- Products

-

-

-

Categories

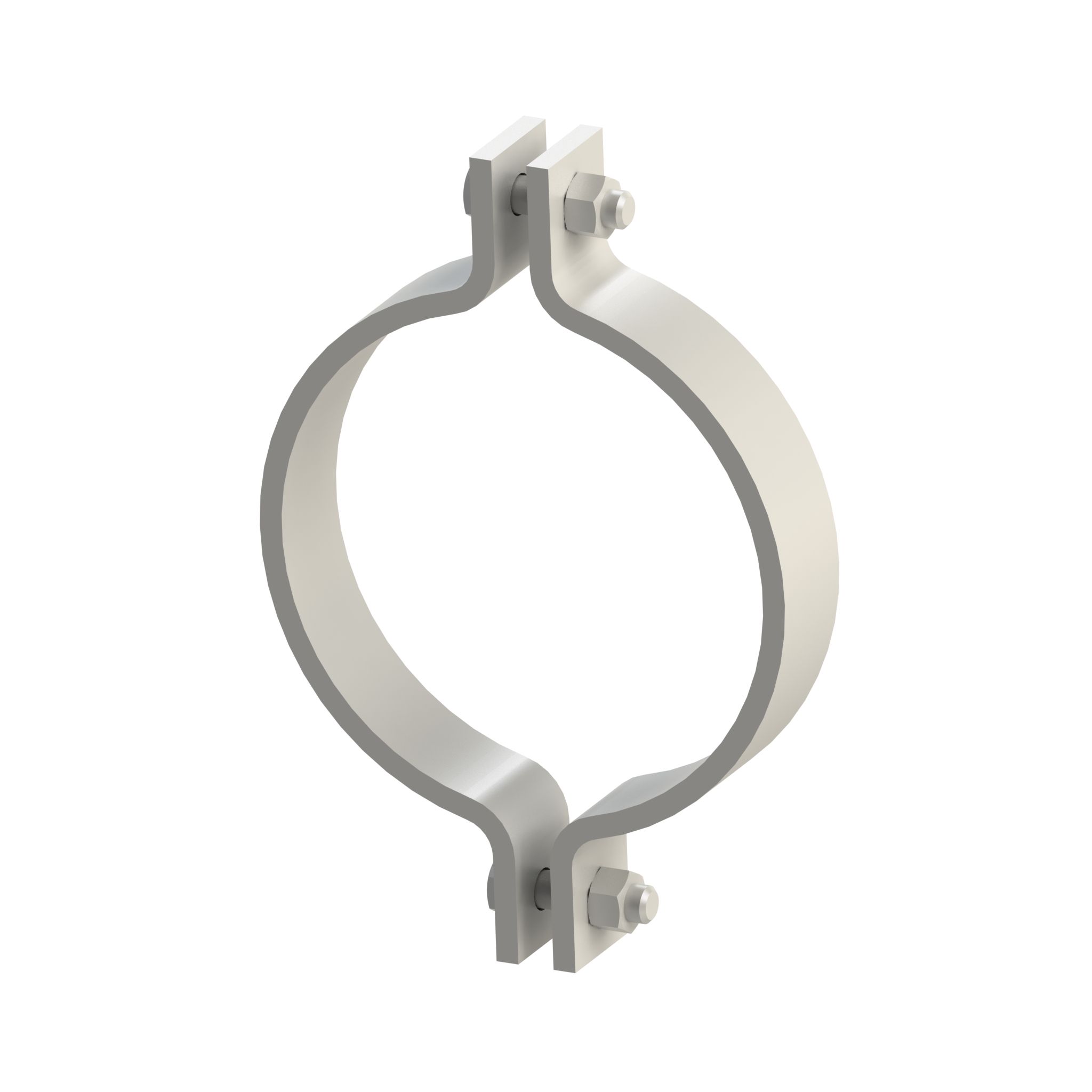

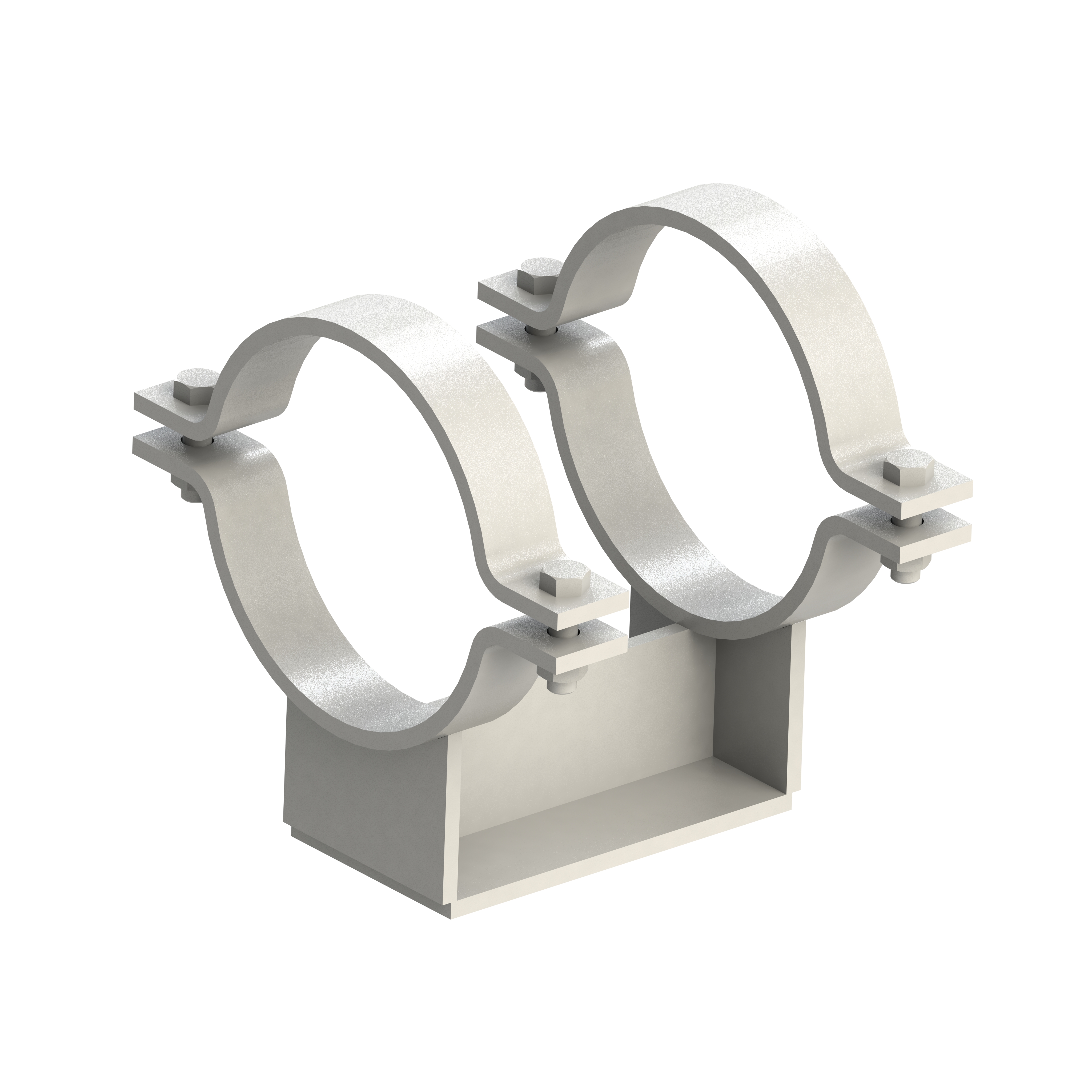

BG100

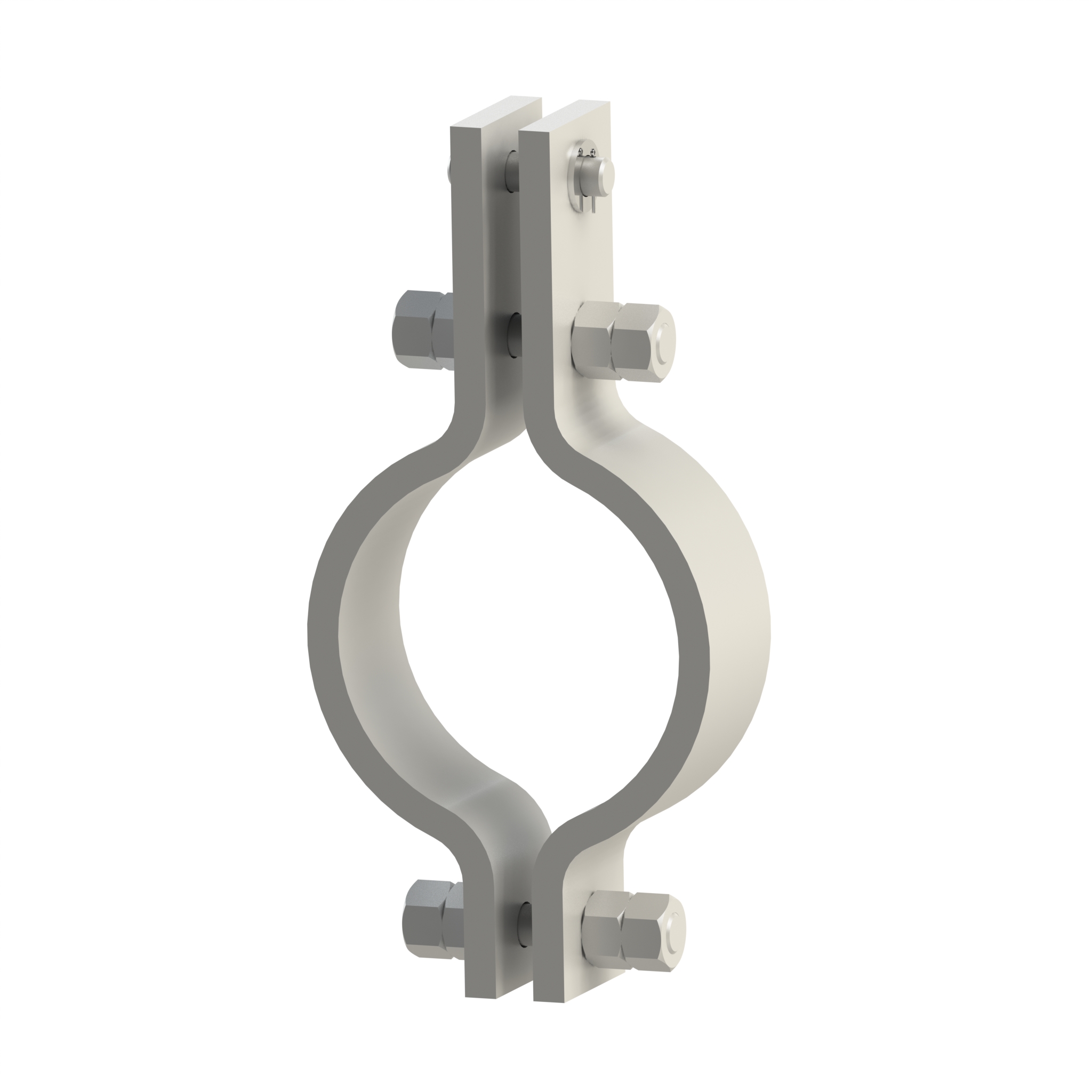

BG100LIGHT DUTY 2-BOLT CLAMP

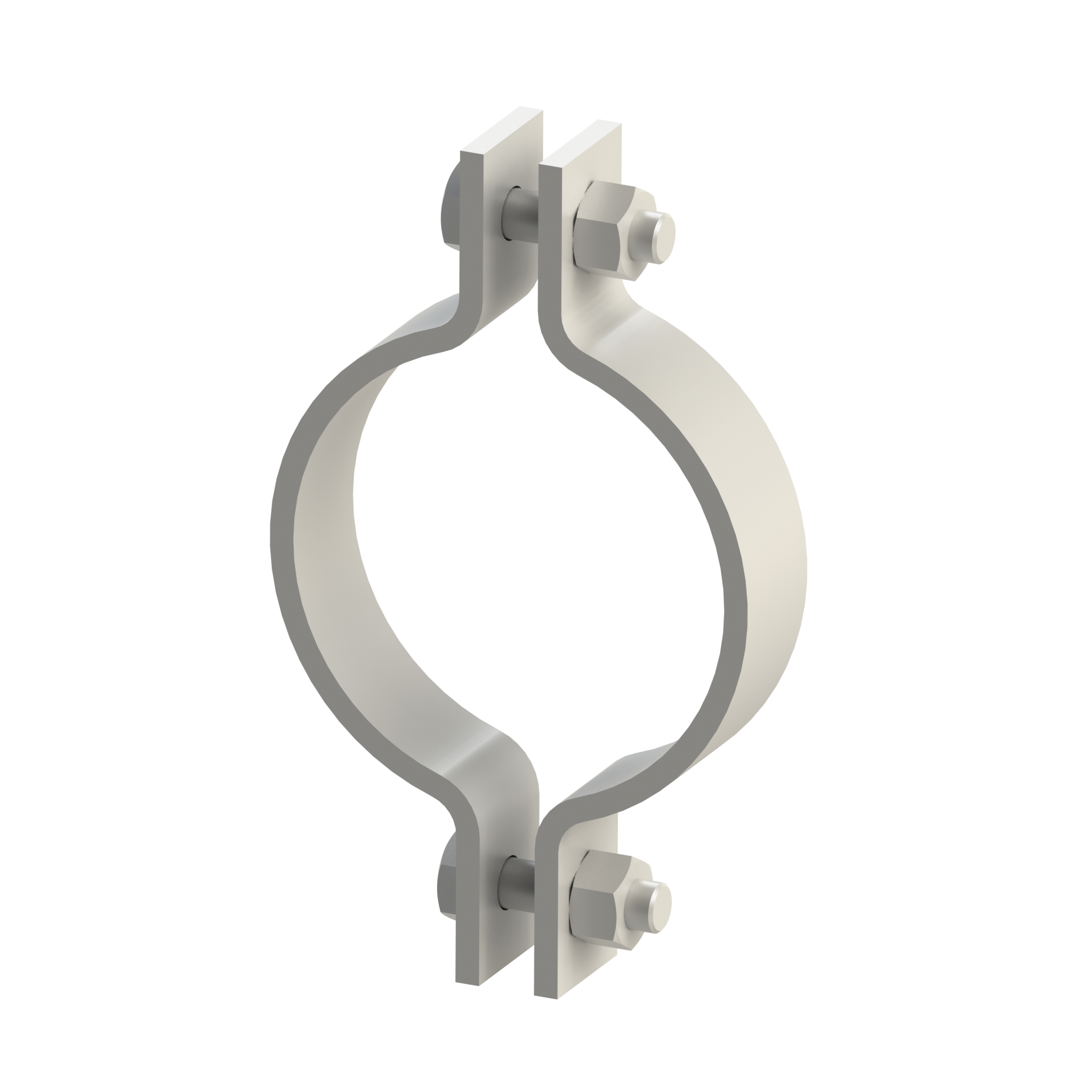

BG170

BG170MEDIUM DUTY 2-BOLT PIPE CLAMP

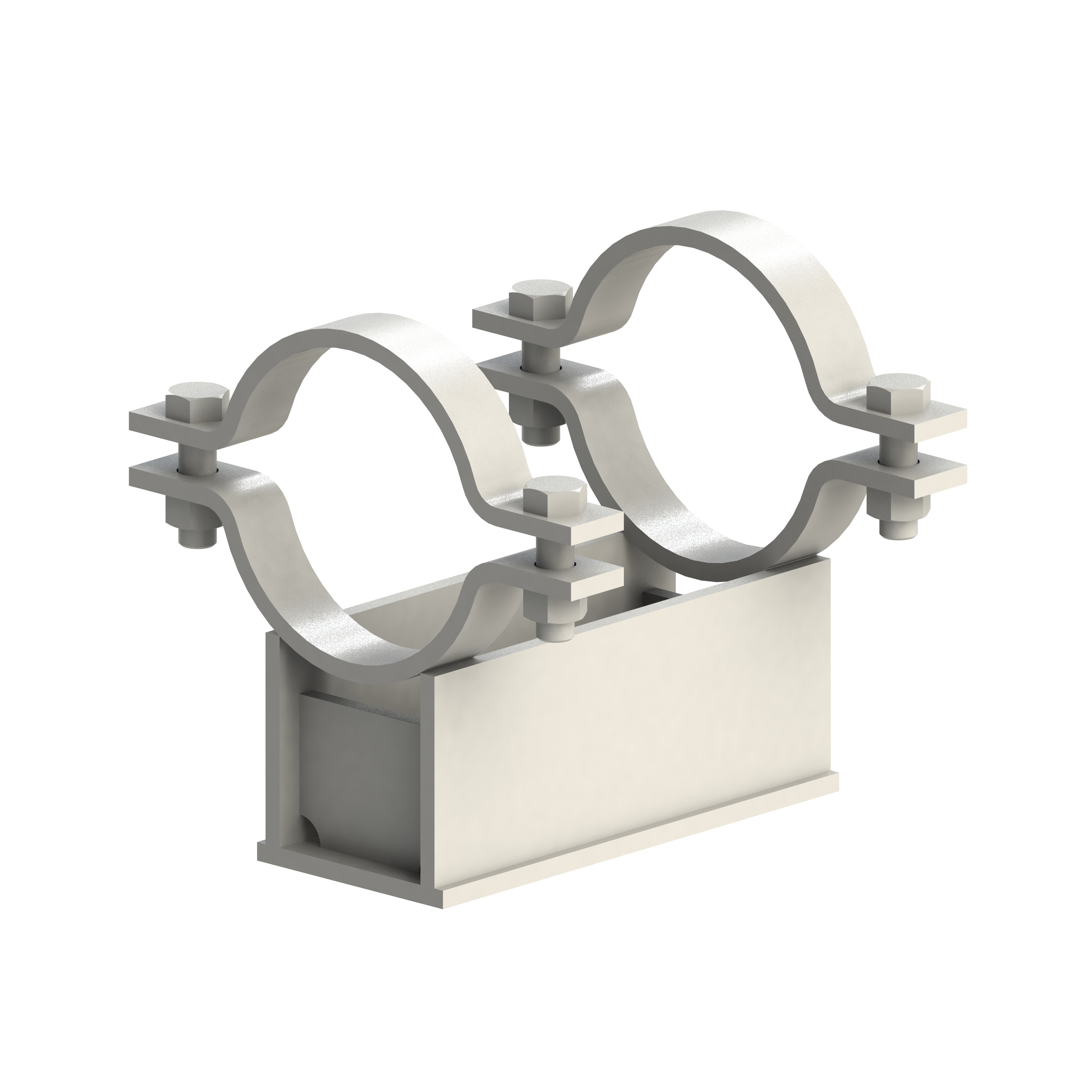

BG50

BG50HEAVY DUTY 2-BOLT PIPE CLAMP

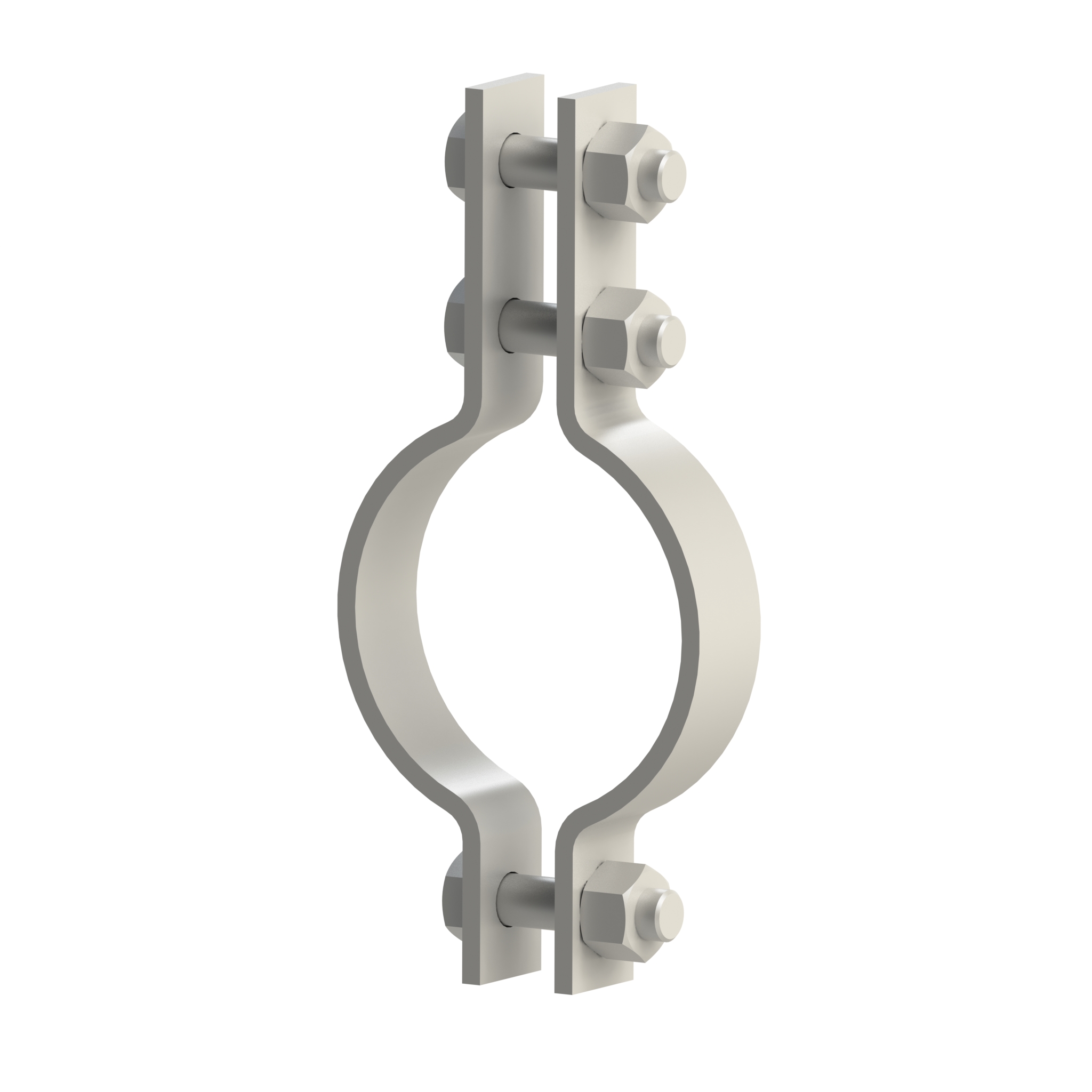

BG101

BG101LIGHT DUTY 3-BOLT PIPE CLAMP

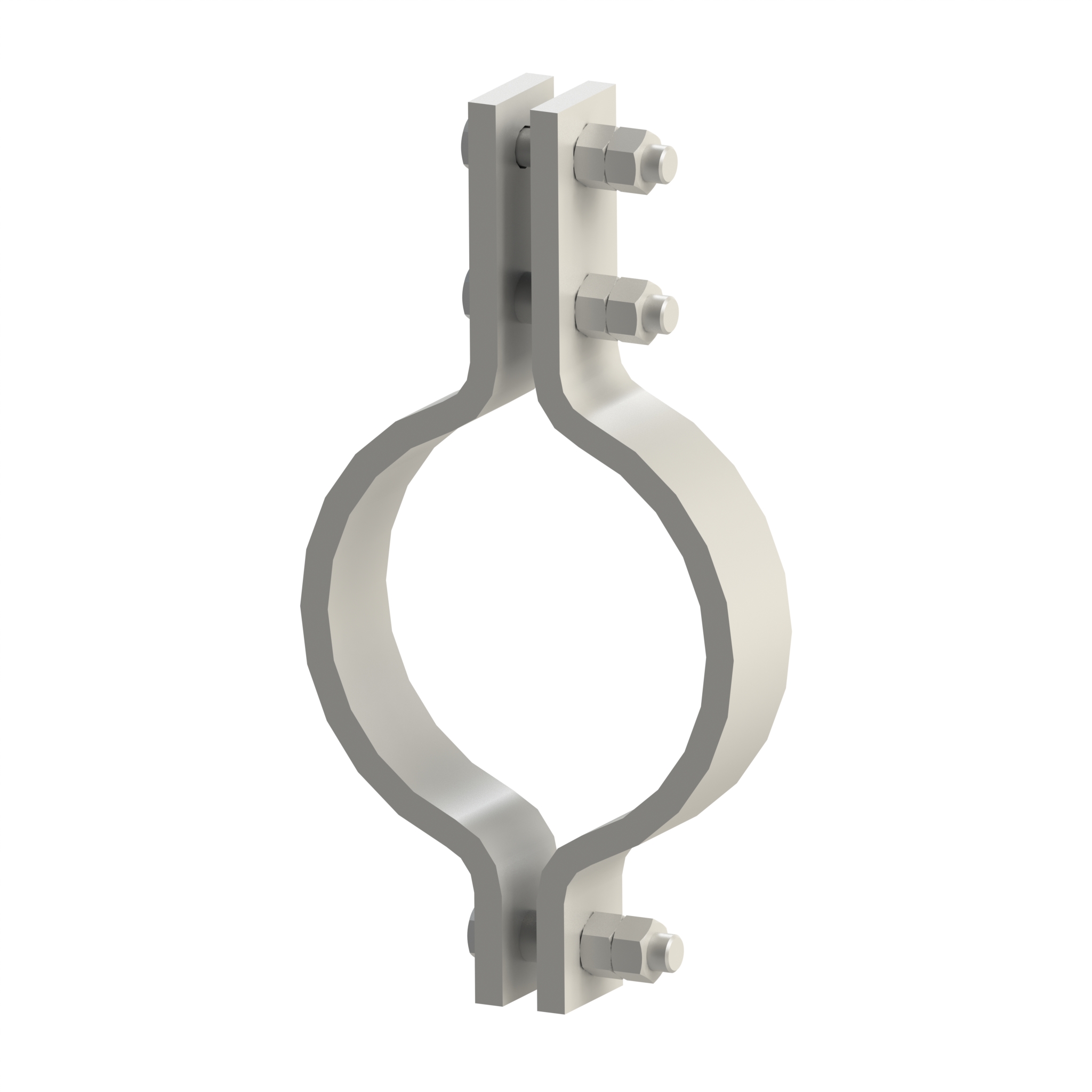

BG171

BG171MEDIUM DUTY 3-BOLT PIPE CLAMP FOR STEEL PIPE

BG75

BG75HEAVY DUTY 3-BOLT PIPE CLAMP

