- Products

-

-

-

Categories

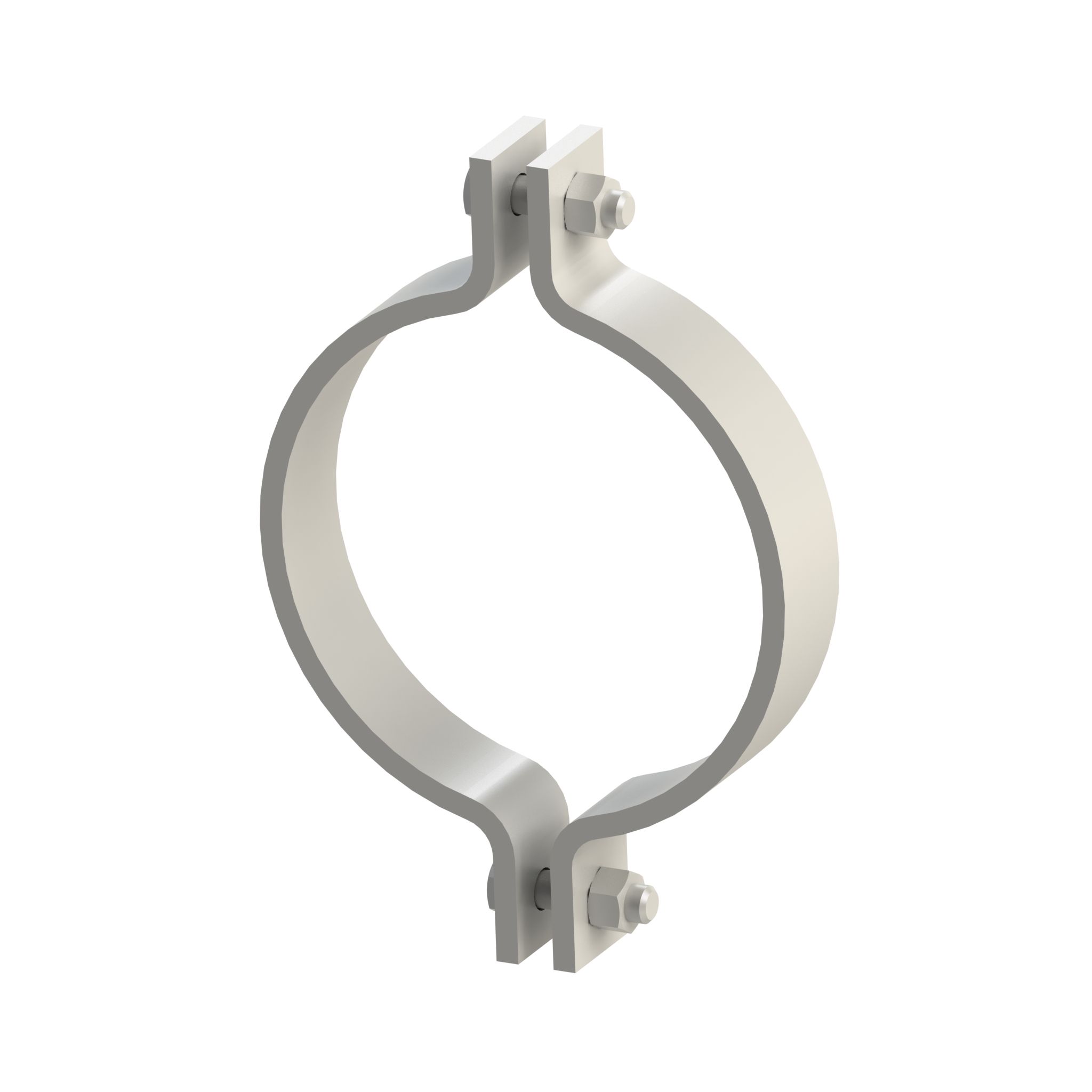

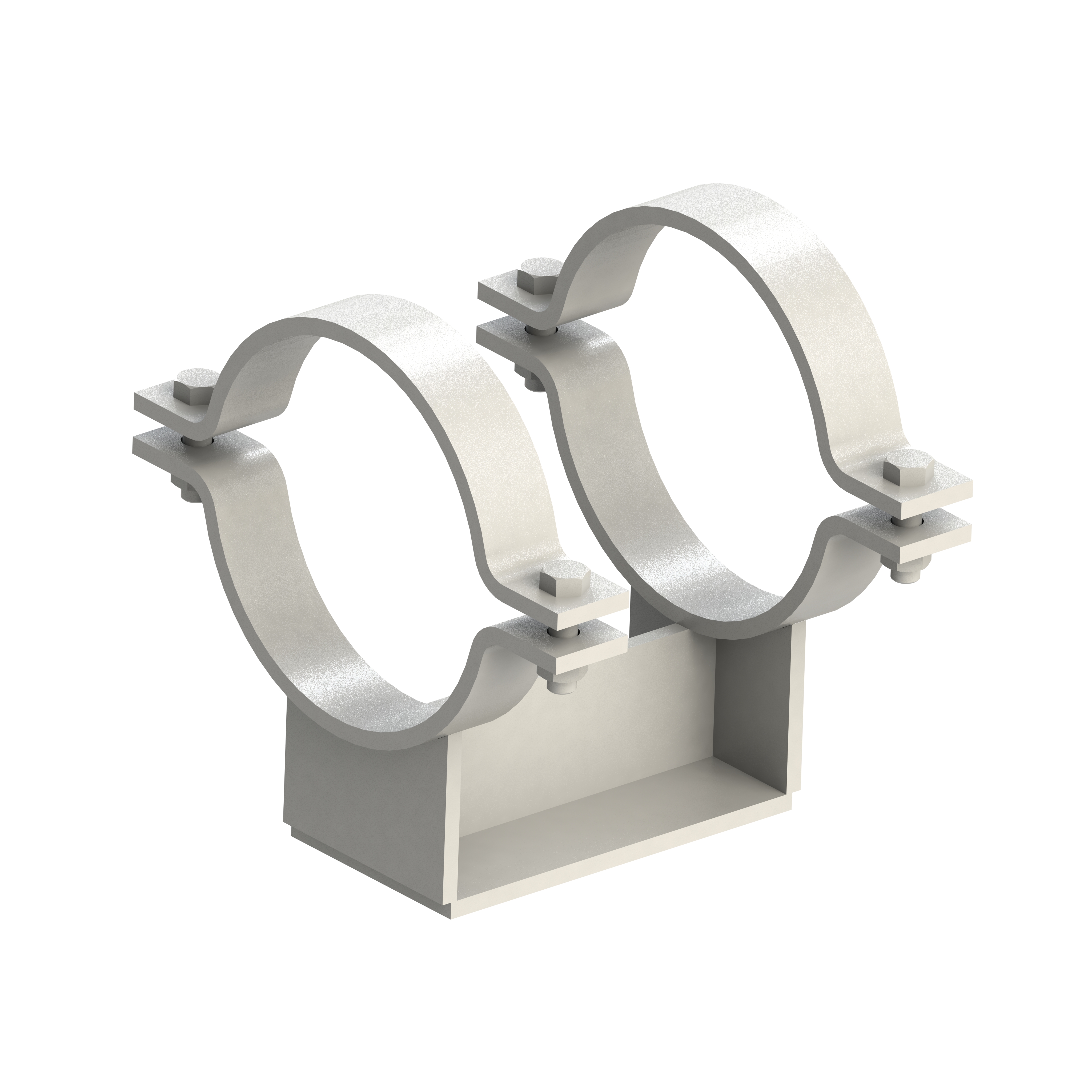

BG100

BG100LIGHT DUTY 2-BOLT CLAMP

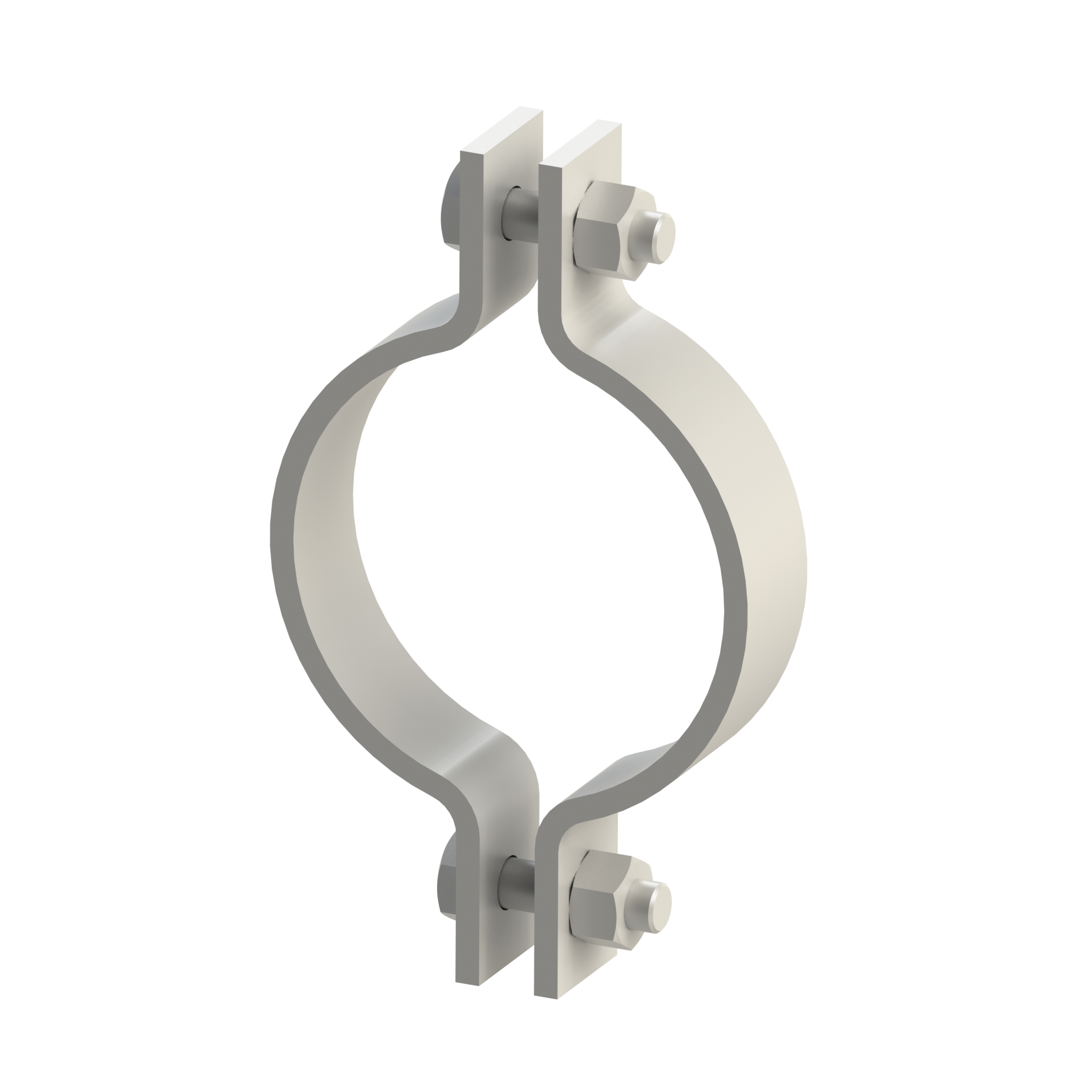

BG170

BG170MEDIUM DUTY 2-BOLT PIPE CLAMP

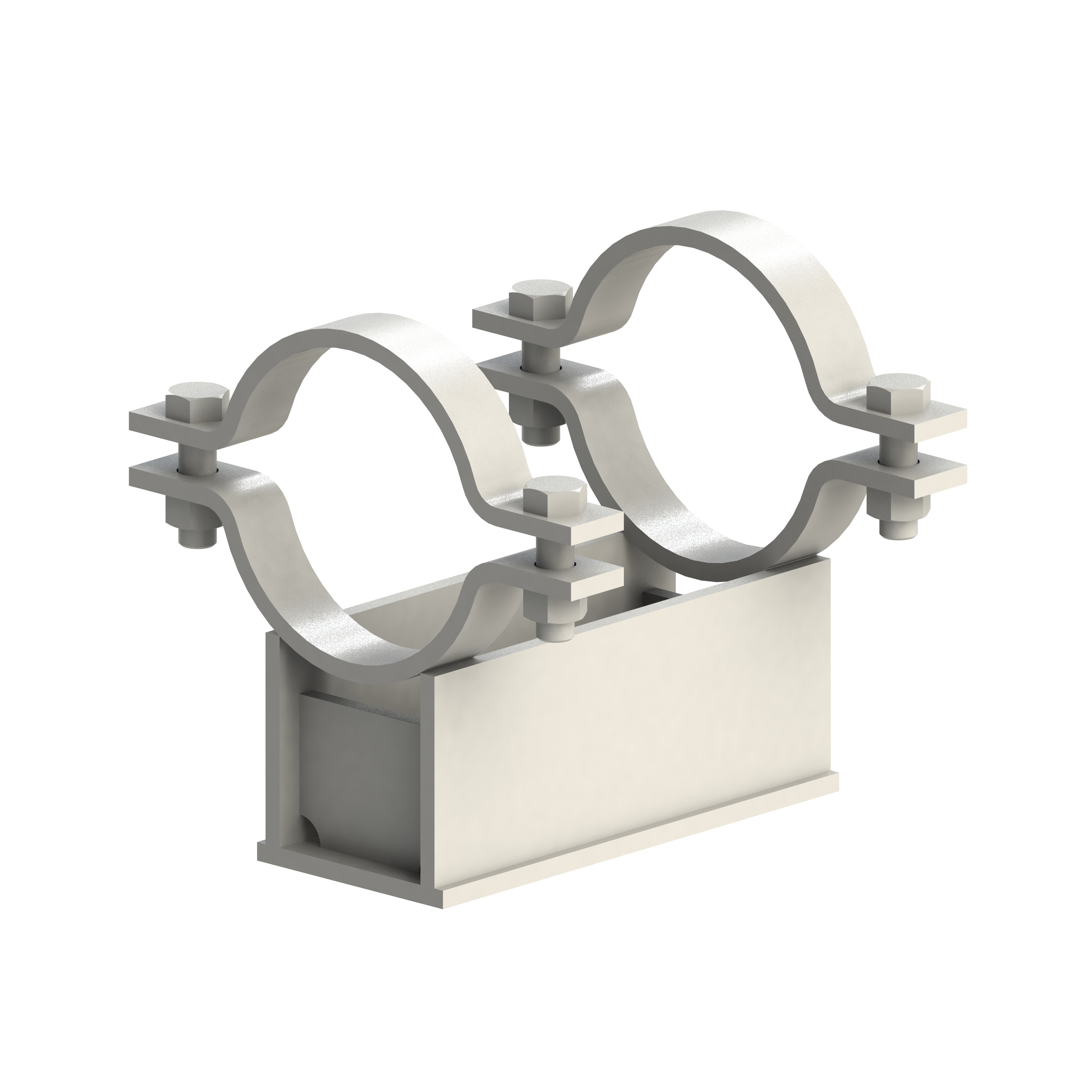

BG50

BG50HEAVY DUTY 2-BOLT PIPE CLAMP

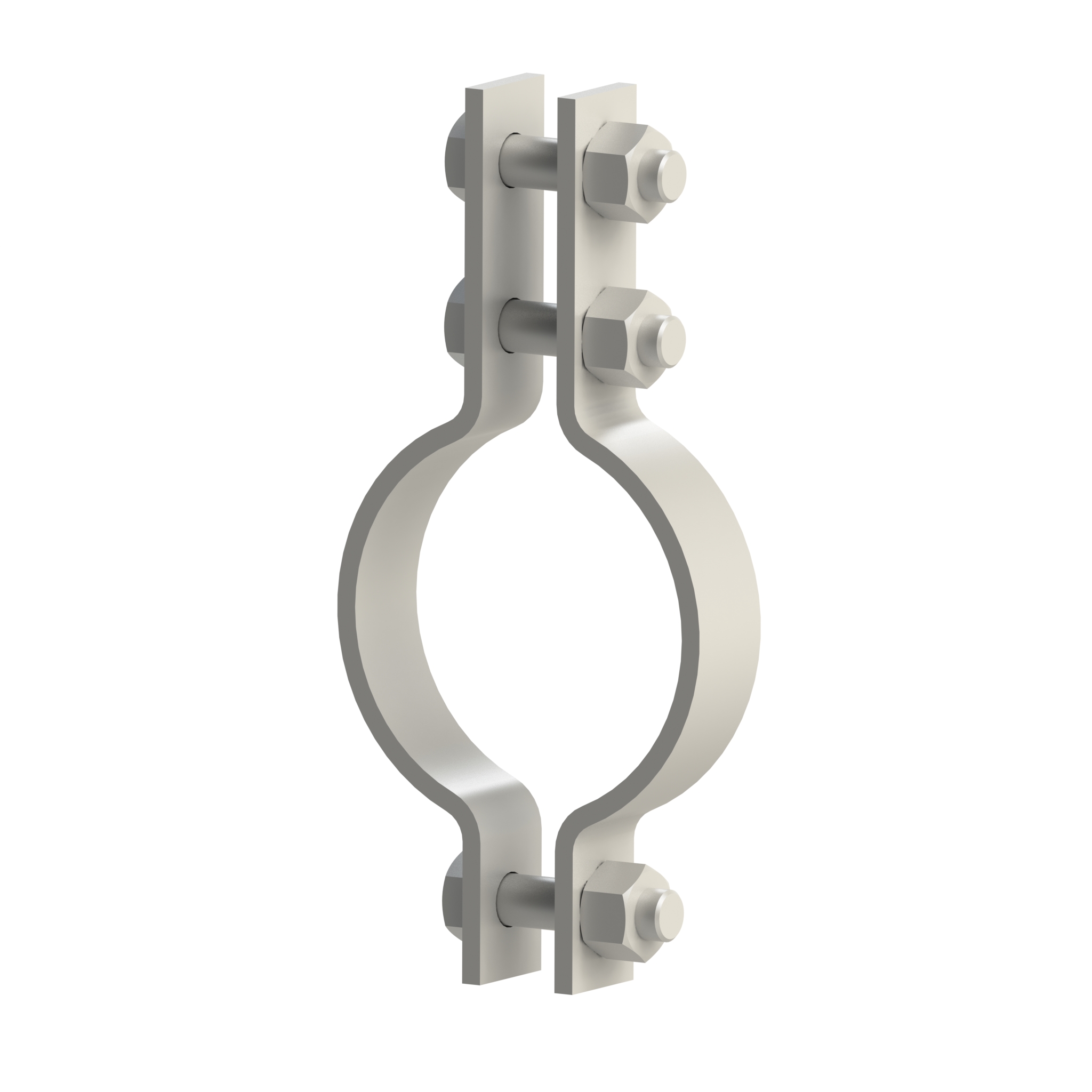

BG101

BG101LIGHT DUTY 3-BOLT PIPE CLAMP

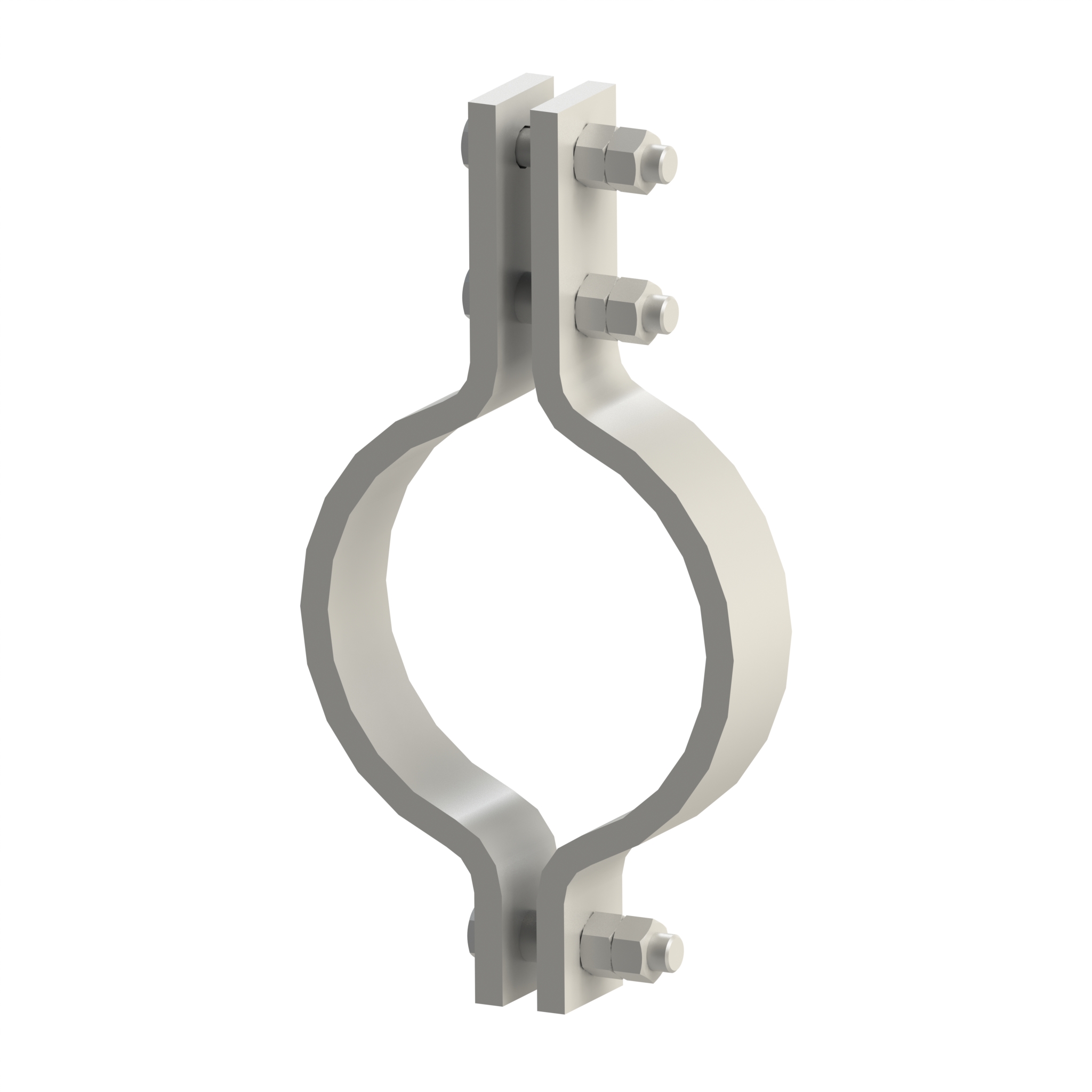

BG171

BG171MEDIUM DUTY 3-BOLT PIPE CLAMP FOR STEEL PIPE

BG75

BG75HEAVY DUTY 3-BOLT PIPE CLAMP

