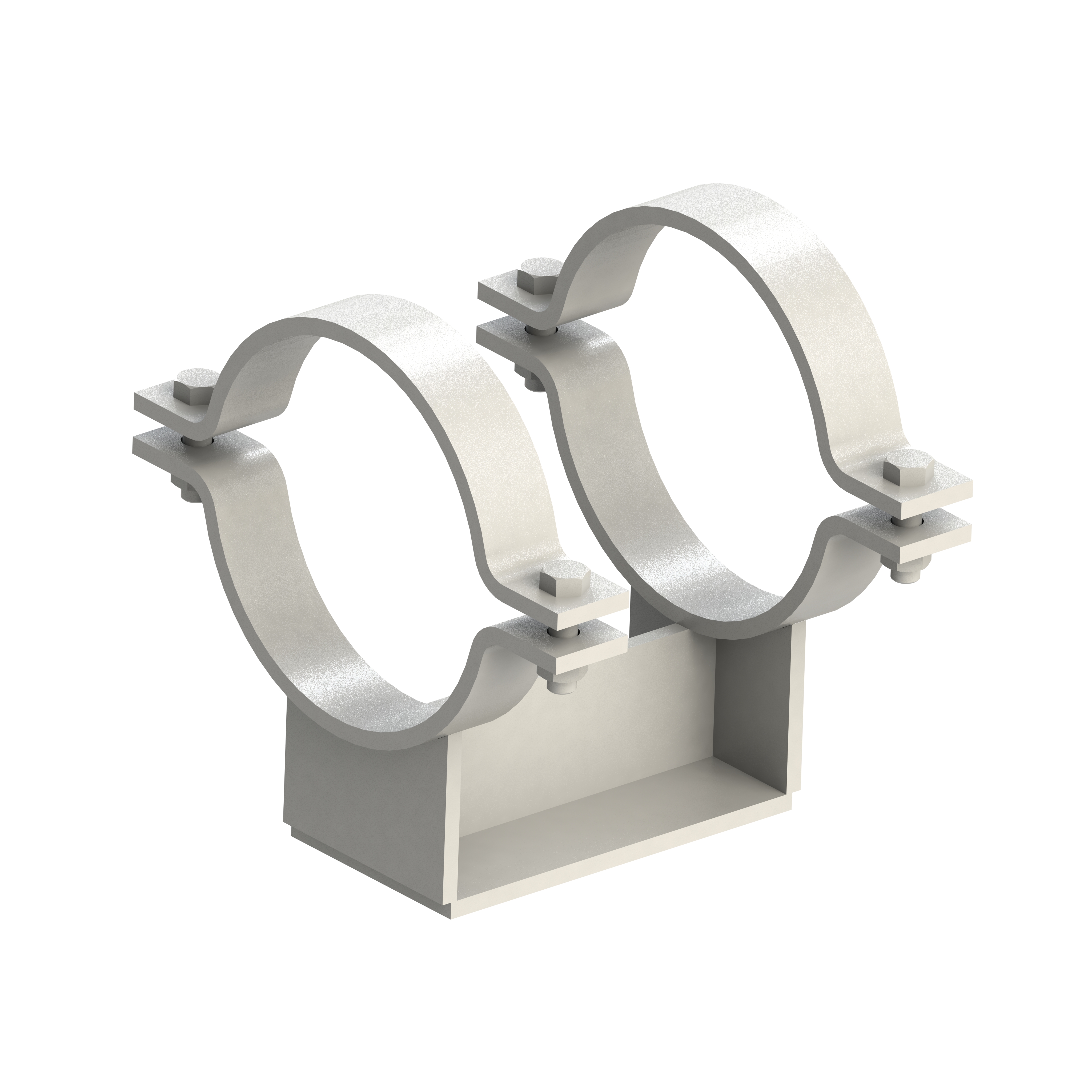

BG50

BG50HEAVY DUTY 2-BOLT PIPE CLAMP

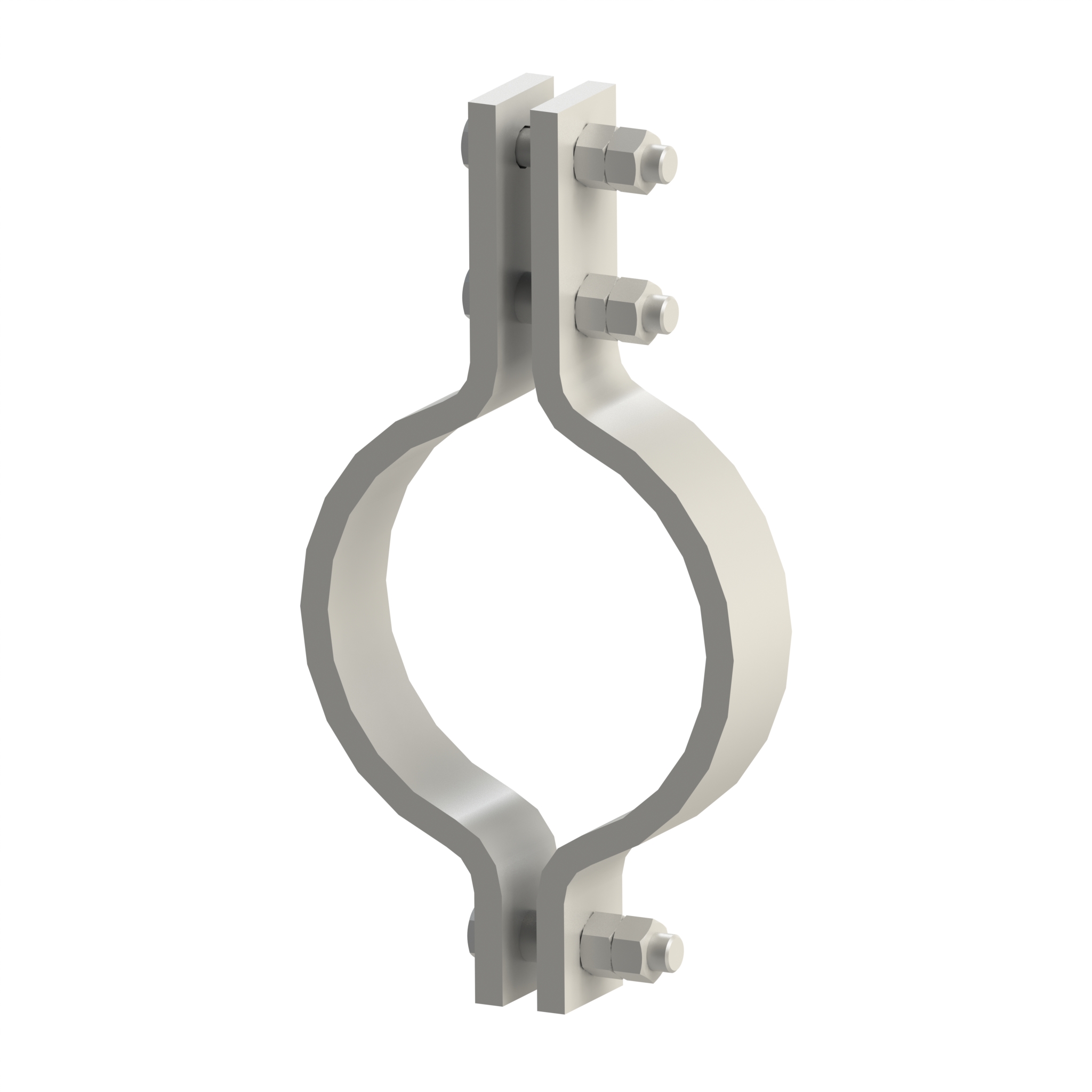

BG101

BG101LIGHT DUTY 3-BOLT PIPE CLAMP

BG171

BG171MEDIUM DUTY 3-BOLT PIPE CLAMP FOR STEEL PIPE

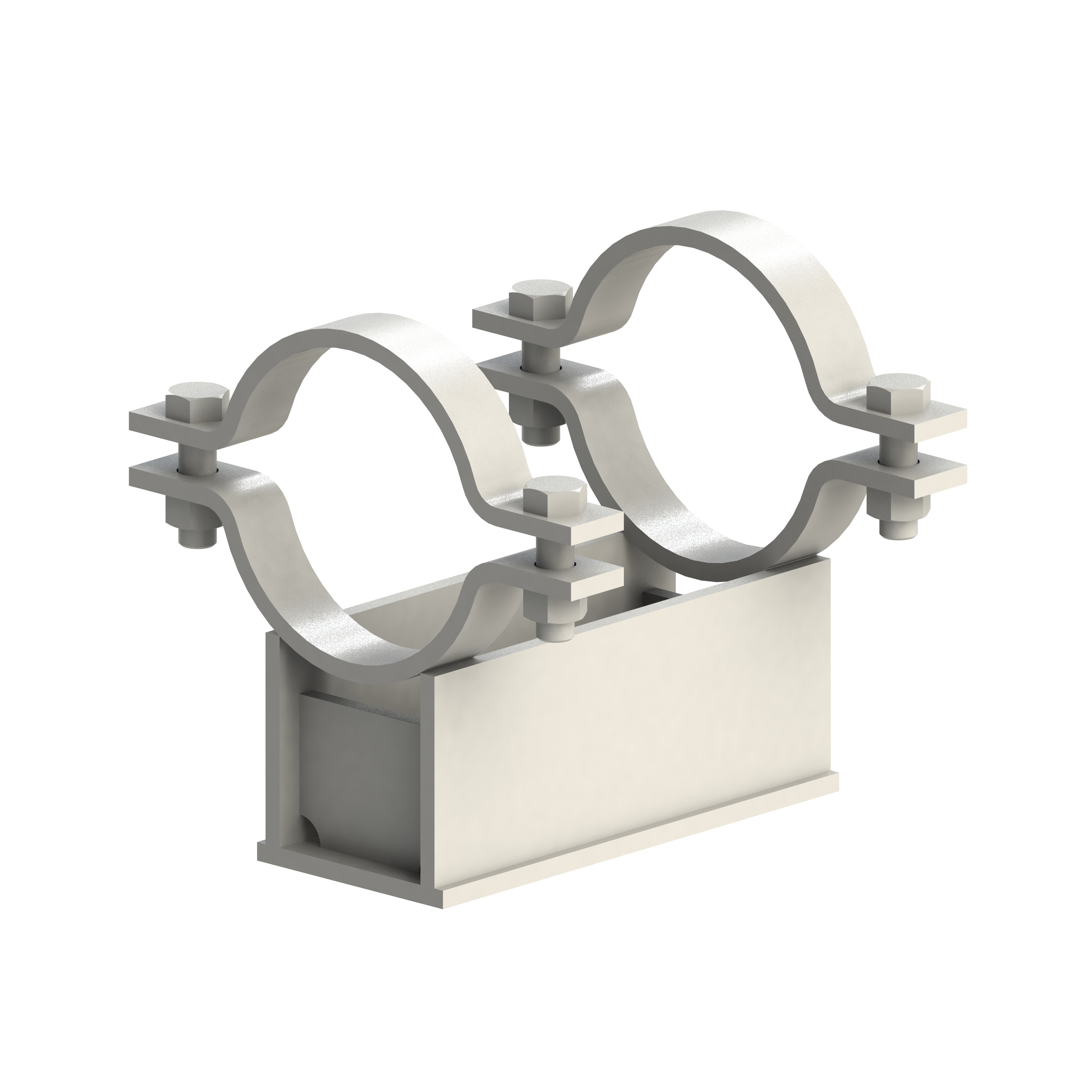

BG75

BG75HEAVY DUTY 3-BOLT PIPE CLAMP

BG172

BG172HIGH TEMPERATURE 3-BOLT PIPE CLAMP

BG173

BG173ALLOY PIPE CLAMP - VERY HIGH TEMPERATURE

BG140

BG140INSULATED 2-BOLT PIPE CLAMP

BG141

BG141INSULATED 2-BOLT PIPE CLAMP FOR CU/NI

