- Products

-

-

-

Categories

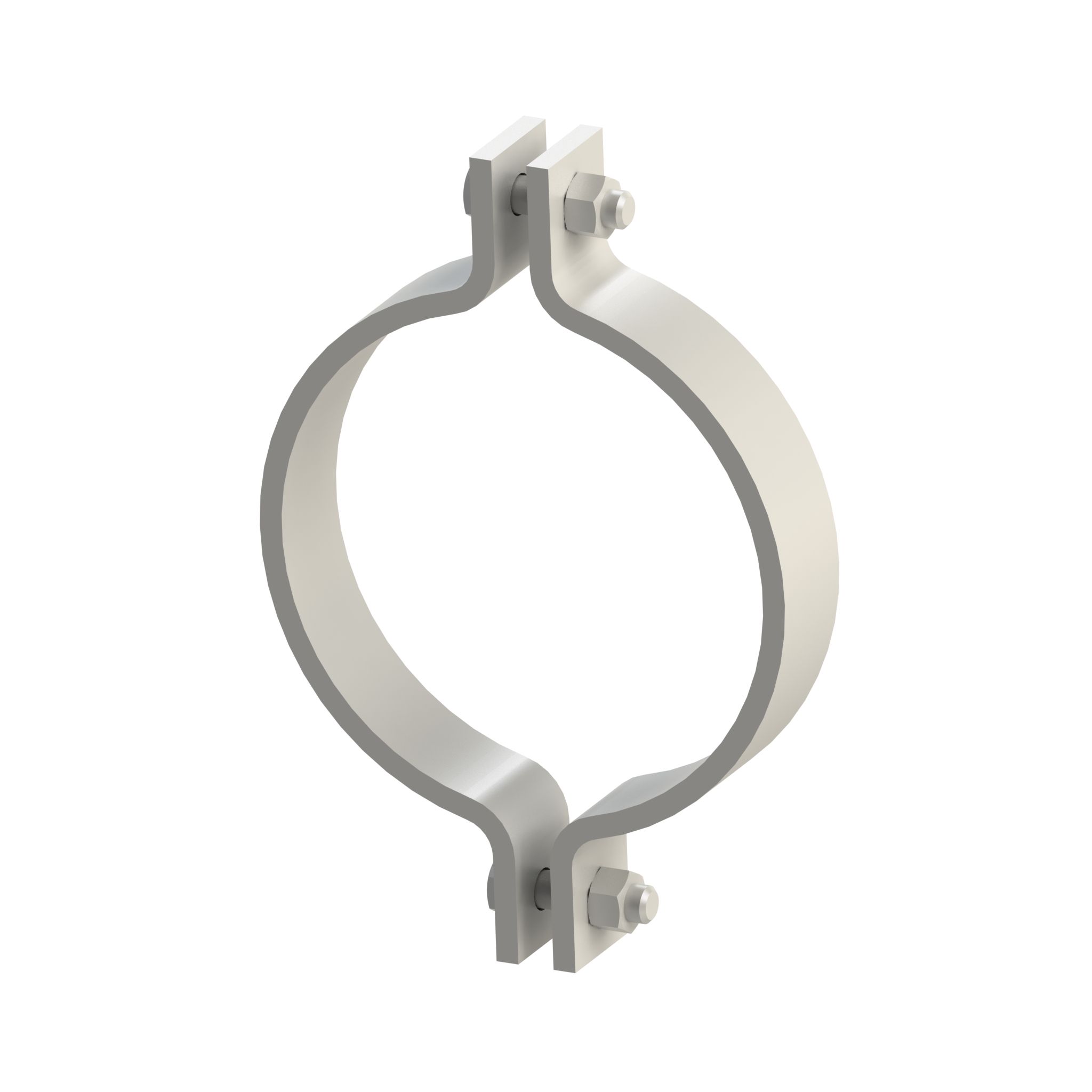

BG100

BG100LIGHT DUTY 2-BOLT CLAMP

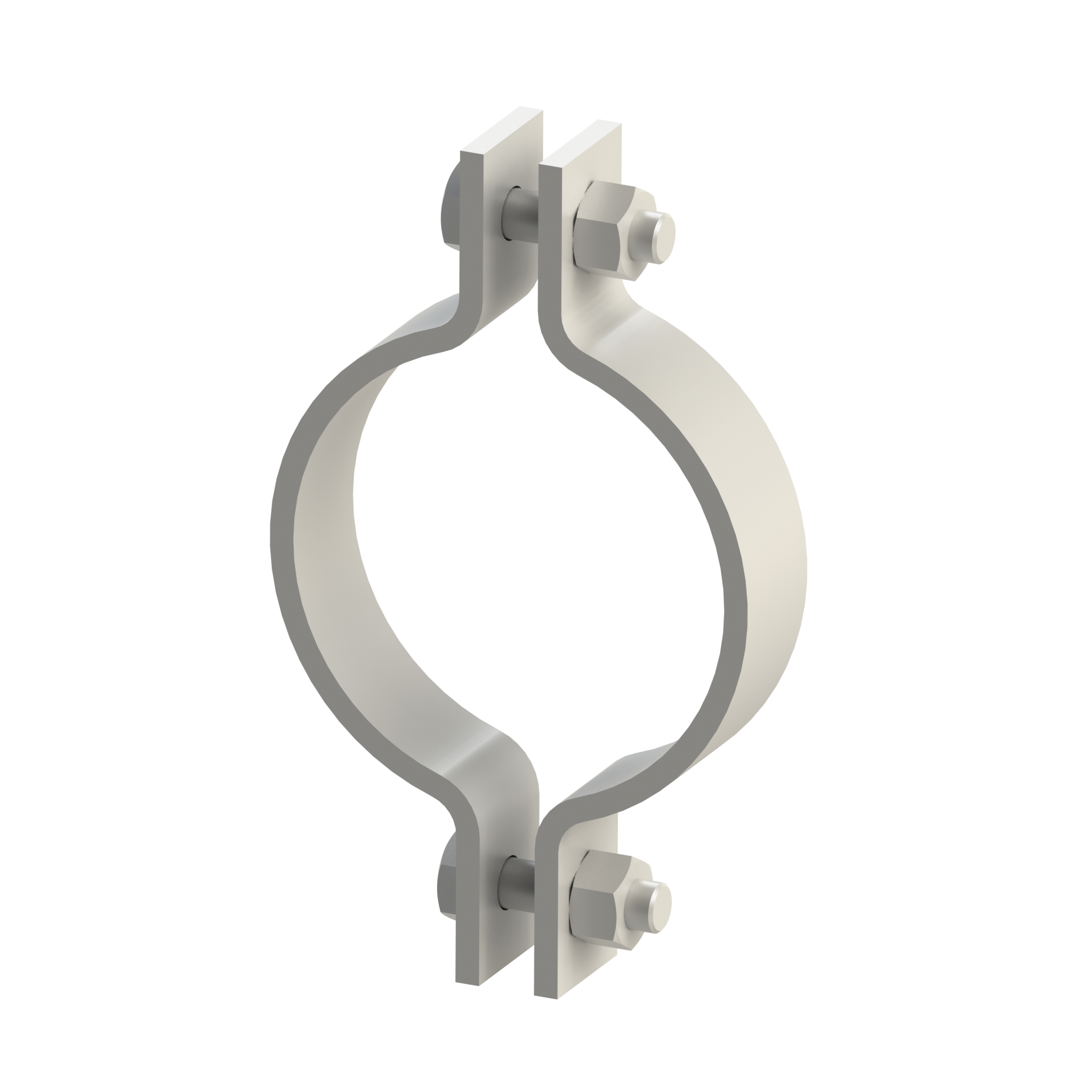

BG170

BG170MEDIUM DUTY 2-BOLT PIPE CLAMP

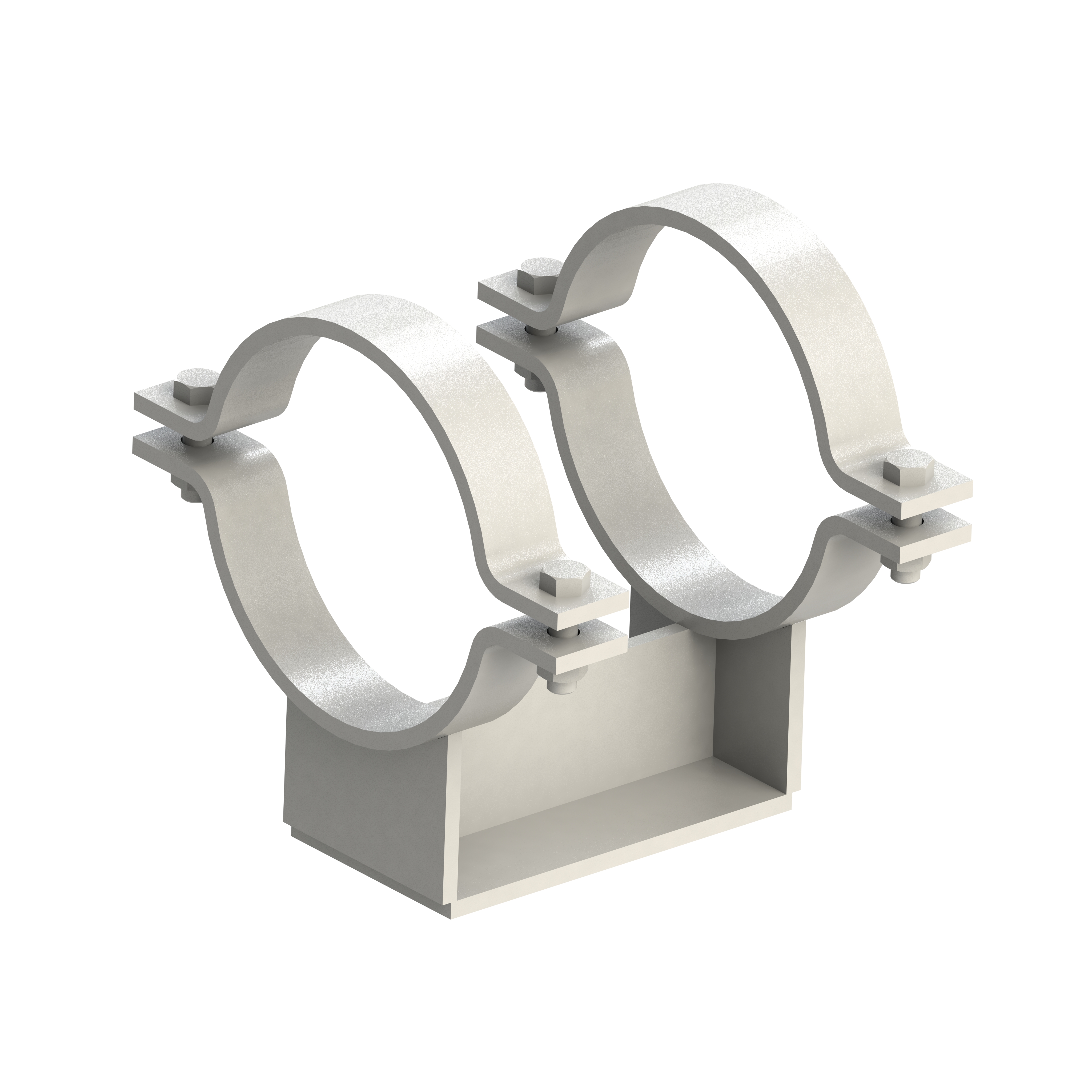

BG50

BG50HEAVY DUTY 2-BOLT PIPE CLAMP

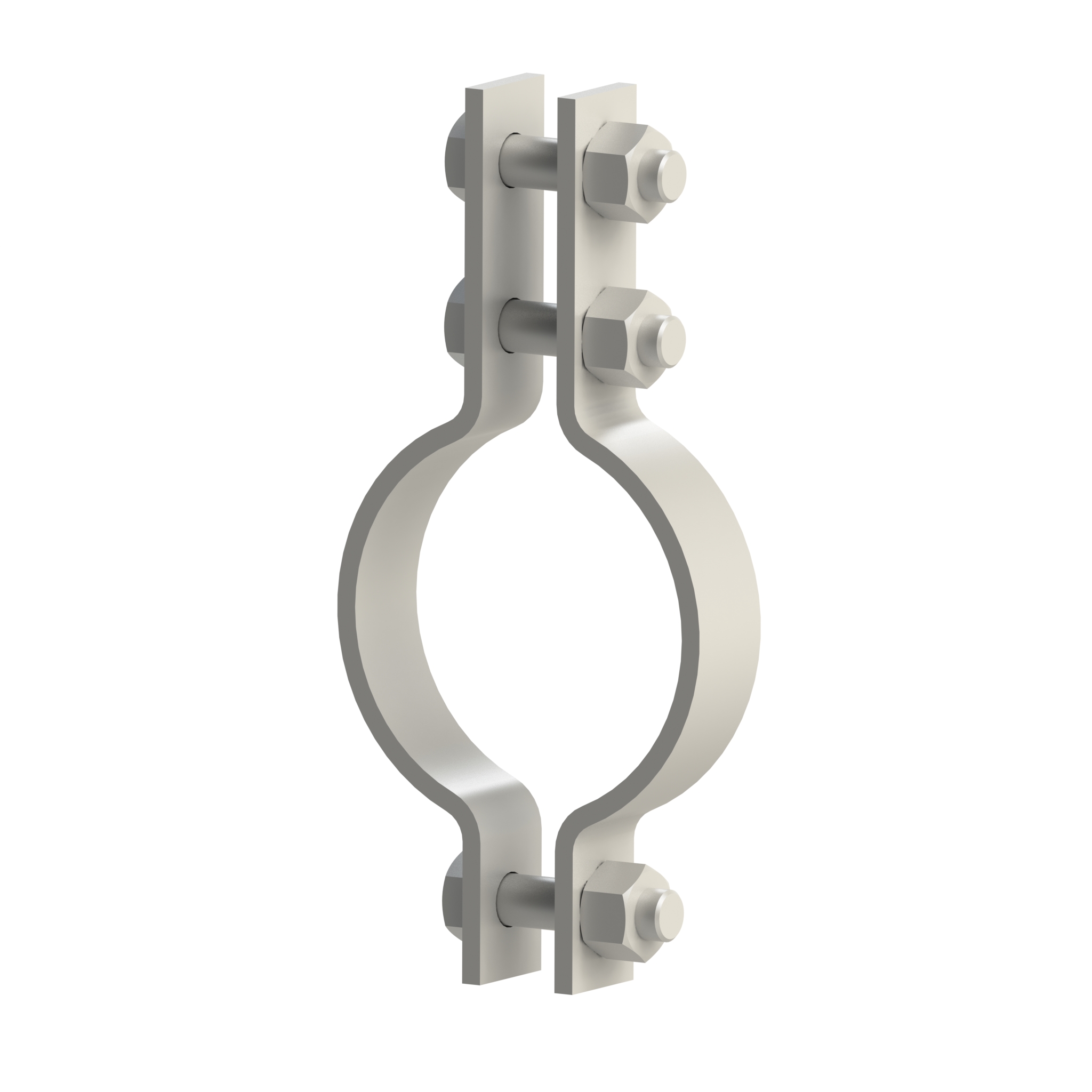

BG101

BG101LIGHT DUTY 3-BOLT PIPE CLAMP

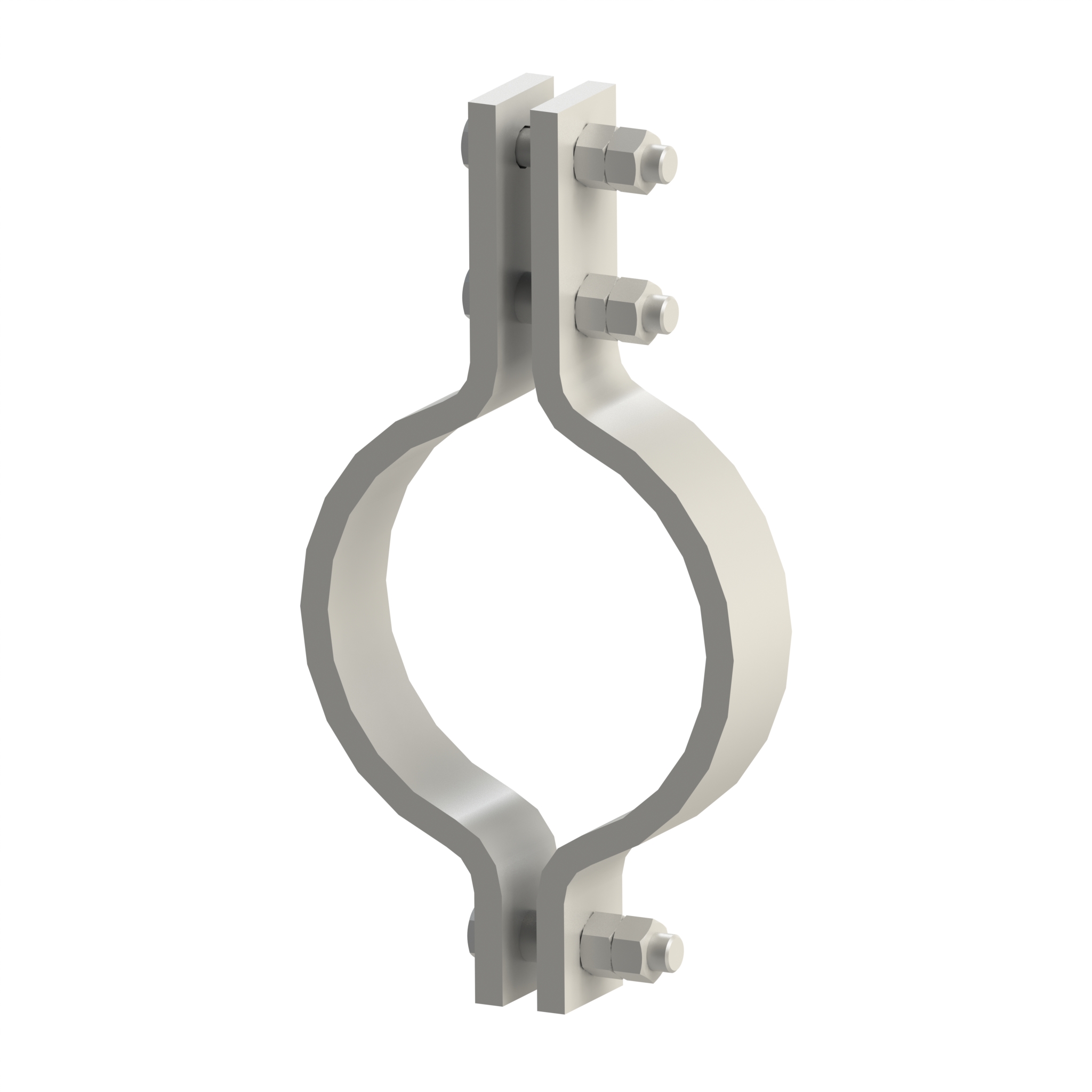

BG171