BG172

BG172HIGH TEMPERATURE 3-BOLT PIPE CLAMP

BG173

BG173ALLOY PIPE CLAMP - VERY HIGH TEMPERATURE

BG140

BG140INSULATED 2-BOLT PIPE CLAMP

BG141

BG141INSULATED 2-BOLT PIPE CLAMP FOR CU/NI

BG145

BG145INSULATED 3-BOLT PIPE CLAMP

BG146

BG146INSULATED 3-BOLT PIPE CLAMP FOR CU/NI

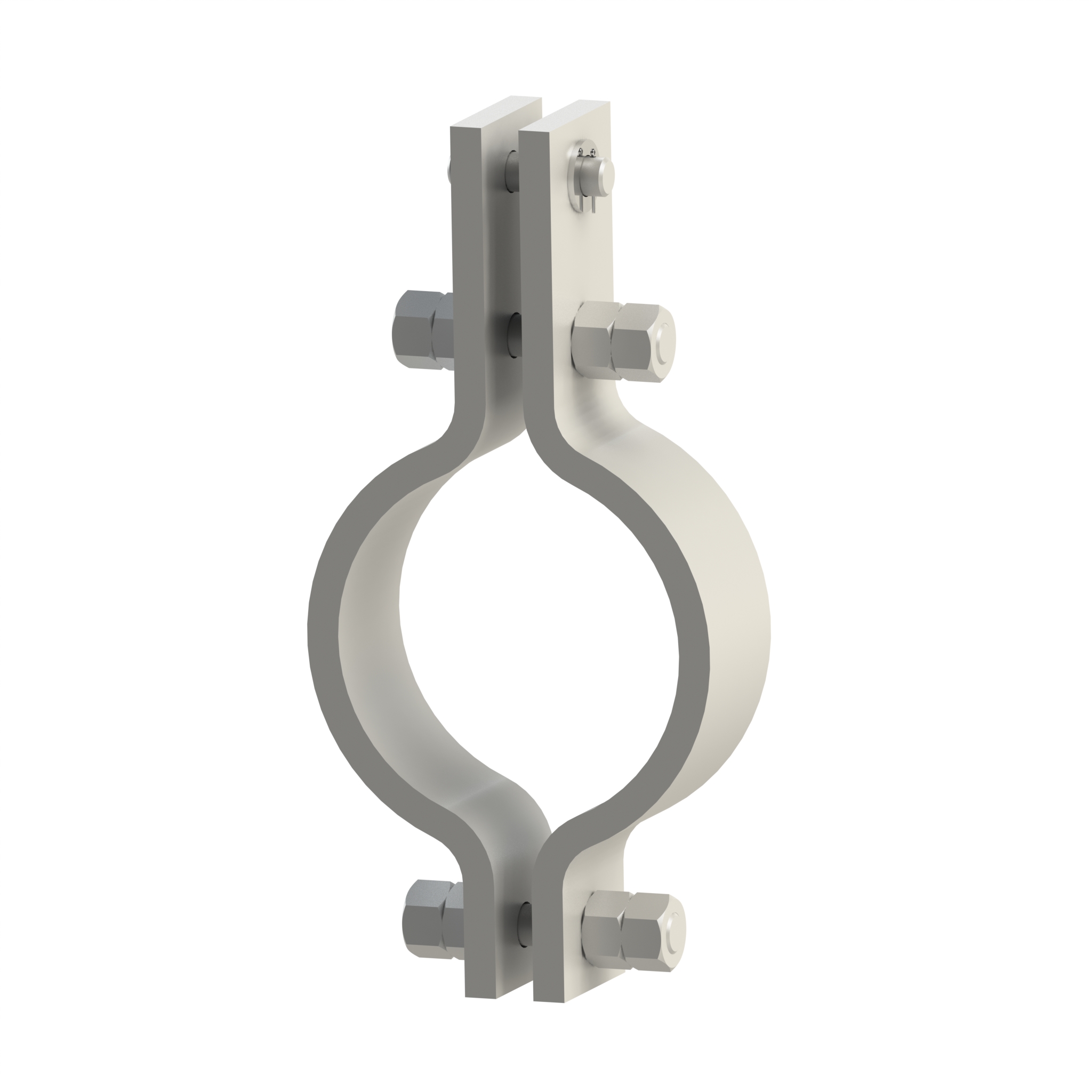

BG108

BG108CLEVIS CLAMP

BG222

BG222BEAM CLAMP

BG174

BG174RISER SUPPORT – STD TEMPERATURE

BG175

BG175RISER SUPPORT – HIGH TEMPERATURE

BG176

BG176ALLOY RISER SUPPORT - VERY HIGH TEMPERATURE

BG202