BG145

BG145INSULATED 3-BOLT PIPE CLAMP

BG146

BG146INSULATED 3-BOLT PIPE CLAMP FOR CU/NI

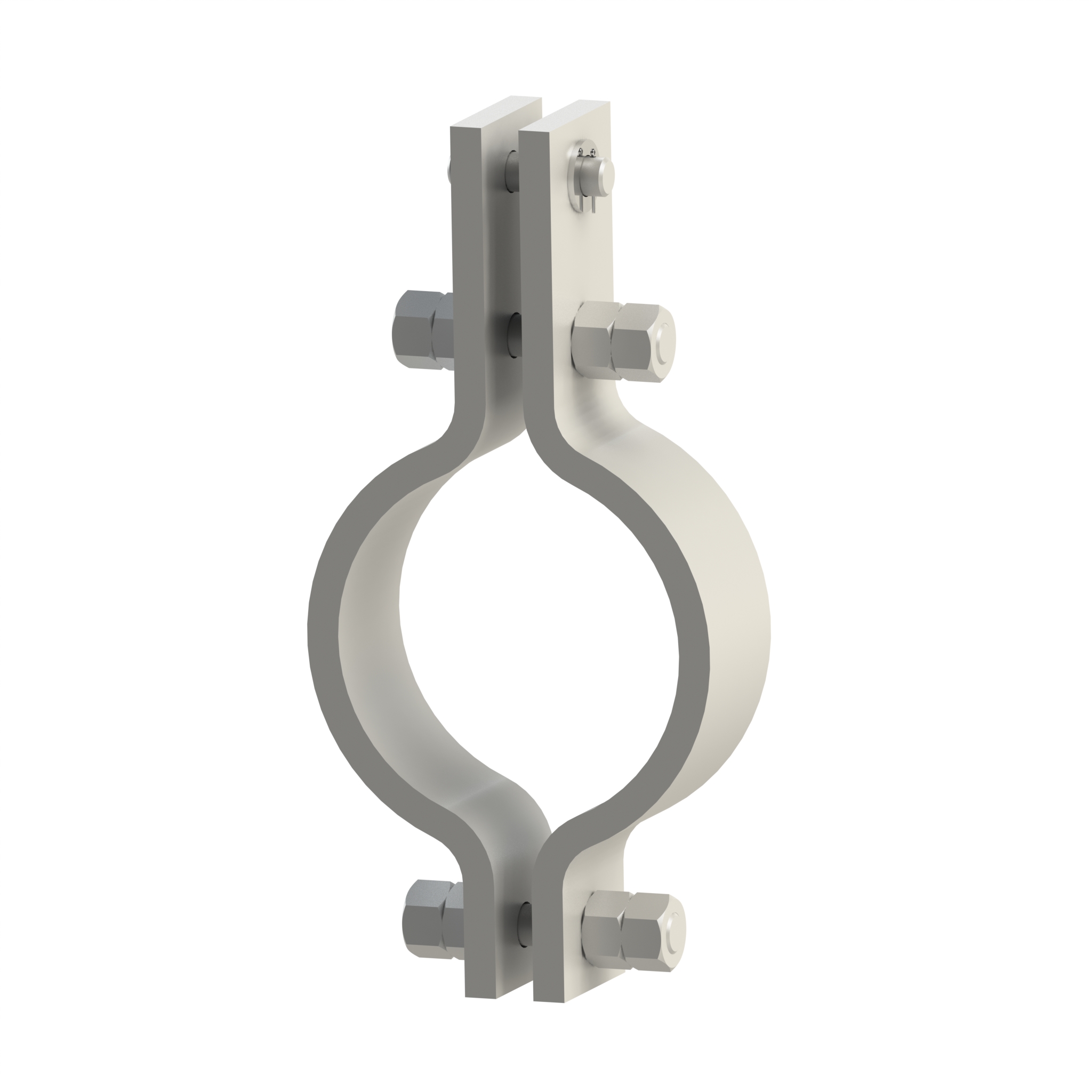

BG108

BG108CLEVIS CLAMP

BG222

BG222BEAM CLAMP

BG174

BG174RISER SUPPORT – STD TEMPERATURE

BG175

BG175RISER SUPPORT – HIGH TEMPERATURE

BG176

BG176ALLOY RISER SUPPORT - VERY HIGH TEMPERATURE

BG202

BG202ALLTHREAD ROD

BG209

BG209FORGED CLEVIS AND PIN

BG210

BG210FORGED TURNBUCKLE

BG204

BG204FORGED WELDLESS EYE NUT

BG215