BG172

BG172HIGH TEMPERATURE 3-BOLT PIPE CLAMP

BG173

BG173ALLOY PIPE CLAMP - VERY HIGH TEMPERATURE

BG140

BG140INSULATED 2-BOLT PIPE CLAMP

BG141

BG141INSULATED 2-BOLT PIPE CLAMP FOR CU/NI

BG145

BG145INSULATED 3-BOLT PIPE CLAMP

BG146

BG146INSULATED 3-BOLT PIPE CLAMP FOR CU/NI

BG108

BG108CLEVIS CLAMP

BG222

BG222BEAM CLAMP

BG174

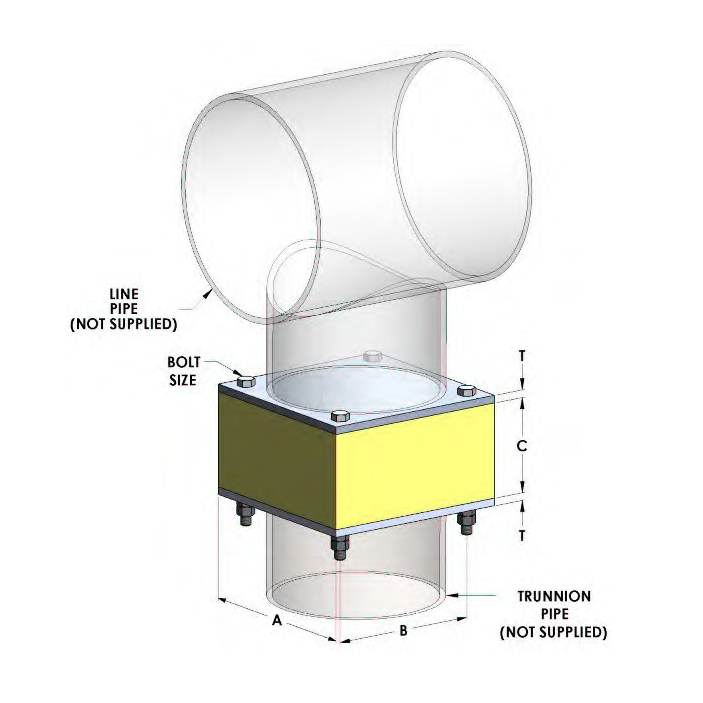

BG174RISER SUPPORT – STD TEMPERATURE

BG175

BG175RISER SUPPORT – HIGH TEMPERATURE

BG176

BG176ALLOY RISER SUPPORT - VERY HIGH TEMPERATURE

BG202

BG202ALLTHREAD ROD

BG209