BG202ALLTHREAD ROD

BG209

BG209FORGED CLEVIS AND PIN

BG210

BG210FORGED TURNBUCKLE

BG204

BG204FORGED WELDLESS EYE NUT

BG215

BG215HEMISPHERICAL CUP

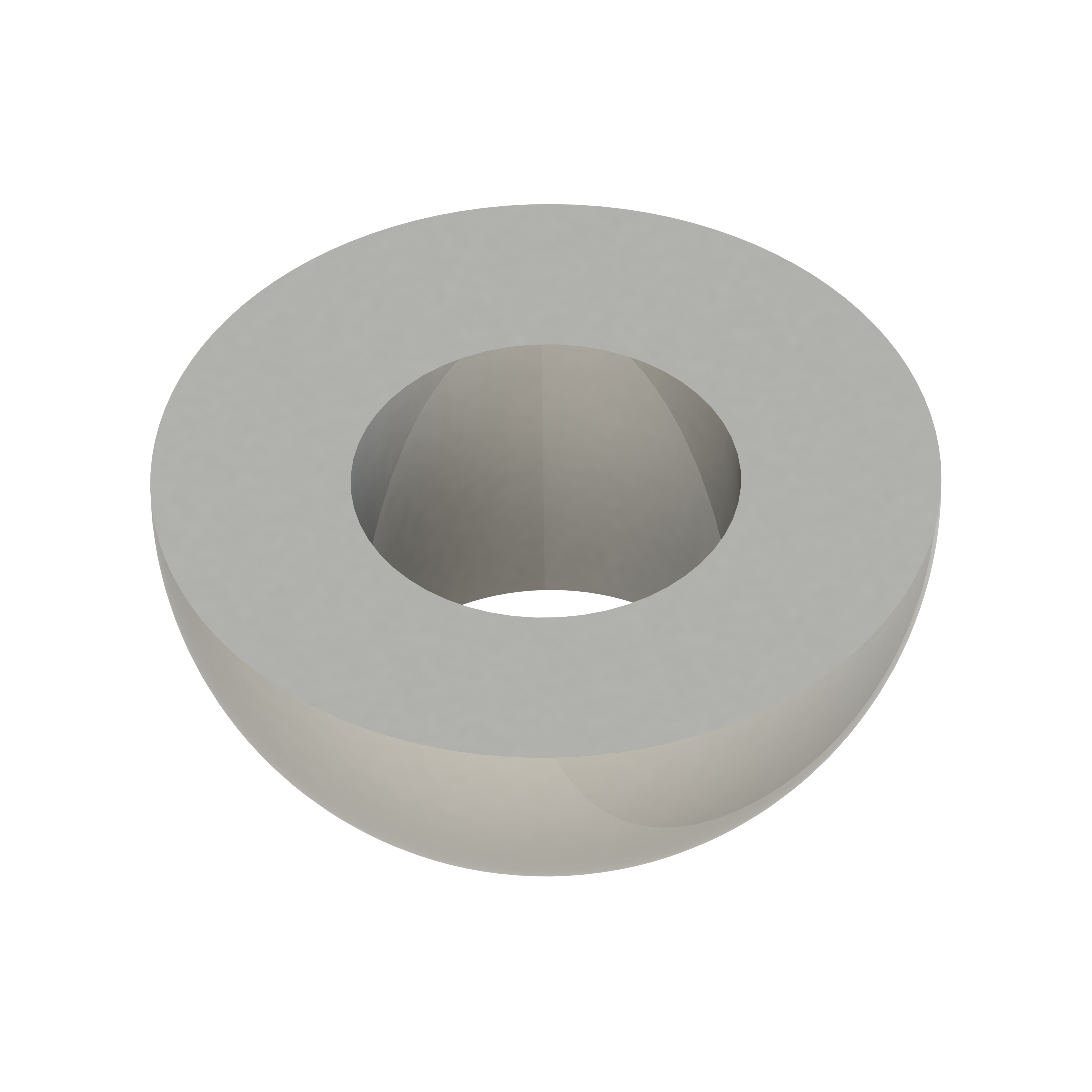

BG214

BG214HEMISPHERICAL WASHER

BG206

BG206HEXAGONAL CONNECTOR

BG216

BG216PIPE WELDING LUG

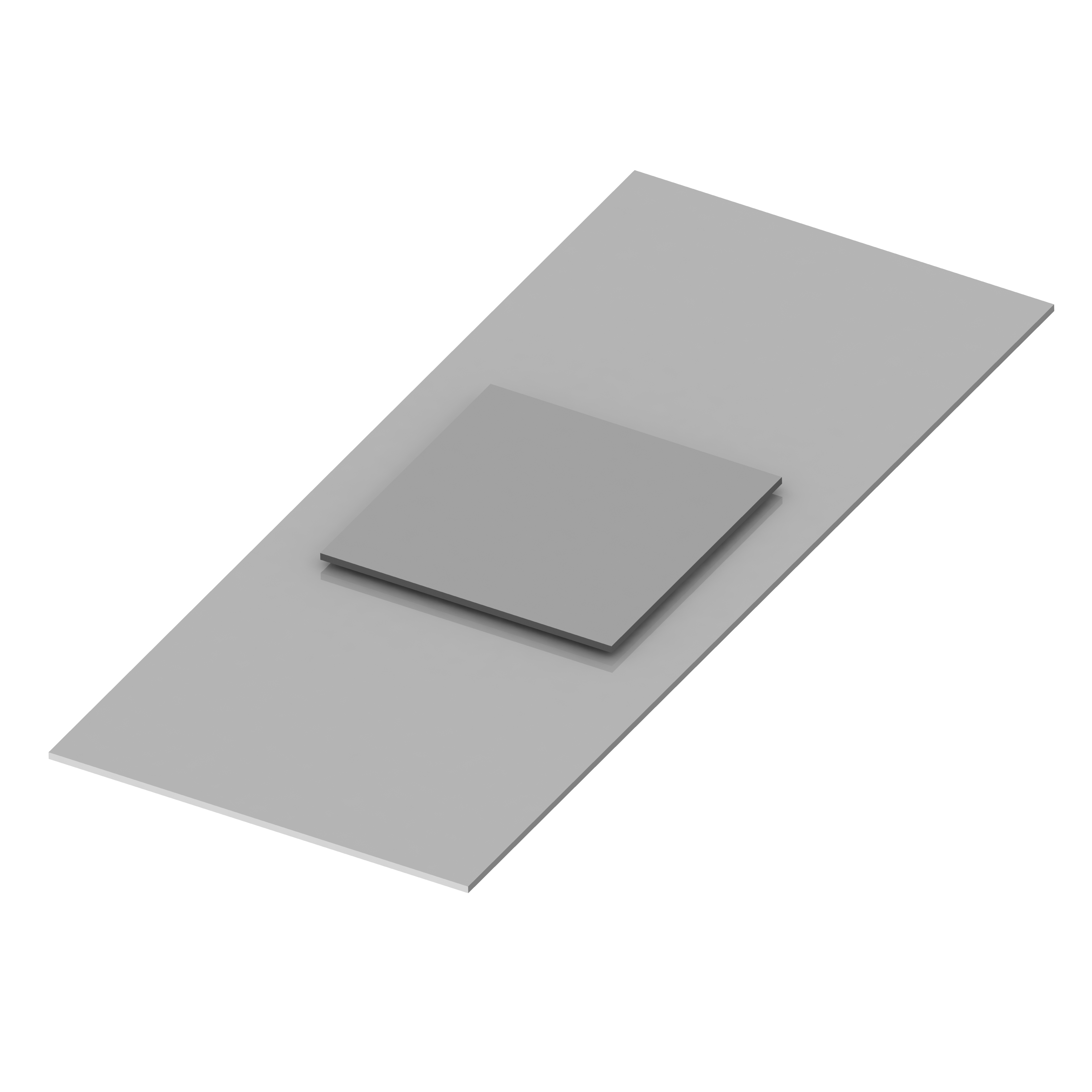

BG217

BG217PLATE WASHER

BG207

BG207SPADE NUT

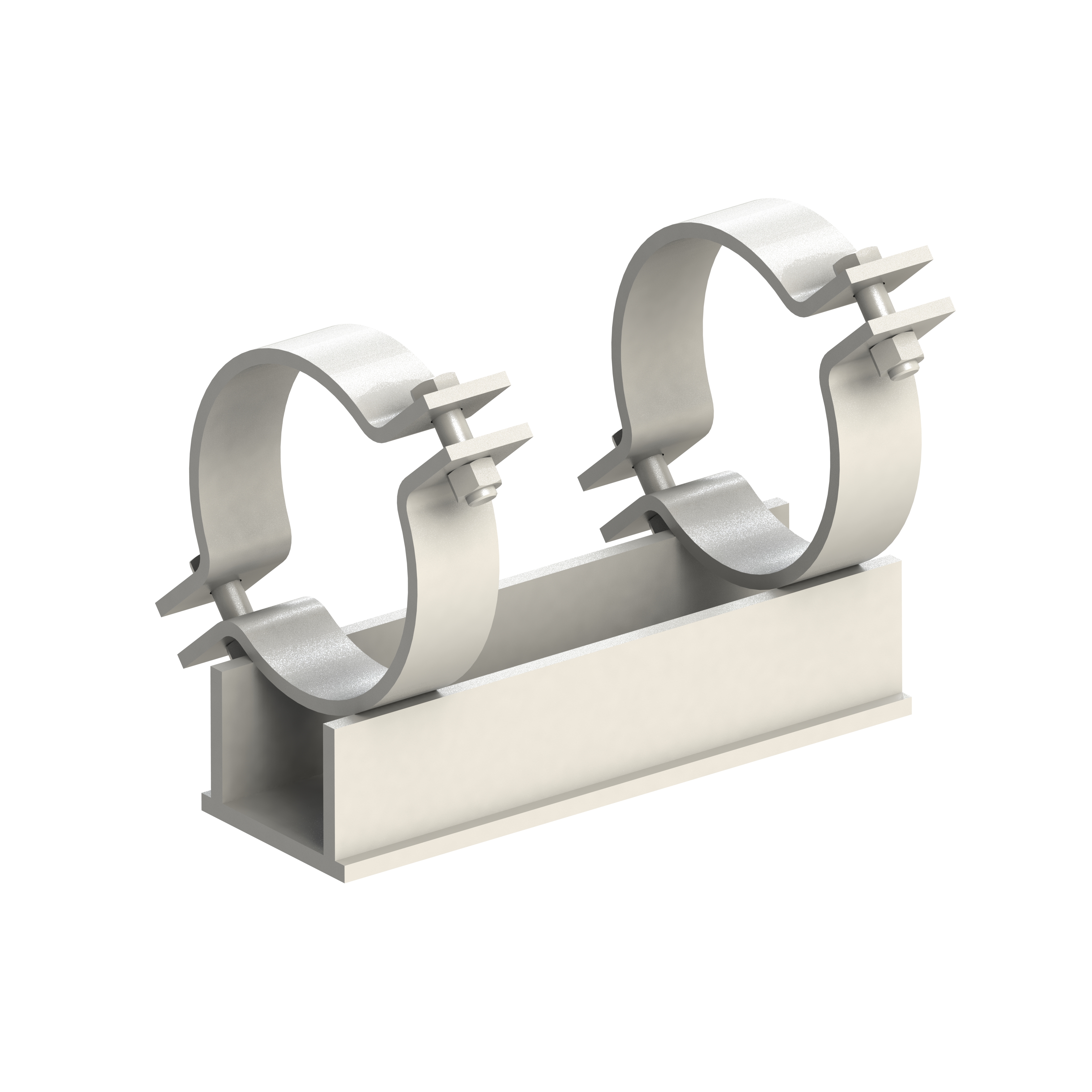

BG245

BG245STANDARD TRAPEZE

BG203

BG203THREADED DROP ROD – RH/LH

BG219

BG219WELDED BEAM ATTACHMENT

BG220