BG215HEMISPHERICAL CUP

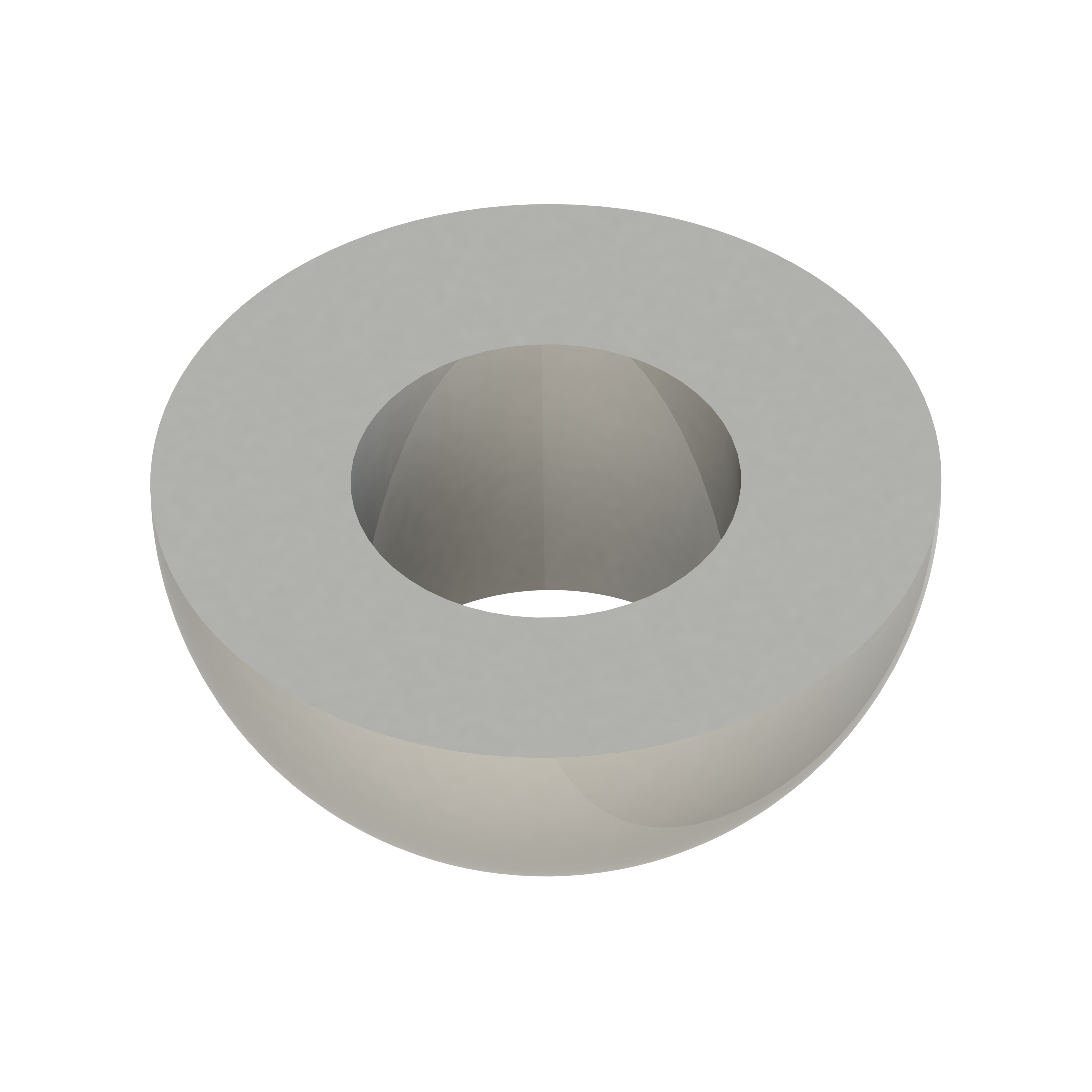

BG214

BG214HEMISPHERICAL WASHER

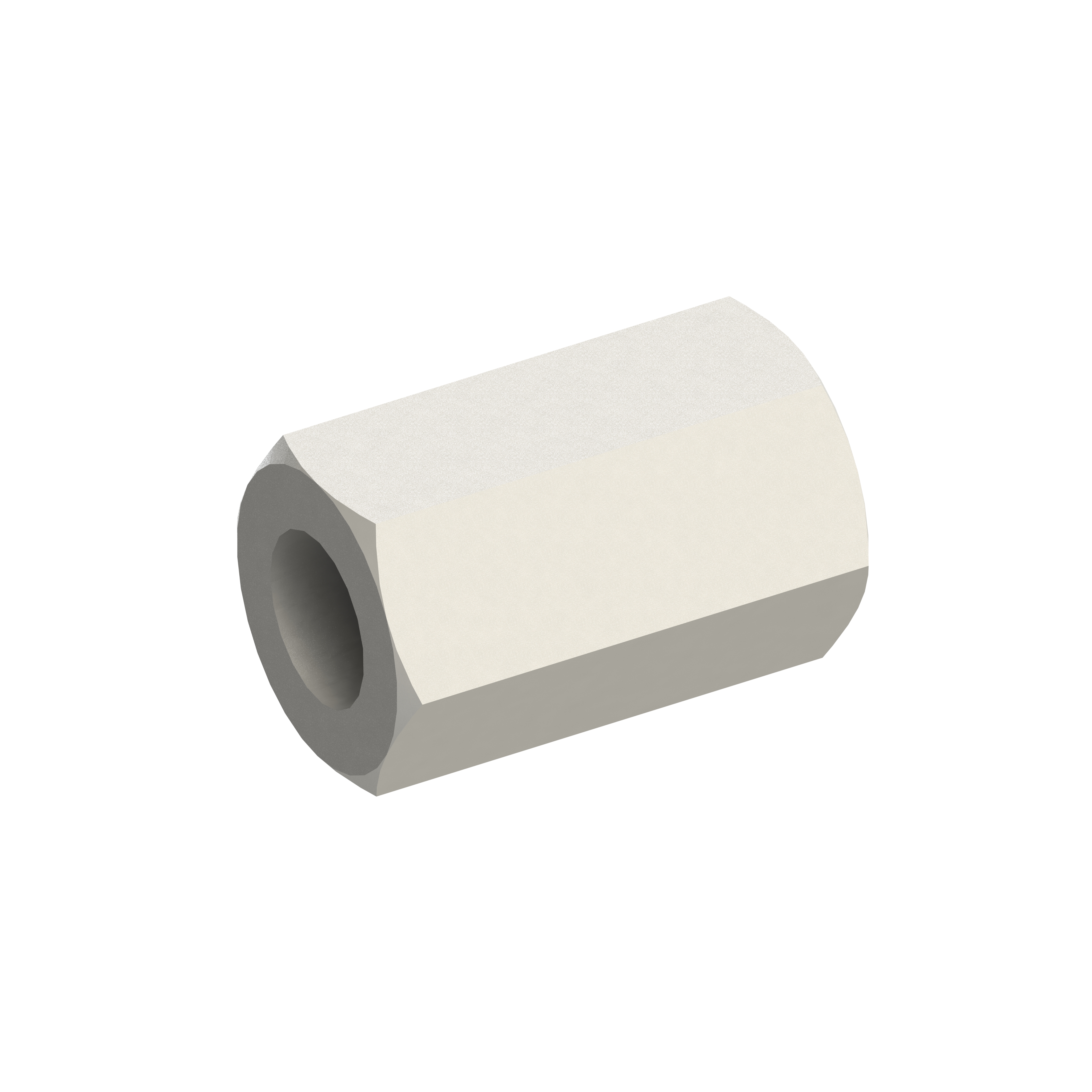

BG206

BG206HEXAGONAL CONNECTOR

BG216

BG216PIPE WELDING LUG

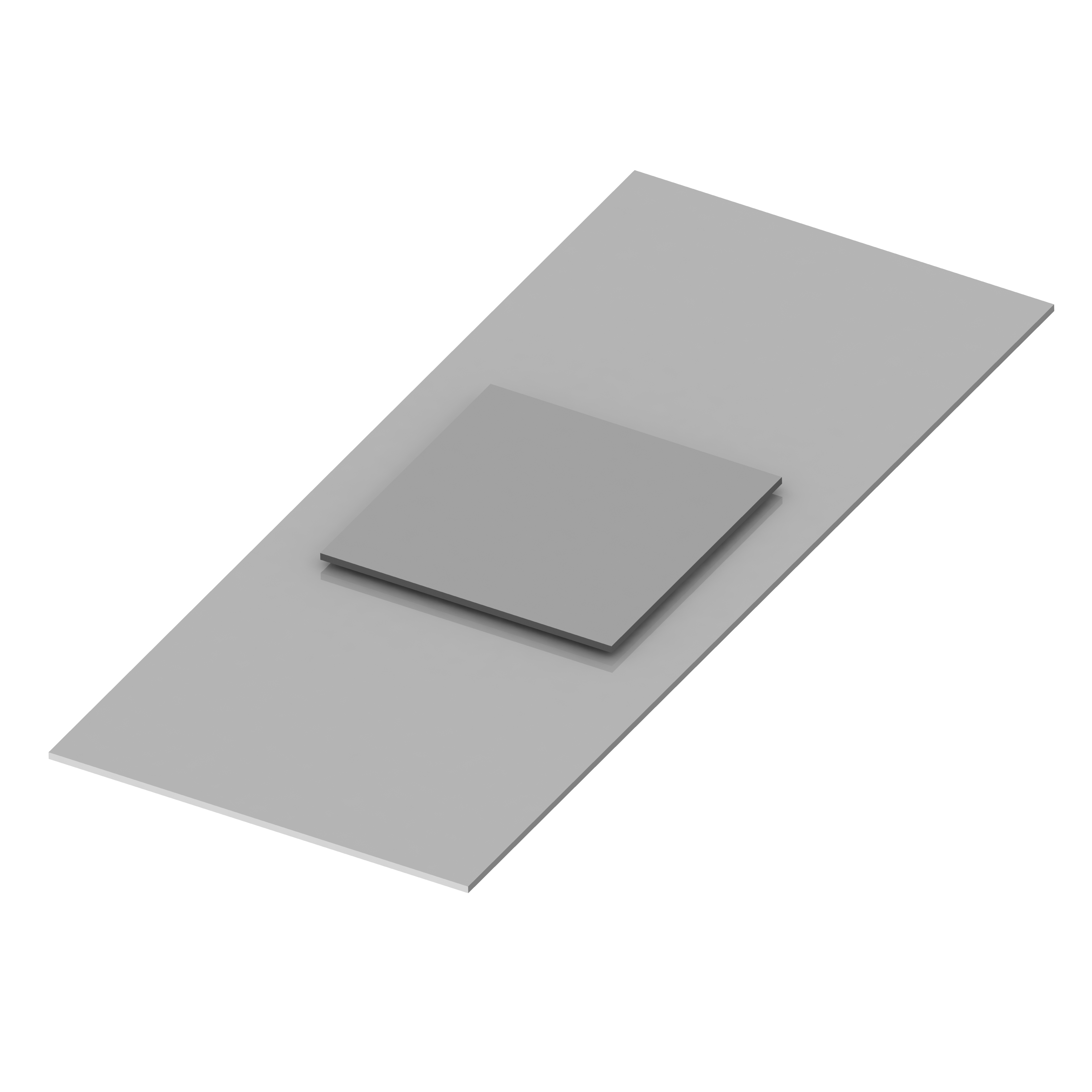

BG217

BG217PLATE WASHER

BG207

BG207SPADE NUT

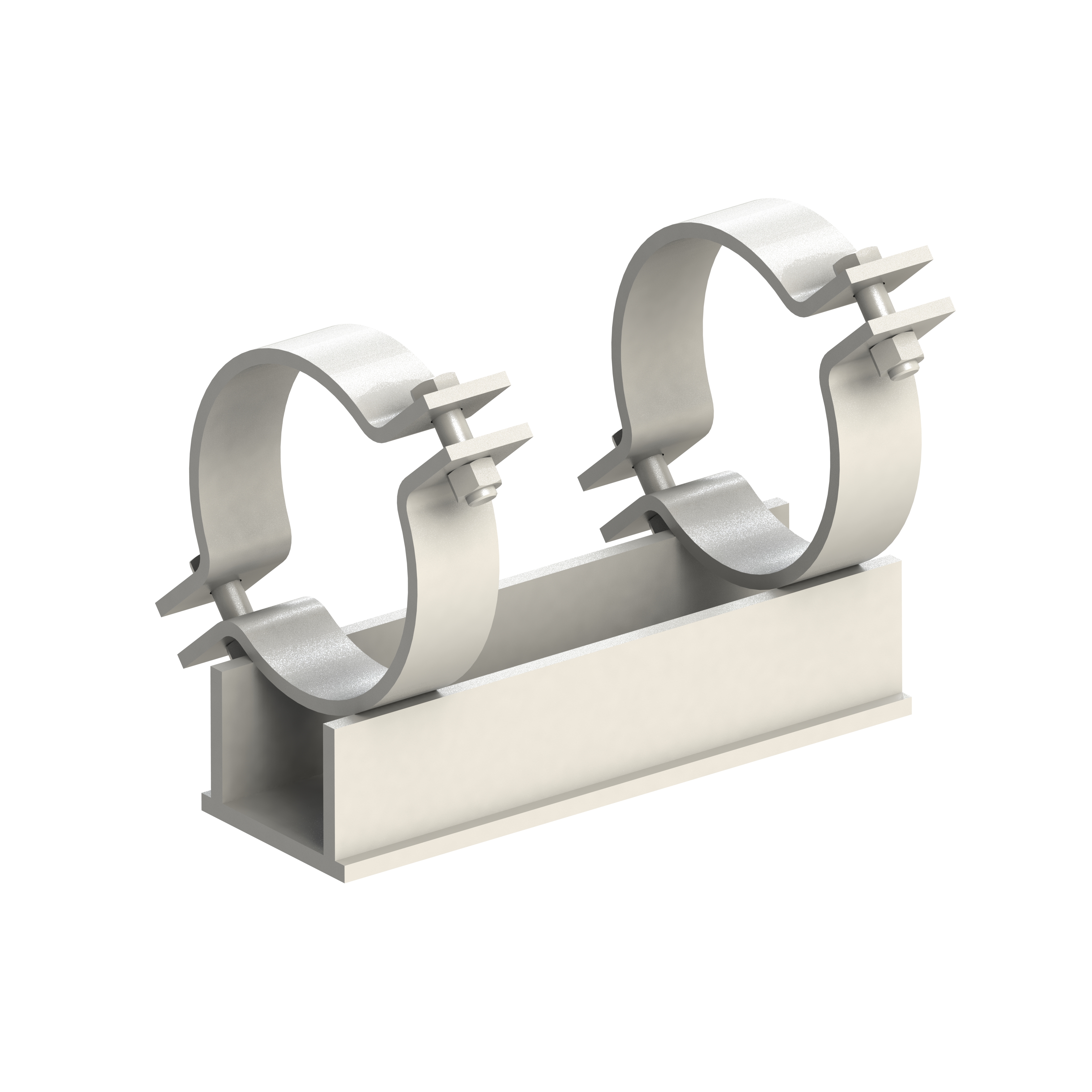

BG245

BG245STANDARD TRAPEZE

BG203

BG203THREADED DROP ROD – RH/LH

BG219

BG219WELDED BEAM ATTACHMENT

BG220

BG220WELDED BEAM ATTACHMENT (WITH LOAD PIN)