BG171MEDIUM DUTY 3-BOLT PIPE CLAMP FOR STEEL PIPE

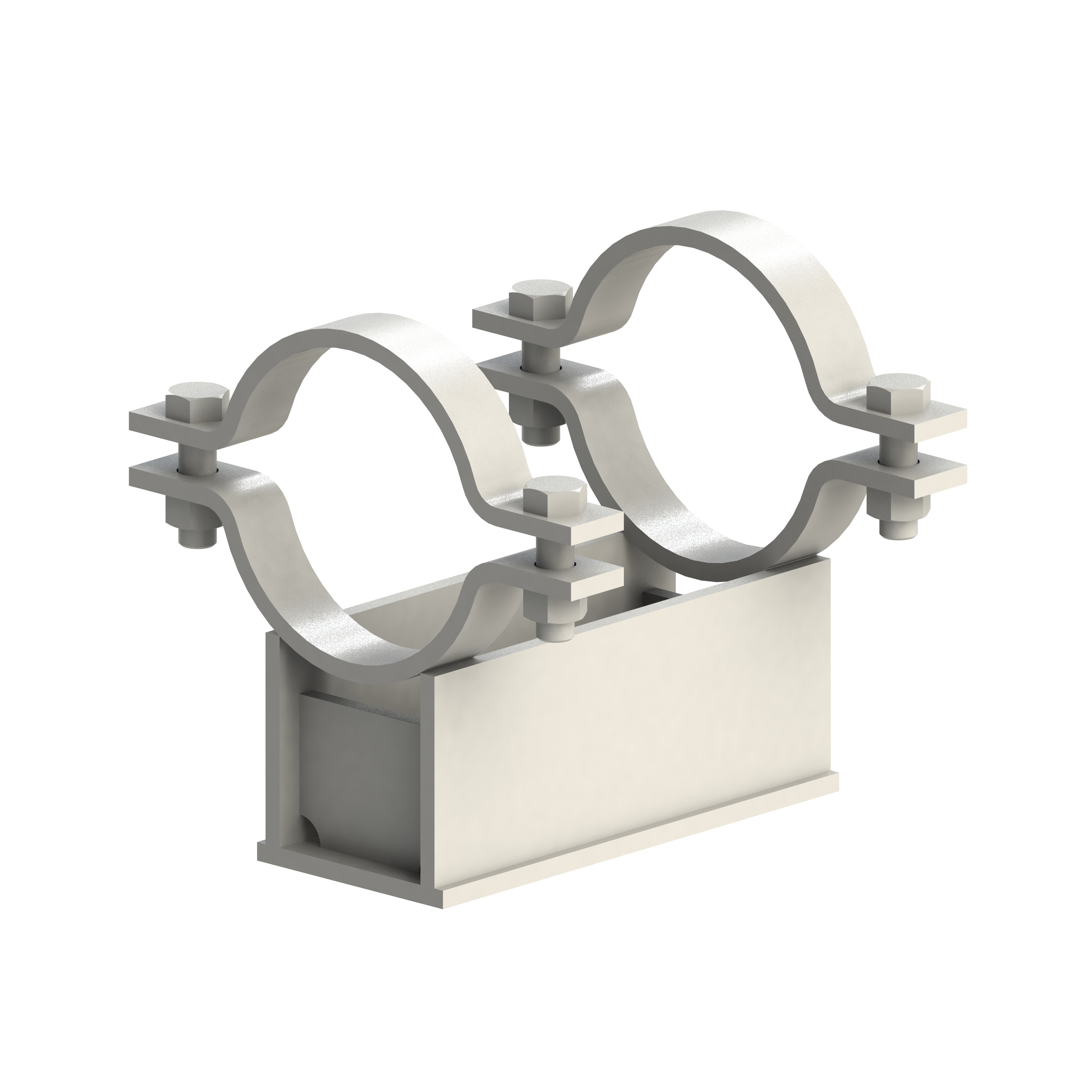

BG75

BG75HEAVY DUTY 3-BOLT PIPE CLAMP

BG172

BG172HIGH TEMPERATURE 3-BOLT PIPE CLAMP

BG173

BG173ALLOY PIPE CLAMP - VERY HIGH TEMPERATURE

BG140

BG140INSULATED 2-BOLT PIPE CLAMP

BG141

BG141INSULATED 2-BOLT PIPE CLAMP FOR CU/NI

BG145

BG145INSULATED 3-BOLT PIPE CLAMP

BG146

BG146INSULATED 3-BOLT PIPE CLAMP FOR CU/NI