BG220WELDED BEAM ATTACHMENT (WITH LOAD PIN)

BG225

BG225WELDING LUG

BG180

BG180U-BOLT GUIDE

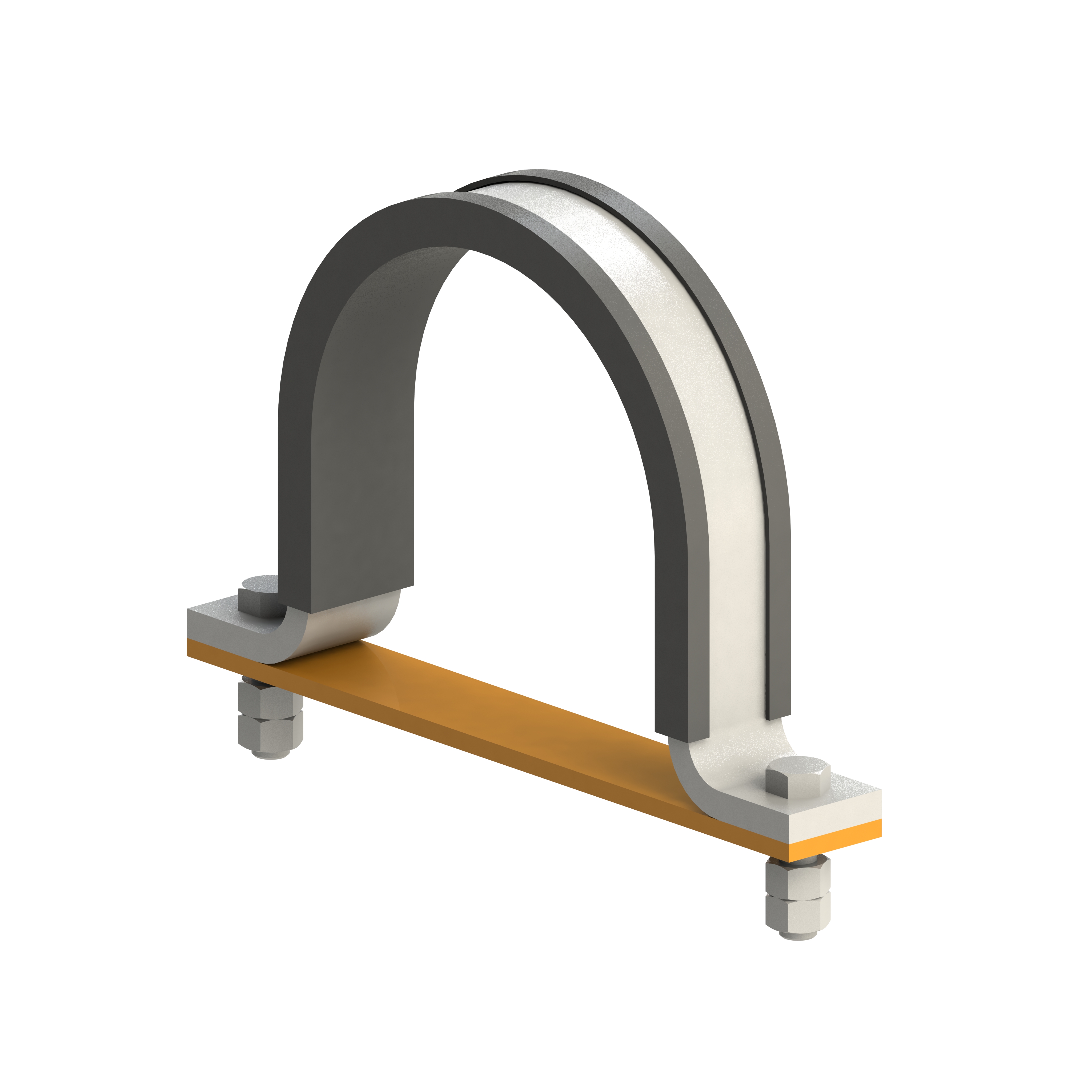

BG181

BG181U-BOLT CLAMP

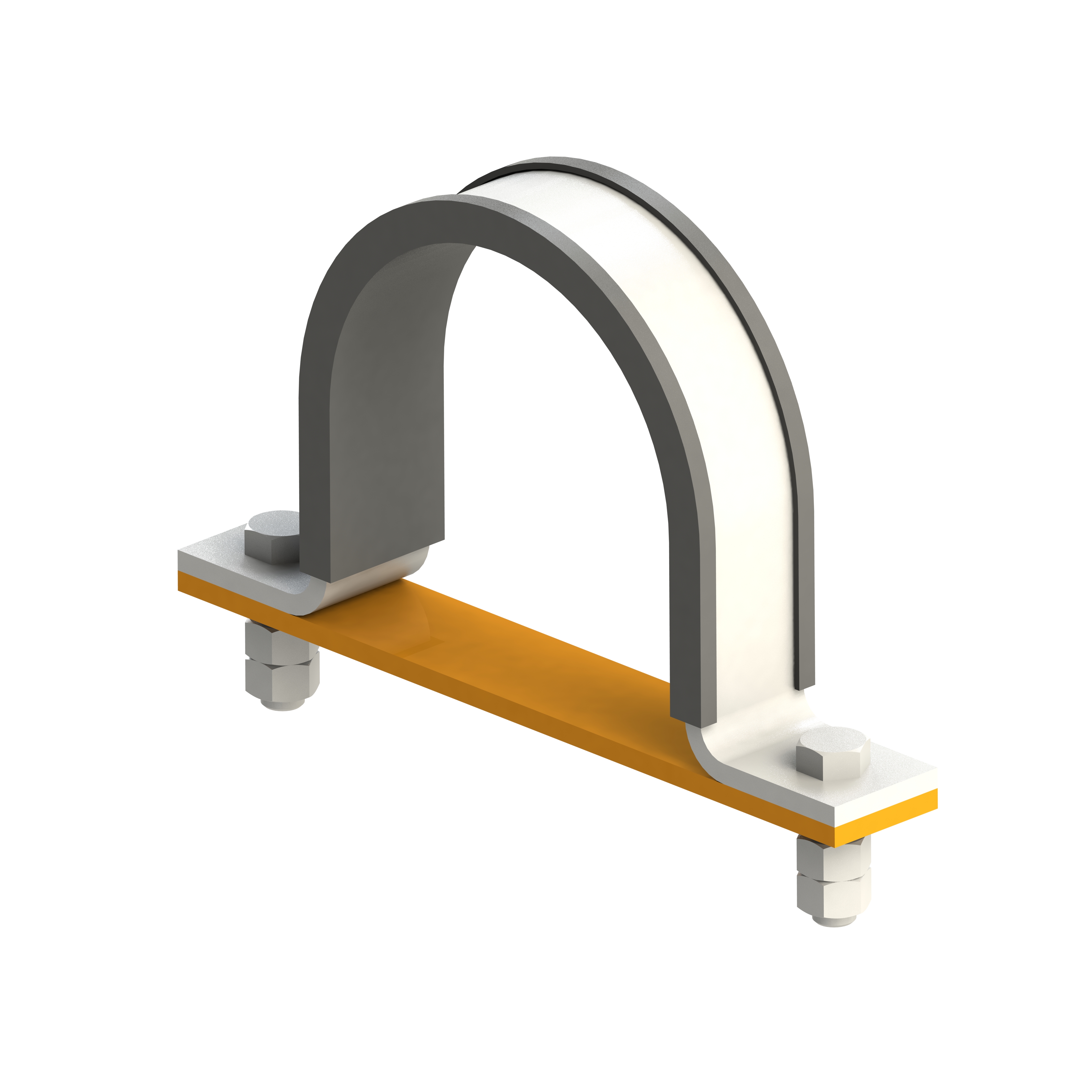

BG150

BG150INSULATED U-BOLT CLAMP

BG152

BG152INSULATED U-BOLT GUIDE

BG154

BG154INSULATED U-BOLT GUIDE (WITH TEFLON)

BG190

BG190INSULATED U-BOLT CLAMP

BG192

BG192INSULATED U-BOLT GUIDE

BG151

BG151INSULATED U-BOLT CLAMP FOR CU/NI

BG153

BG153INSULATED U-BOLT GUIDE FOR CU/NI

For Cu/Ni Pipe BG155

BG155INSULATED U-BOLT GUIDE (WITH TEFLON)