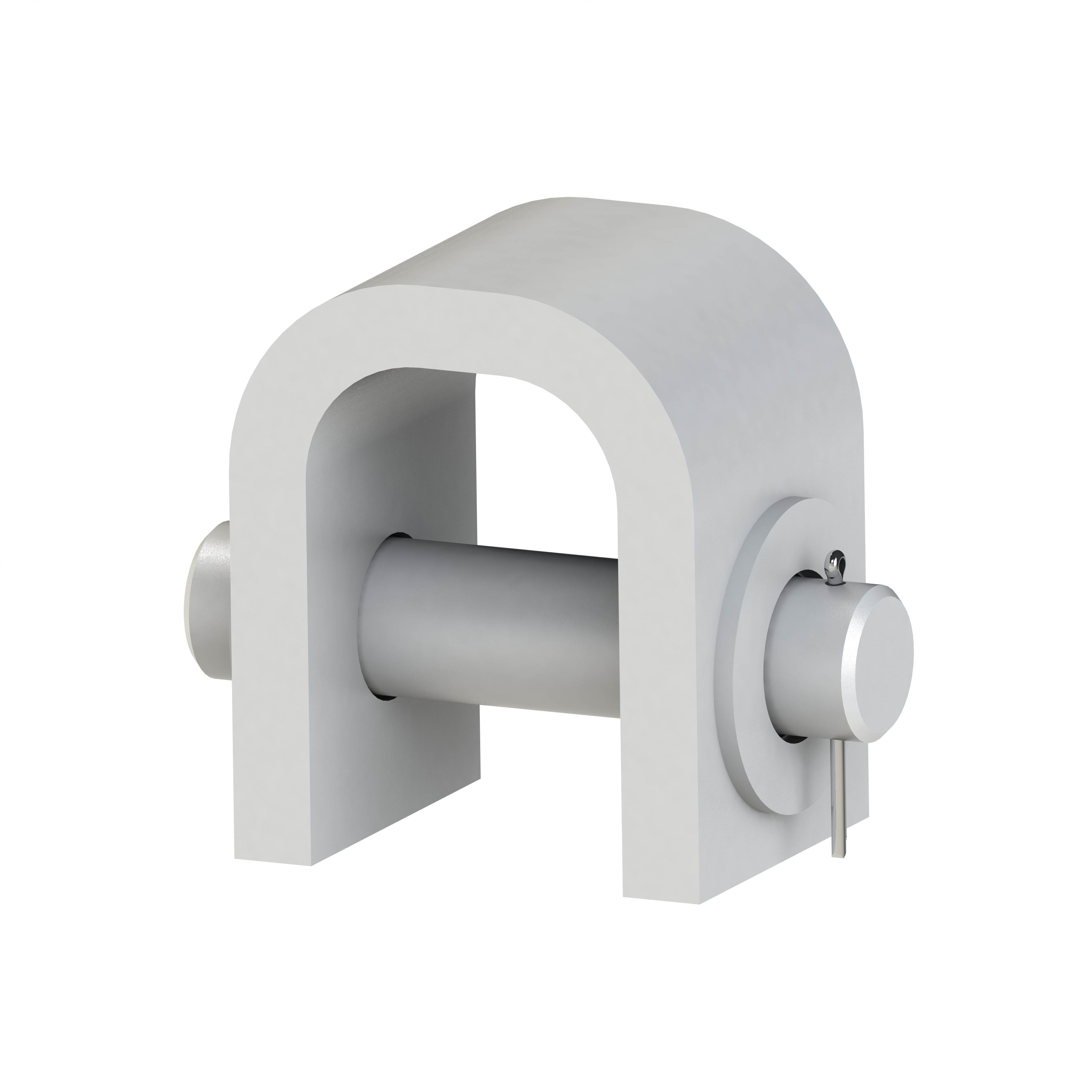

BG209FORGED CLEVIS AND PIN

BG210

BG210FORGED TURNBUCKLE

BG204

BG204FORGED WELDLESS EYE NUT

BG215

BG215HEMISPHERICAL CUP

BG214

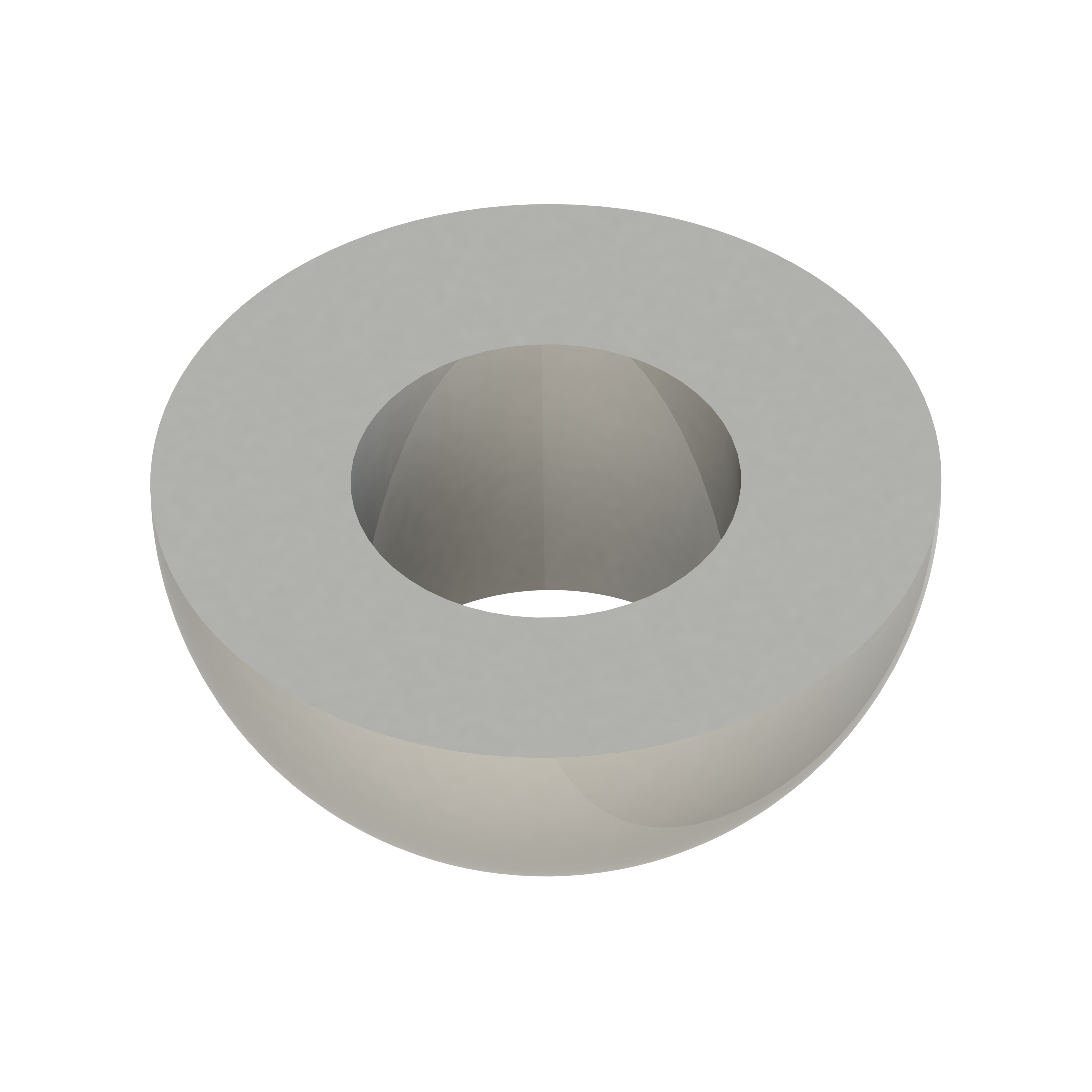

BG214HEMISPHERICAL WASHER

BG206

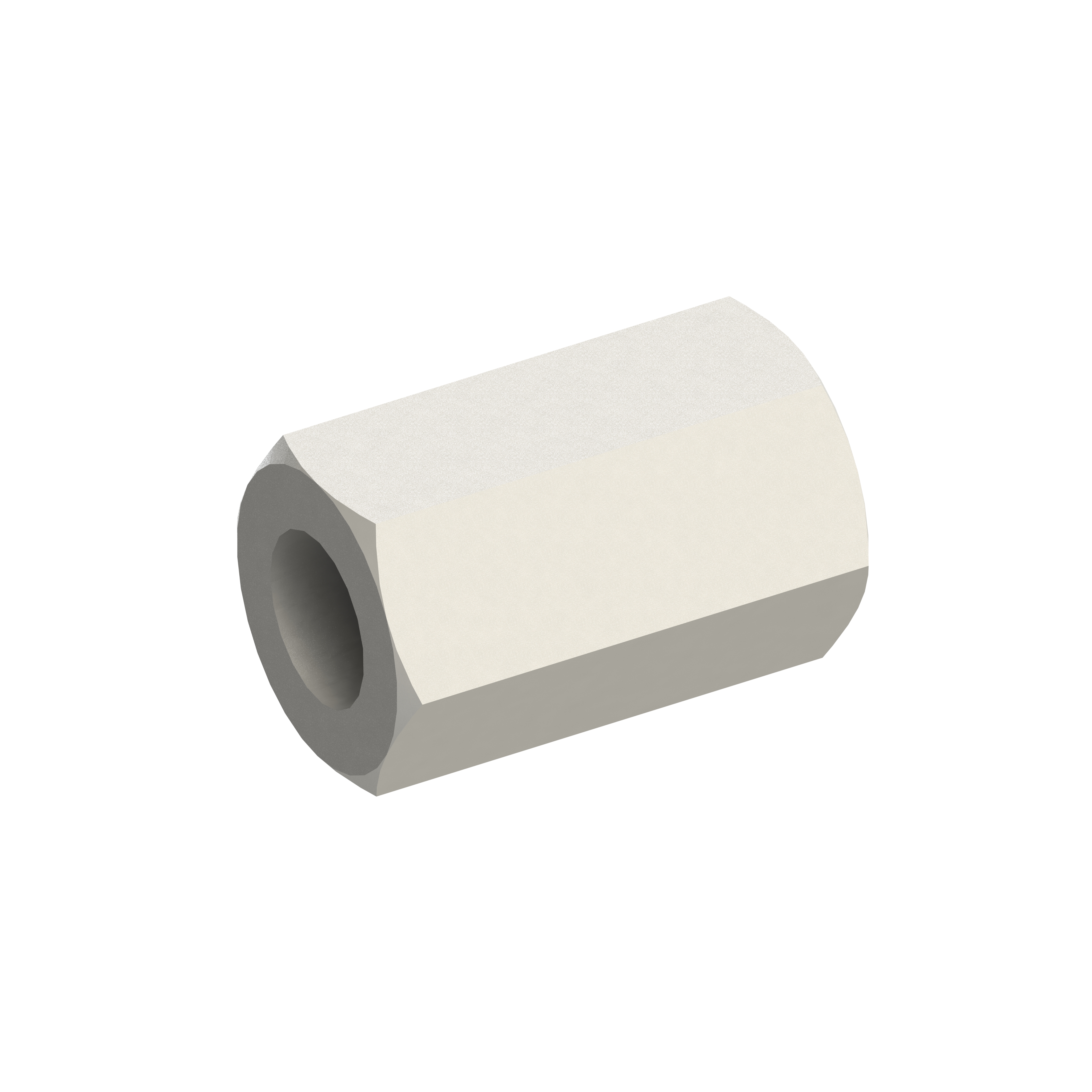

BG206HEXAGONAL CONNECTOR

BG216

BG216PIPE WELDING LUG

BG217

BG217PLATE WASHER

BG207

BG207SPADE NUT

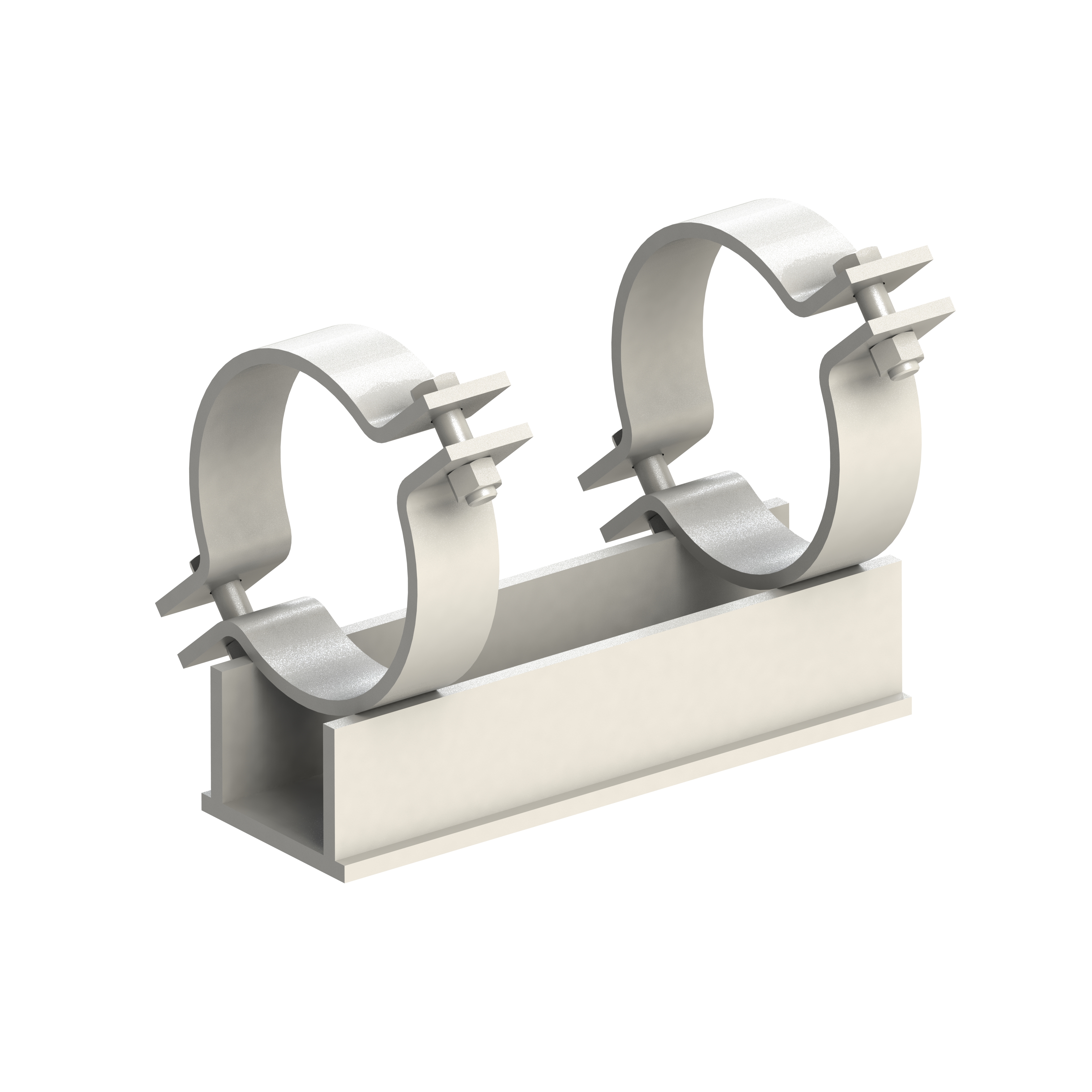

BG245

BG245STANDARD TRAPEZE

BG203

BG203THREADED DROP ROD – RH/LH

BG219

BG219WELDED BEAM ATTACHMENT

BG220

BG220WELDED BEAM ATTACHMENT (WITH LOAD PIN)