BG225

BG225WELDING LUG

BG180

BG180U-BOLT GUIDE

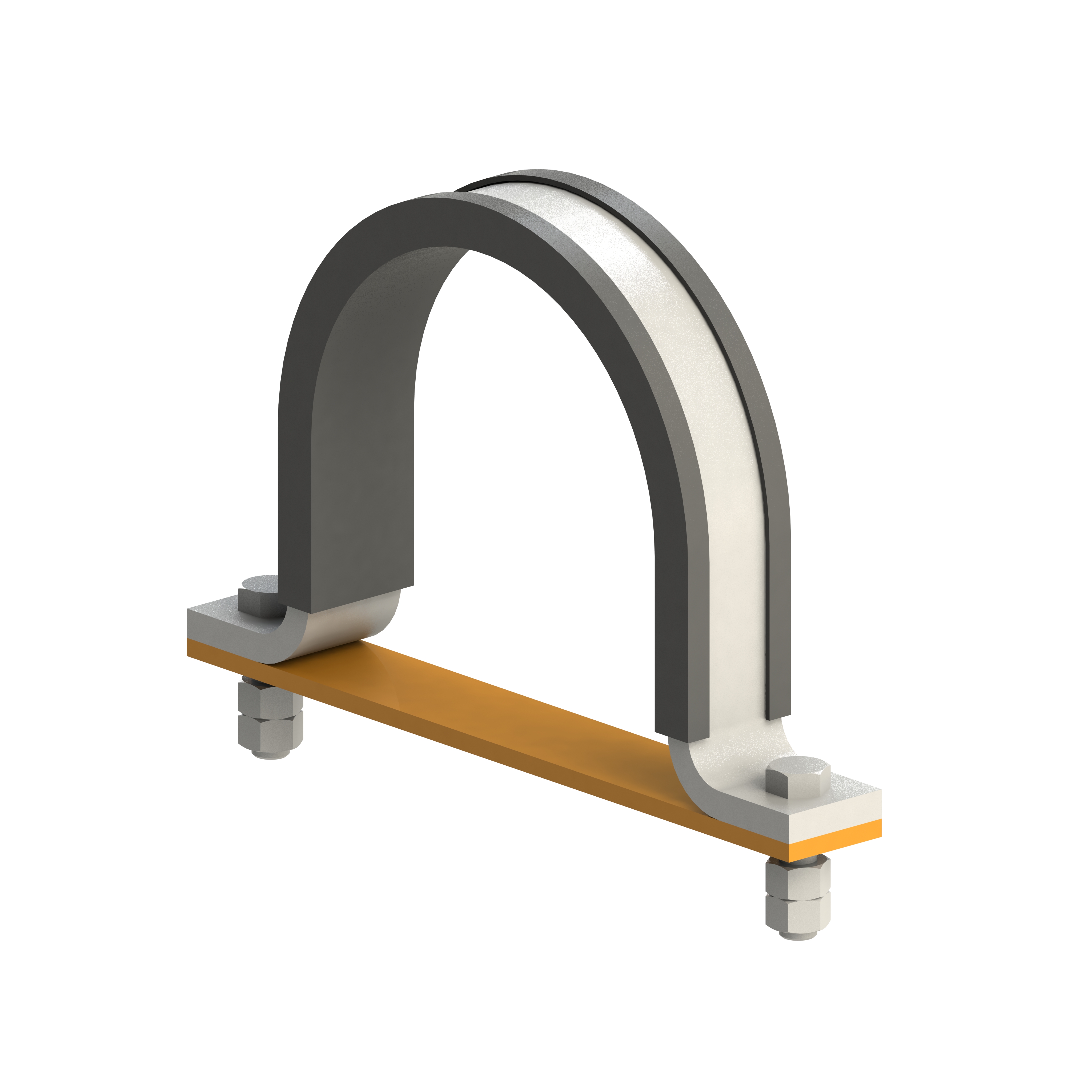

BG181

BG181U-BOLT CLAMP

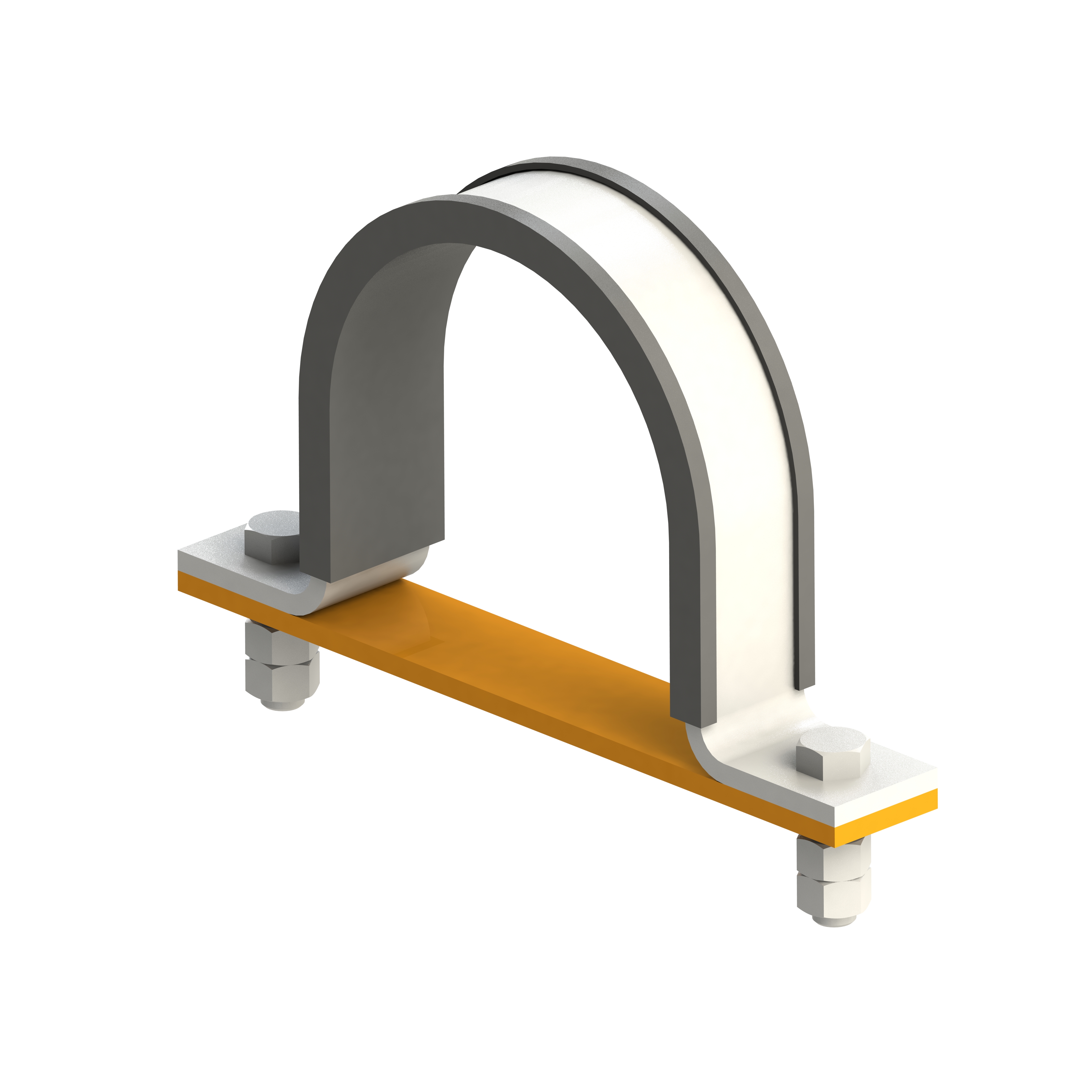

BG150

BG150INSULATED U-BOLT CLAMP

BG152

BG152INSULATED U-BOLT GUIDE

BG154

BG154INSULATED U-BOLT GUIDE (WITH TEFLON)

BG190

BG190INSULATED U-BOLT CLAMP

BG192

BG192INSULATED U-BOLT GUIDE

BG151

BG151INSULATED U-BOLT CLAMP FOR CU/NI

BG153

BG153INSULATED U-BOLT GUIDE FOR CU/NI

For Cu/Ni Pipe BG155

BG155INSULATED U-BOLT GUIDE (WITH TEFLON)