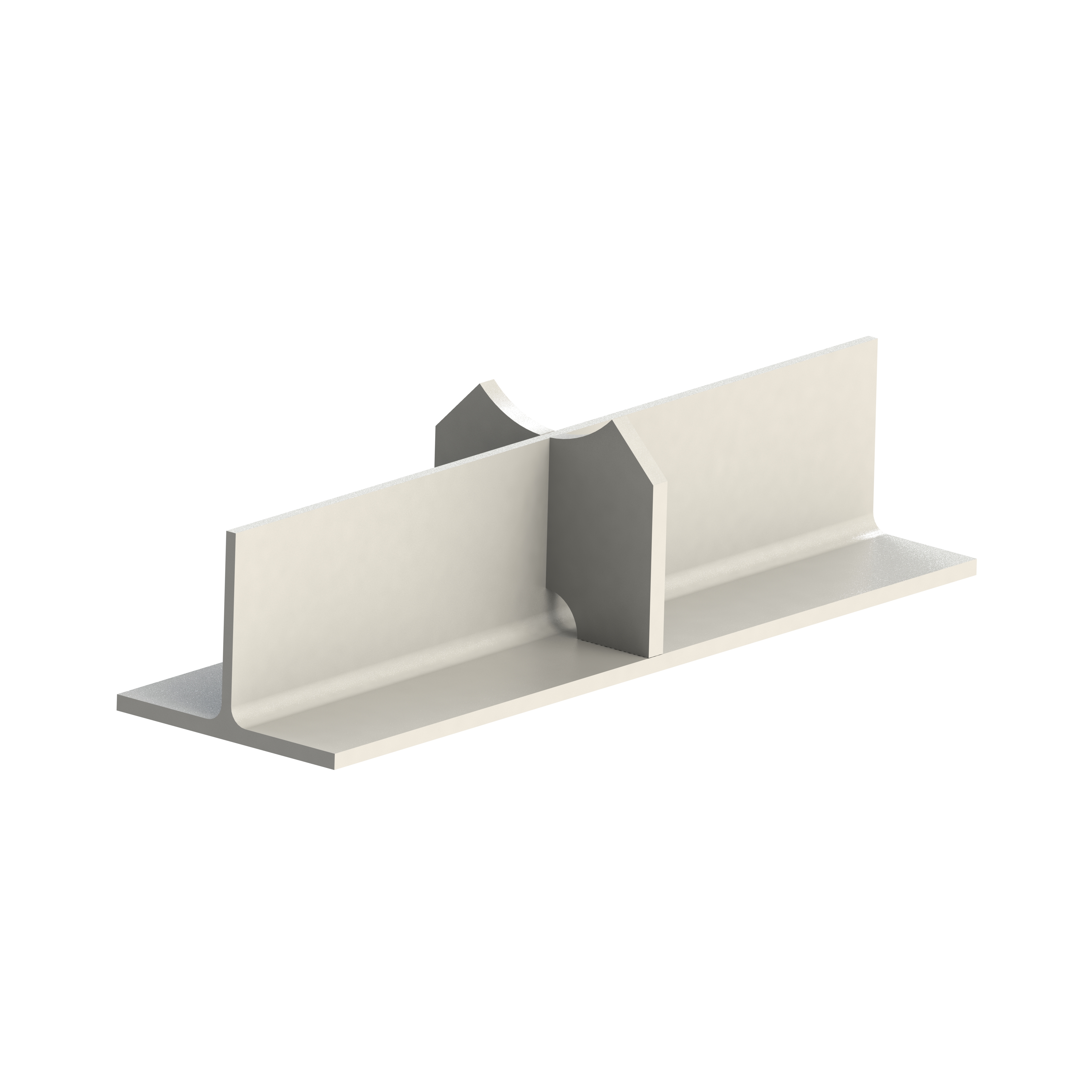

For Cu/Ni Pipe BG177

BG177SADDLE GUIDE

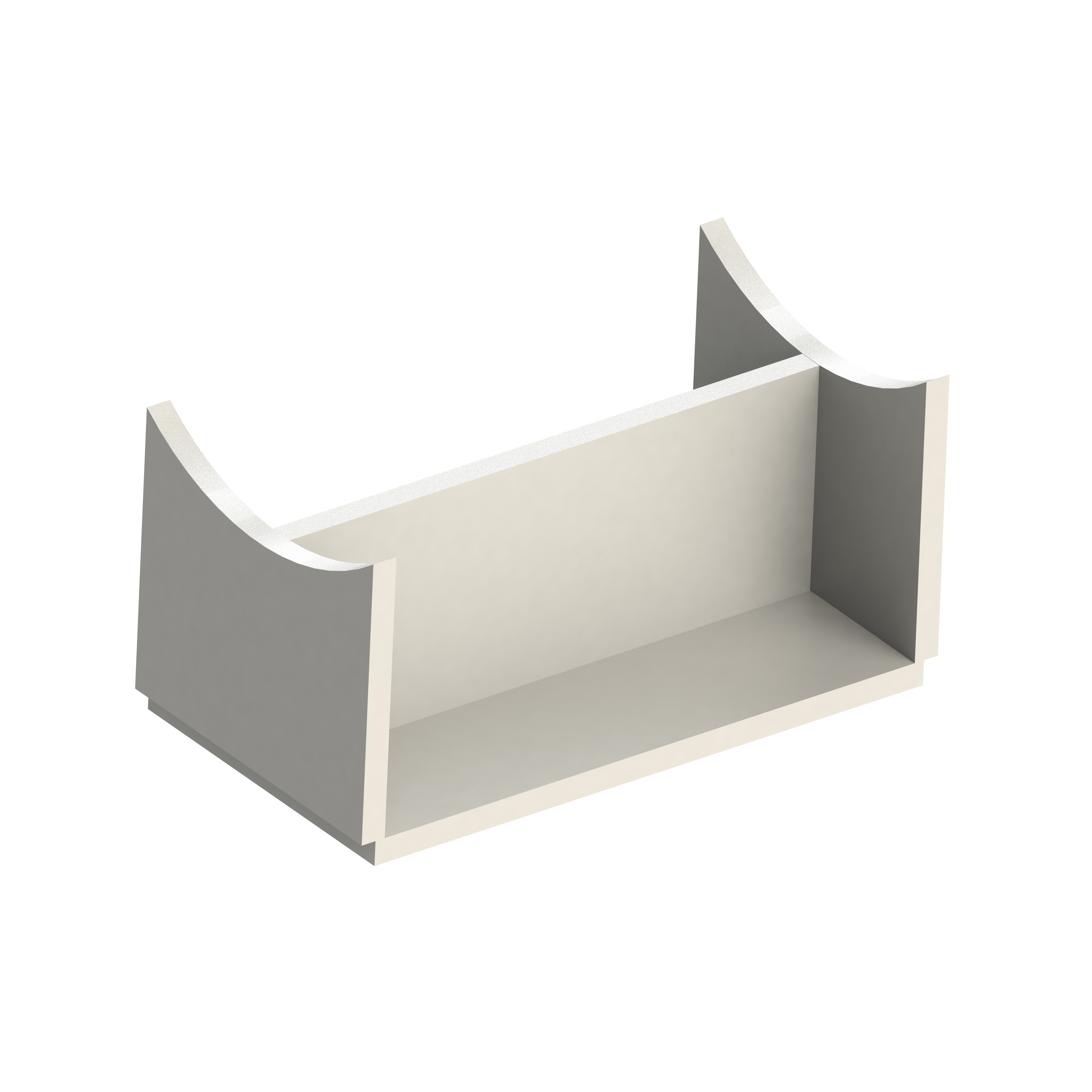

BG178

BG178SADDLE CLAMP

BG160

BG160INSULATED PIPE SADDLE

BG161

BG161INSULATED PIPE SADDLE

BG162

BG162INSULATED PIPE SADDLE

BG135-136

BG135-136ADJUSTABLE PIPE STANDS

BG515

BG515STANDARD CLAMPED PIPE SHOE

BG550

BG550SLIDE PLATES

BG517