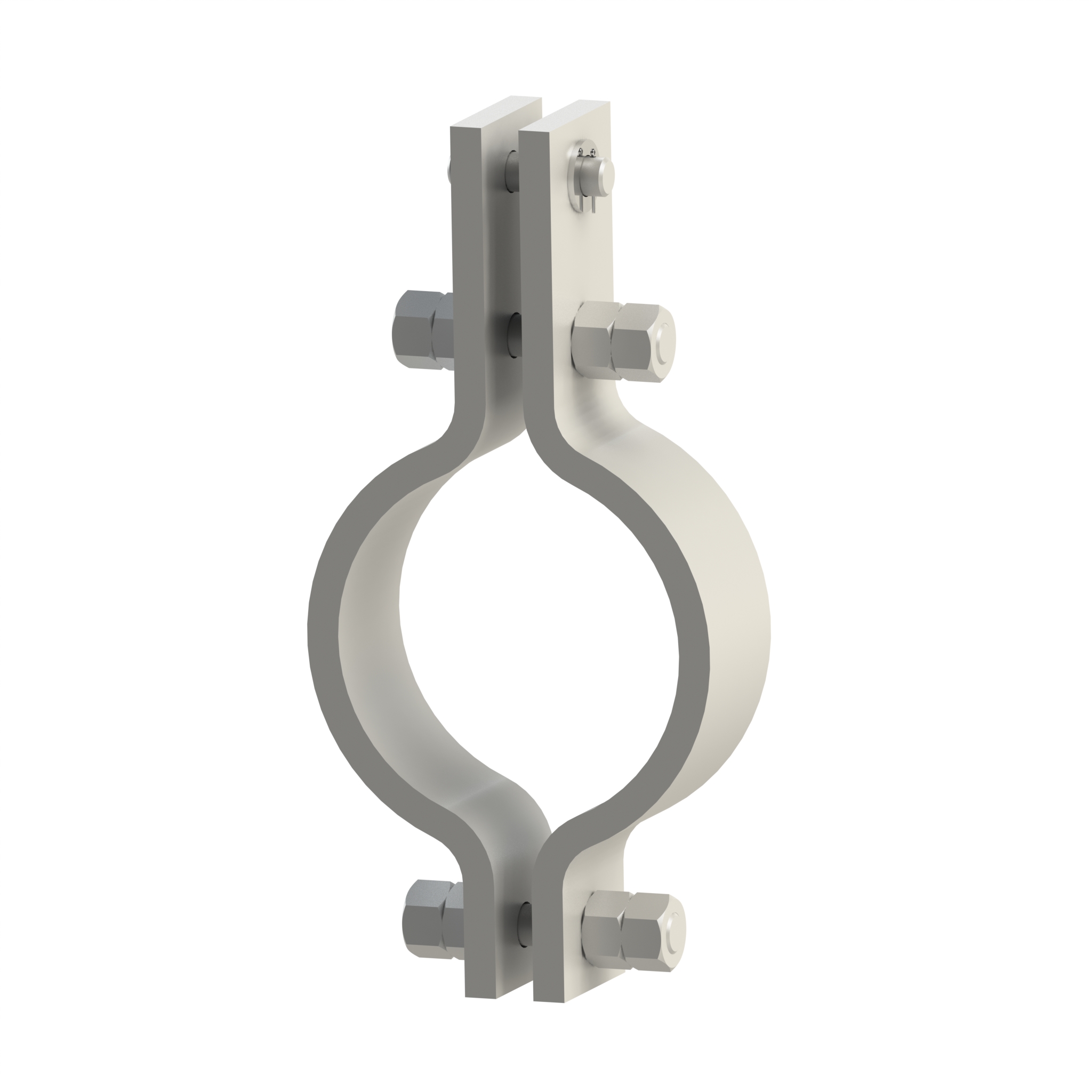

BG108

BG108CLEVIS CLAMP

BG222

BG222BEAM CLAMP

BG174

BG174RISER SUPPORT – STD TEMPERATURE

BG175

BG175RISER SUPPORT – HIGH TEMPERATURE

BG176

BG176ALLOY RISER SUPPORT - VERY HIGH TEMPERATURE

BG202

BG202ALLTHREAD ROD

BG209

BG209FORGED CLEVIS AND PIN

BG210

BG210FORGED TURNBUCKLE

BG204

BG204FORGED WELDLESS EYE NUT

BG215

BG215HEMISPHERICAL CUP