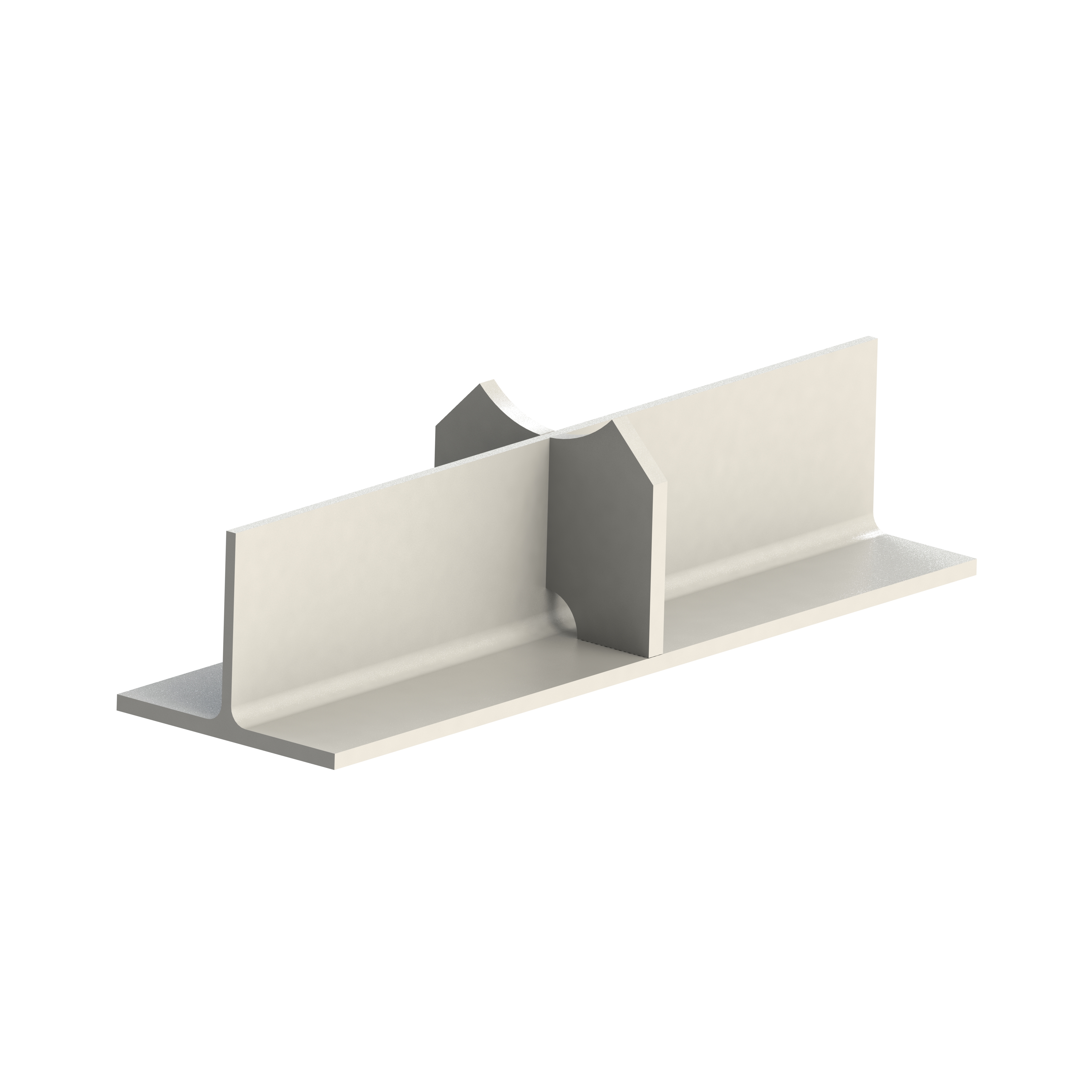

For Cu/Ni Pipe BG177

BG177SADDLE GUIDE

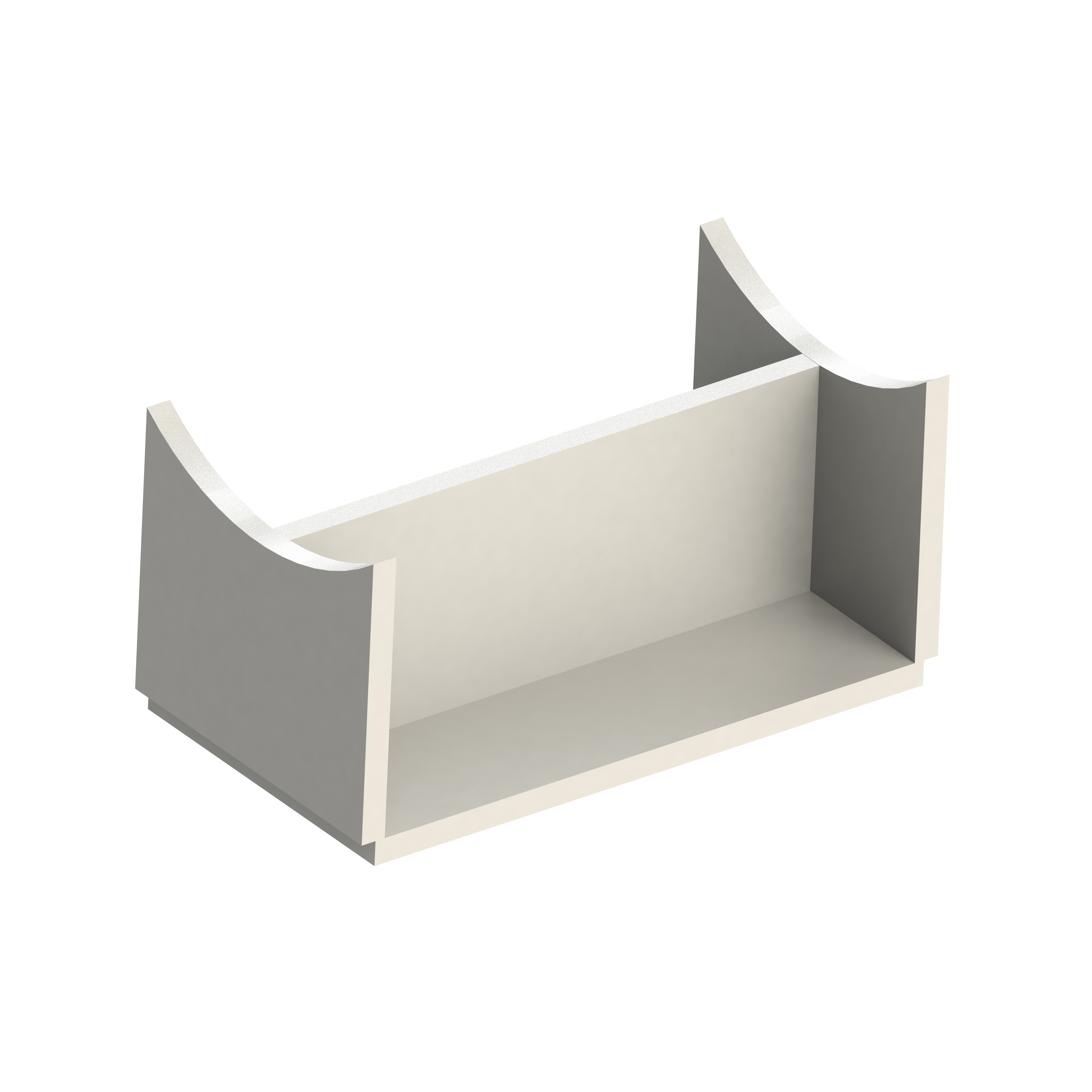

BG178

BG178SADDLE CLAMP

BG160

BG160INSULATED PIPE SADDLE

BG161

BG161INSULATED PIPE SADDLE

BG162

BG162INSULATED PIPE SADDLE

BG135-136

BG135-136ADJUSTABLE PIPE STANDS

BG515

BG515STANDARD CLAMPED PIPE SHOE

BG550

BG550SLIDE PLATES