BG517COMPACT PIPE SHOE

BG400

BG400CLAMPED HOT PIPE SHOE

BG156

BG156INSULATED PIPE SHOE

BG157

BG157INSULATED PIPE SHOE

BG510

BG510STANDARD WELDED PIPE SHOE

BG518

BG518COMPACT WELDED PIPE SHOE

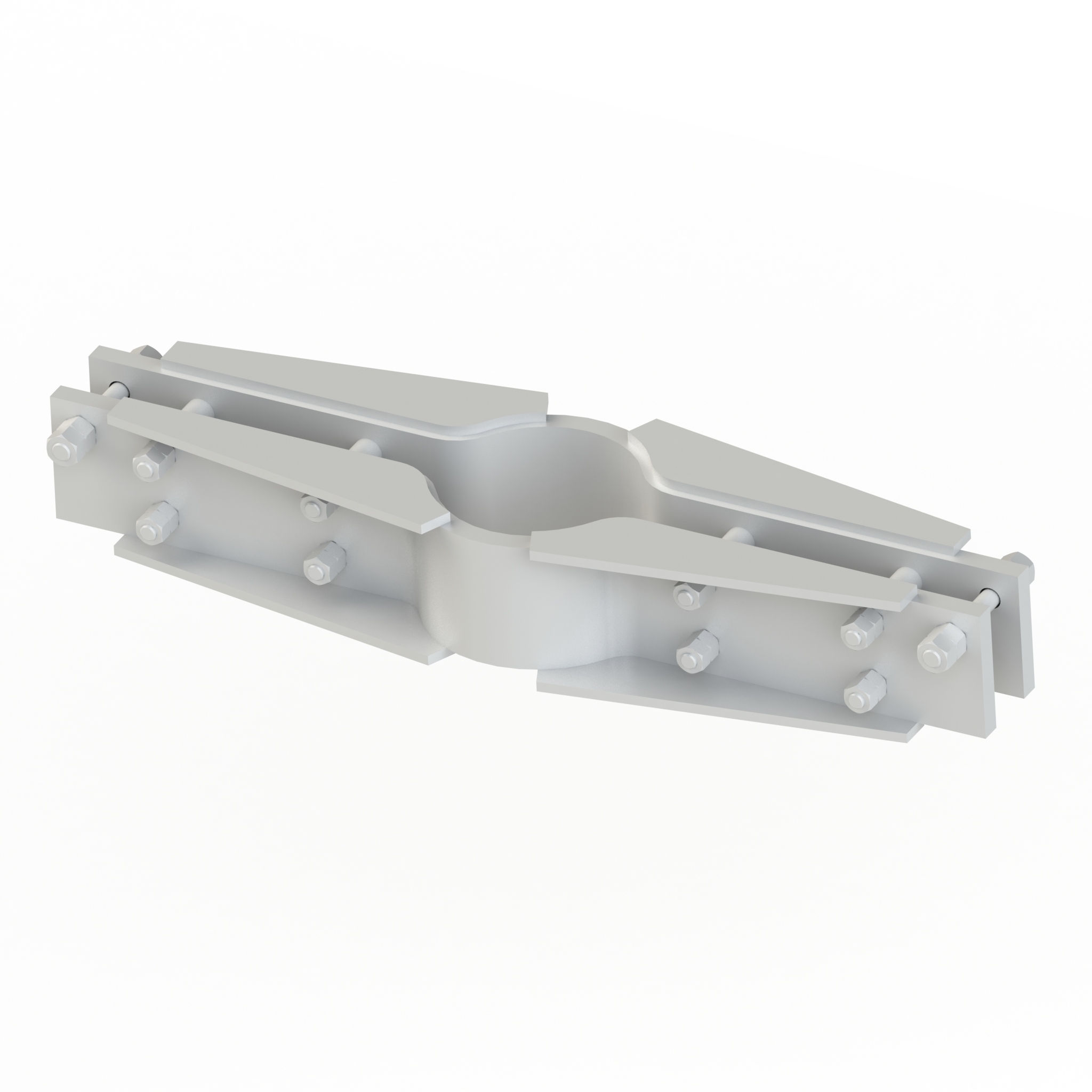

BG555

BG555STANDARD LINE STOPS

BG560

BG560STANDARD PIPE GUIDES

BG570

BG570STANDARD SHOE GUIDES

BG580

BG580STANDARD SHOE GUIDES