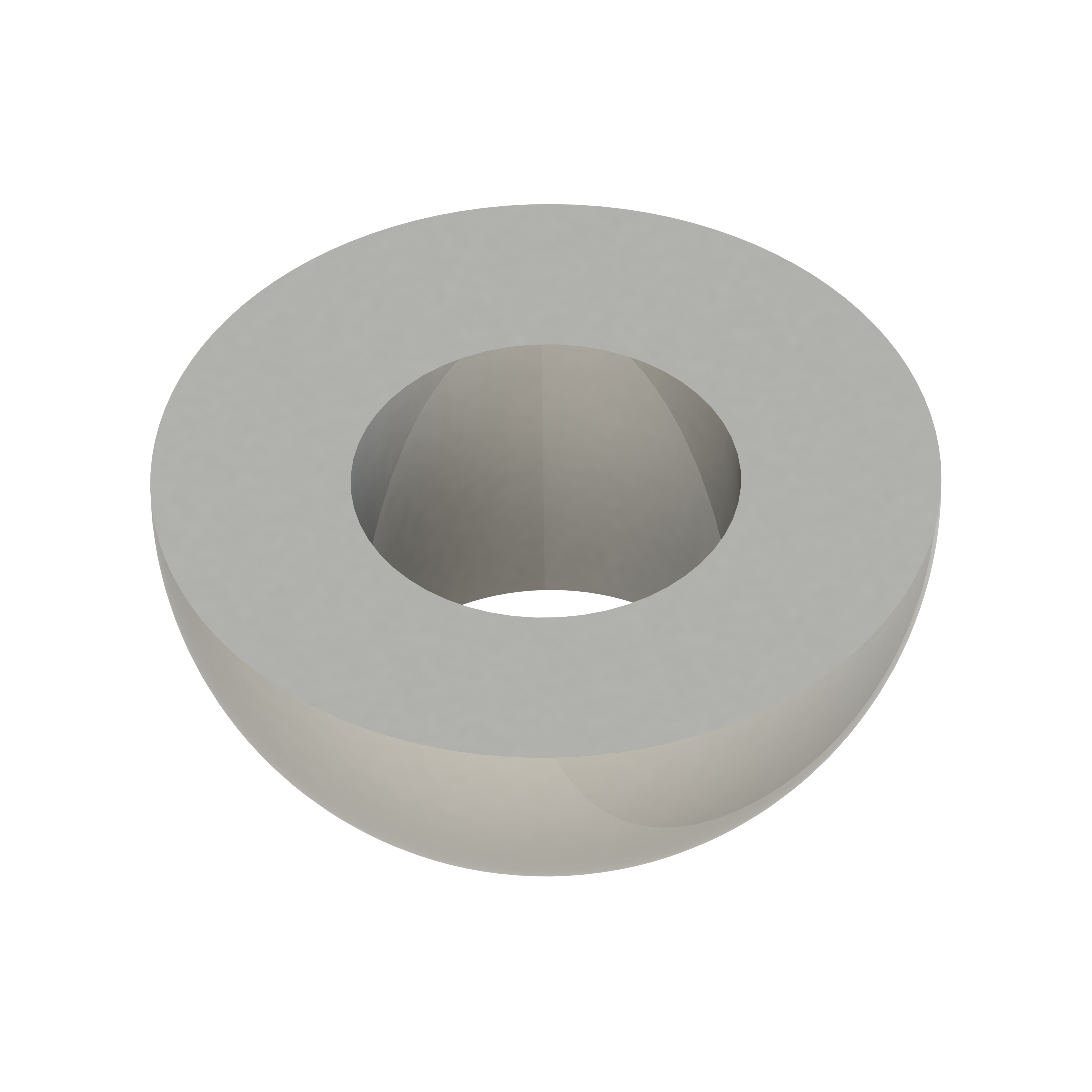

BG214

BG214HEMISPHERICAL WASHER

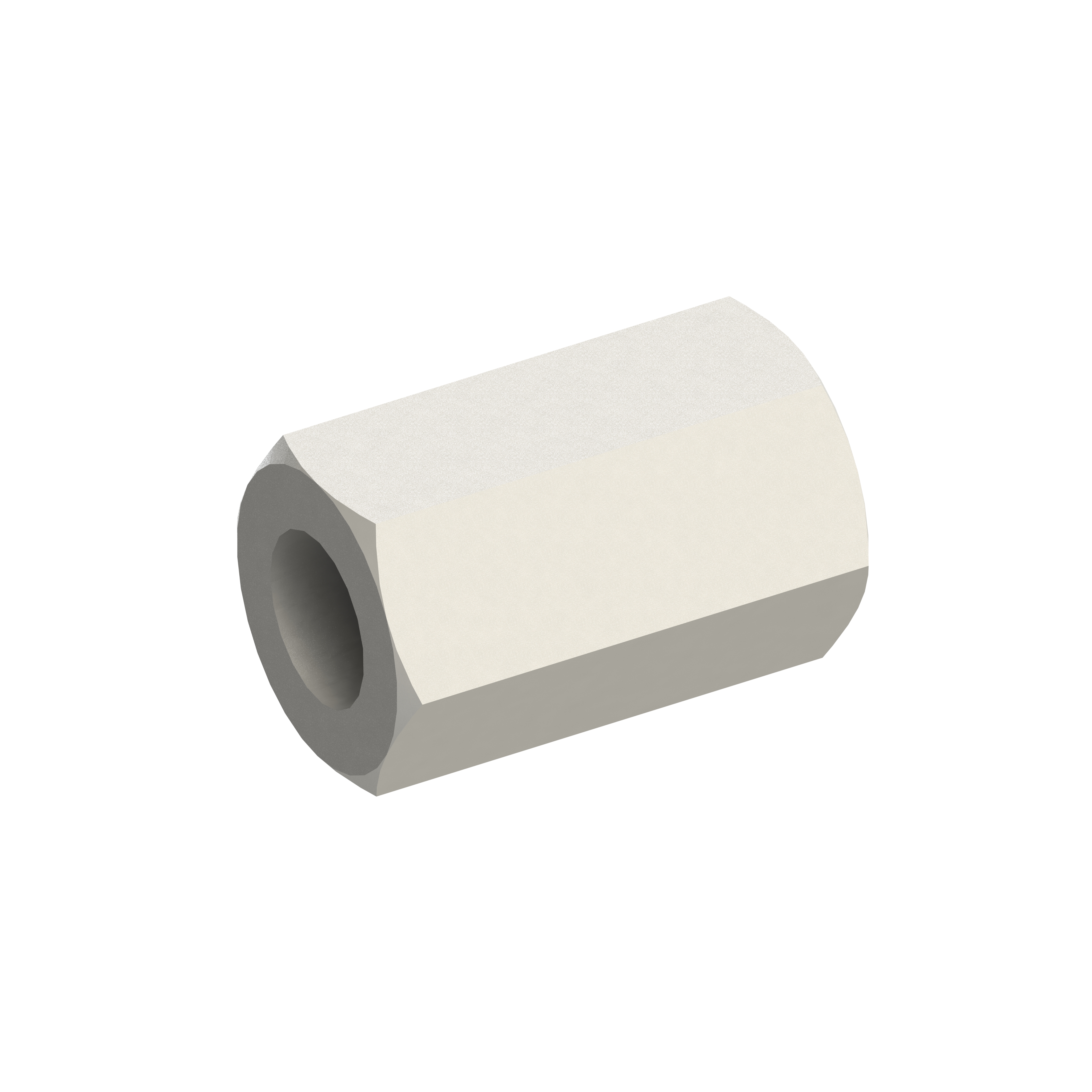

BG206

BG206HEXAGONAL CONNECTOR

BG216

BG216PIPE WELDING LUG

BG217

BG217PLATE WASHER

BG207

BG207SPADE NUT

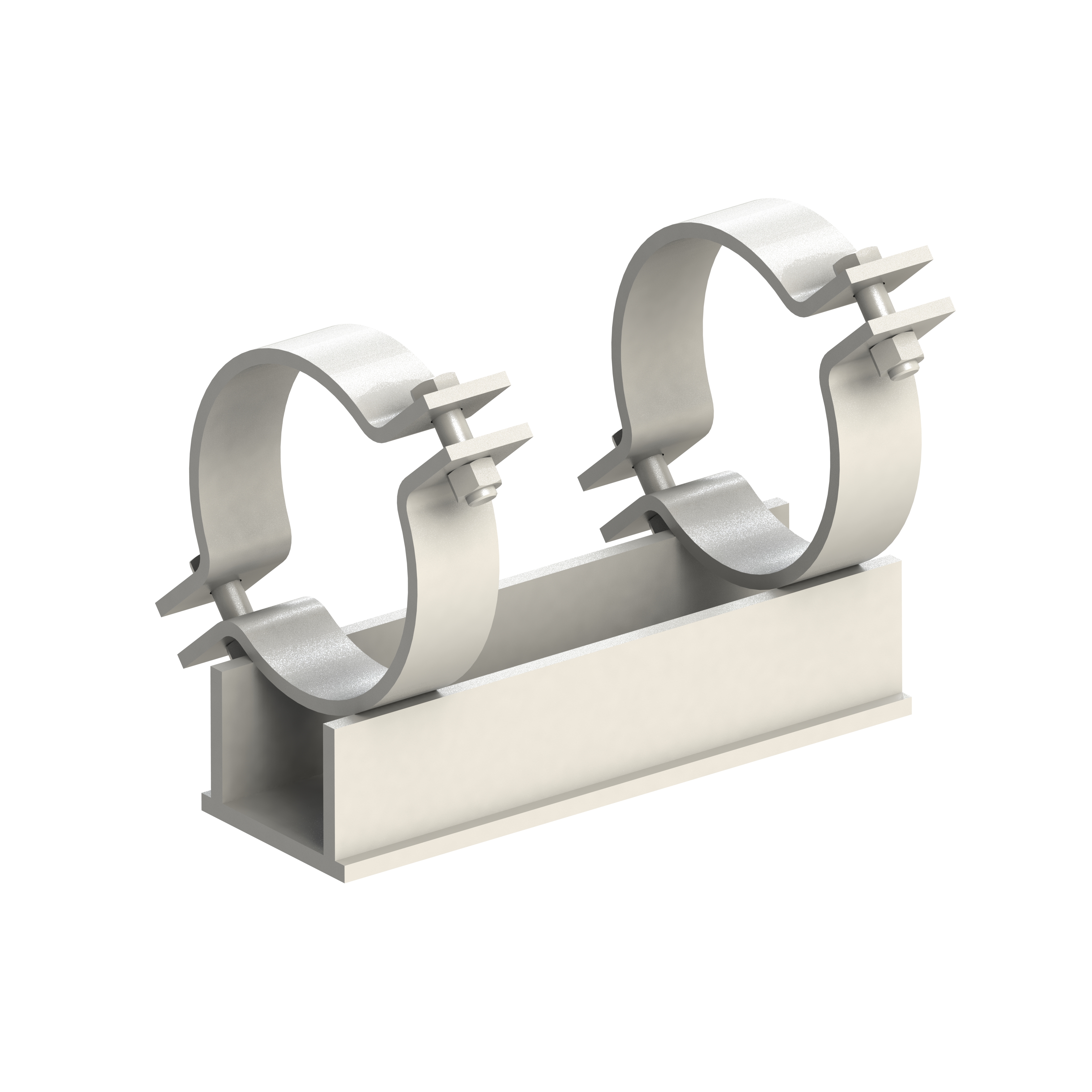

BG245

BG245STANDARD TRAPEZE

BG203

BG203THREADED DROP ROD – RH/LH

BG219

BG219WELDED BEAM ATTACHMENT

BG220

BG220WELDED BEAM ATTACHMENT (WITH LOAD PIN)