BG517

BG517COMPACT PIPE SHOE

BG400

BG400CLAMPED HOT PIPE SHOE

BG156

BG156INSULATED PIPE SHOE

BG157

BG157INSULATED PIPE SHOE

BG510

BG510STANDARD WELDED PIPE SHOE

BG518

BG518COMPACT WELDED PIPE SHOE

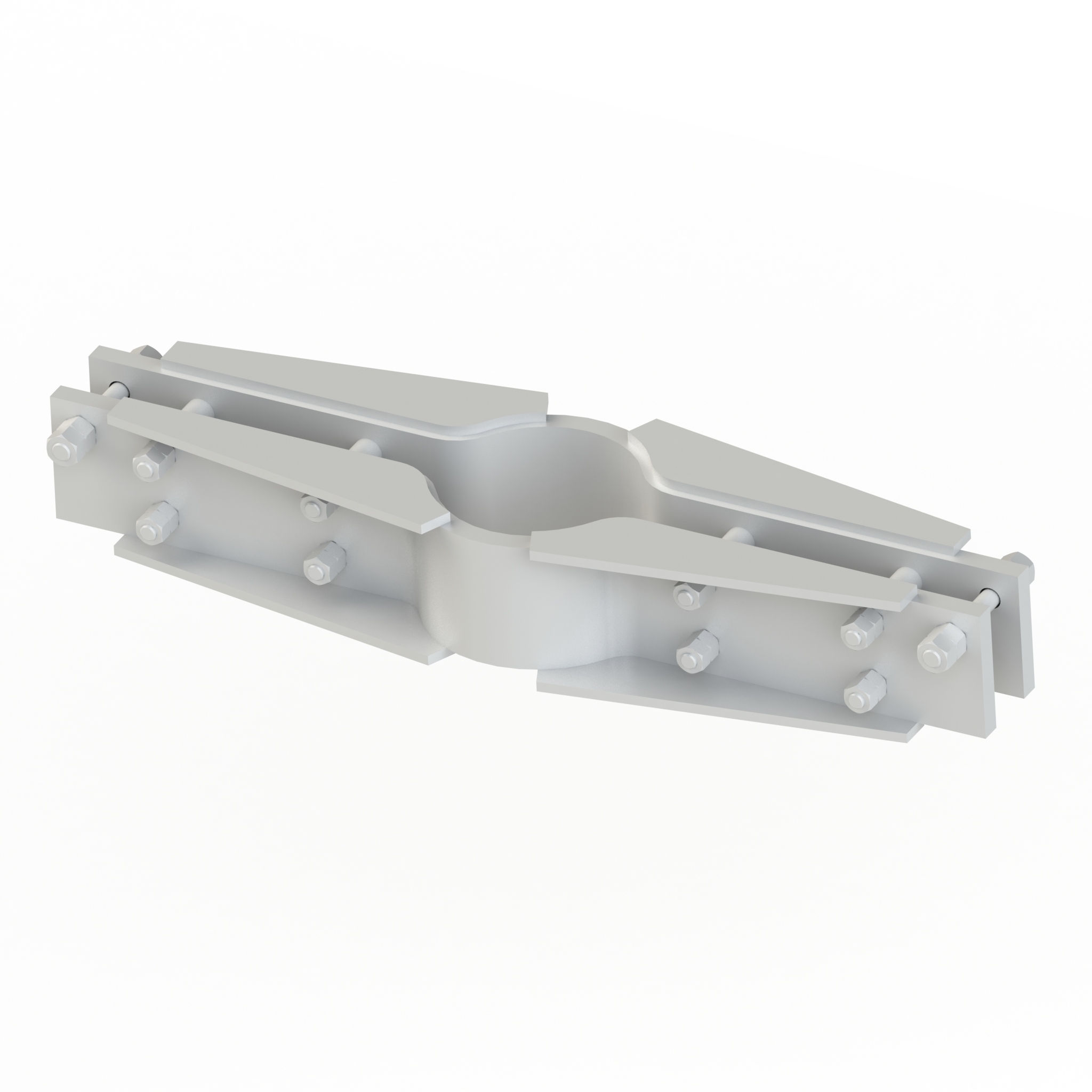

BG555

BG555STANDARD LINE STOPS

BG560

BG560STANDARD PIPE GUIDES

BG570

BG570STANDARD SHOE GUIDES