BG225

BG225WELDING LUG

BG180

BG180U-BOLT GUIDE

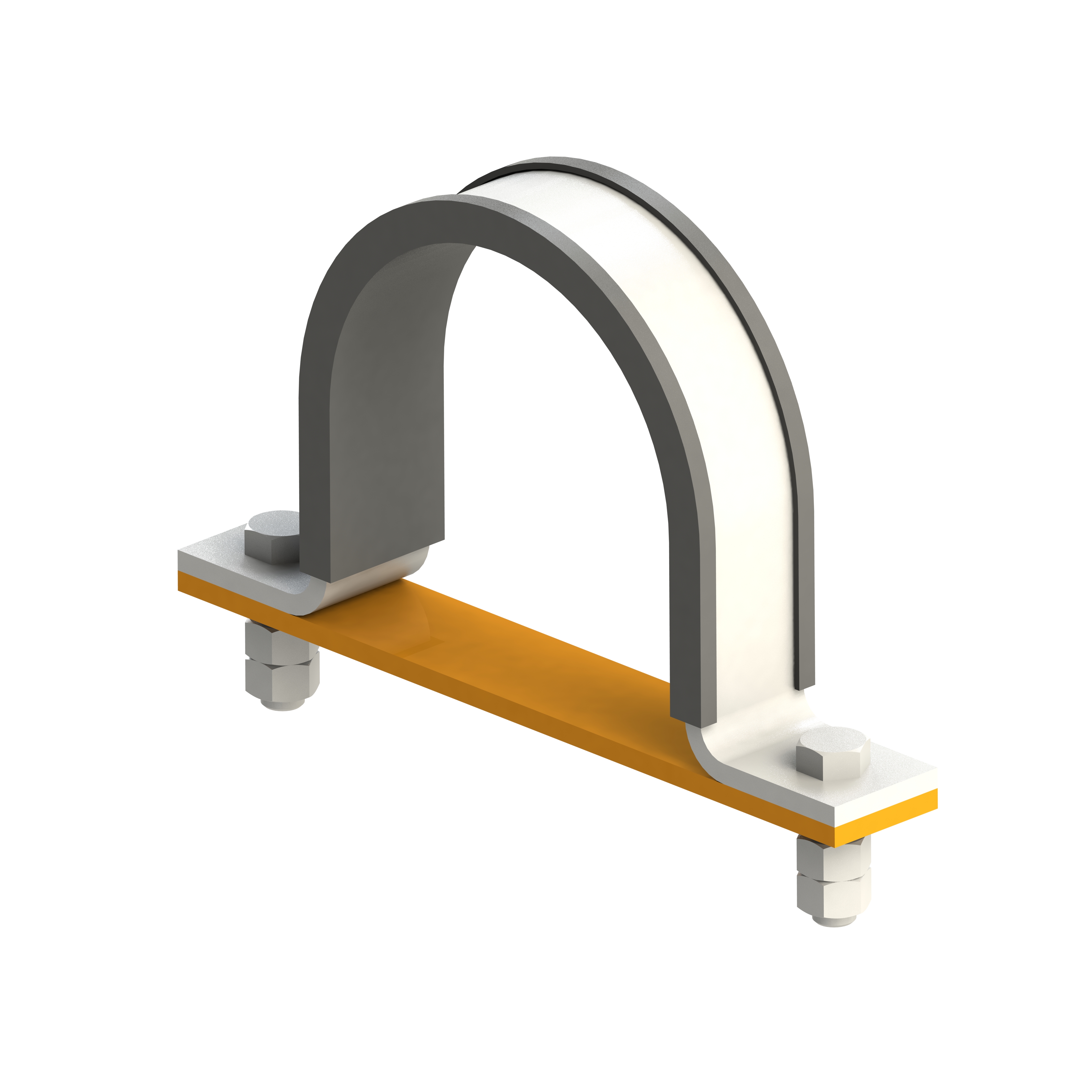

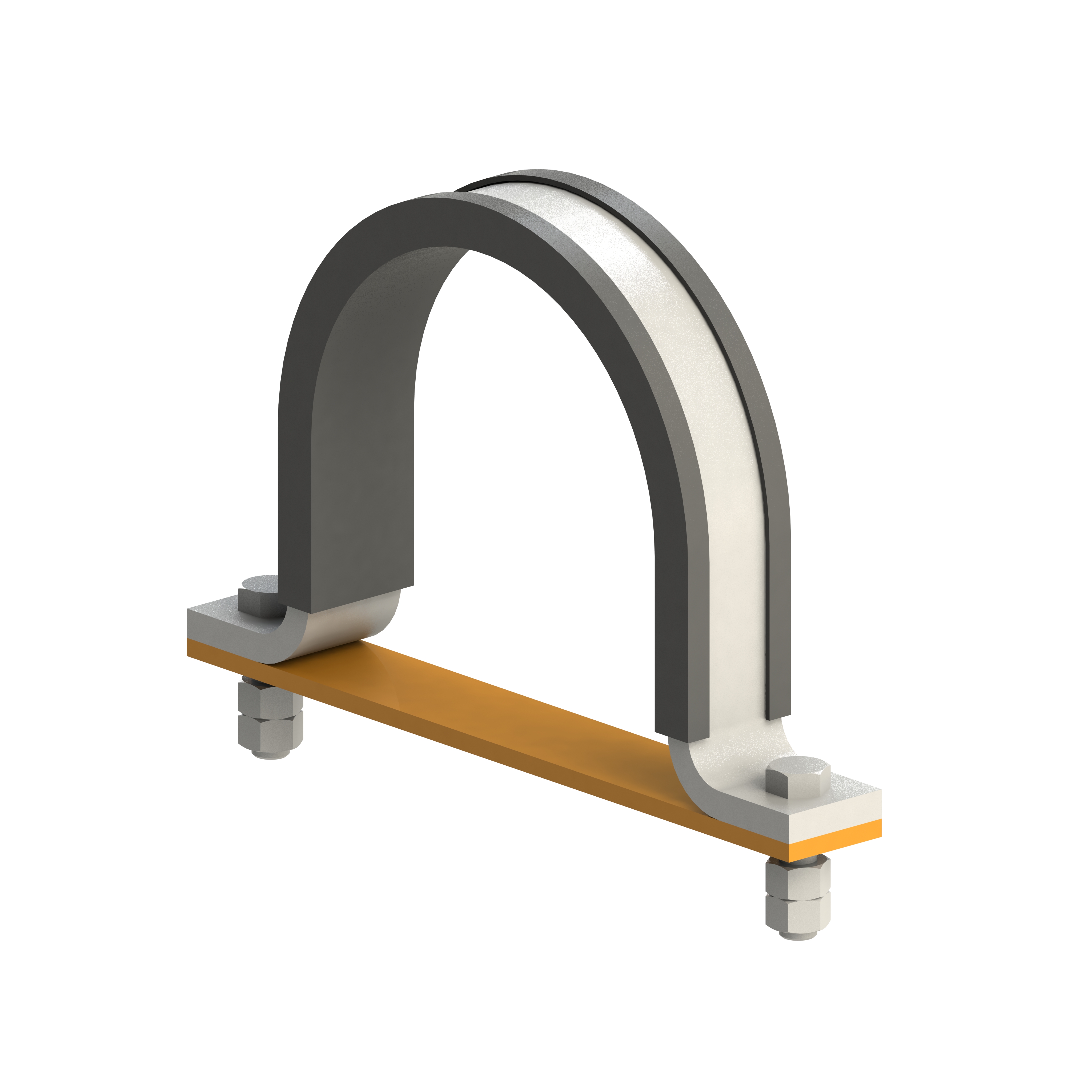

BG181

BG181U-BOLT CLAMP

BG150

BG150INSULATED U-BOLT CLAMP

BG152

BG152INSULATED U-BOLT GUIDE

BG154

BG154INSULATED U-BOLT GUIDE (WITH TEFLON)

BG190

BG190INSULATED U-BOLT CLAMP

BG192

BG192INSULATED U-BOLT GUIDE

BG151

BG151INSULATED U-BOLT CLAMP FOR CU/NI

BG153

BG153INSULATED U-BOLT GUIDE FOR CU/NI

For Cu/Ni Pipe BG155

BG155INSULATED U-BOLT GUIDE (WITH TEFLON)