BG225

BG225WELDING LUG

BG180

BG180U-BOLT GUIDE

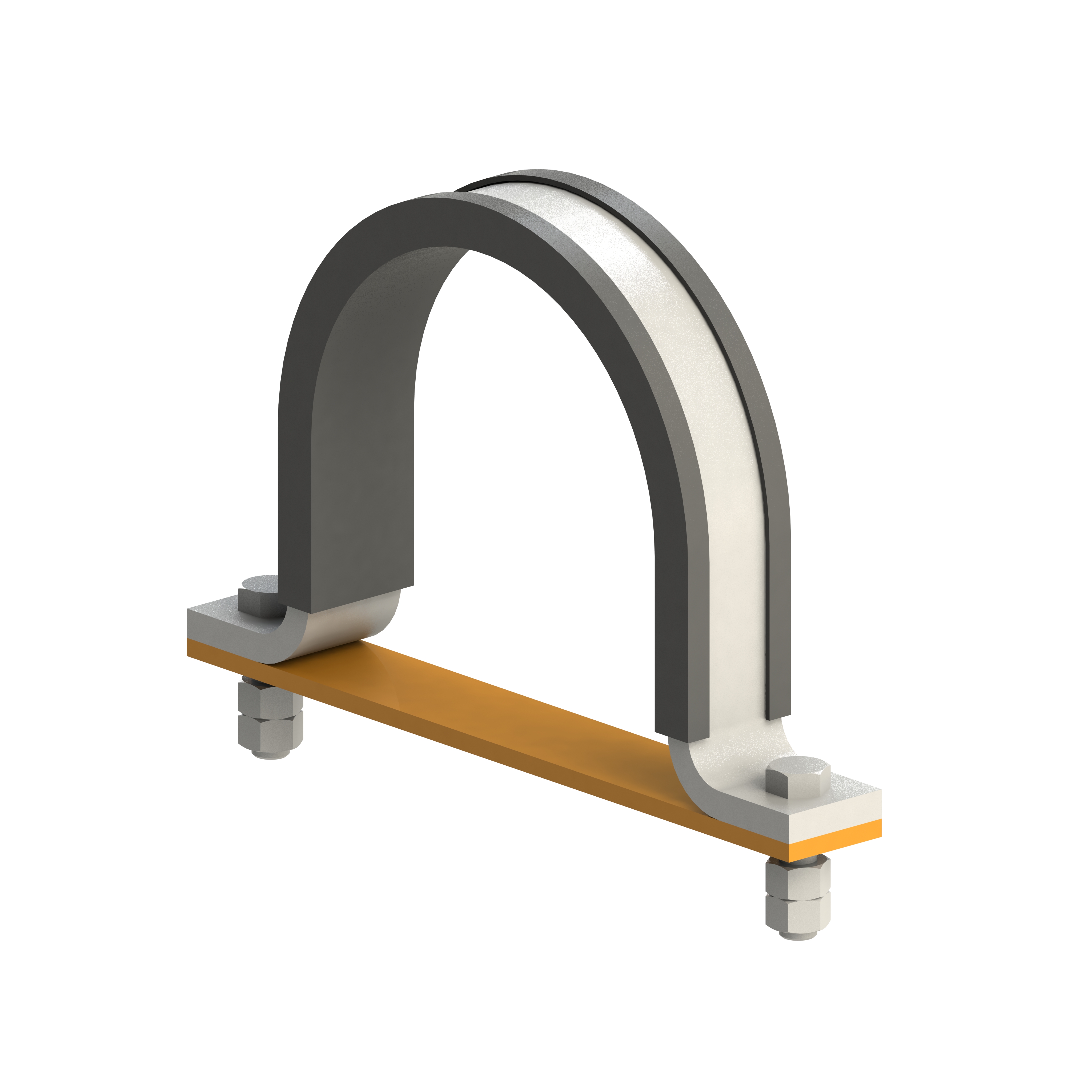

BG181

BG181U-BOLT CLAMP

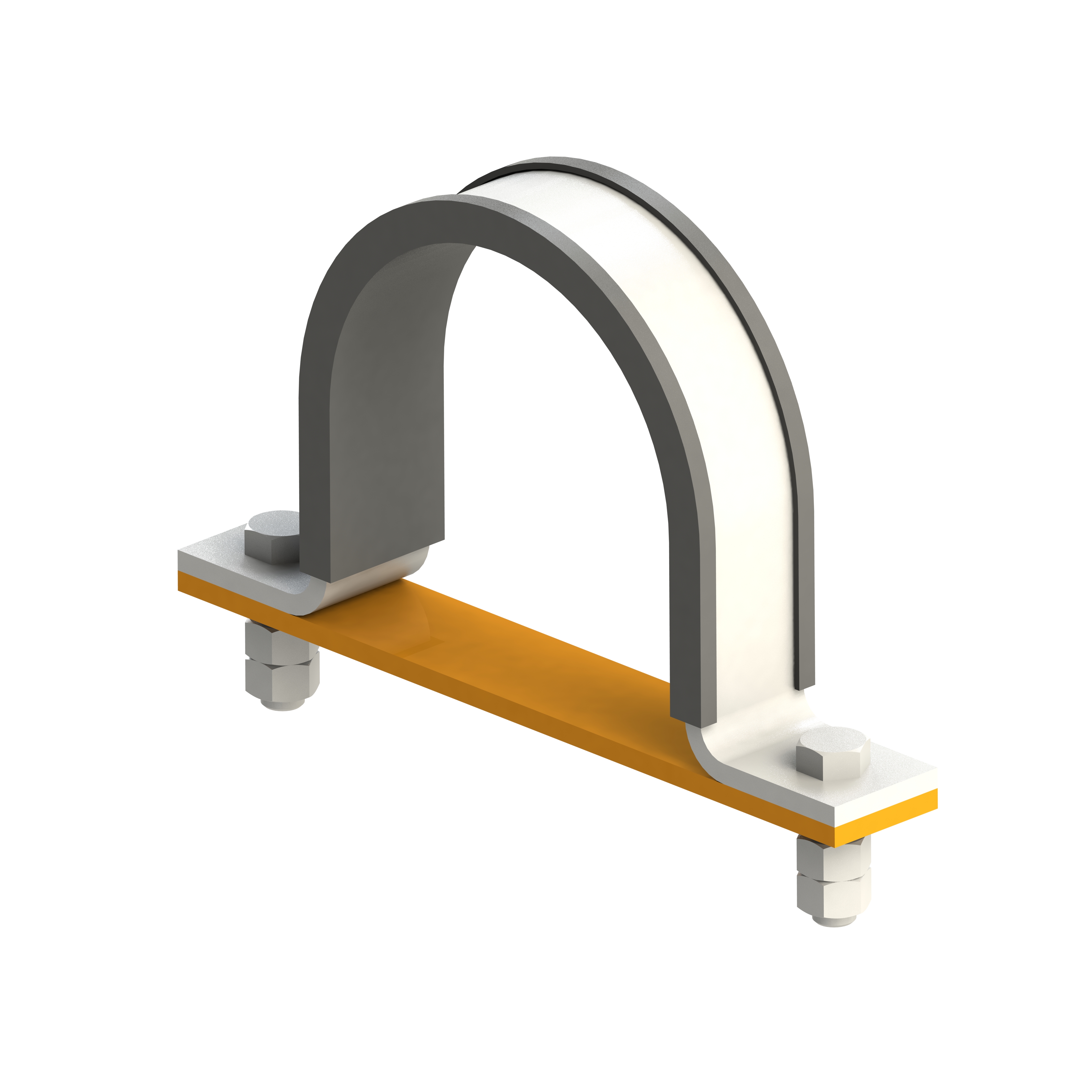

BG150

BG150INSULATED U-BOLT CLAMP

BG152

BG152INSULATED U-BOLT GUIDE

BG154

BG154INSULATED U-BOLT GUIDE (WITH TEFLON)

BG190

BG190INSULATED U-BOLT CLAMP

BG192

BG192INSULATED U-BOLT GUIDE

BG151

BG151INSULATED U-BOLT CLAMP FOR CU/NI

BG153

BG153INSULATED U-BOLT GUIDE FOR CU/NI

For Cu/Ni Pipe BG155

BG155INSULATED U-BOLT GUIDE (WITH TEFLON)