BG580

BG580STANDARD SHOE GUIDES

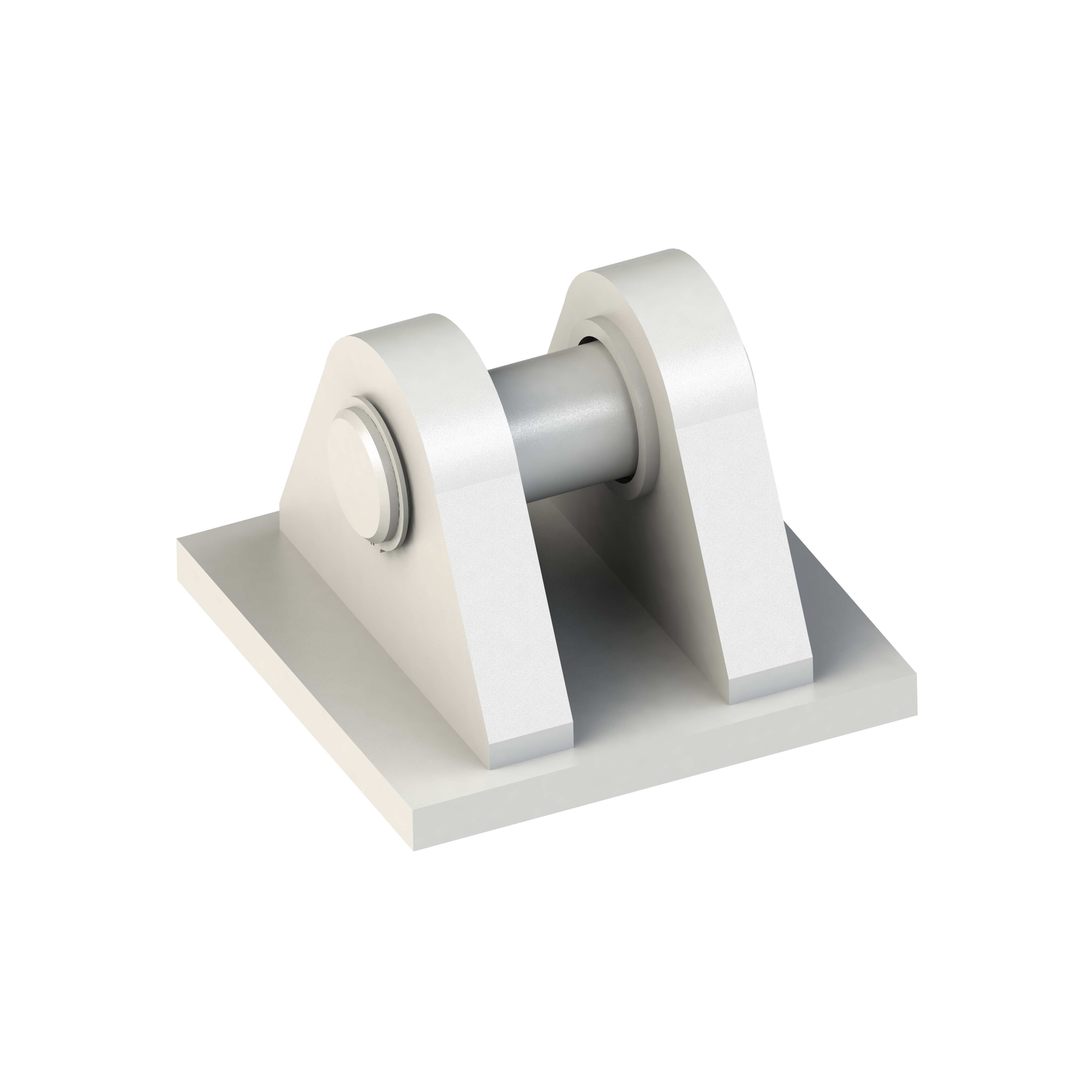

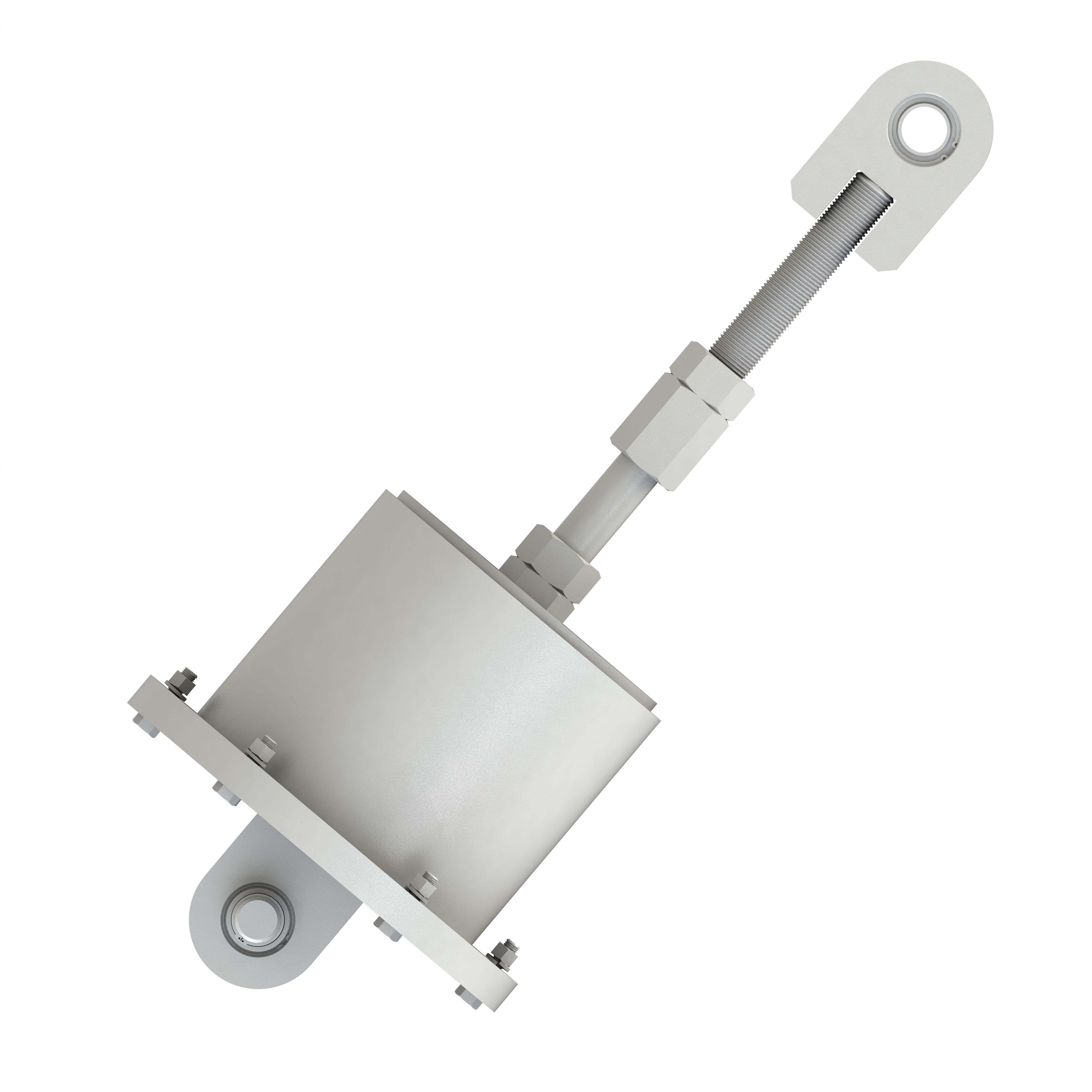

BG315

BG315END ATTACHMENT FOR HYDRAULIC SNUBBERS

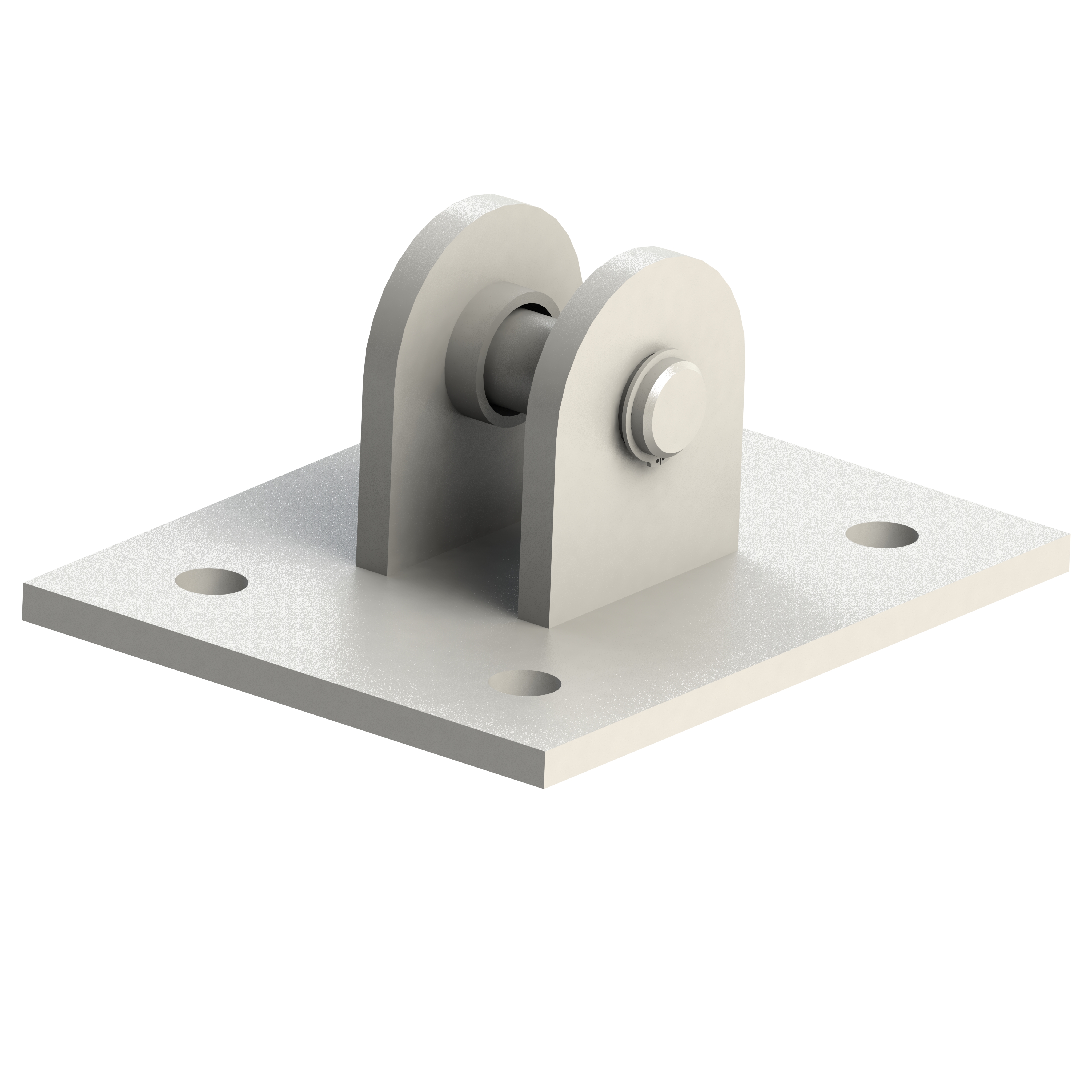

BG355

BG355END ATTACHMENT FOR RIGID STRUT & SWAY BRACE

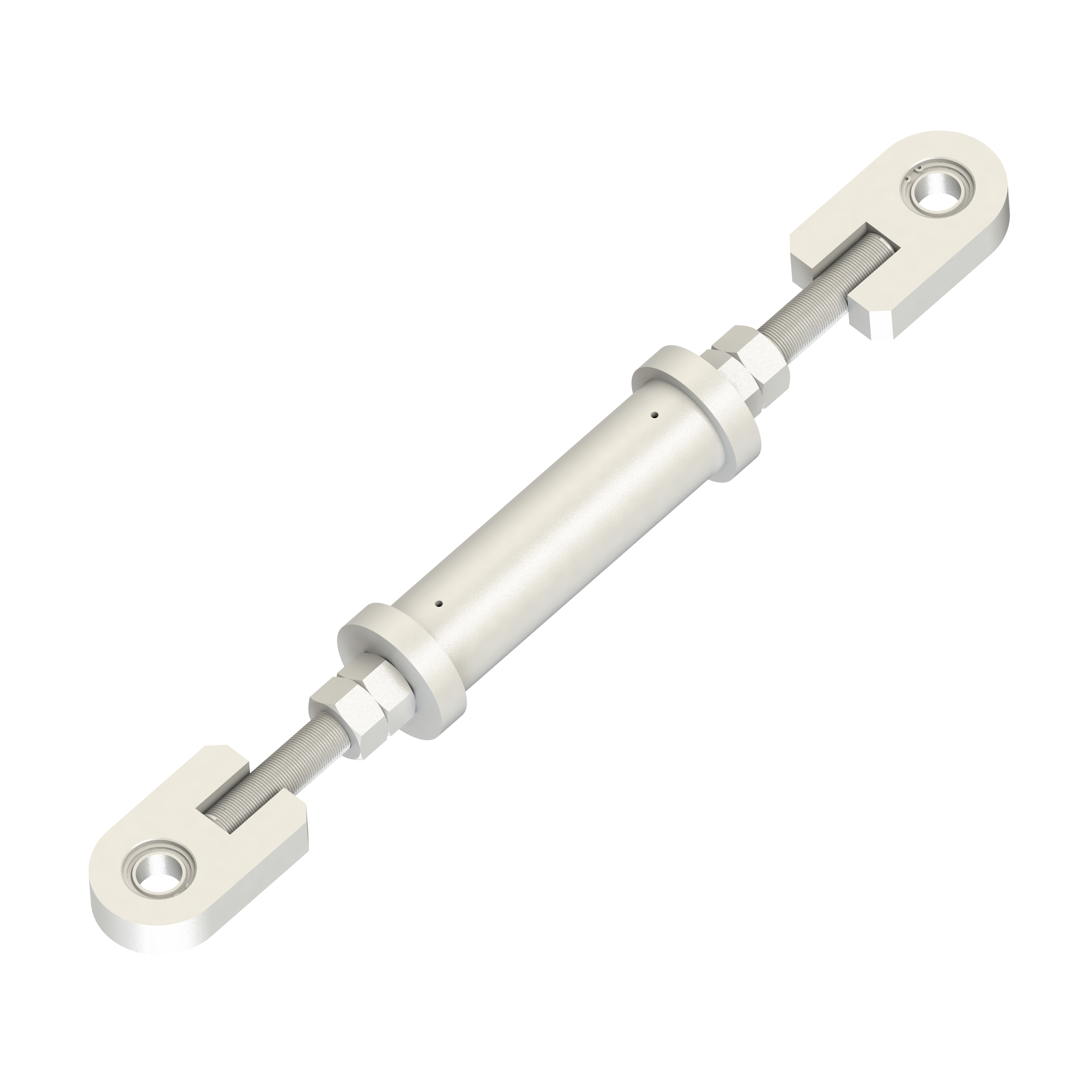

BG310

BG310HYDRAULIC SNUBBERS (SHOCK ARRESTORS)