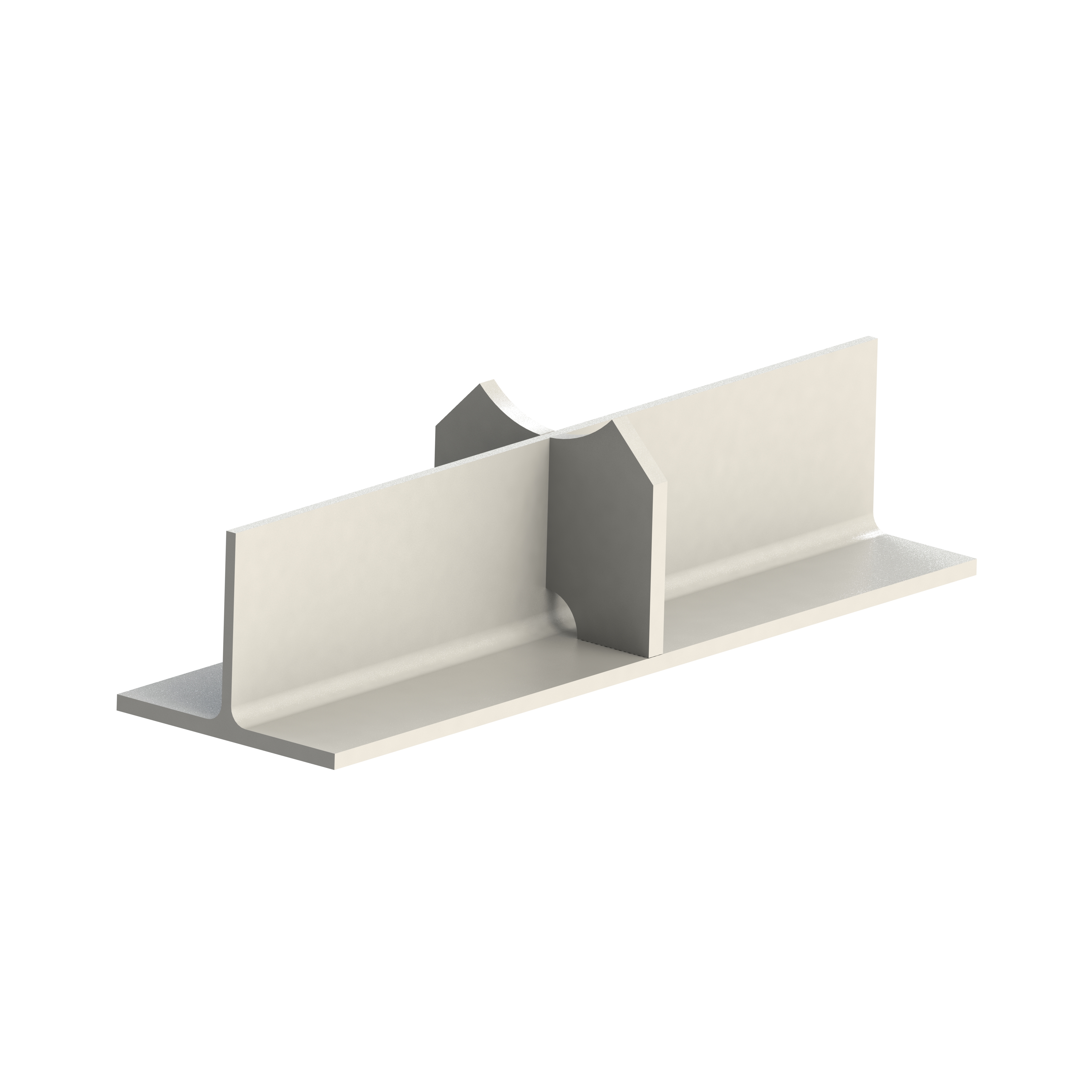

For Cu/Ni Pipe BG177

BG177SADDLE GUIDE

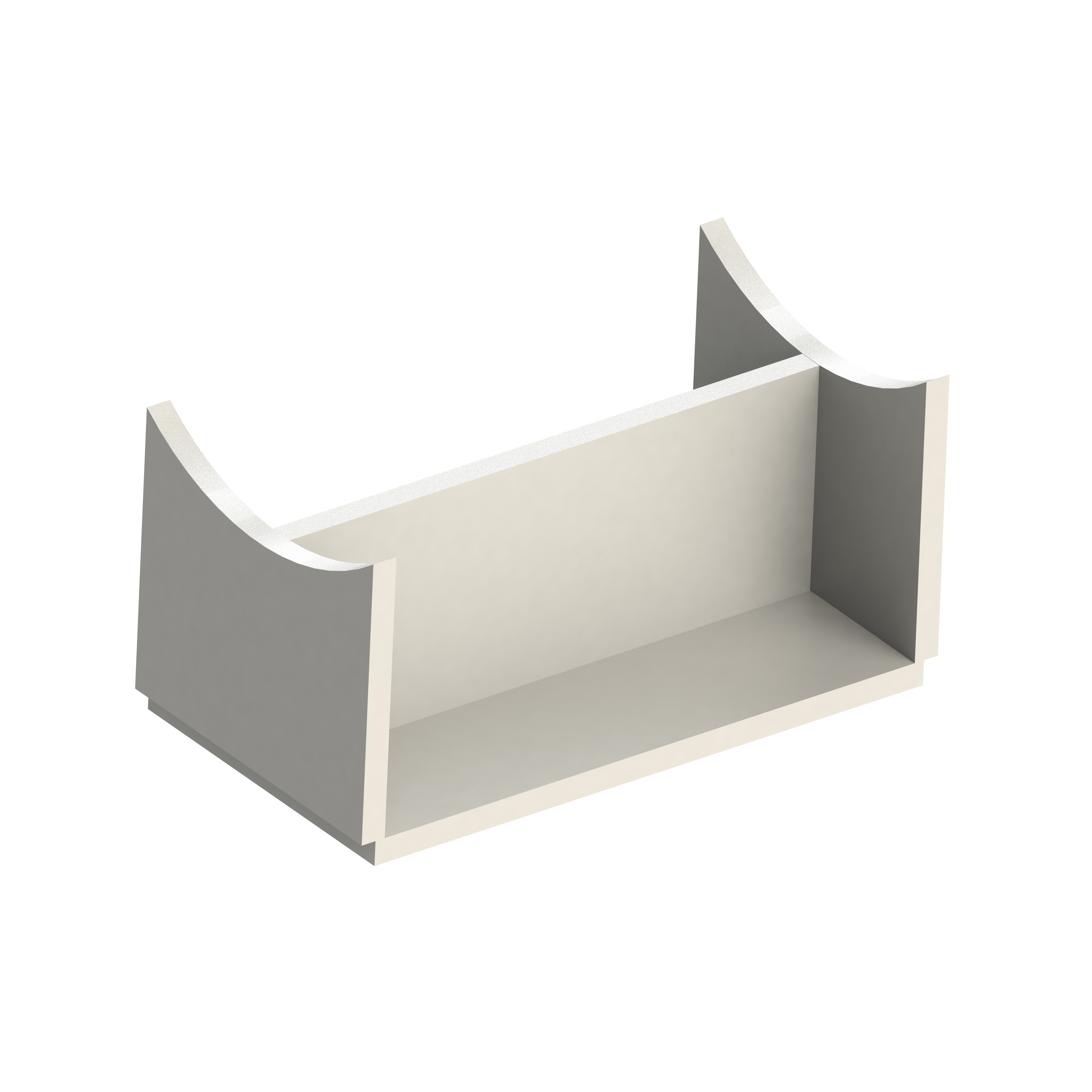

BG178

BG178SADDLE CLAMP

BG160

BG160INSULATED PIPE SADDLE

BG161

BG161INSULATED PIPE SADDLE

BG162

BG162INSULATED PIPE SADDLE

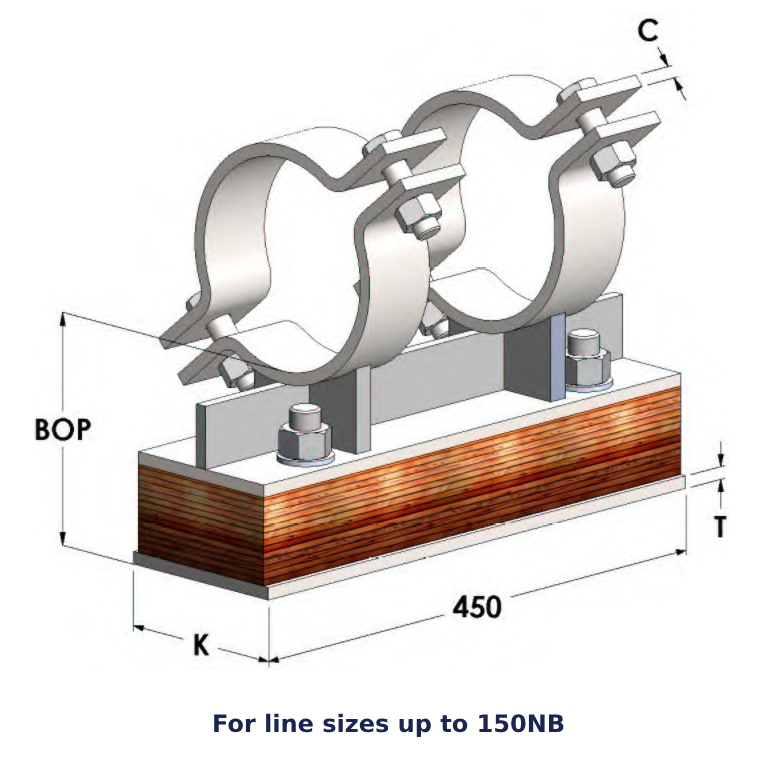

BG135-136

BG135-136ADJUSTABLE PIPE STANDS

BG515

BG515STANDARD CLAMPED PIPE SHOE