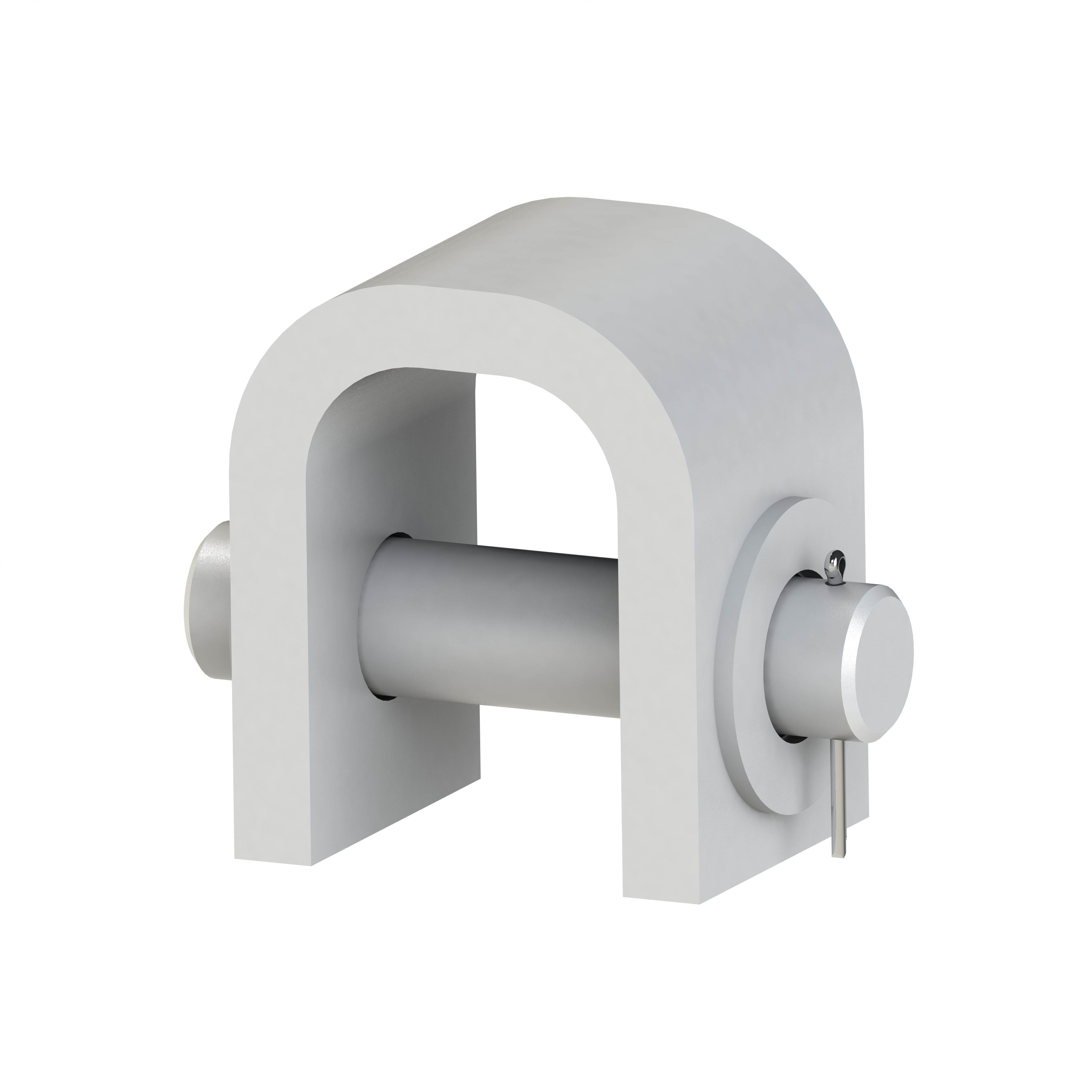

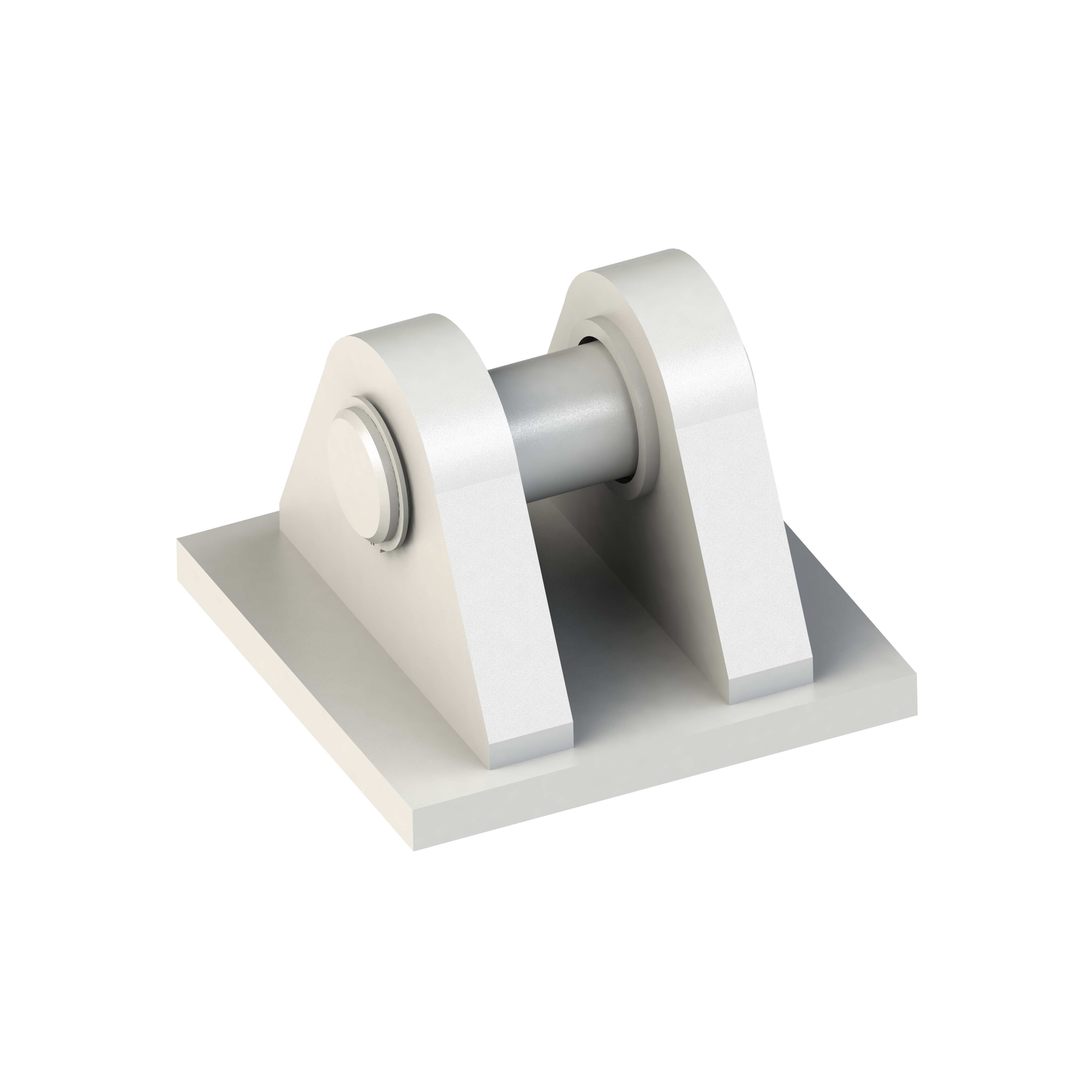

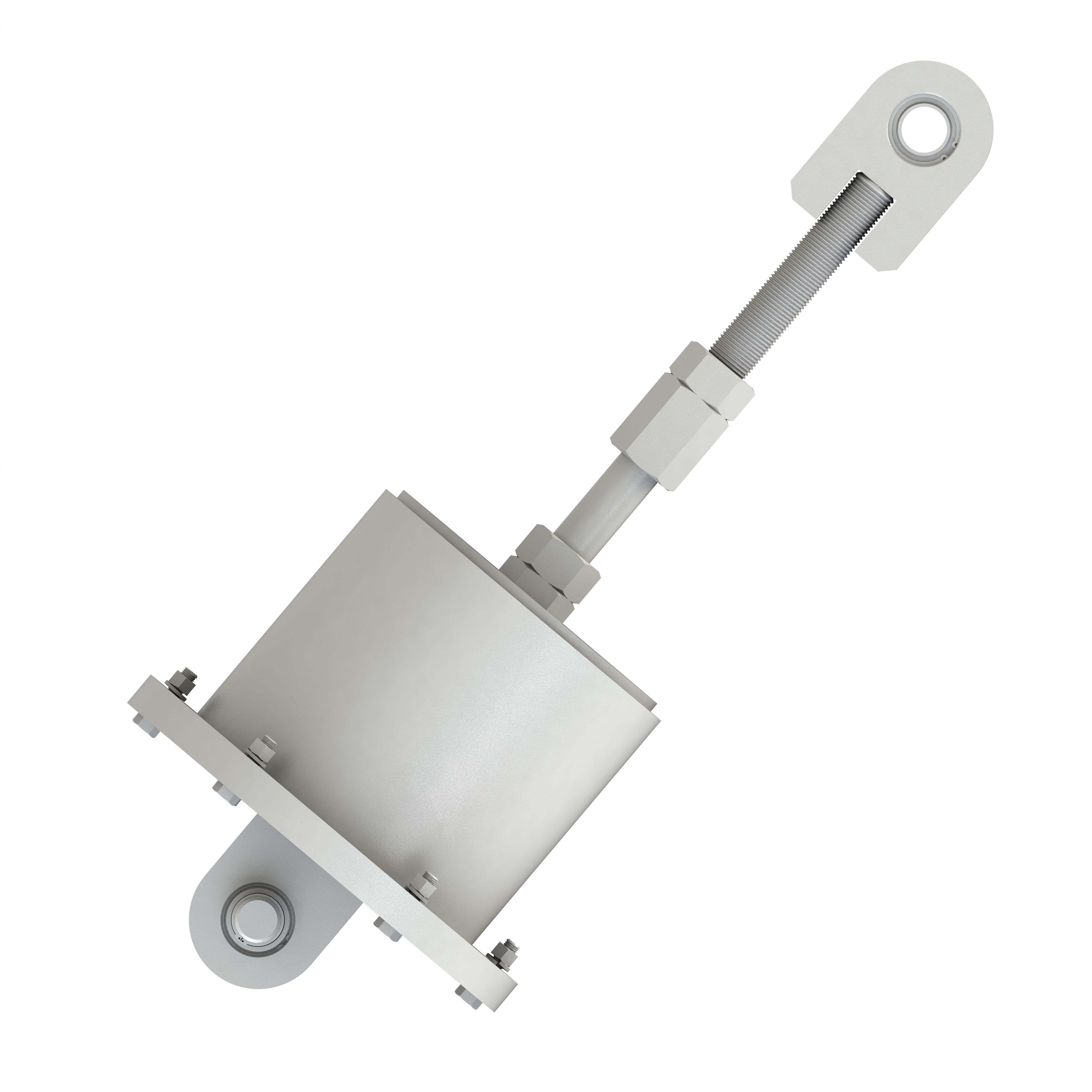

BG315

BG315END ATTACHMENT FOR HYDRAULIC SNUBBERS

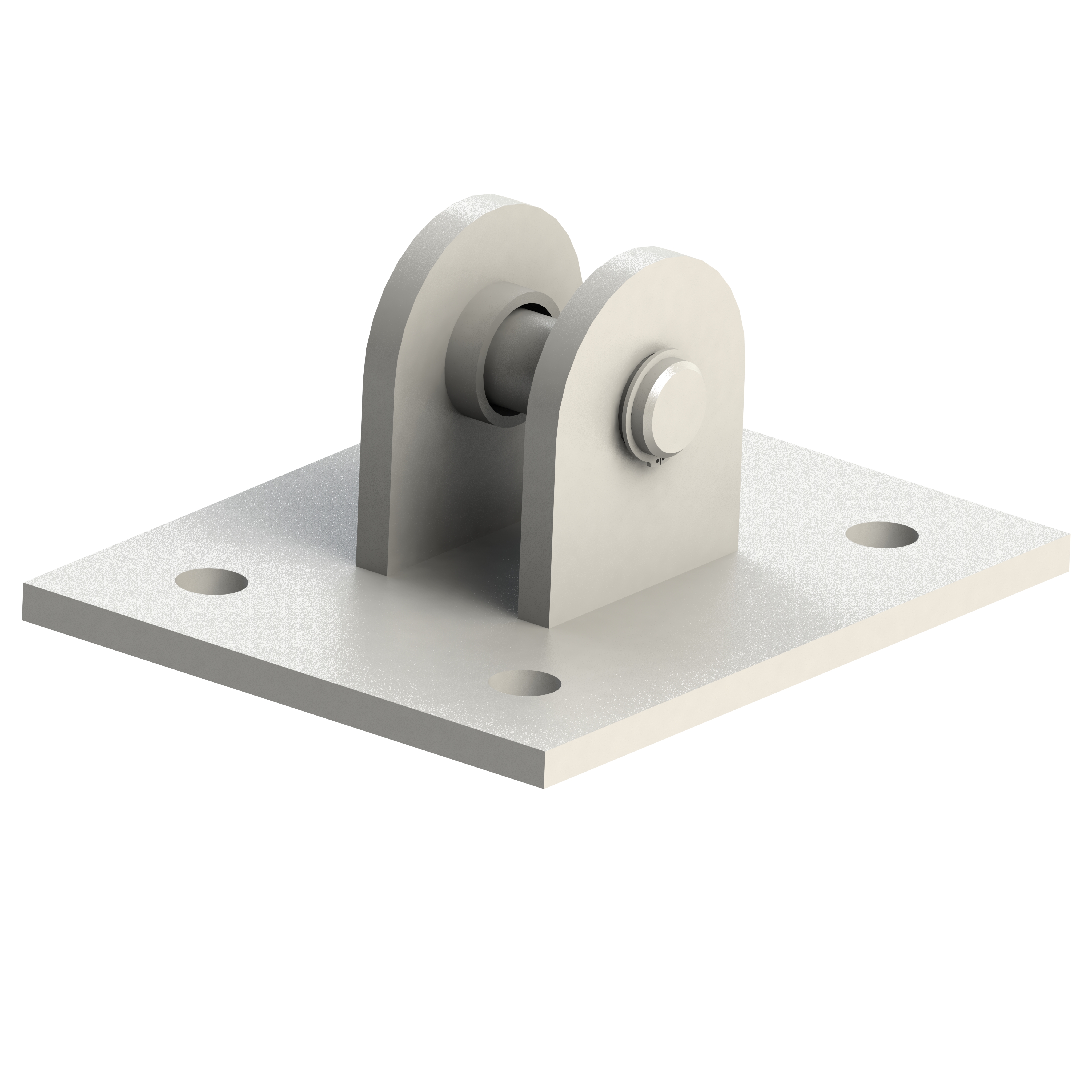

BG355

BG355END ATTACHMENT FOR RIGID STRUT & SWAY BRACE

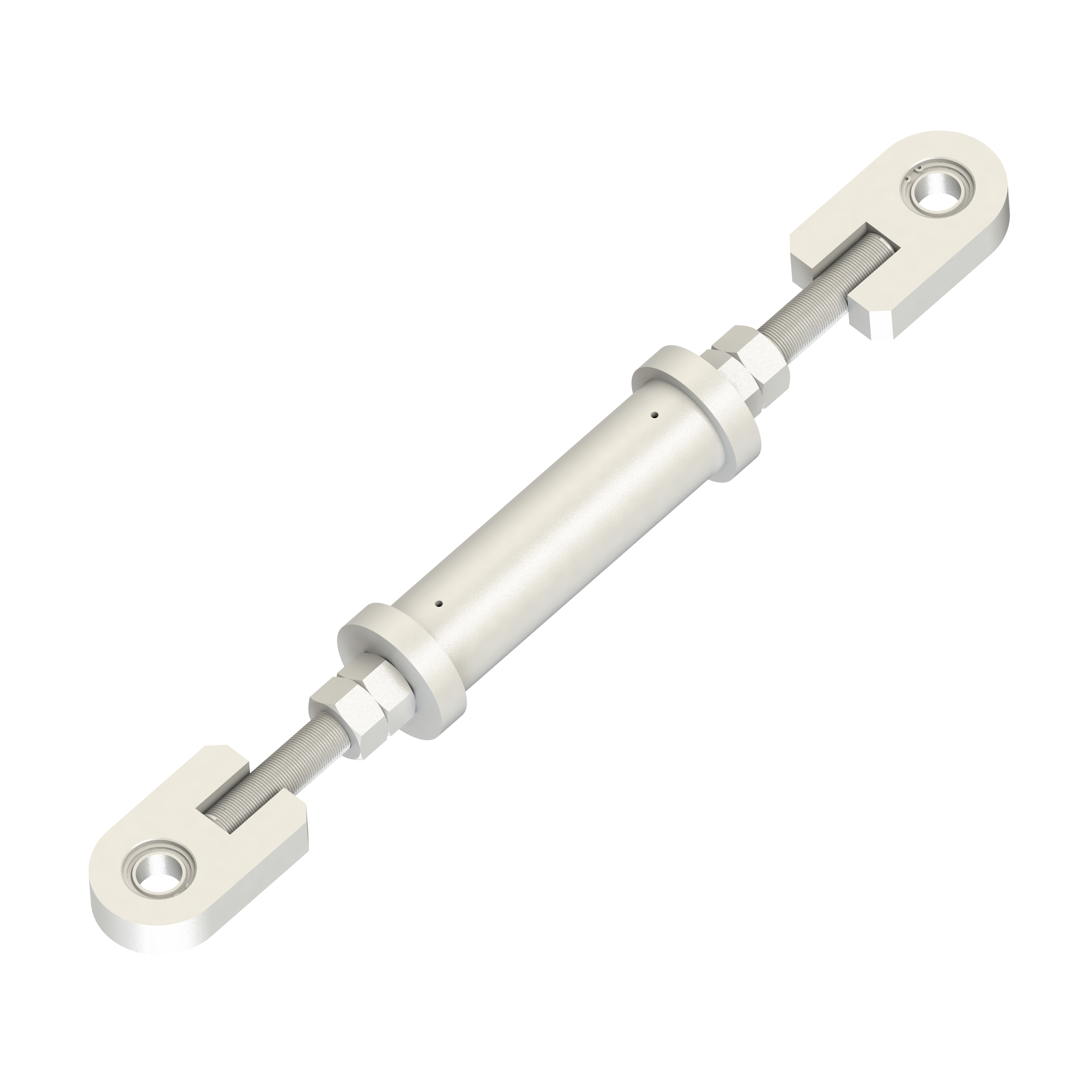

BG310

BG310HYDRAULIC SNUBBERS (SHOCK ARRESTORS)