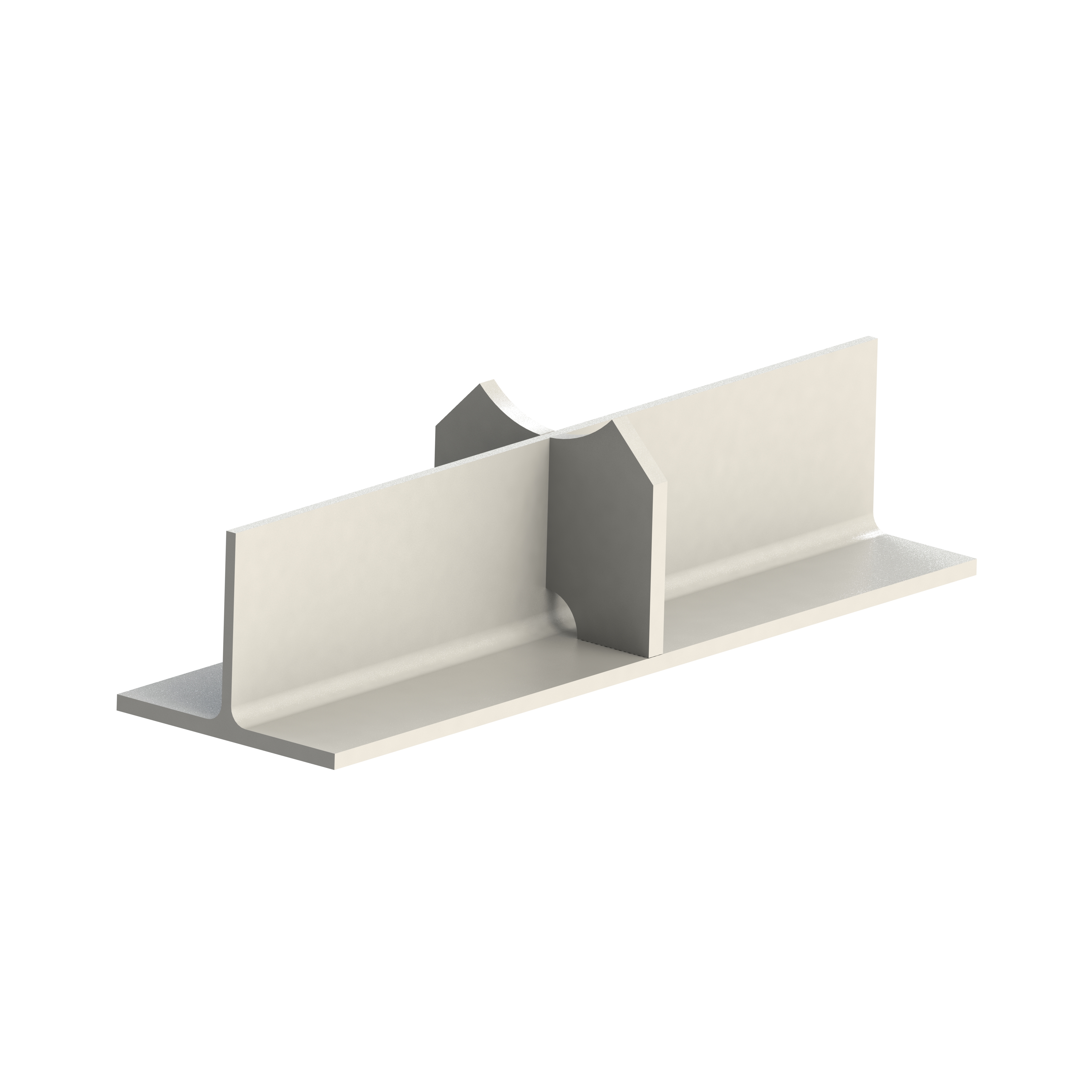

For Cu/Ni Pipe BG177

BG177SADDLE GUIDE

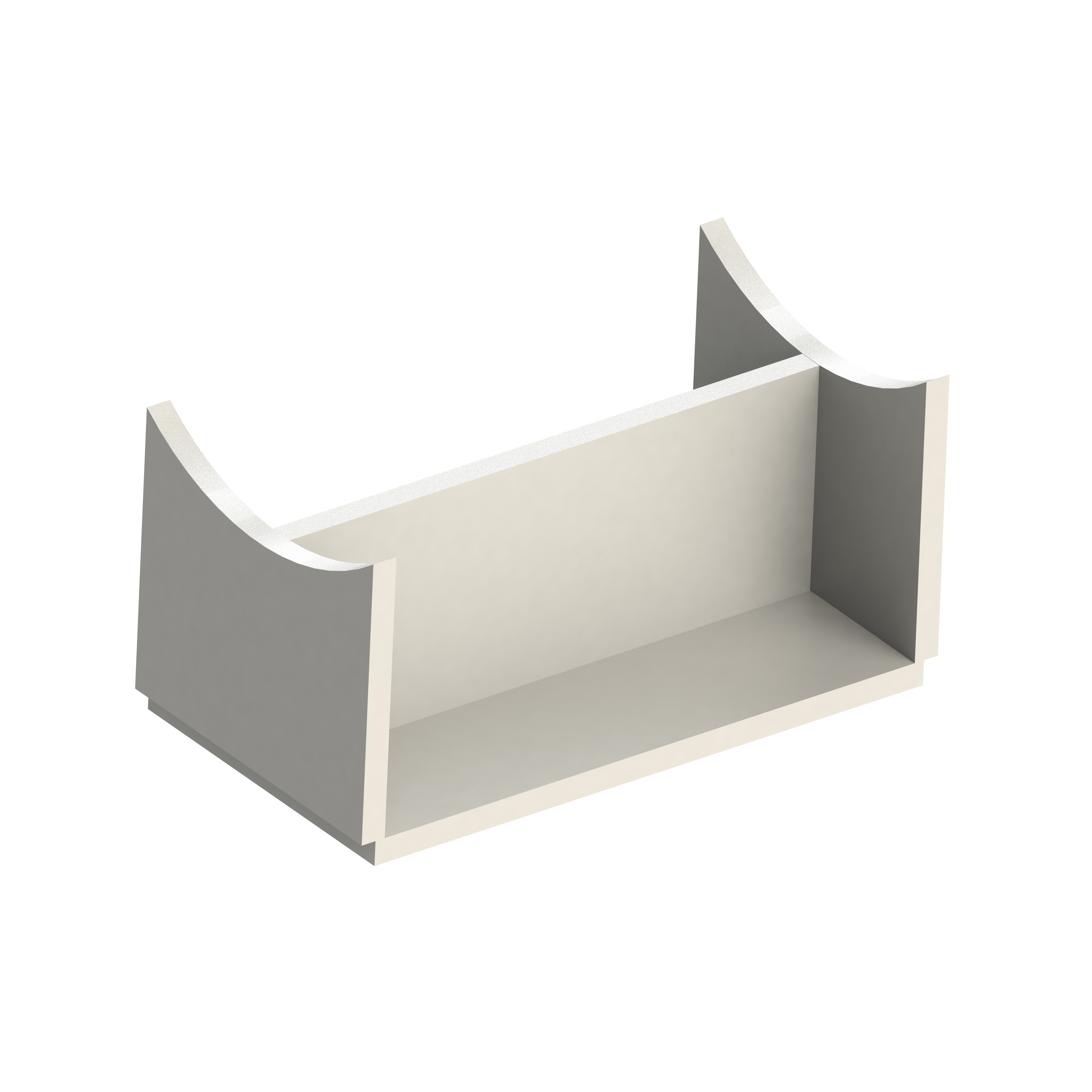

BG178

BG178SADDLE CLAMP

BG160

BG160INSULATED PIPE SADDLE

BG161

BG161INSULATED PIPE SADDLE

BG162

BG162INSULATED PIPE SADDLE

BG135-136

BG135-136ADJUSTABLE PIPE STANDS

BG515

BG515STANDARD CLAMPED PIPE SHOE

BG550

BG550SLIDE PLATES

BG517

BG517COMPACT PIPE SHOE

BG400

BG400CLAMPED HOT PIPE SHOE

BG156

BG156INSULATED PIPE SHOE

BG157

BG157INSULATED PIPE SHOE

BG510

BG510STANDARD WELDED PIPE SHOE