BG321

BG321PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG322

BG322PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

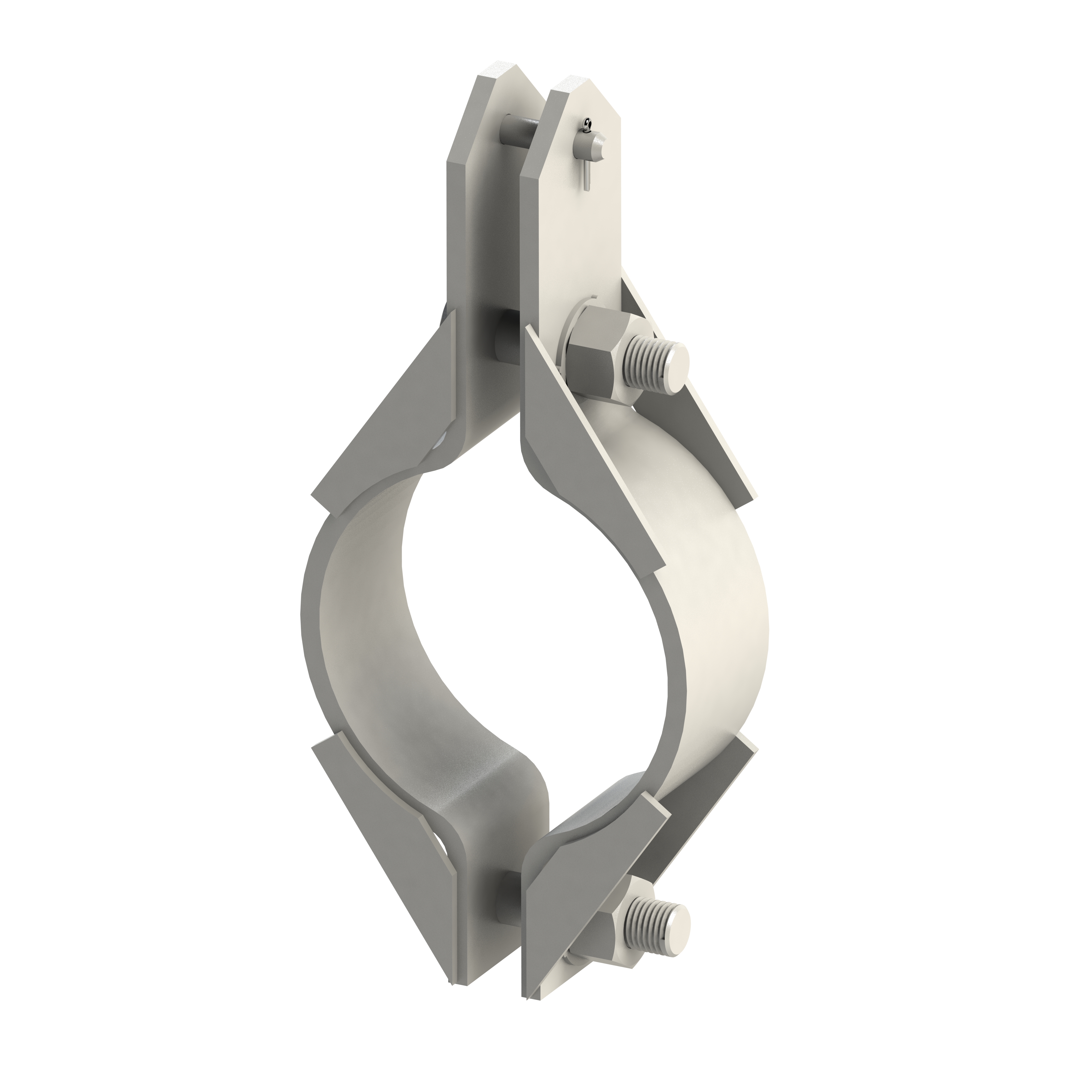

BG320

BG320PIPE CLAMP FOR HYDRAULIC SNUBBER – LOW TEMPERATURE

BG350

BG350RIGID STRUTS

BG340

BG340SWAY BRACE

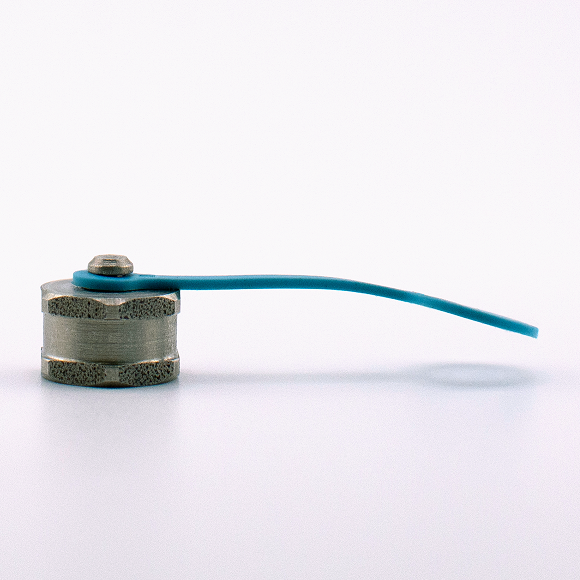

#691028

#691028All Stainless Steel Gauge Adapter #691028

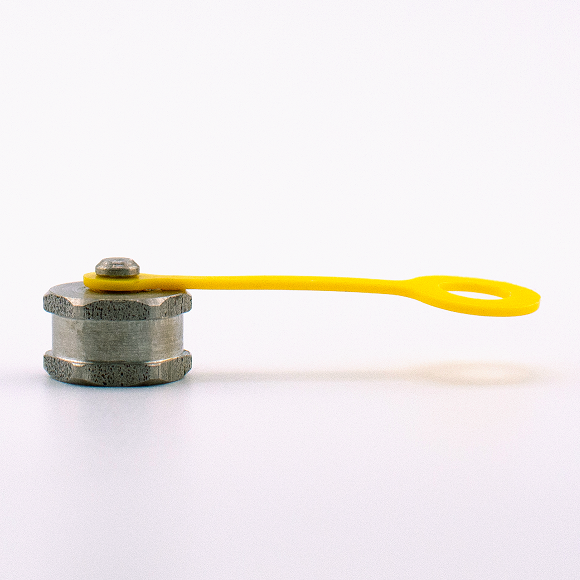

#520XL

#520XLAll Stainless Steel Gauge Adapter #520XL

#691023

#691023Brass Gauge Adapter #691023

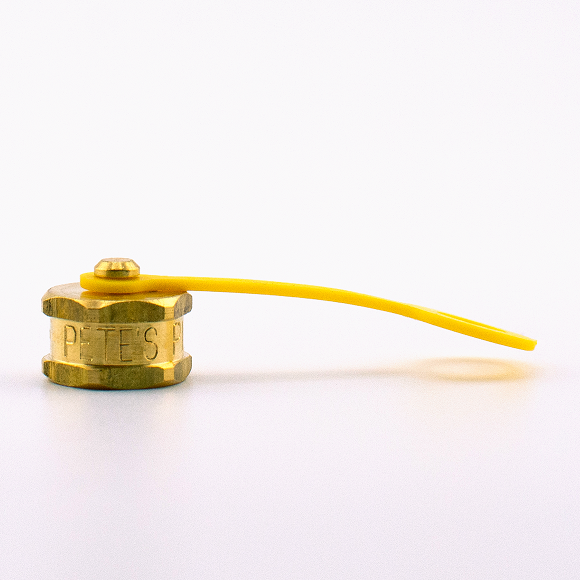

#500BSP

#500BSPBrass Gauge Adapter #500BSP

#691024

#691024Brass Gauge Adapter #691024

#500XLBSP

#500XLBSPBrass Gauge Adapter #500XLBSP

691026

691026Brass Gauge Adapter #691026

#691027

#691027Brass Gauge Adapter #691027

#104-1BS

#104-1BSCap Assembly #104-1BS

#104-1YS

#104-1YSCap Assembly #104-1YS

#104-2BS

#104-2BSCap Assembly #104-2BS

#104-2YS

#104-2YSCap Assembly #104-2YS

#691003

#691003Pete's Plug #691003

#691002

#691002Pete's Plug #691002

#691010

#691010Pete's Plug #691010

#691001

#691001Pete's Plug #691001

#691000

#691000Pete's Plug #691000

#691017

#691017Pete's Plug #691017

#12510

#12510Pete's Plug #12510

691020

691020Pete's Plug #691020

#691008

#691008Pete's Plug #691008

#691005

#691005Pete's Plug #691005

#691007

#691007Pete's Plug #691007

#691004

#691004Pete's Plug #691004

#572

#572Pete's Plug #572

#691019

#691019Pete's Plug #691019

#691018

#691018Pete's Plug #691018

#760

#760Pete's Plug #760

#691016

#691016Pete's Plug #691016

#691022

#691022Pete's Plug #691022

#691021

#691021Pete's Plug #691021

#691014

#691014Pete’s Plug #691014

#691013

#691013Pete’s Plug #691013

#562

#562Pete’s Plug #562

#691012

#691012Pete’s Plug #691012

#691011

#691011Pete’s Plug #691011

#750XL

#750XLPete’s Plug #750XL

#691015

#691015Pete’s Plug #691015

#691029

#691029Pressure & Temperature Test Kit 0-100psi

#691030

#691030Pressure & Temperature Test Kit 0-100psi for XL

#1500-5

#1500-5Pressure Gauge 0-100 PSI BSP Stem

#1500-4

#1500-4Pressure Gauge 0-100 PSI NPT Stem

#606

#606Thermometer -58°F to 550°F

-

-

-

- About

- Resources

- Contact

strategic shutdown preparation: mitigating risks with pipe supports.

In the high-stakes environment of the oil and gas sector, unplanned shutdowns can quickly escalate into substantial financial losses, with costs reaching up to millions per hour in downtime. For engineers, project managers, and procurement teams, avoiding these setbacks is paramount. Effective planning, particularly concerning pipe supports, plays a crucial role—ensuring that projects meet compliance standards like AS/NZS 5601.1:2022 and AS/NZS 1163. This article addresses strategies that reduce compliance risks, protect operational integrity, and maximize project efficiency through advanced preparation and custom-engineered pipe supports.

Early Gains: The Importance of Pre-Shutdown Preparation

Effective shutdown preparation is invaluable, as illustrated by a project team saving four days by confirming site-fit tolerances and organizing QA packs ahead of inspections. This proactive strategy underscores the value of early preparation:

- Advanced coordination of pipe supports, especially during critical outages, minimizes last-minute adjustments, reducing the risk of delays and cost overruns. Properly aligned and documented pipe supports significantly decrease unexpected issues during implementation.

- Aligning teams on documentation requirements at the outset prevents costly rework, ensuring all parties understand the project scope and regulatory compliance, thus mitigating non-compliance risks.

Efficient shutdown preparation enhances operational efficiency and forms the backbone of successful project management in high-stakes industries.

QA and Compliance Pre-Inspection Strategies

Adhering to AS/NZS 5601.1:2022 is crucial in avoiding non-compliance issues during shutdowns. This standard affects project documentation and schematics, with non-adherence leading to costly delays. Securing complete QA pipe support files and site-specific data before independent verification helps verify compliance and streamlines the audit process. Thorough upfront checks prevent shutdown delays caused by insufficient compliance evidence, ensuring all regulatory needs are addressed. Binder’s Custom-Engineered Pipe Supports and Documentation Pack / QA/QC Sets offer traceability and compliance documentation, reinforcing inspection integrity.

Certification and Documentation Best Practices

Compliance with AS/NZS 1163 necessitates meticulous verification of steel compositions and weld quality during pipe support configuration. It’s imperative for project managers to ensure material specifications meet rigorous requirements, affirming durability and safety. Standardised checklists maintain a compliance focus throughout each project phase:

- Developing a comprehensive QA checklist for pipe supports pre-inspection ensures all mechanical properties and load limits are traceable before audits. This offers systematic guidelines for project managers to confirm load-bearing capabilities, reducing operational failure risk.

- A shutdown playbook streamlines documentation approval, preventing costly penalties. By integrating Binder’s Custom-Engineered Pipe Supports, projects gain from detailed documentation that satisfies audit trails and compliance standards, enhancing transparency and reducing execution risks.

Risk Mitigation with Updated Standards

Future-proofing a shutdown checklist is critical for project managers. Utilizing updated guidelines under AS/NZS 3500 enhances clarity in pipe support inspection, reducing rework risks from ambiguous rules. This strategy aids in understanding regulatory shifts and aligning inspection processes with current compliance expectations. Implementing updates provides a structured approach to pipe support inspection, enhancing safety and minimizing oversight needs. Standardising installation steps during staging in mining shutdowns safeguards project schedules against delays caused by misalignment or compliance failures. Documenting installation protocols ensures industry standards are met, maintaining timelines and budget integrity.

Preparing for and Mitigating Risks in Shutdowns

Reliable documentation of pipe supports for shutdown compliance is essential. The PIPA Guidelines ensure material compatibility and joint integrity, assisting engineers in aligning projects with Australian standards:

- Chemical Compatibility and Joint Integrity: Following these guidelines verifies material coexistence and maintains joint integrity during shutdowns, reducing operational faults that delay audits.

- Standard Alignment: For LNG shutdowns, applying these guidelines early mitigates risks. Preemptive compliance fosters smoother audits, minimizing disruptions.

Thorough pre-planning for LNG shutdowns flags design constraints that could cause delays. Early identification allows timely rectification, preventing operational barriers when the shutdown commences.

Conclusion: Strengthening Operational Alignment in High-Stakes Environments

For engineers and project managers in the oil and gas sector, strategic shutdown preparation is not just a procedural necessity, it’s a vital component of maintaining operational integrity and financial stability. By leveraging Binder’s custom-engineered solutions, projects can ensure compliance, minimize shutdown delays, and optimize efficiency. This approach aligns with industry priorities, providing the reliability and safety needed in today’s demanding environments.