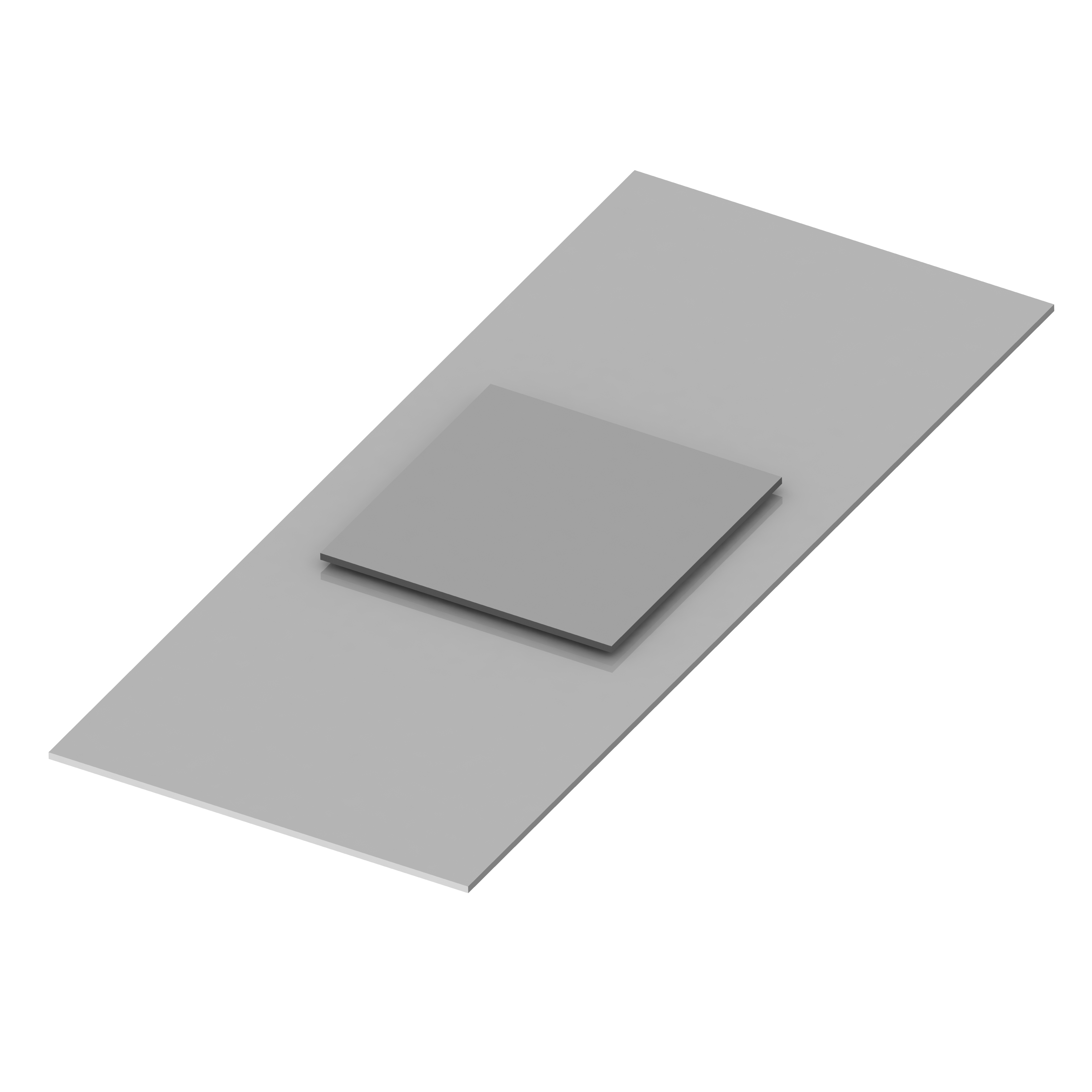

BG550

BG550SLIDE PLATES

BG517

BG517COMPACT PIPE SHOE

BG400

BG400CLAMPED HOT PIPE SHOE

BG156

BG156INSULATED PIPE SHOE

BG157

BG157INSULATED PIPE SHOE

BG510

BG510STANDARD WELDED PIPE SHOE

BG518

BG518COMPACT WELDED PIPE SHOE

BG555

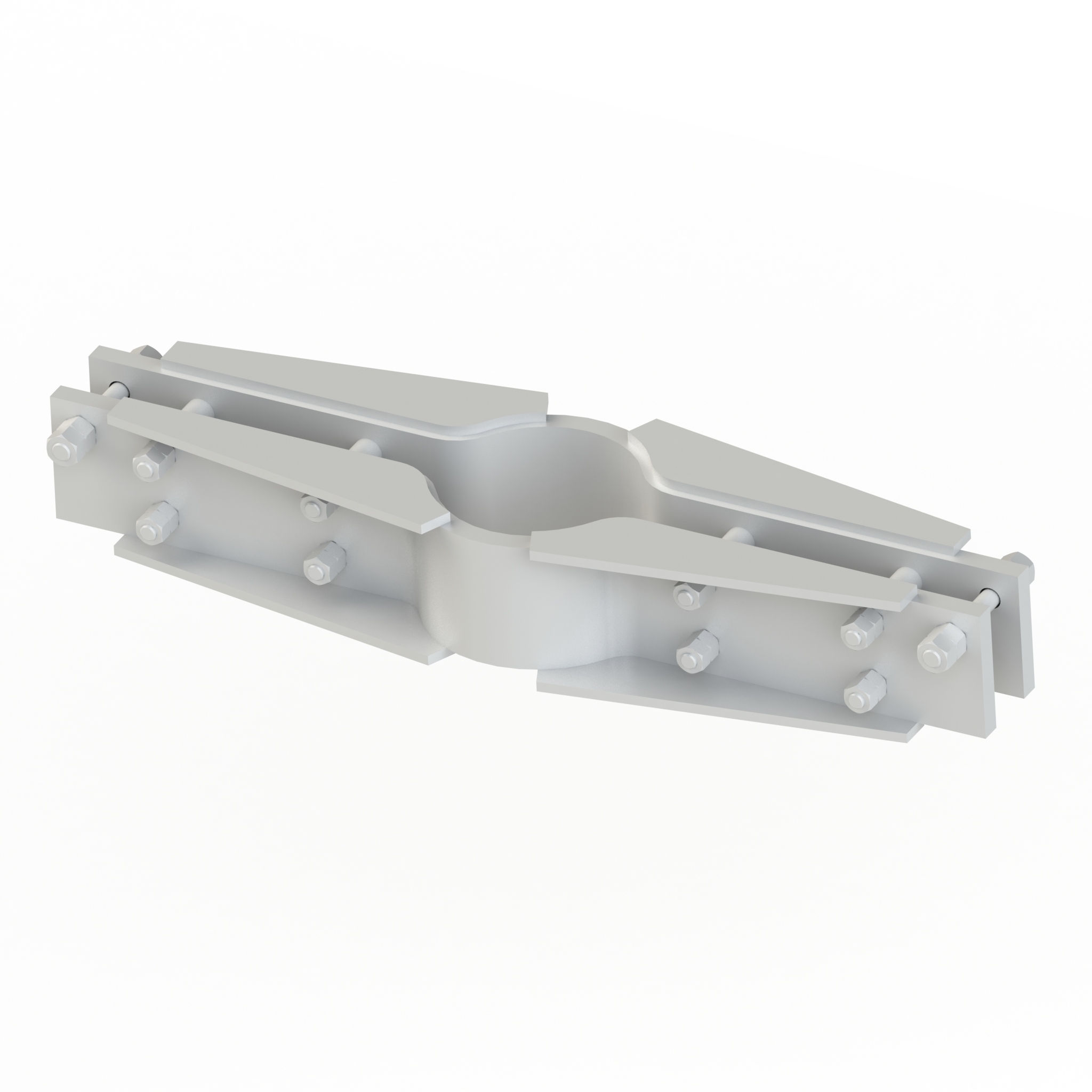

BG555STANDARD LINE STOPS

BG560

BG560STANDARD PIPE GUIDES

BG570