BG518

BG518COMPACT WELDED PIPE SHOE

BG555

BG555STANDARD LINE STOPS

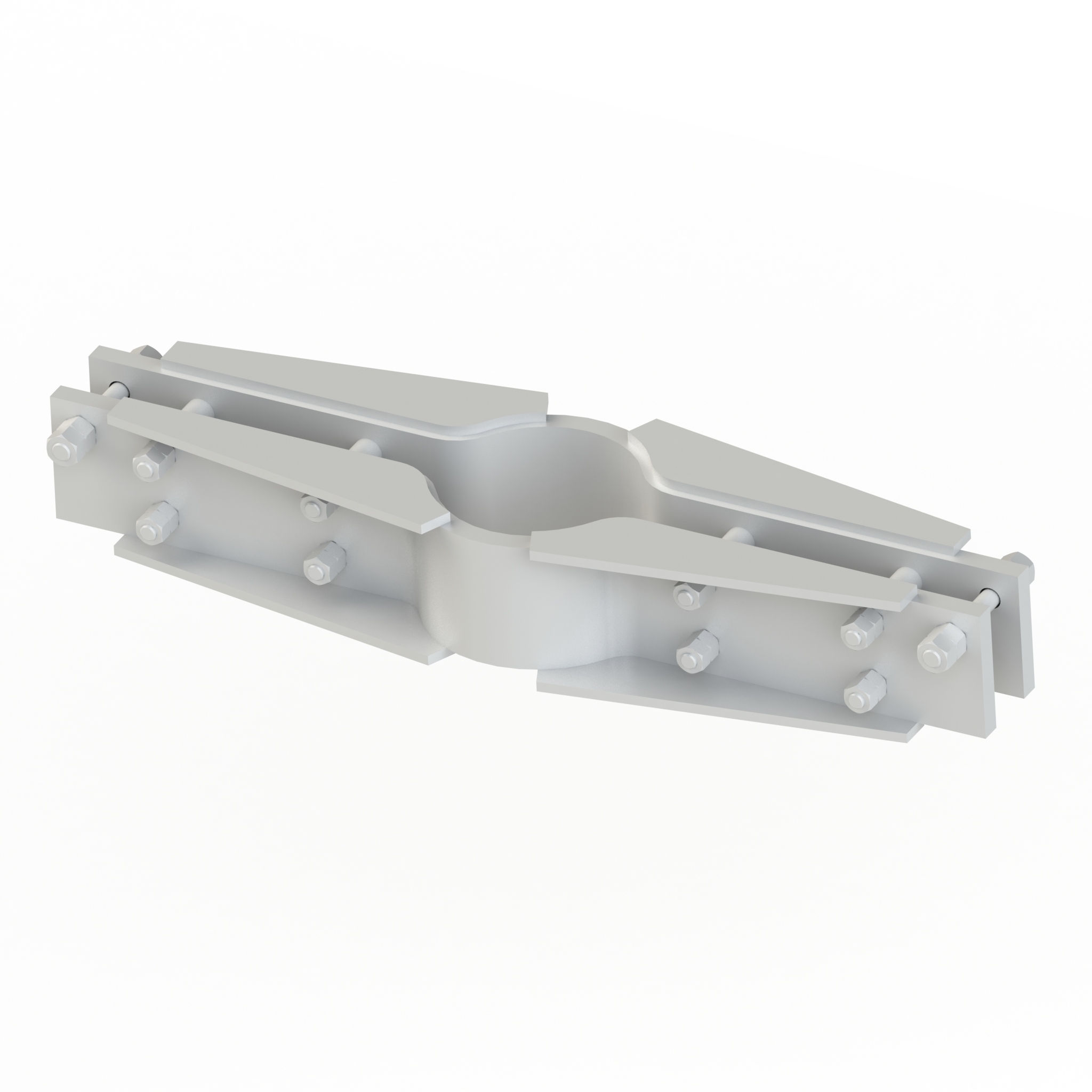

BG560

BG560STANDARD PIPE GUIDES

BG570

BG570STANDARD SHOE GUIDES

BG580

BG580STANDARD SHOE GUIDES

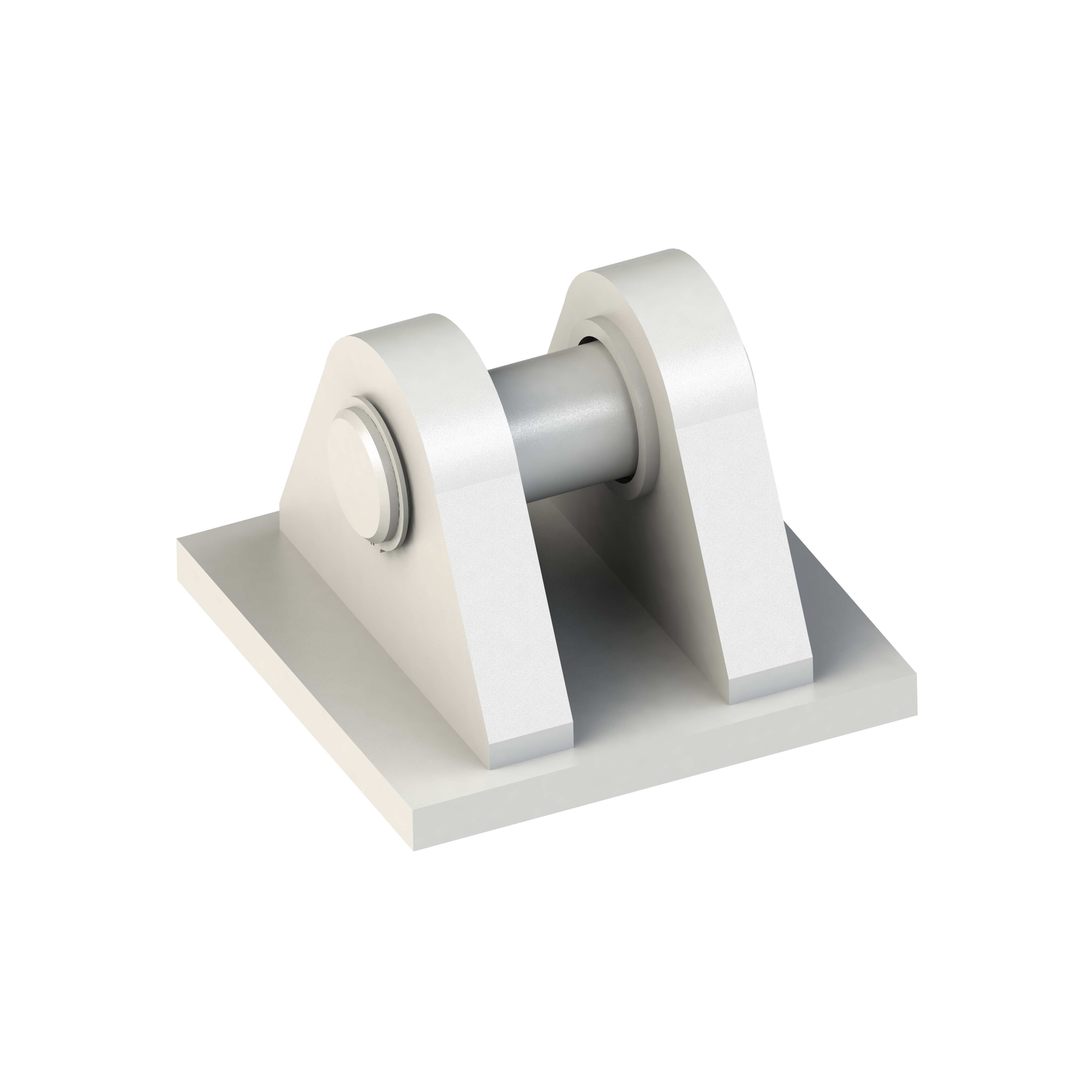

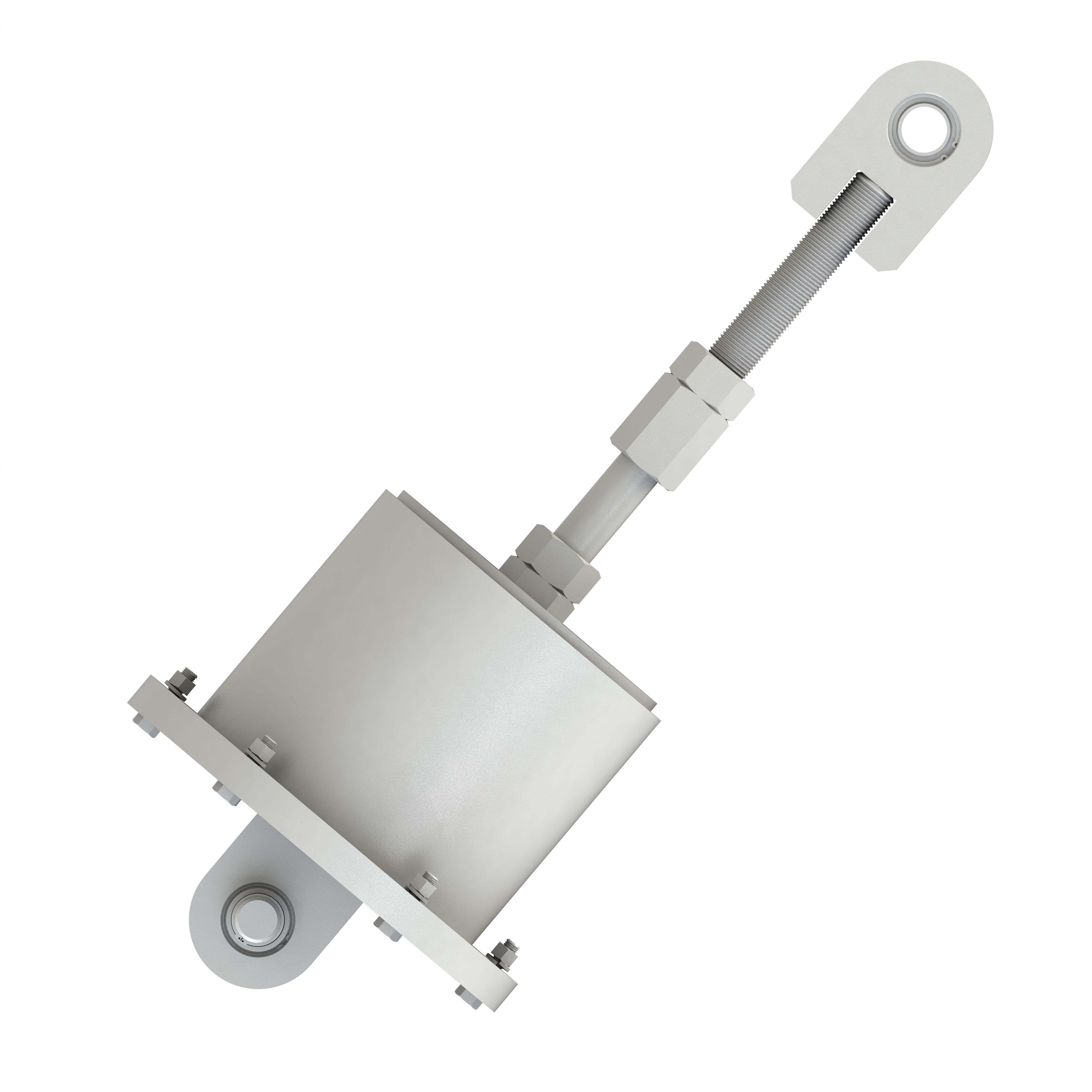

BG315

BG315END ATTACHMENT FOR HYDRAULIC SNUBBERS

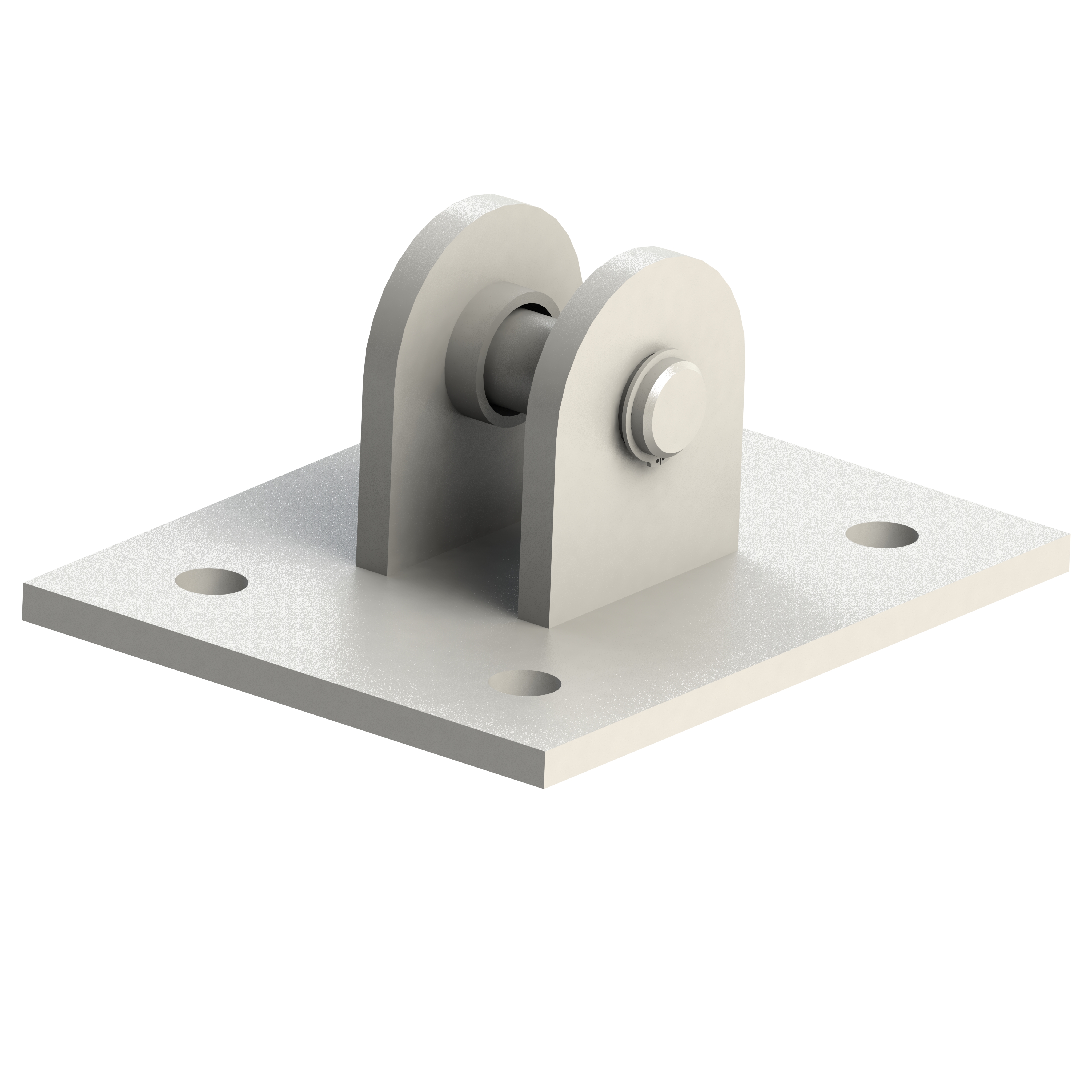

BG355

BG355END ATTACHMENT FOR RIGID STRUT & SWAY BRACE

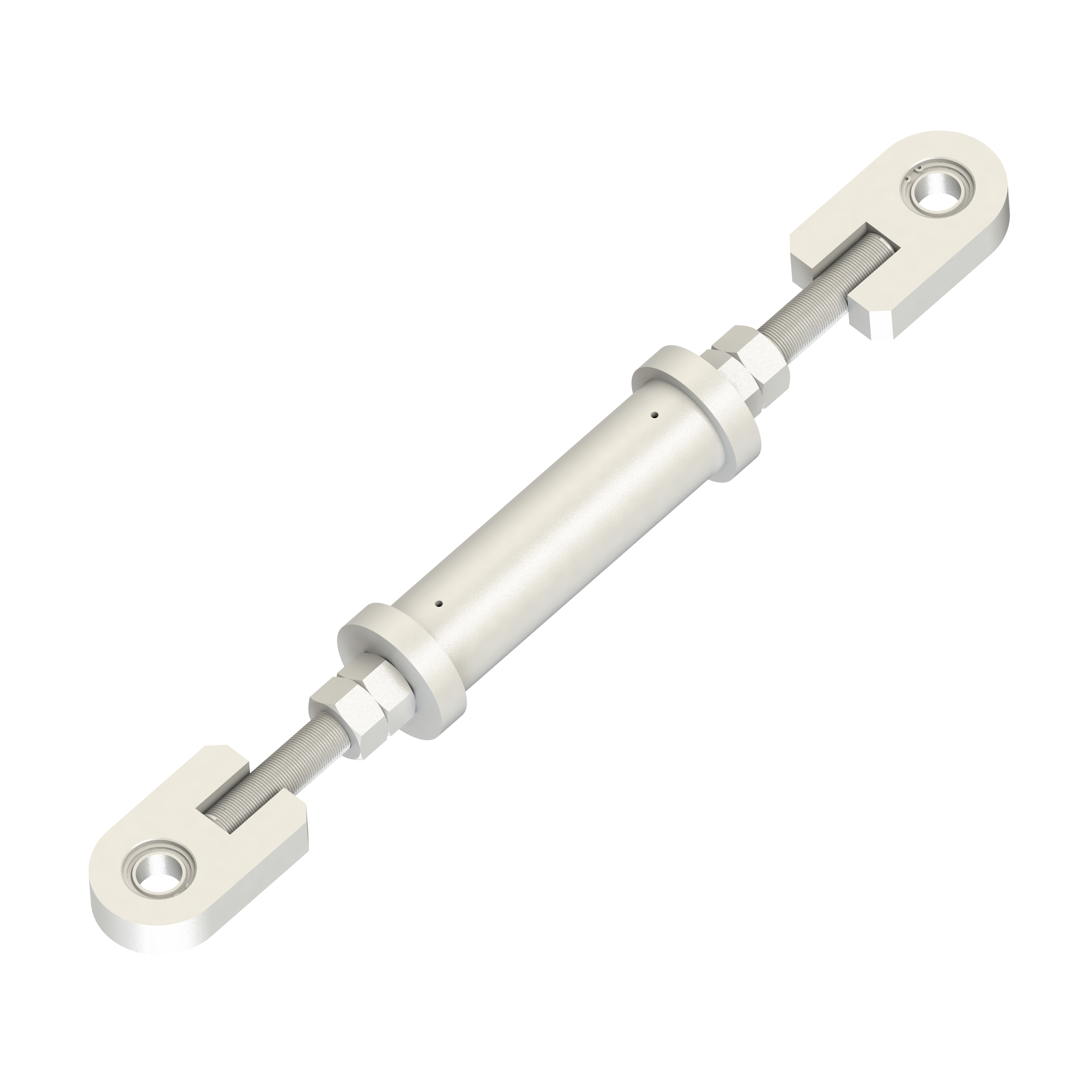

BG310

BG310HYDRAULIC SNUBBERS (SHOCK ARRESTORS)