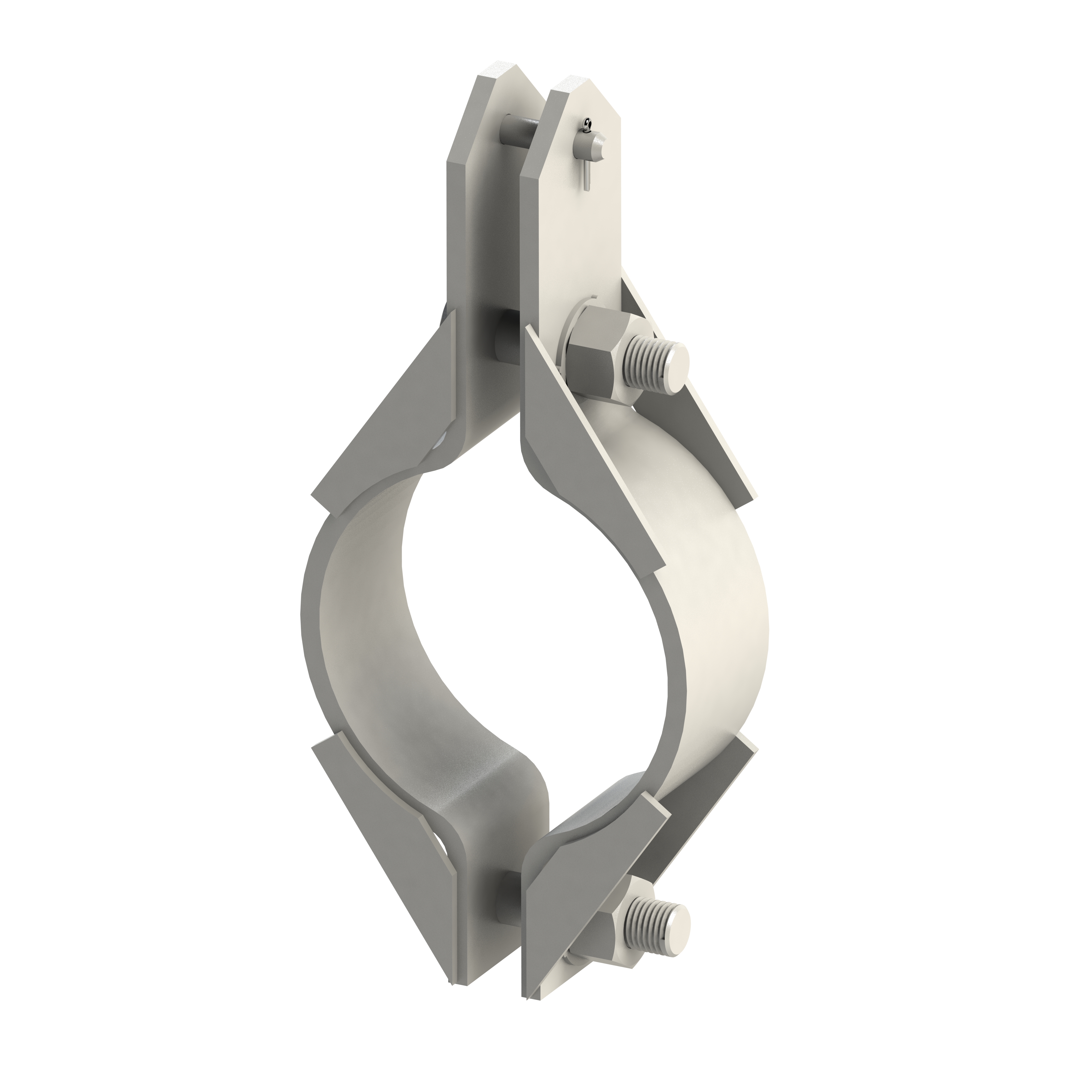

BG321

BG321PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG322

BG322PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG320

BG320PIPE CLAMP FOR HYDRAULIC SNUBBER – LOW TEMPERATURE

BG350

BG350RIGID STRUTS

BG340

BG340SWAY BRACE

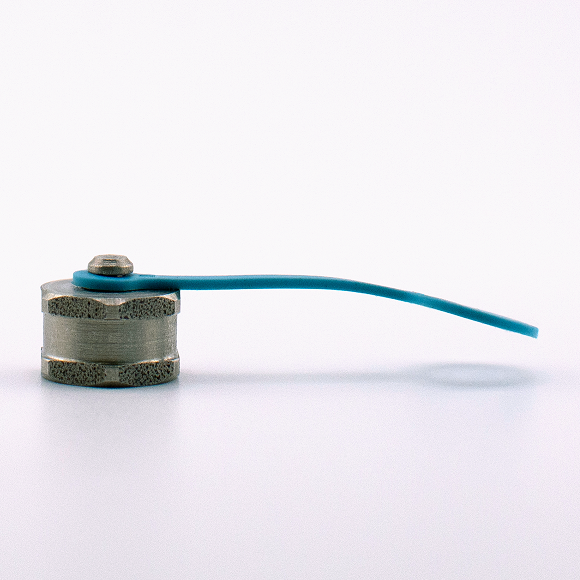

#691028

#691028All Stainless Steel Gauge Adapter #691028

#520XL

#520XLAll Stainless Steel Gauge Adapter #520XL

#691023

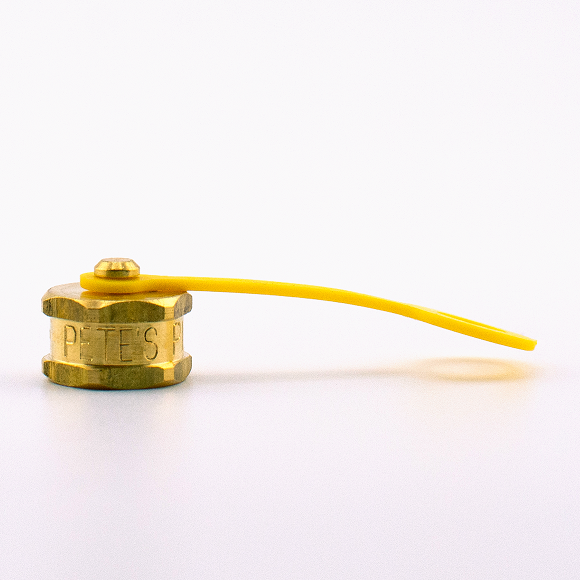

#691023Brass Gauge Adapter #691023

#500BSP

#500BSPBrass Gauge Adapter #500BSP

#691024

#691024Brass Gauge Adapter #691024

#500XLBSP

#500XLBSPBrass Gauge Adapter #500XLBSP

691026

691026Brass Gauge Adapter #691026

#691027

#691027Brass Gauge Adapter #691027

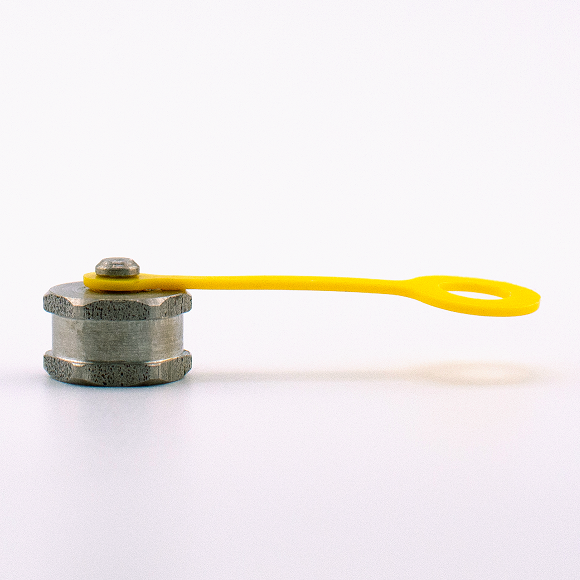

#104-1BS

#104-1BSCap Assembly #104-1BS

#104-1YS

#104-1YSCap Assembly #104-1YS

#104-2BS

#104-2BSCap Assembly #104-2BS

#104-2YS

#104-2YSCap Assembly #104-2YS

#691003

#691003Pete's Plug #691003

#691002

#691002Pete's Plug #691002

#691010

#691010Pete's Plug #691010

#691001

#691001Pete's Plug #691001

#691000

#691000Pete's Plug #691000

#691017

#691017Pete's Plug #691017

#12510

#12510Pete's Plug #12510

691020

691020Pete's Plug #691020

#691008

#691008Pete's Plug #691008

#691005

#691005Pete's Plug #691005

#691007

#691007Pete's Plug #691007

#691004

#691004Pete's Plug #691004

#572

#572Pete's Plug #572

#691019

#691019Pete's Plug #691019

#691018

#691018Pete's Plug #691018

#760

#760Pete's Plug #760

#691016

#691016Pete's Plug #691016

#691022

#691022Pete's Plug #691022

#691021

#691021Pete's Plug #691021

#691014

#691014Pete’s Plug #691014

#691013

#691013Pete’s Plug #691013

#562

#562Pete’s Plug #562

#691012

#691012Pete’s Plug #691012

#691011

#691011Pete’s Plug #691011

#750XL

#750XLPete’s Plug #750XL

#691015

#691015Pete’s Plug #691015

#691029

#691029Pressure & Temperature Test Kit 0-100psi

#691030

#691030Pressure & Temperature Test Kit 0-100psi for XL

#1500-5

#1500-5Pressure Gauge 0-100 PSI BSP Stem

#1500-4

#1500-4Pressure Gauge 0-100 PSI NPT Stem

#606

#606Thermometer -58°F to 550°F

-

-

-

- About

- Resources

- Contact

Downtime Costs Millions: Why Investing in High-Quality Pipe Supports Pays Off

In Australia’s heavy industries, the cost of unplanned downtime is not just a nuisance; it is a major financial threat. The average cost of downtime for Australian industrial businesses sits at $349,000 AUD per hour, substantially higher than the global average of $194,000 AUD. In high-risk sectors like mining and oil and gas, strategic investments in infrastructure, including something as overlooked as pipe supports, can have an outsized impact on operational continuity and financial stability.

High-quality pipe supports are often treated as a secondary consideration, yet failures here can trigger significant downtime and costly repercussions. Understanding how these seemingly small components affect the bigger financial picture is key to safeguarding operations and reputation.

Downtime’s Real Cost in Heavy Industry

Australian mining operations alone are at risk of losing upwards of $130,000 to $180,000 AUD per hour during downtime incidents, with industry-wide losses reaching an estimated $10 billion AUD annually. These figures put into sharp relief the fragility of operational uptime in resource-driven sectors.

Globally, manufacturing industries are burdened with more than $50 billion USD in annual losses due to downtime. Given the size and scale of Australia’s mining and energy industries, the cost pressure is even more acute domestically. A single equipment failure can ripple through supply chains, delaying deliverables, escalating repair costs, and exposing companies to reputational damage.

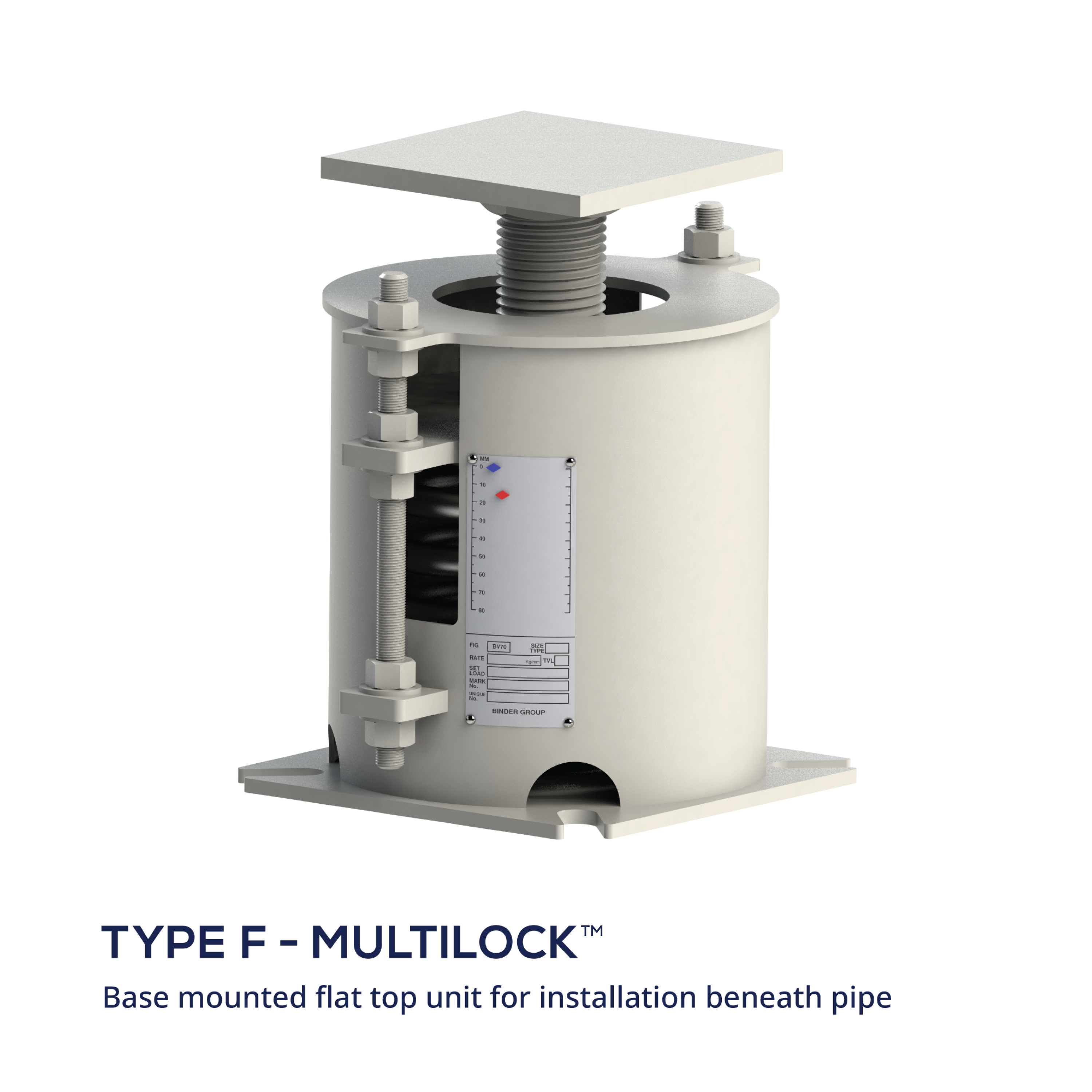

Pipe Supports: A Small Part with Outsized Risk

When infrastructure fails, the assumption is often that the fault lies with major systems like compressors, turbines, or processing equipment. But neglected elements like pipe supports can be an invisible risk. A failed pipe support may not only disrupt the pipeline itself but also cause structural damage to surrounding assets, magnifying repair costs and prolonging downtime.

Beyond immediate repair costs, companies face secondary financial risks:

- Equipment damage leading to extended shutdowns

- Safety incidents increasing liability exposure

- Regulatory fines tied to environmental breaches

- Contract penalties for delayed delivery

- Reputational harm that could cost future contracts

While precise figures on the percentage of downtime directly attributable to pipe support failures are limited, the risks they pose make them a crucial part of preventive infrastructure planning.

The Shift Toward Preventive Maintenance

Across Australia’s industrial landscape, preventive maintenance is gaining ground. A majority of companies acknowledge the cost benefits of moving from reactive “run-to-fail” maintenance, still used by around 24% of Australian businesses, to outcome-based maintenance strategies.

Preventive maintenance reduces unplanned downtime, and high-quality components play a crucial role in that effort. Durable pipe supports, engineered to withstand high loads, thermal expansion, and environmental stressors, extend the operating life of critical assets and reduce emergency interventions.

ABB’s survey found that 92% of businesses implementing reliability-centered maintenance saw improvements in operational uptime, with 38% reporting over 25% gains. This signals a clear trend: planned investments outperform reactive fixes, and support systems are a vital part of that investment.

Investing in Pipe Supports: More Than Just Hardware

Premium pipe supports are not just about holding pipes in place. They are engineered systems designed to:

- Absorb mechanical stress

- Compensate for thermal expansion and contraction

- Reduce vibration and fatigue on pipelines

- Support compliance with safety and industry standards

Ignoring the quality of these components risks pushing maintenance costs higher and damaging operational resilience. It is not just a purchase; it is an insurance policy against both direct and indirect costs.

Conclusion: A Strategic Move Toward Reliability

Project managers and procurement teams should view pipe supports not as a commodity but as a strategic investment. While the upfront cost is marginal compared to other infrastructure expenses, the financial consequences of failure can be immense.

Investing in engineered, high-quality pipe supports is a direct action to:

- Minimise downtime risk

- Protect budget integrity

- Preserve reputation

- Support regulatory compliance

In industries where every hour of downtime costs hundreds of thousands of dollars, seemingly small decisions like the choice of a pipe support can have major financial consequences. For companies committed to staying competitive, it is time to treat these components with the strategic importance they deserve.

Ready to Strengthen Your Infrastructure?

If you are reviewing your asset reliability strategy or want to discuss how engineered pipe supports can reduce your operational risks, get in touch with the Binder team. We will help you find a solution designed to keep your operations running and downtime off your balance sheet.