BG570STANDARD SHOE GUIDES

BG580

BG580STANDARD SHOE GUIDES

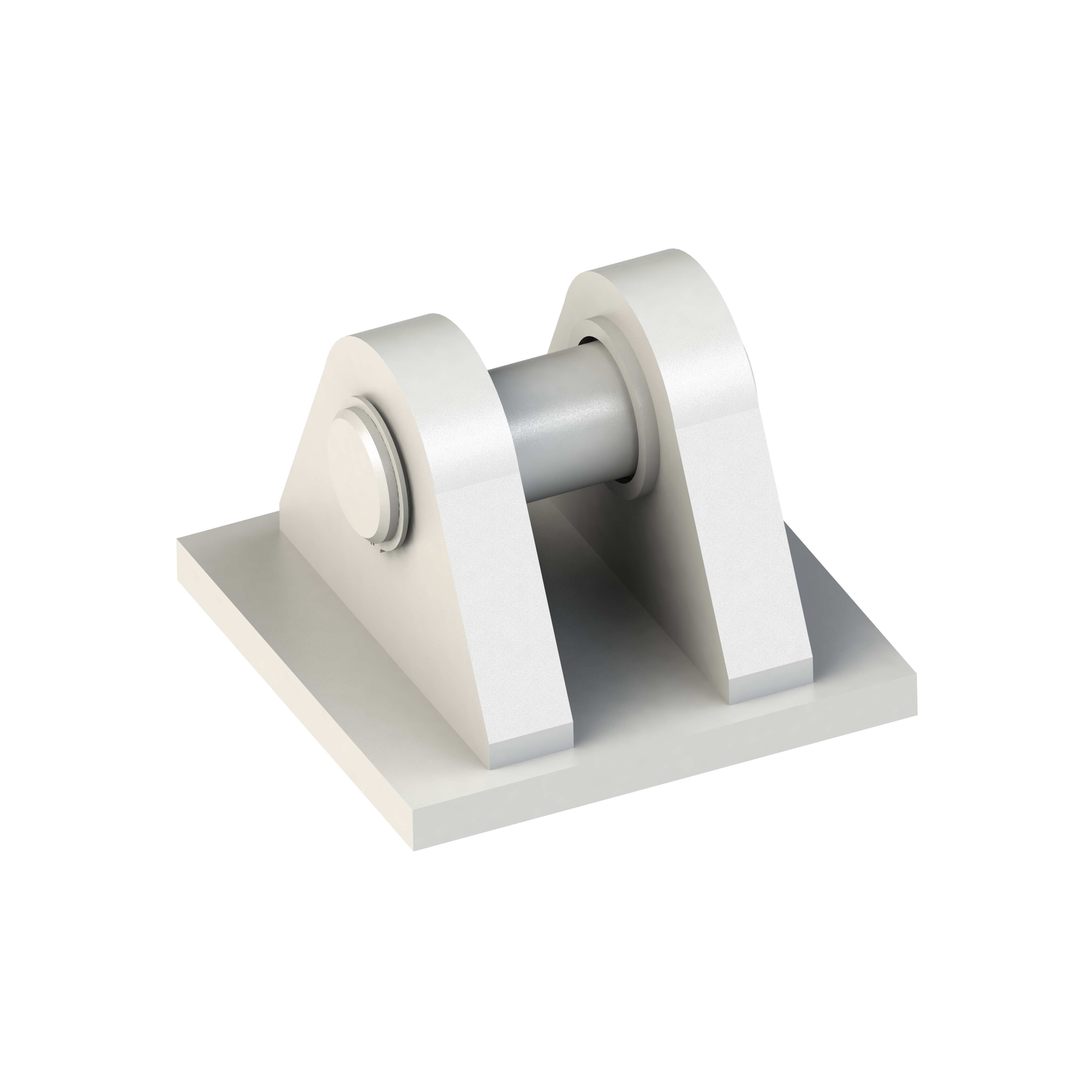

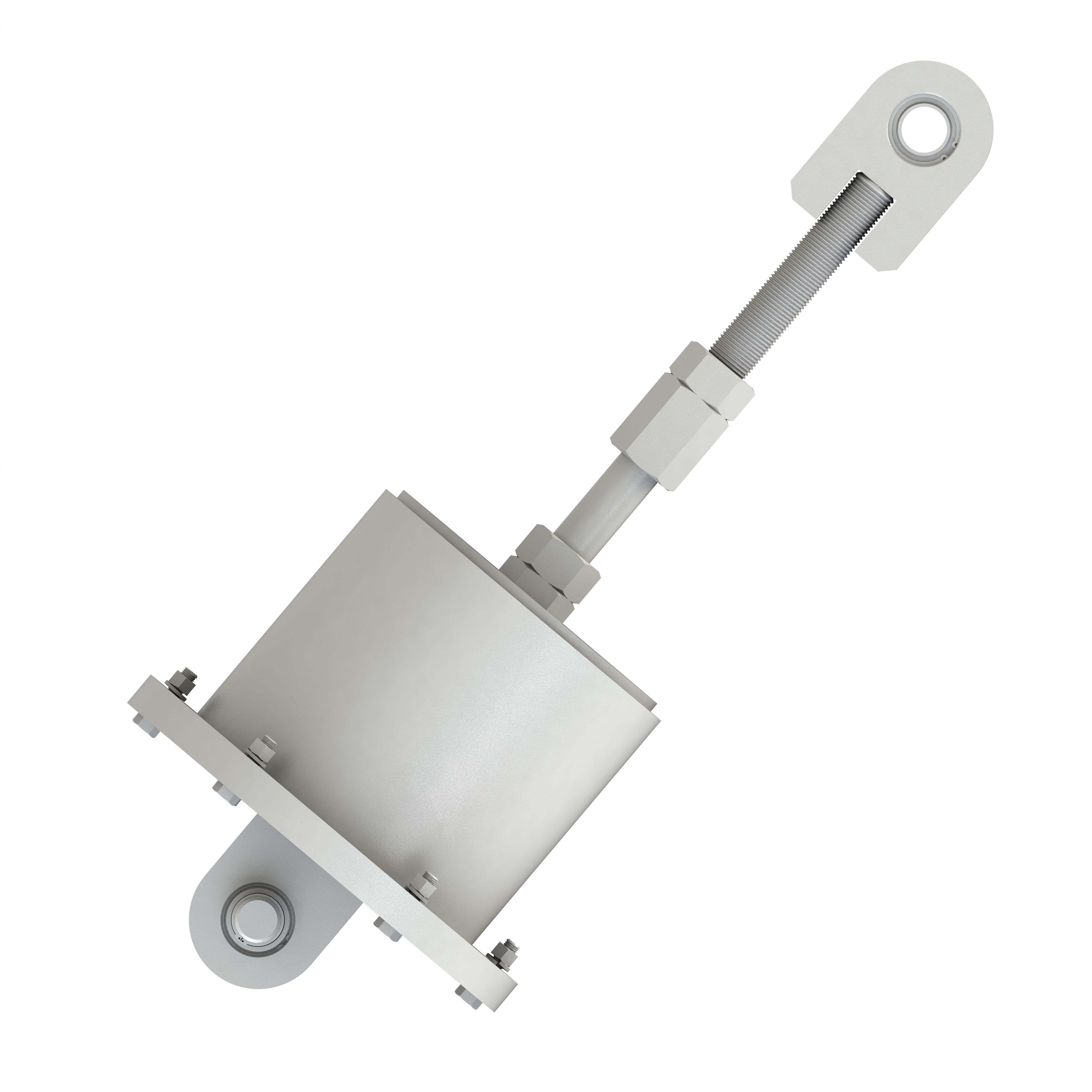

BG315

BG315END ATTACHMENT FOR HYDRAULIC SNUBBERS

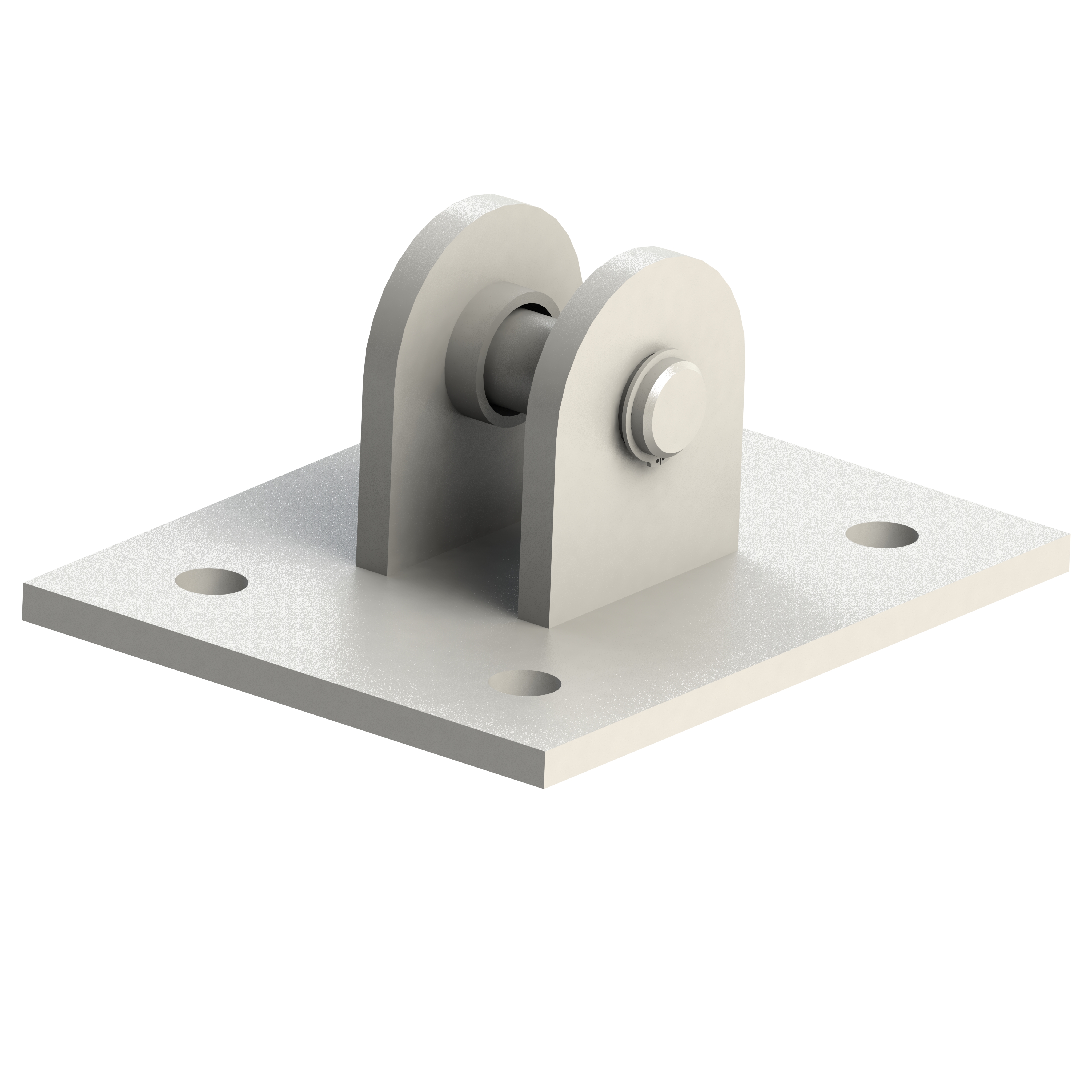

BG355

BG355END ATTACHMENT FOR RIGID STRUT & SWAY BRACE

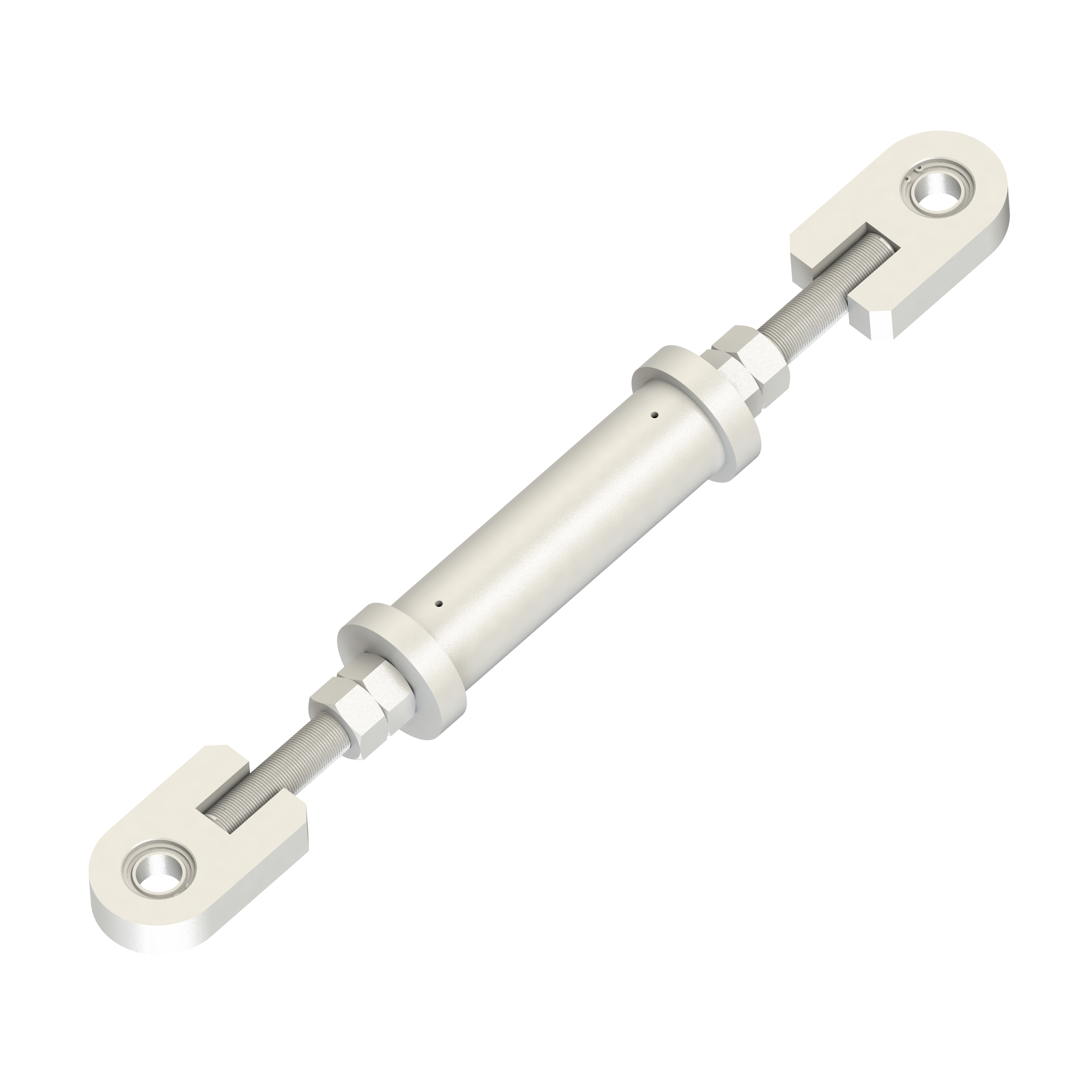

BG310

BG310HYDRAULIC SNUBBERS (SHOCK ARRESTORS)