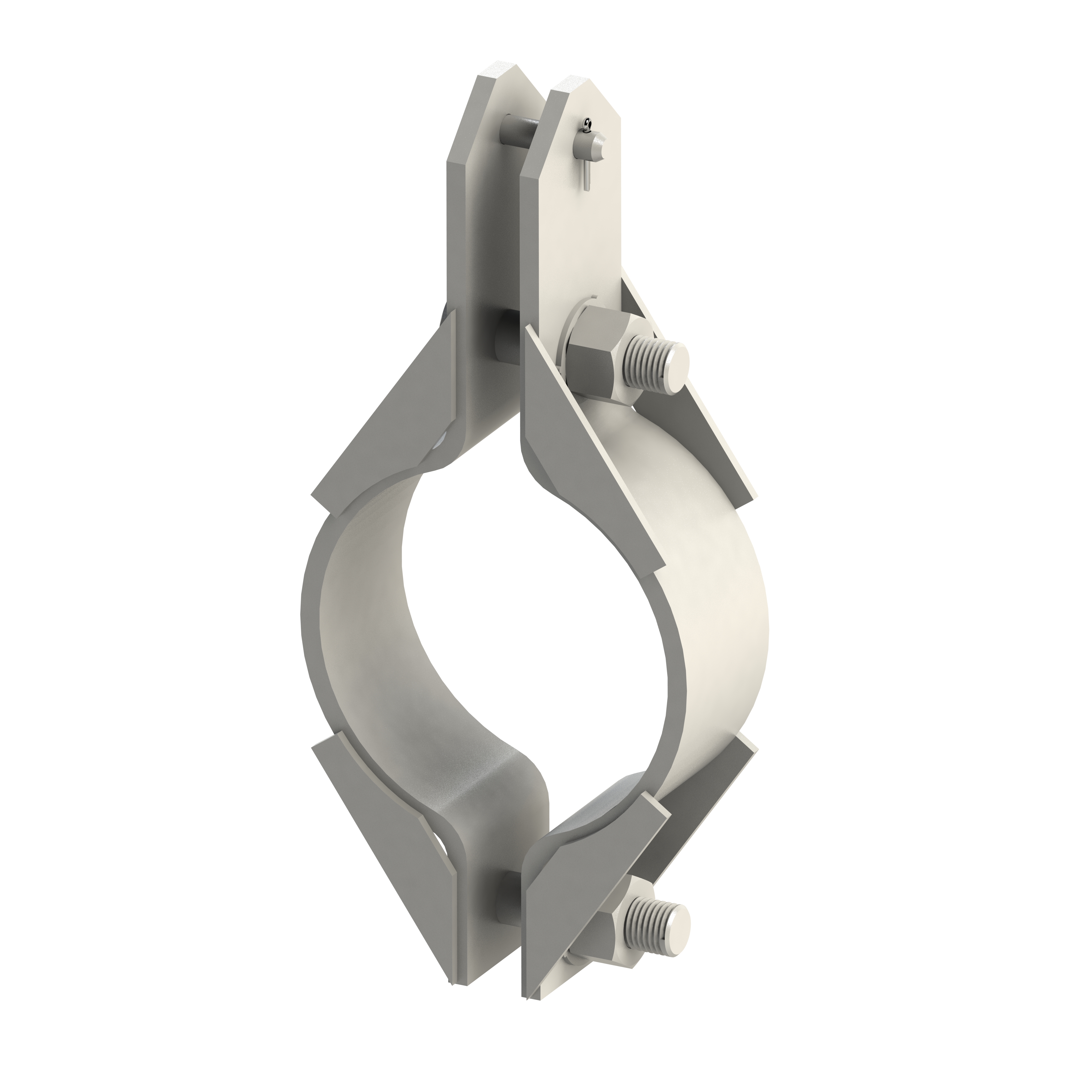

BG321

BG321PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG322

BG322PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG320

BG320PIPE CLAMP FOR HYDRAULIC SNUBBER – LOW TEMPERATURE

BG350

BG350RIGID STRUTS

BG340

BG340SWAY BRACE

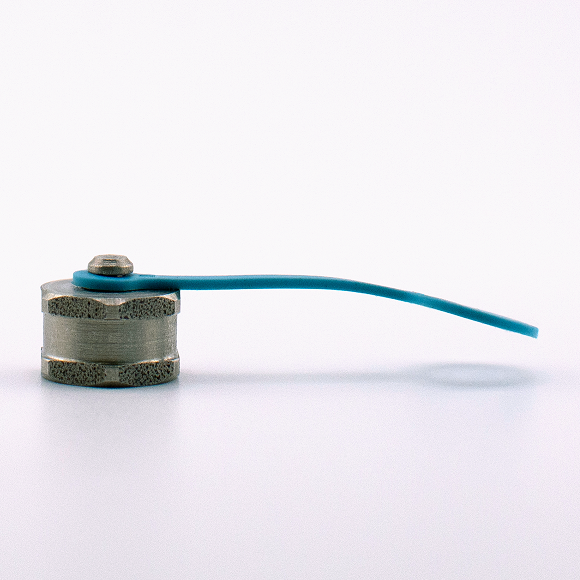

#691028

#691028All Stainless Steel Gauge Adapter #691028

#520XL

#520XLAll Stainless Steel Gauge Adapter #520XL

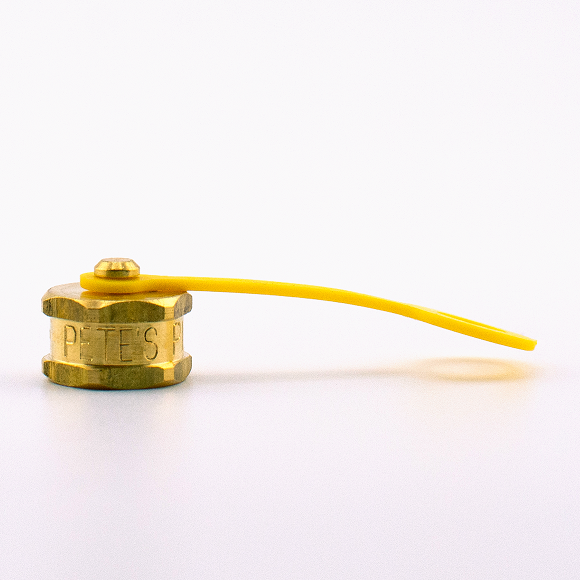

#691023

#691023Brass Gauge Adapter #691023

#500BSP

#500BSPBrass Gauge Adapter #500BSP

#691024

#691024Brass Gauge Adapter #691024

#500XLBSP

#500XLBSPBrass Gauge Adapter #500XLBSP

691026

691026Brass Gauge Adapter #691026

#691027

#691027Brass Gauge Adapter #691027

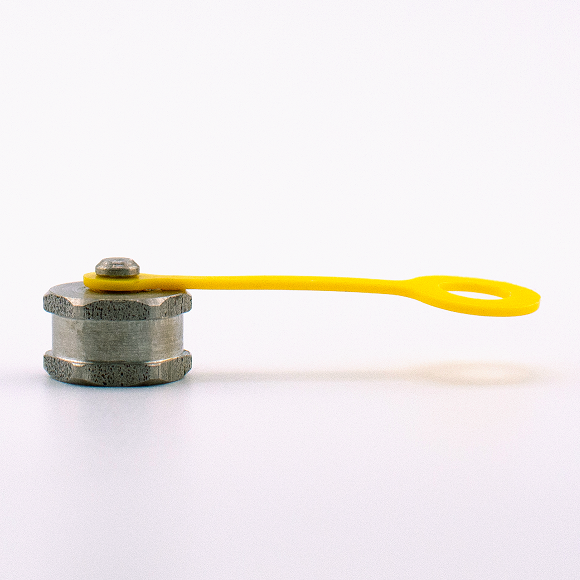

#104-1BS

#104-1BSCap Assembly #104-1BS

#104-1YS

#104-1YSCap Assembly #104-1YS

#104-2BS

#104-2BSCap Assembly #104-2BS

#104-2YS

#104-2YSCap Assembly #104-2YS

#691003

#691003Pete's Plug #691003

#691002

#691002Pete's Plug #691002

#691010

#691010Pete's Plug #691010

#691001

#691001Pete's Plug #691001

#691000

#691000Pete's Plug #691000

#691017

#691017Pete's Plug #691017

#12510

#12510Pete's Plug #12510

691020

691020Pete's Plug #691020

#691008

#691008Pete's Plug #691008

#691005

#691005Pete's Plug #691005

#691007

#691007Pete's Plug #691007

#691004

#691004Pete's Plug #691004

#572

#572Pete's Plug #572

#691019

#691019Pete's Plug #691019

#691018

#691018Pete's Plug #691018

#760

#760Pete's Plug #760

#691016

#691016Pete's Plug #691016

#691022

#691022Pete's Plug #691022

#691021

#691021Pete's Plug #691021

#691014

#691014Pete’s Plug #691014

#691013

#691013Pete’s Plug #691013

#562

#562Pete’s Plug #562

#691012

#691012Pete’s Plug #691012

#691011

#691011Pete’s Plug #691011

#750XL

#750XLPete’s Plug #750XL

#691015

#691015Pete’s Plug #691015

#691029

#691029Pressure & Temperature Test Kit 0-100psi

#691030

#691030Pressure & Temperature Test Kit 0-100psi for XL

#1500-5

#1500-5Pressure Gauge 0-100 PSI BSP Stem

#1500-4

#1500-4Pressure Gauge 0-100 PSI NPT Stem

#606

#606Thermometer -58°F to 550°F

-

-

-

- About

- Resources

- Contact

Elevating Project Success with Precision Pipe Support Standards

Navigating AS/NZS pipe support standards is a critical challenge for specifiers, particularly in high-stakes environments such as oil & gas, mining, and infrastructure. These standards, including AS/NZS 5131, are essential for ensuring the structural integrity and reliability of pipe supports. Specifiers aim to align these standards with specific project requirements to avoid costly over-specification or non-compliance, which can severely impact project viability. This article addresses the primary challenges specifiers face with the Construction Category and other frameworks. Understanding these can prevent engineering risks and support better adherence to compliance benchmarks. The insights provided here aim to help project managers and specifiers make informed decisions to safeguard budget and project quality.

when pipe support standards are misread

Misinterpretations of AS/NZS 5131 and API rules can lead to design choices that inflate budgets unnecessarily. A notable incident involved an estimator incorrectly applying these standards, selecting overly complex specifications that escalated project costs significantly.

Specifiers frequently juggle multiple compliance frameworks, often encountering confusion with overlapping safety margins and fabrication requirements. Clear understanding and application of these standards are critical to managing costs effectively and ensuring practicality in project specifications.

Key frameworks like AS 1170 are vital for maintaining Australia’s project compliance landscape. With Binder’s Documentation Pack and QA/QC Sets, specifiers gain structured assurance, facilitating smooth project handovers without unexpected financial burdens.

Construction Category and Its Impact on Compliance

Under the AS/NZS 5131 standard, determining a project’s Construction Category specifies the required level of quality assurance and inspection for pipe supports. This ensures alignment with fabrication standards, avoiding issues with overbuilt or insufficient components. By adhering to these categories, specifiers link design objectives directly to effective fabrication practices, significantly reducing the need for costly rectifications. Binder’s Documentation Pack and QA/QC Sets are instrumental in addressing compliance comprehensively before project handover.

Certification and its role in reducing engineering

With Binder’s full traceability in QA/QC Sets, specifiers ensure compliance throughout manufacturing and installation, minimizing oversight risks and boosting project achievements.

importance of performance-based traceability

AS/NZS 5131 requires a rigorous performance-based traceability system to guarantee the integrity of pipe support structures. This meticulous tracking from materials to final component ensures compliance and quality standards are met, facilitating seamless audits. Prioritizing traceability enhances project transparency, mitigates potential non-compliance risks, and supports stakeholders’ confidence in adherence to AS/NZS 5131 standards. Binder’s Documentation Pack aligns with these practices, providing transparency and aiding efficient inspections and audits, helping specifiers manage timelines and ensure quality outcomes.

integration of as/nzs 1170 with as/nzs 5131 for safety

AS/NZS 1170 establishes a structure’s Importance Level, vital for safety compliance and engineering rigour. This categorization defines necessary safety and design measures.

AS/NZS 5131’s Construction Category complements this by detailing construction specifications, particularly crucial in high-stakes projects, reducing potential risk through clear guidelines.

Synchronizing these standards ensures that pipe support systems not only fulfil structural requirements but also meet overarching project safety and regulatory standards throughout project lifecycles.

practical checks for specifiers

Confirm standards like AS/NZS 5131, AS 1170, and applicable API regulations are detailed in contract documents, outlining specifiers’ responsibilities in meeting statutory needs.

Initiating early compliance audits aligns supporting documents with the Construction Category, avoiding costly delays and securing necessary approvals.