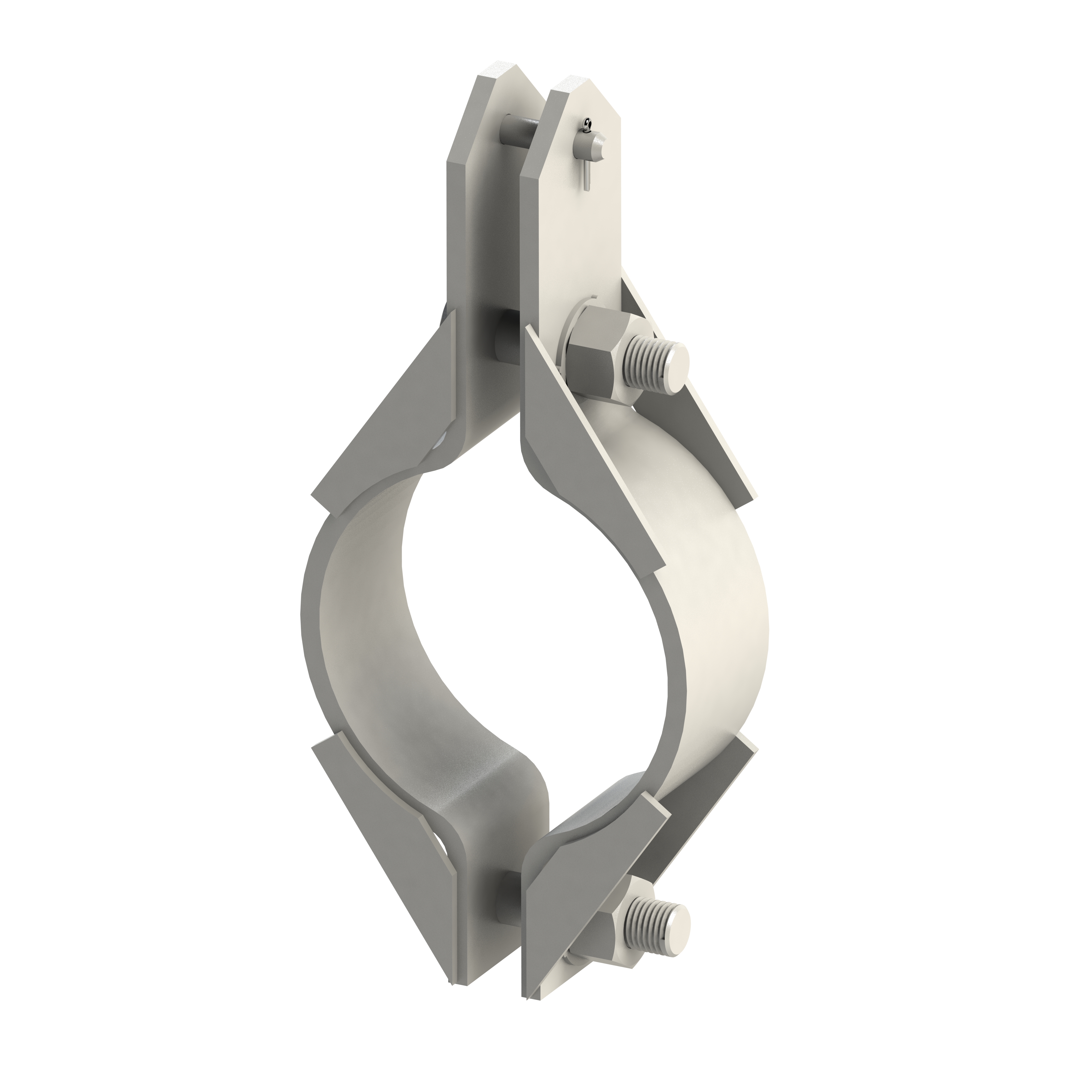

BG321

BG321PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG322

BG322PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG320

BG320PIPE CLAMP FOR HYDRAULIC SNUBBER – LOW TEMPERATURE

BG350

BG350RIGID STRUTS

BG340

BG340SWAY BRACE

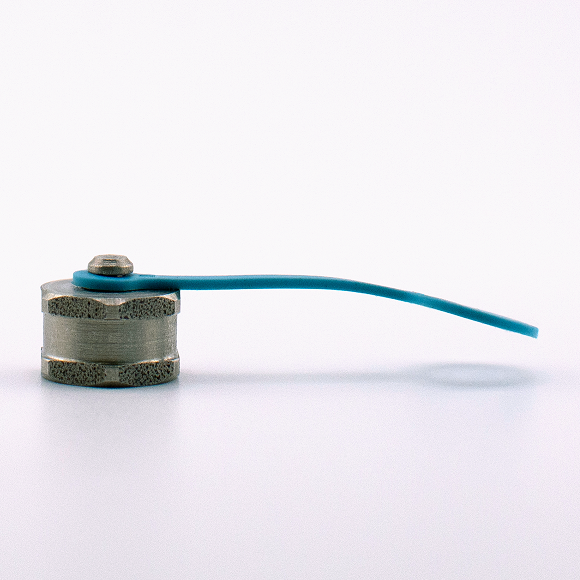

#691028

#691028All Stainless Steel Gauge Adapter #691028

#520XL

#520XLAll Stainless Steel Gauge Adapter #520XL

#691023

#691023Brass Gauge Adapter #691023

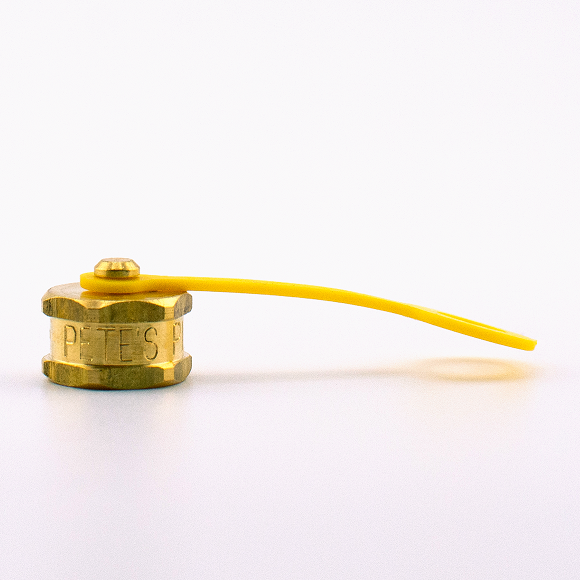

#500BSP

#500BSPBrass Gauge Adapter #500BSP

#691024

#691024Brass Gauge Adapter #691024

#500XLBSP

#500XLBSPBrass Gauge Adapter #500XLBSP

691026

691026Brass Gauge Adapter #691026

#691027

#691027Brass Gauge Adapter #691027

#104-1BS

#104-1BSCap Assembly #104-1BS

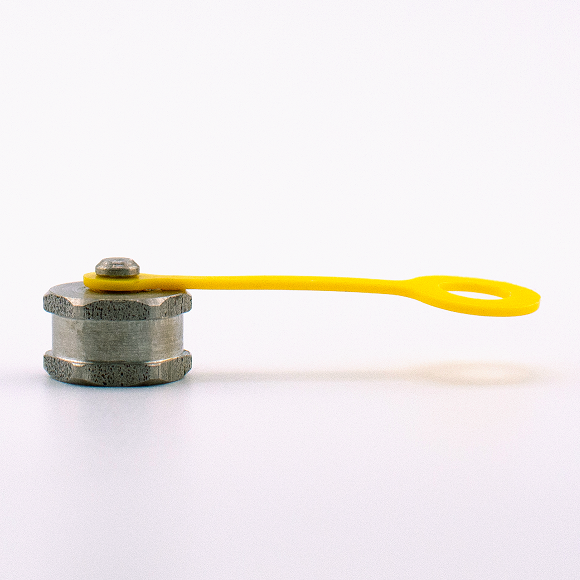

#104-1YS

#104-1YSCap Assembly #104-1YS

#104-2BS

#104-2BSCap Assembly #104-2BS

#104-2YS

#104-2YSCap Assembly #104-2YS

#691003

#691003Pete's Plug #691003

#691002

#691002Pete's Plug #691002

#691010

#691010Pete's Plug #691010

#691001

#691001Pete's Plug #691001

#691000

#691000Pete's Plug #691000

#691017

#691017Pete's Plug #691017

#12510

#12510Pete's Plug #12510

691020

691020Pete's Plug #691020

#691008

#691008Pete's Plug #691008

#691005

#691005Pete's Plug #691005

#691007

#691007Pete's Plug #691007

#691004

#691004Pete's Plug #691004

#572

#572Pete's Plug #572

#691019

#691019Pete's Plug #691019

#691018

#691018Pete's Plug #691018

#760

#760Pete's Plug #760

#691016

#691016Pete's Plug #691016

#691022

#691022Pete's Plug #691022

#691021

#691021Pete's Plug #691021

#691014

#691014Pete’s Plug #691014

#691013

#691013Pete’s Plug #691013

#562

#562Pete’s Plug #562

#691012

#691012Pete’s Plug #691012

#691011

#691011Pete’s Plug #691011

#750XL

#750XLPete’s Plug #750XL

#691015

#691015Pete’s Plug #691015

#691029

#691029Pressure & Temperature Test Kit 0-100psi

#691030

#691030Pressure & Temperature Test Kit 0-100psi for XL

#1500-5

#1500-5Pressure Gauge 0-100 PSI BSP Stem

#1500-4

#1500-4Pressure Gauge 0-100 PSI NPT Stem

#606

#606Thermometer -58°F to 550°F

-

-

-

- About

- Resources

- Contact

Preventing Pipe Support Failures: Strategic Insights for Engineers and Project Managers

Corrosion, misalignment, and vibration significantly threaten pipe support integrity within the oil, gas, and mining sectors. Engineers face the challenge of managing operational risks from undetected failures and outdated standards, which can lead to steep repair costs and unscheduled downtime. This article focuses on identifying early warning signs for pipe support replacement, emphasizing structural vulnerabilities like corrosion and signs of load fatigue such as misalignment. It aims to equip engineers with methodologies for early detection, including routine visual and non-destructive testing (NDT) inspections aligned with recent AS/NZS compliance updates. By adopting these proactive strategies, engineers can mitigate the high costs associated with pipe support failures, ensuring pipeline integrity and maintaining operational compliance across critical infrastructure projects.

Detecting Early Signs of Pipe Support Corrosion

Corrosion in pipe supports often occurs in poorly drained areas or crevices, quietly reducing structural integrity until catastrophic failure results. Engineers should be vigilant for rust streaks or discolouration, which are signs demanding prompt investigation. Ignoring these early indicators can lead to significant operational disruptions and increased maintenance expenses.

Regular visual inspections and NDT, aligned with Quality Assurance (QA) protocols, are essential early warning systems for identifying potential pipe support failures before they escalate. The Deepwater Corrosion Services Technical Library underscores the importance of such preventive actions. An established inspection framework can reveal anomalies that are not immediately visible.

Custom-engineered pipe supports, designed to withstand specific environmental challenges, provide enhanced longevity and reliability for industrial infrastructures. Binder’s engineered supports are crafted to combat corrosion, fortifying the integrity and safety of industrial piping systems.

Recognising Misalignment and Sagging as Warning Indicators

Misalignment and sagging in piping systems signal potential structural integrity issues. Misalignment often indicates degraded pipe supports, compromising overall stability. Load fatigue can cause misalignment through uneven stress distribution, increasing pressure on supports.

Sagging typically results from inadequate support spacing or initial load fatigue and can foreshadow broader structural problems or major leakages. Routine inspections, including alignment verification, are crucial to preempting significant disruptions. Binder’s custom-engineered pipe supports tackle these challenges, preserving alignment integrity and preventing support degradation.

Excessive Vibration and Load Fatigue Symptoms

Persistent vibration in piping systems suggests load fatigue and may indicate inadequacies in support structures or material ageing. Sustained operational stress heightens load fatigue risks, necessitating immediate investigation by engineers upon discovery of unexplained vibrations or noise. Proactive intervention maintains system integrity, preventing minor issues from developing into major failures.

Custom-engineered pipe supports, specifically rated for certain load conditions, effectively mitigate fatigue-related vibration risks, reducing stress and stabilising infrastructure. Employing solutions suited to industrial environments prevents catastrophic pipe support failures, safeguards critical infrastructure, and ensures operational continuity in sectors like oil and gas. Binder’s tailored pipe supports represent a strategic investment, enhancing operational efficiency in line with industry demands.

Updating Documentation for Compliance Standards

Recent updates to AS/NZS 2033:2024 and AS/NZS 3500 underscore the need for updated structural designs and QA/QC documentation. Engineers need to integrate these updates to maintain compliance and safety, aligning documentation with revised standards.

Systematic engineering reviews ensure documentation accuracy and compliance with current pipe support requirements, mitigating risks from documentation discrepancies.

Promptly addressing compliance standard gaps prevents nonconformance, shielding against potential system failures and financial and operational setbacks. Binder’s Documentation Pack and QA/QC Sets assist in thorough alignment and oversight, ensuring adherence to updated standards.

Operational Cost Risks of Delaying Pipe Support Replacement

Overlooking early indicators of pipe support failure can significantly inflate repair costs, potentially reaching $10,000 per location, as outlined by Deepwater Corrosion Services – The Cost of a Bad Pipe Support. Such expenses rise when support failures precipitate catastrophic incidents, prolonging repair timelines and disrupting operations.

Periodic audits evaluating pipe support lifespan and installation integrity are essential for mitigating these risks. These audits expose vulnerabilities, helping avoid unscheduled downtimes that impede project timelines and efficiency. Proactive measures ensure maintenance schedules align with financial and operational goals.

Consequences of catastrophic failure extend beyond repair costs. System halts can hinder both upstream and downstream operations, threaten safety, and may incur regulatory penalties if compliance benchmarks for environmental protection are breached. Integrating Binder’s Custom-Engineered Pipe Supports into maintenance schedules ensures durability and operationational standards.

Planning Preventative Replacement to Secure Long-Term Integrity

Accurate forecasting and proactive replacement schedules are key to sustained pipeline integrity and safety. By using advanced inspection technologies and analysing historical data, engineers can develop predictive maintenance protocols that prevent breakdowns and extend asset lifespan. Real-time inspection data enables informed decisions, avoiding costly unplanned downtimes.

Combining historical trends with real-time data allows engineers to identify frequent failure points or wear areas, initiating timely preventive interventions. This strategy minimizes unexpected outages, extends pipeline infrastructure lifespan, and reduces long-term costs.

Selecting custom-engineered pipe supports ensures systems are future-proof against corrosion, fatigue, and compliance changes. Tailored to endure site-specific conditions, these supports assure resilience and compliance. Binder’s Custom-Engineered Pipe Supports exemplify thoughtful investment, guaranteeing enduring durability critical for the highest safety and operational standards.